Alkali-free glass and alkali-free glass substrate

A technology of alkali-free glass and substrate, applied in the direction of instruments, electrical components, optics, etc., can solve the problems of limited use, unoptimized use, high toxicity, etc., to improve productivity, reduce energy costs or environmental load, and improve bubble elimination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0097] Hereinafter, the present invention will be described in detail based on Examples (sample Nos. 1 to 56).

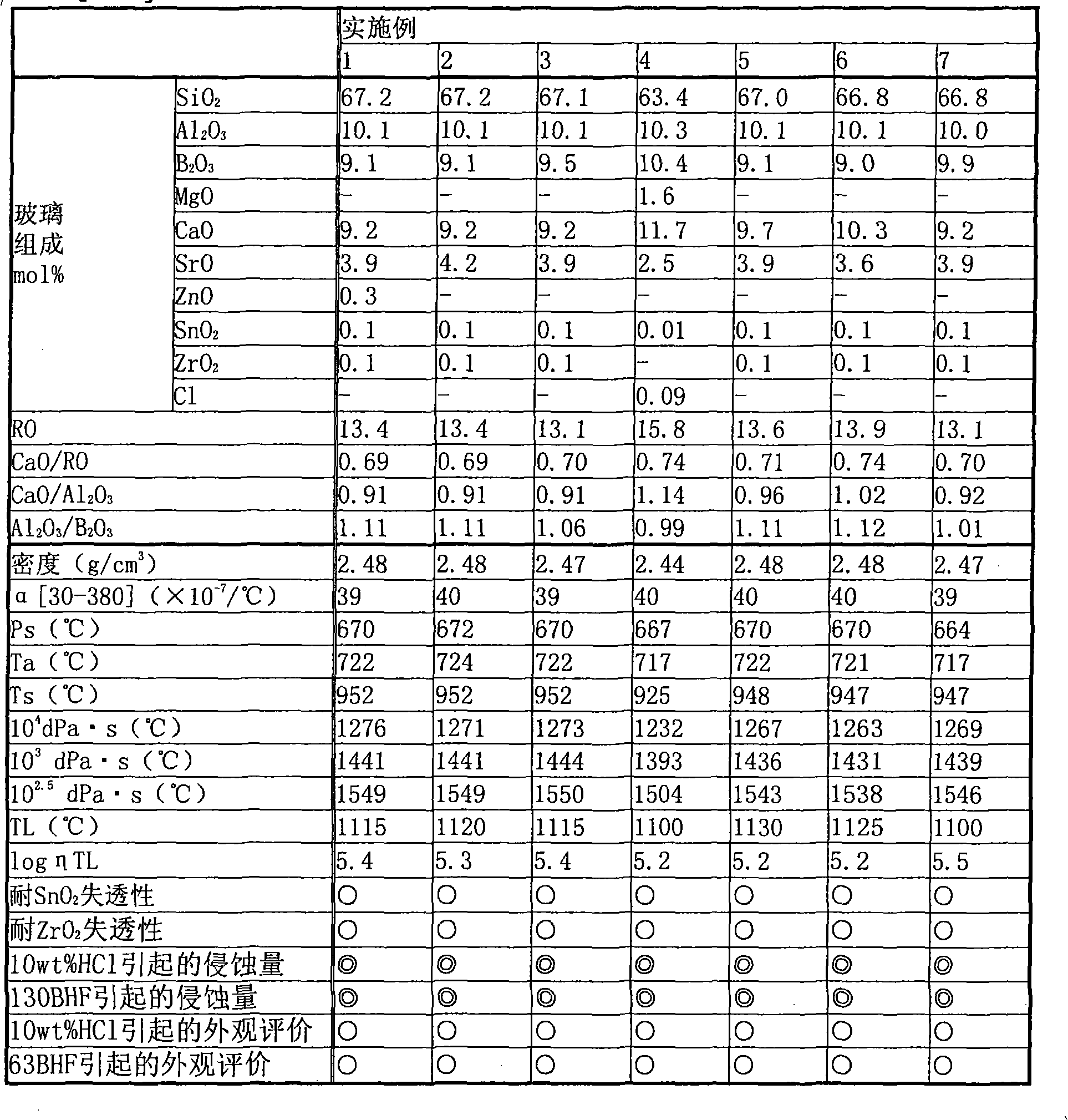

[0098] [Table 1]

[0099]

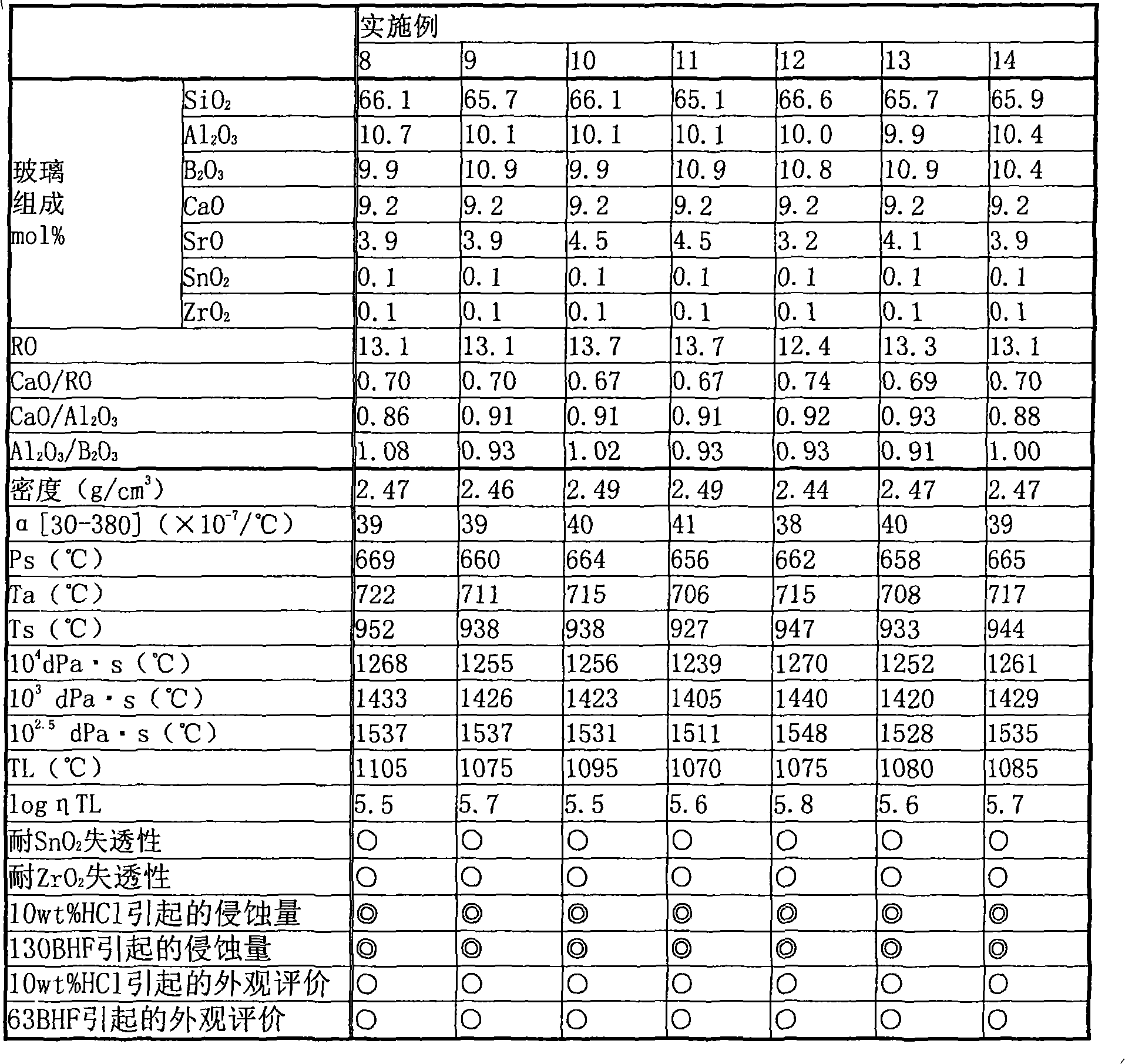

[0100] [Table 2]

[0101]

[0102] [table 3]

[0103]

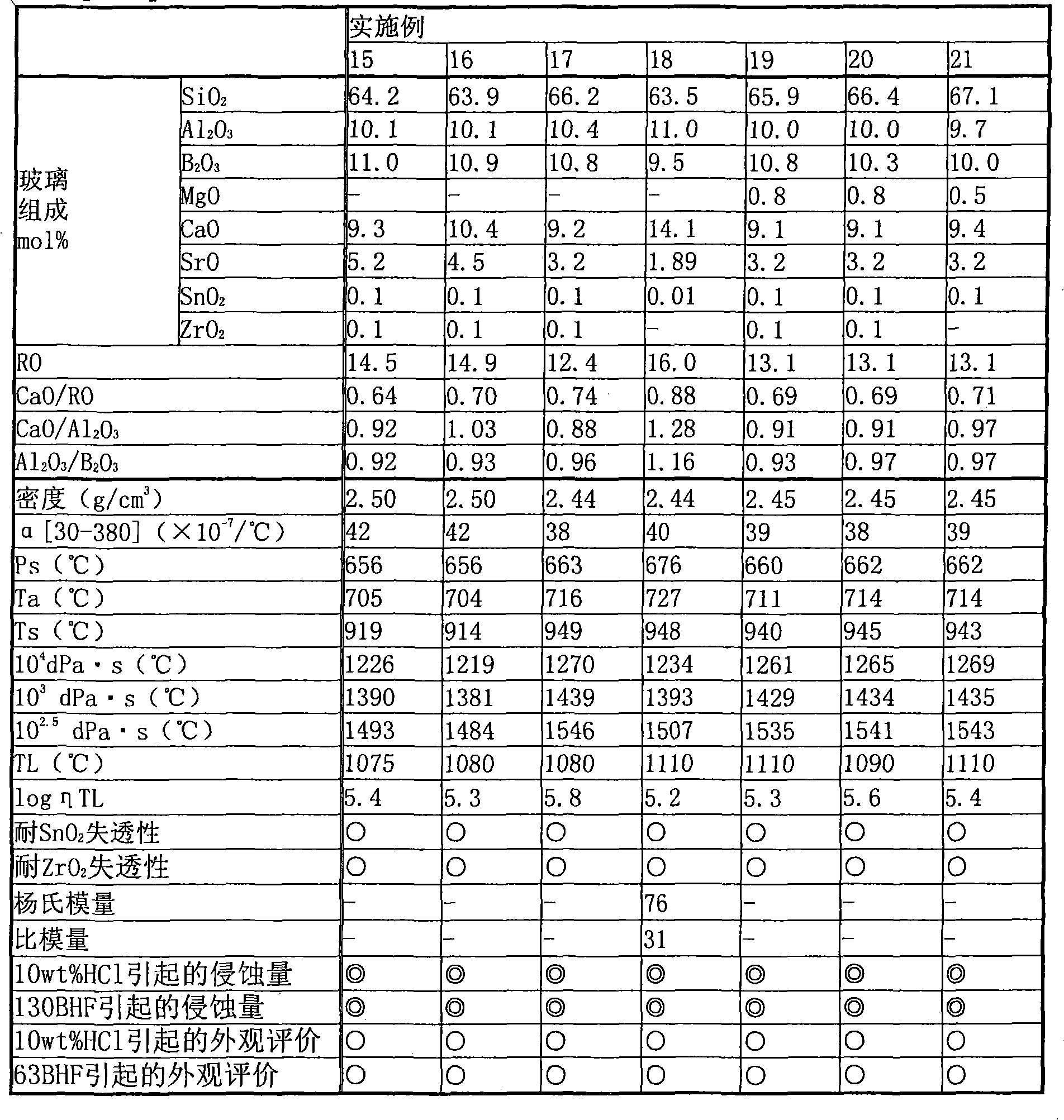

[0104] [Table 4]

[0105]

[0106] [table 5]

[0107]

[0108] [Table 6]

[0109]

[0110] [Table 7]

[0111]

[0112] [Table 8]

[0113]

[0114] Glass samples were produced as follows. A batch of raw materials prepared in a predetermined ratio was put into a platinum crucible, melted at 1600°C for 24 hours, and then flowed out on a carbon plate to form a plate shape.

[0115] Using this glass sample, various properties such as density, strain point, and high-temperature viscosity were measured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strain point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com