Caliper brake device for vehicle

A brake device and caliper-type technology, which is applied in the direction of brake types, railway brake systems, axial brakes, etc., can solve the problems of inability to reduce the friction coefficient of brake pads, uneven wear of brake pads, temperature rise, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

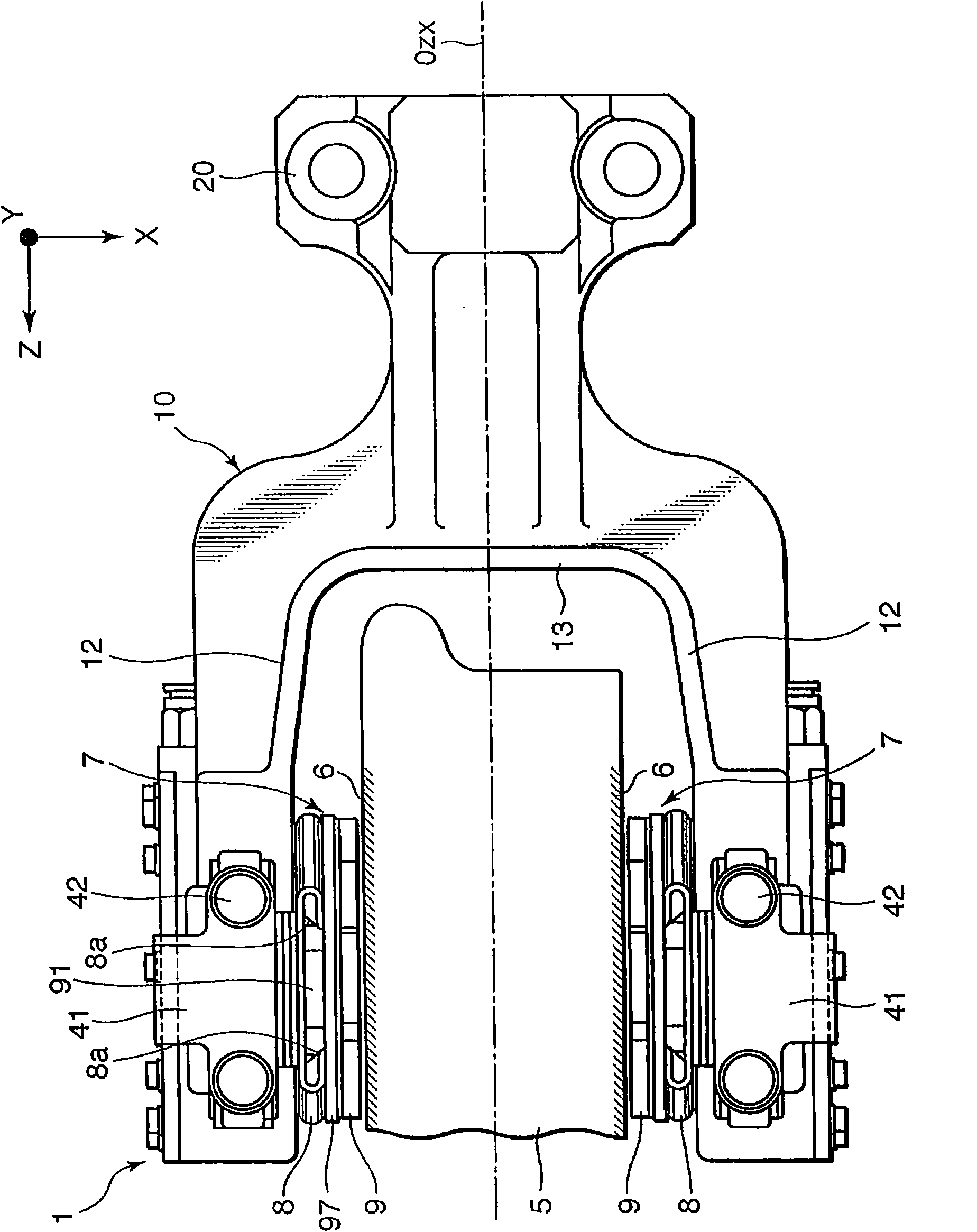

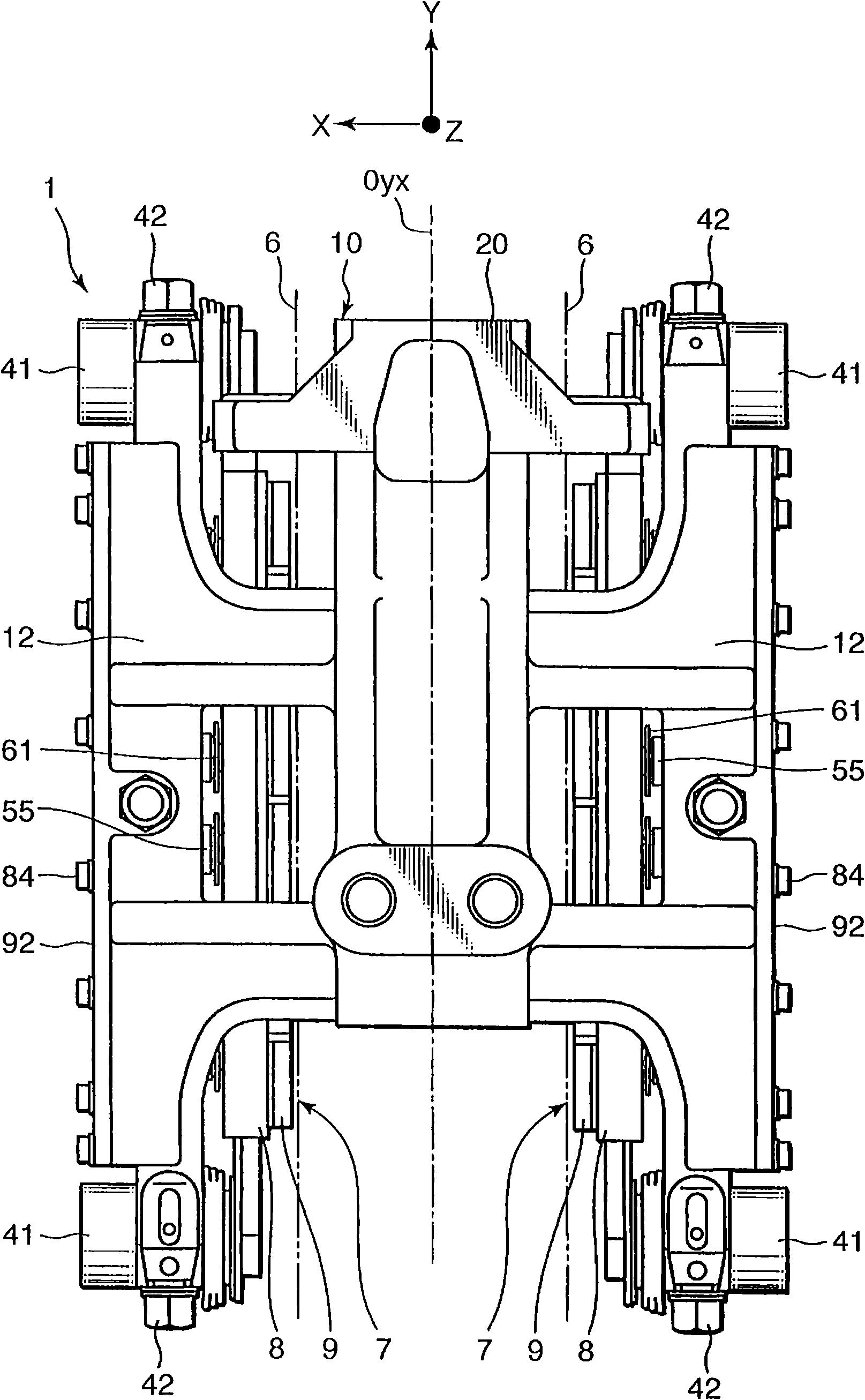

[0021] refer to figure 1 A caliper brake device 1 for a railway vehicle uses a pair of brake pads 7 to brake the rotation of a wheel 5 . In the figure, the X-axis corresponds to the axial direction of the wheel 5 , the Y-axis corresponds to the vertical direction, and the Z-axis corresponds to the front-rear direction. On both side surfaces of the wheel 5 , a pair of friction surfaces 6 are formed in advance for a pair of brake pads 7 .

[0022] A pair of brake pads 7 are respectively supported on the front ends of a pair of caliper arms 12 . A pair of caliper arms 12 is branched into two forks from a yoke 13 of the caliper 10 across the wheel 5 . The brake caliper 10 includes a flange portion 20 . The flange part 20 is fixed to the dolly of the railway vehicle with bolts.

[0023] Brake caliper 10 has a relative figure 1 centerline O zx shown and figure 2 The centerline Oyx symmetric shape shown.

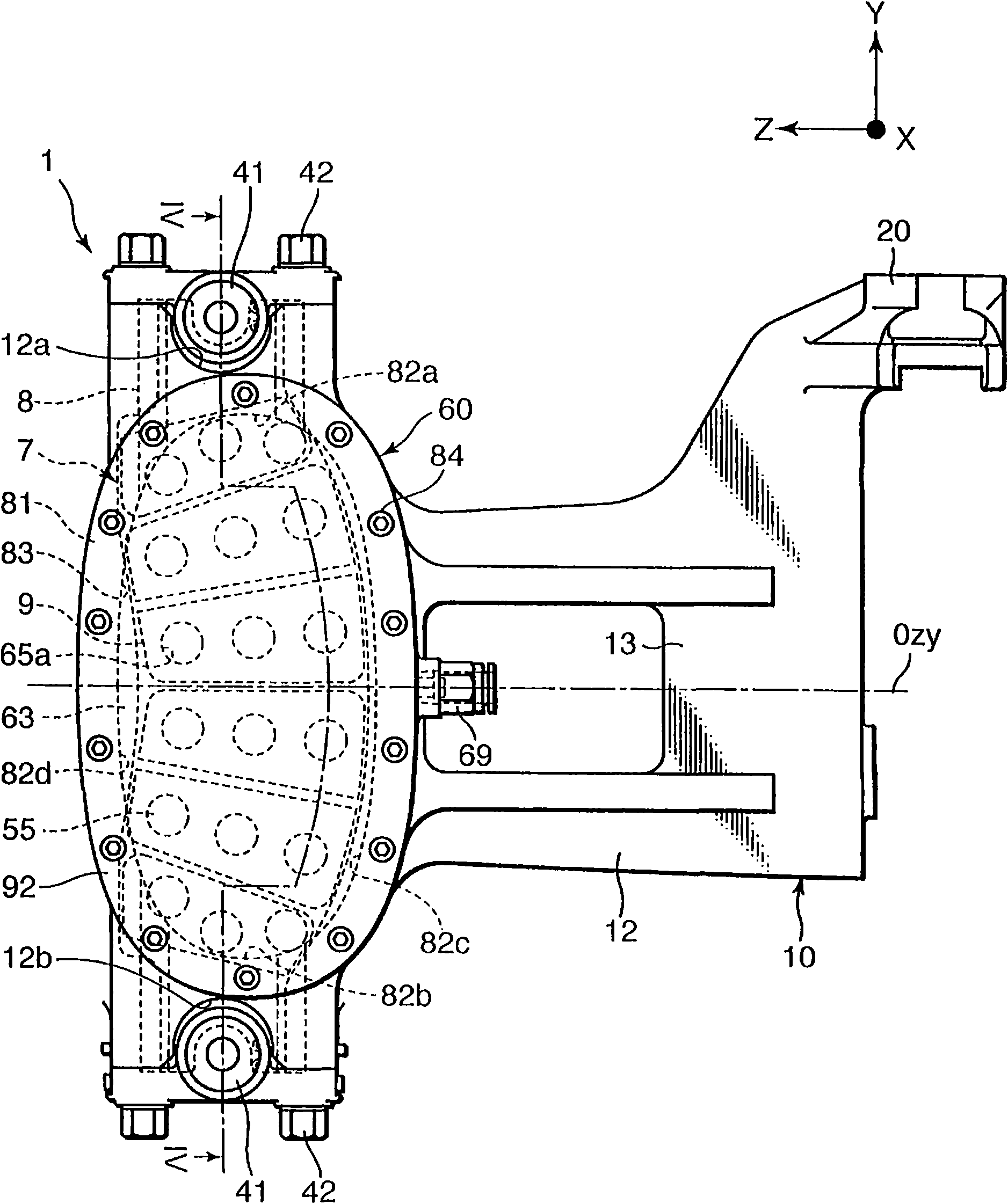

[0024] refer to image 3 and Figure 4 , in order to drive the bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com