Trans-critical CO2 heat pump system meeting requirements of high return water temperature and different heating conditions and manipulation method of trans-critical CO2 heat pump system

A technology of high return water temperature and heat pump system, which is applied in the direction of fluid heaters, lighting and heating equipment, etc., can solve problems such as not being able to meet the needs of high-temperature circulation heating, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings of the specification.

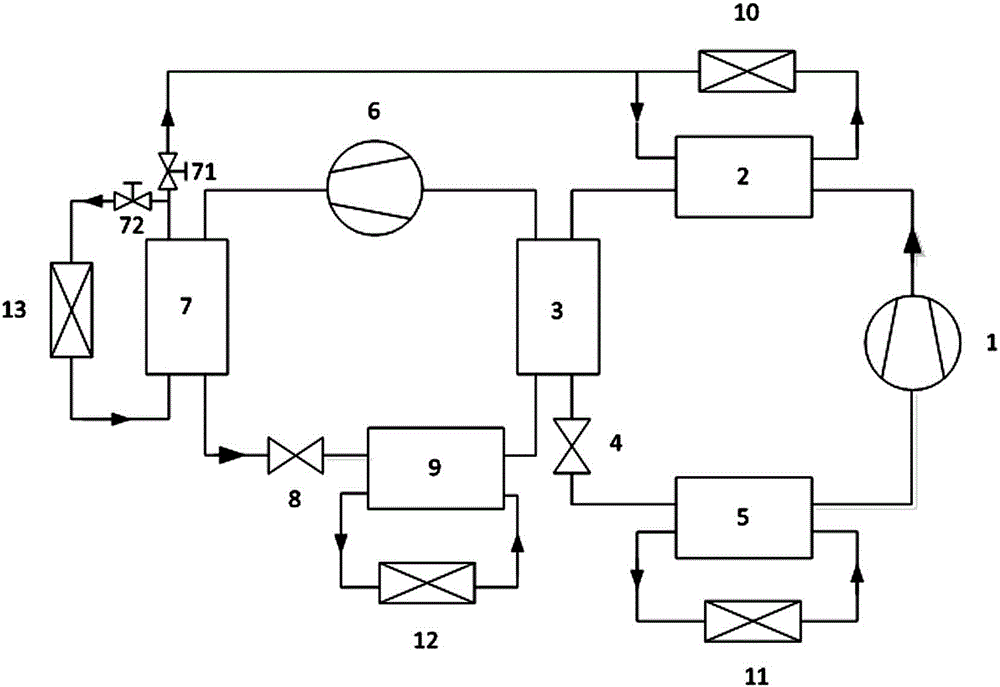

[0021] The invention realizes the high return water temperature and the transcritical CO required by different heating conditions 2 Heat pump system, such as figure 1 As shown, the system is composed of a subcritical circulation loop with medium and high temperature refrigerant as the refrigerant and CO 2 A heat pump system composed of a transcritical circulation loop of refrigerant;

[0022] The transcritical circulation loop includes a compressor A1, a gas cooler 2, an evaporative cooler 3, a throttle valve A4 and an evaporator 5 connected in sequence. The gas cooler 2 is used to connect to the 70~90℃ cycle. For the hot water demand user 10, the evaporator 5 is connected to a heat source A11, and the evaporative cooler 3 is the auxiliary gas cooler of the transcritical circulation loop;

[0023] The subcritical circulation loop includes a compressor B6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com