In-log trap

A trap and well logging technology, applied in surveying, wellbore/well components, earthwork drilling, etc., can solve the problems of high labor intensity of operators, unfavorable high-pressure well testing, complex process structure, etc. Realistic application value and effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

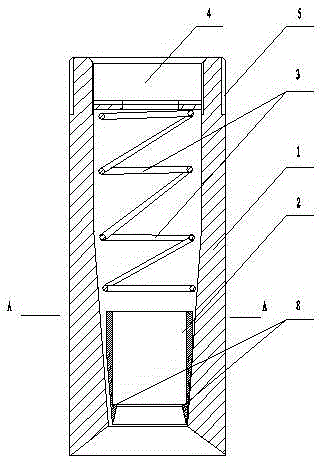

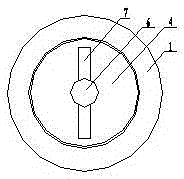

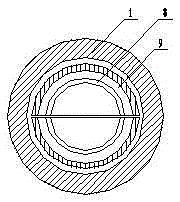

[0019] According to attached figure 1 , 2 As shown in and 3, the trap in the well logging includes a cylindrical trap cover 1, the inner diameter of the lower end of the trap cover 1 is smaller than the inner diameter of the upper end, and an adjusting shrapnel 4 is threadedly connected to the upper inner part of the catch cover 1. There are slips 2 in the inner and lower part of the catcher coat 1, and a control spring 3 is arranged between the slips 2 and the regulating shrapnel 4, and the inside section of the bottom of the catcher coat 1 is inverted conical. There is a through hole 6 in the center of the regulating shrapnel and a groove 7 at the top. There is an external thread 5 on the outside of the upper part of the catcher jacket 1, and an annular boss 8 is arranged on the inner and lower part of the slip 2, and the slip 2 is composed of two arc-shaped slips 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com