Sliding door of factory building

A technology for sliding doors and workshops, which is applied in the direction of architecture, building structure, door/window accessories, etc. It can solve problems such as deformation of the lower guide rail, loose door closing, and changes in the verticality of the door leaves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

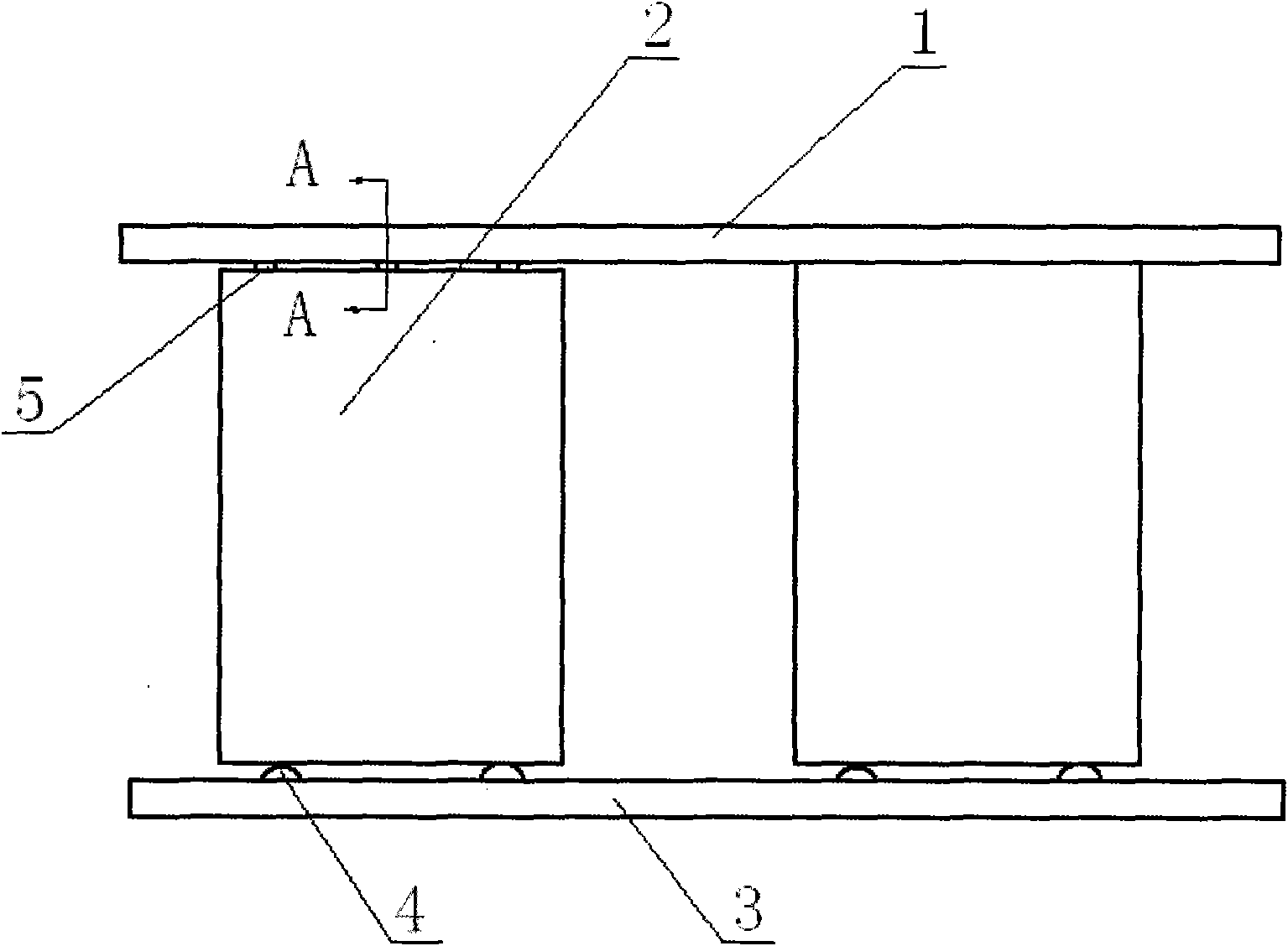

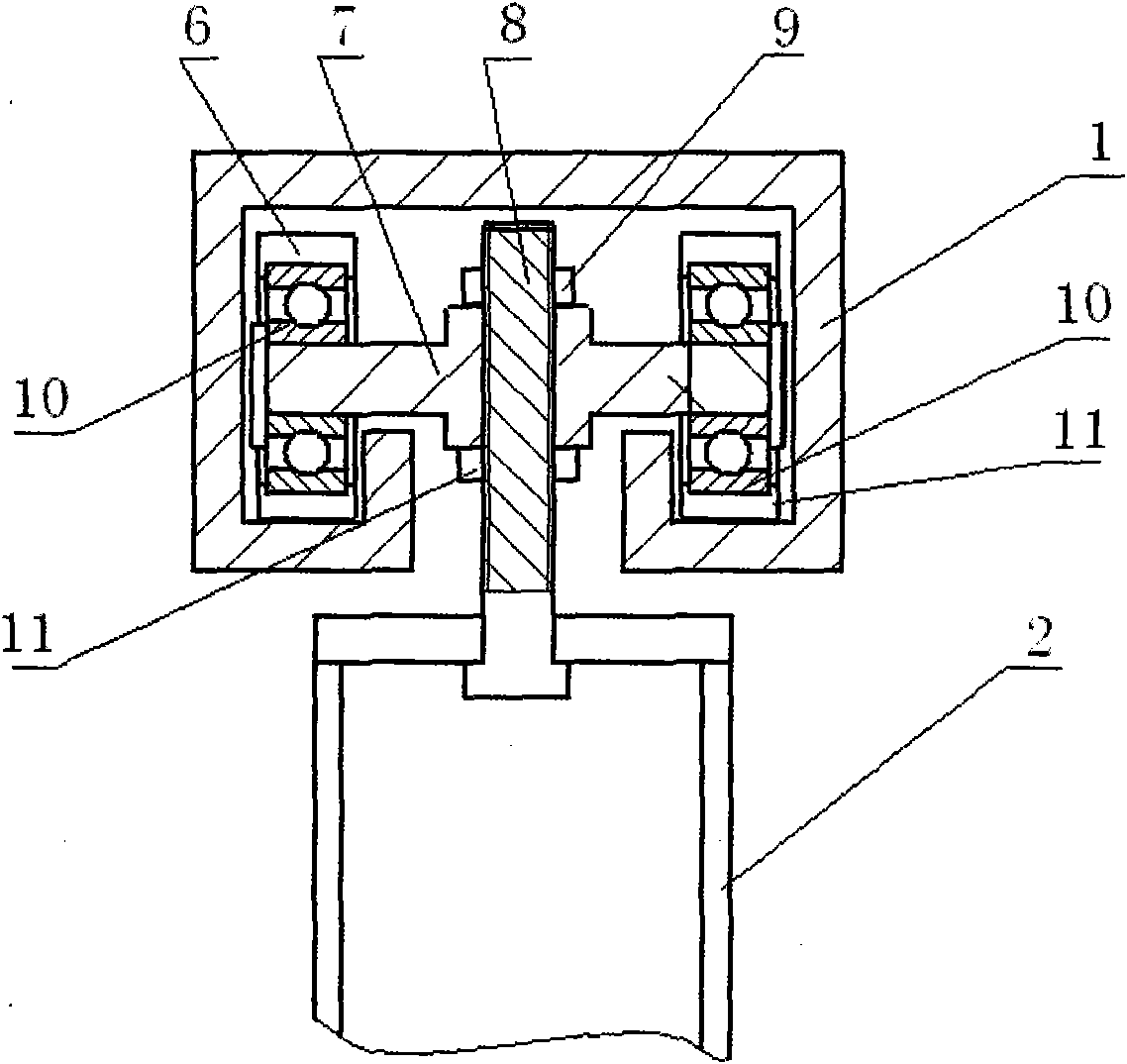

[0012] Such as figure 1 , figure 2 As shown, a sliding door structure of a building workshop includes an upper beam 1, a lower guide rail 3 and a door leaf. The door leaf is composed of a door body 2, two rollers 4 below the door body 2 and three moving parts 5 above the door body 2. A moving part 5 consists of a support 7, two bearings 10, two rolling sleeves 6, a long bolt 8, an upper nut 9 and a lower nut 11. The two ends of the support 7 have mounting bearing sections, and the middle of the support 7 has The long bolt passes through the bolt hole, the bearing 10 is fixed to the mounting bearing section of the support 7 through a snap ring, the rolling sleeve 6 is sleeved on the bearing 10, the long bolt 8, the upper nut 9 and the lower nut 11 connect the support 10 to the door body The tops of 2 are connected. In this way, the weight of the door leaf is shared by the upper beam. When the door is pushed and pulled, the moving parts roll along the upper beam and the rollers rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com