Co2 refrigerant system with tandem compressors, expander and economizer

A refrigerant system and refrigerant technology, applied in irreversible cycle compression machines, compressors, refrigerators, etc., to achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

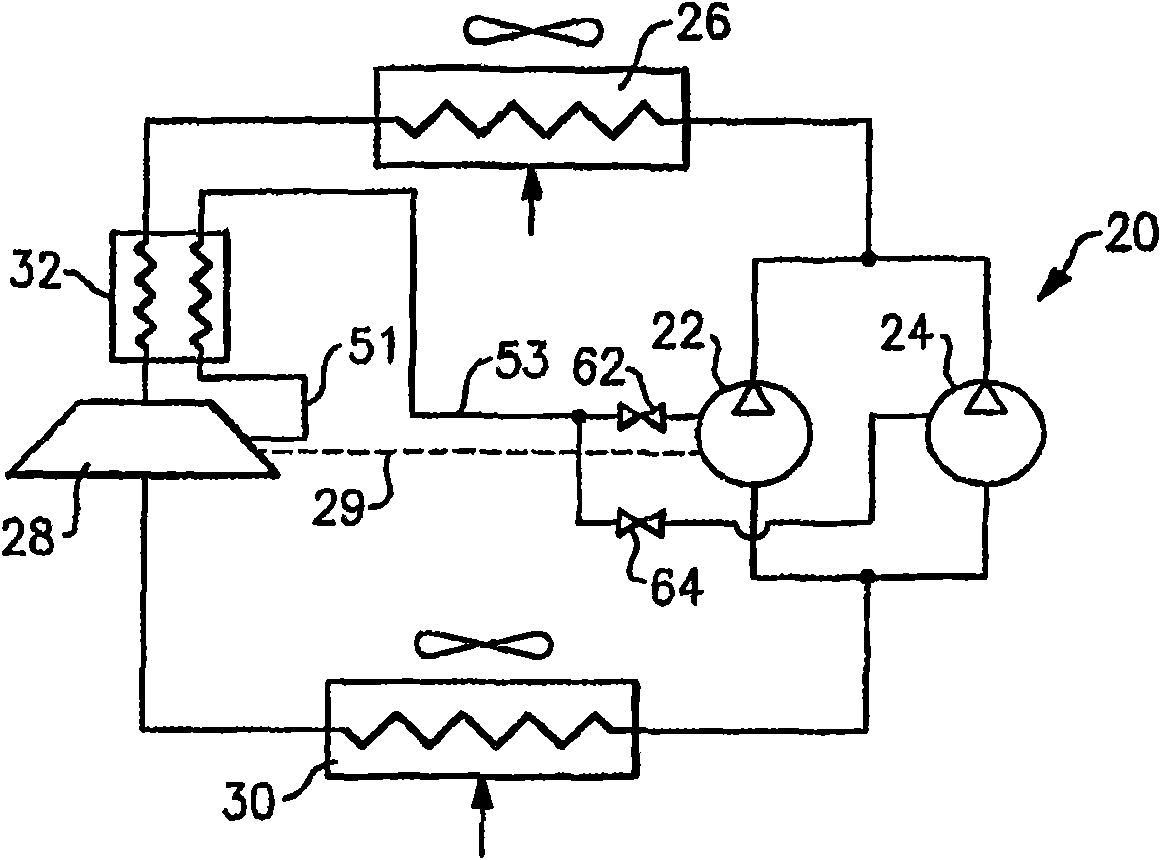

[0015] figure 1 Refrigerant system 20 is illustrated. As shown, two compressors 22 and 24 operate in tandem to provide compressed refrigerant and deliver the refrigerant throughout refrigerant system 20 . Obviously, more than two compressors can be arranged in parallel and operated simultaneously or individually according to the heat load demand in the conditioned space. Although in figure 1 In the conventional arrangement shown, the tandem compressors have a common suction header and a common discharge header, as known to those skilled in the art, but the tandem compressors could also have a common suction header. Gas headers and separate exhaust lines, as well as having separate suction lines and common exhaust headers. Additionally, tandem compressors 22 and 24 may have oil and steam balance lines (not shown), as known to those skilled in the art.

[0016] The compressed refrigerant flows through heat exchanger 26 and to expander 28 downstream. As known to those skille...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com