Piston cooling structure

A technology of piston cooling and structure, applied in the direction of engine components, machine/engine, engine lubrication, etc., can solve the problems of poor workability, not necessarily excellent workability, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Next, the best mode for carrying out the present invention will be described using examples.

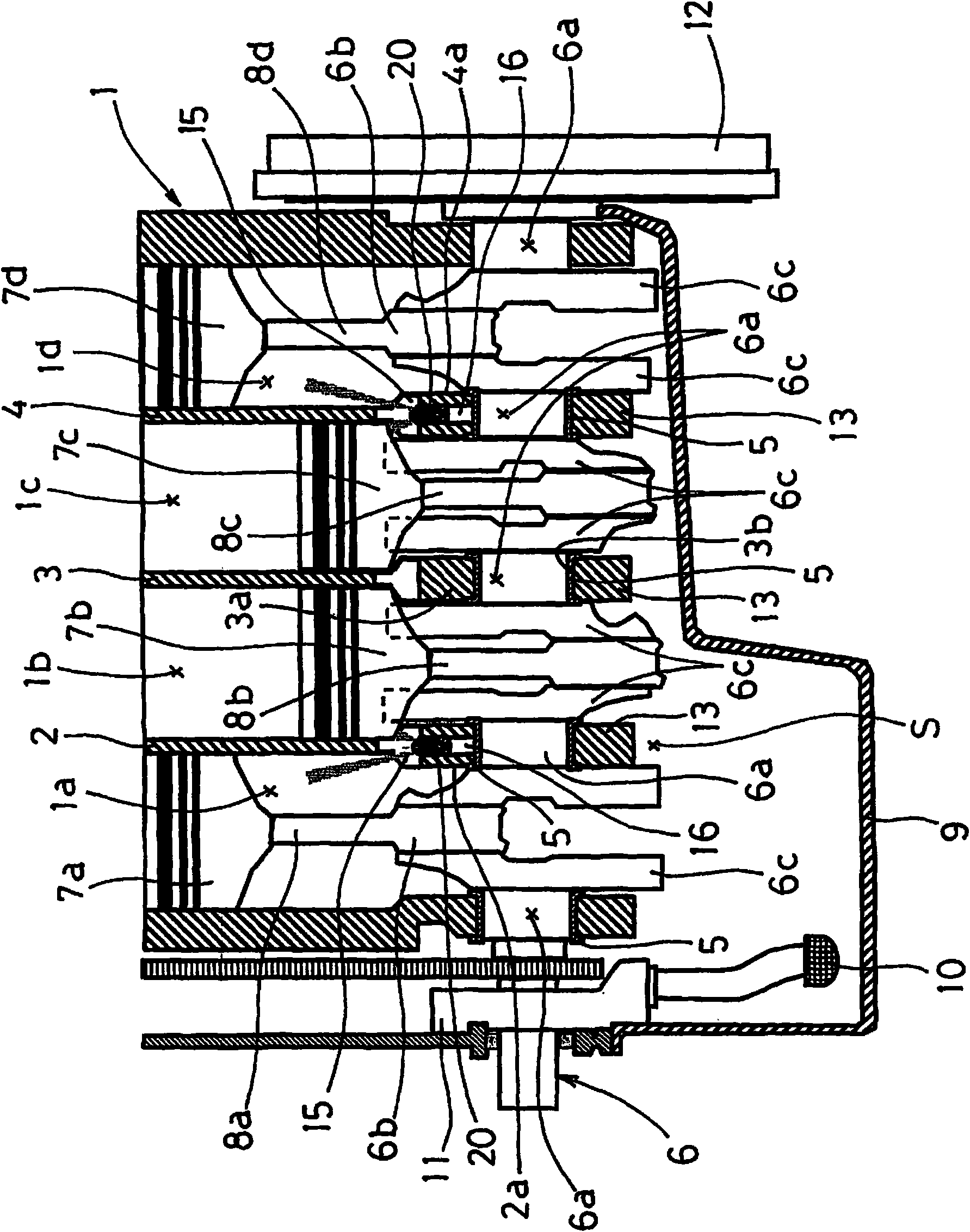

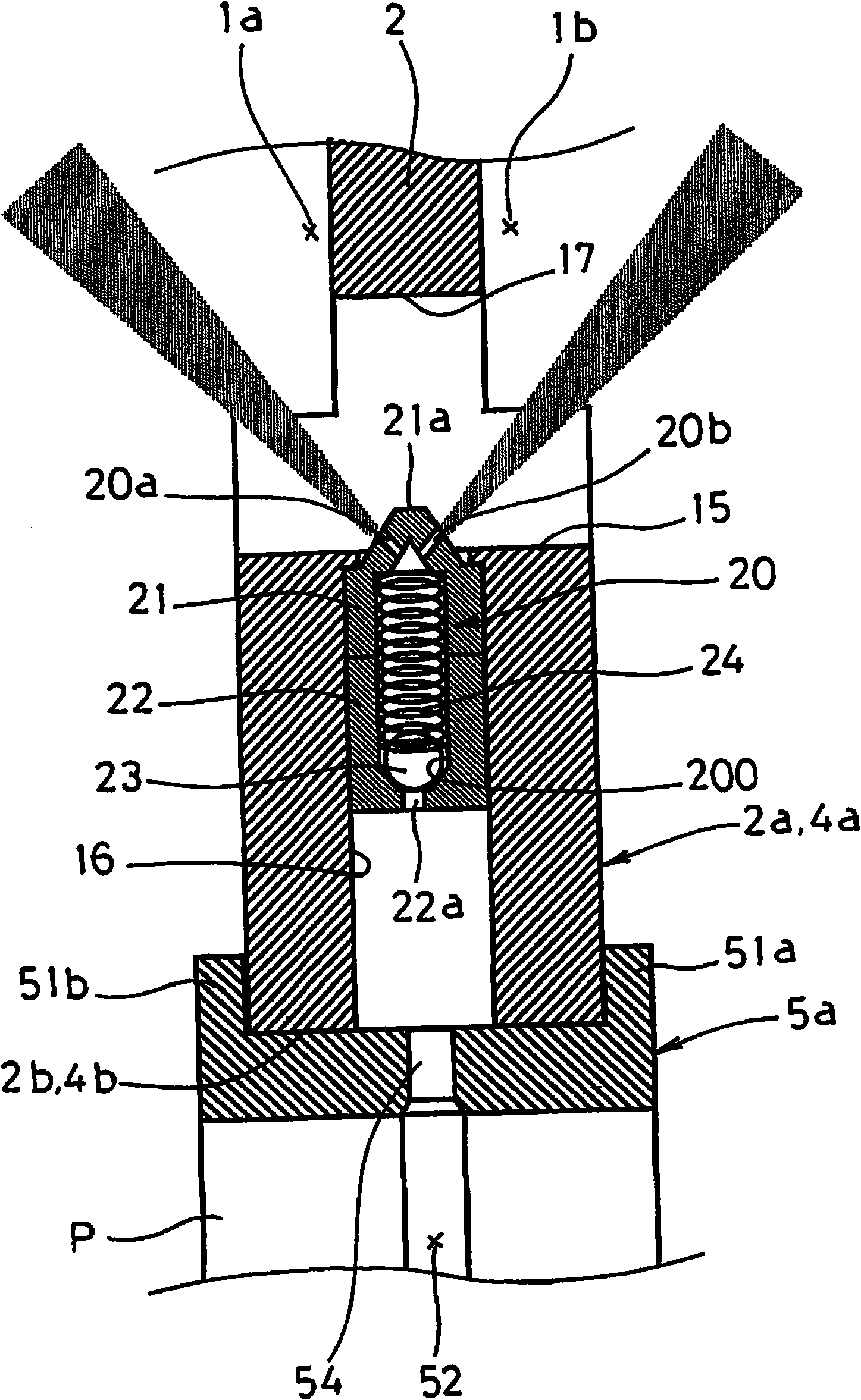

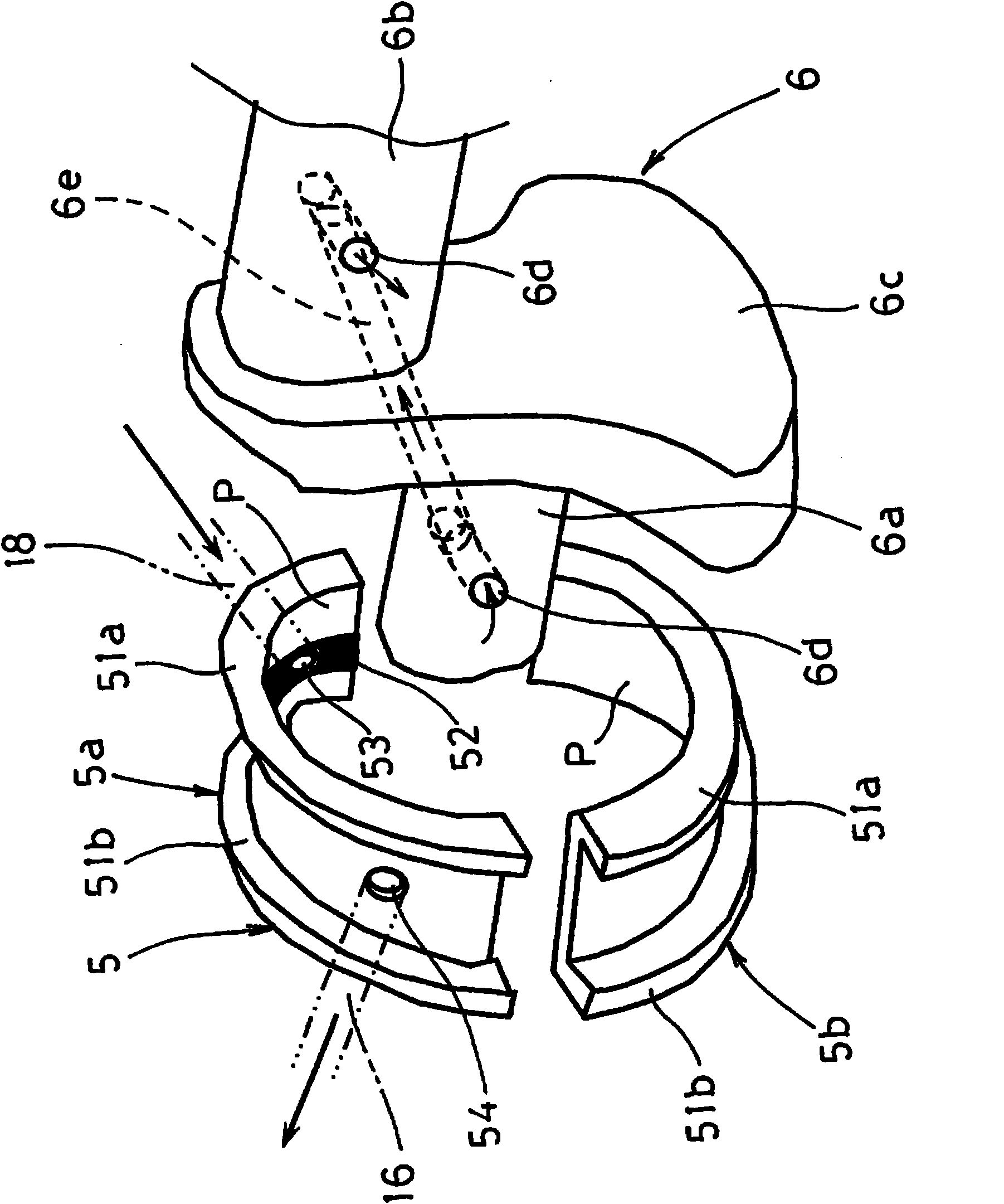

[0032] figure 1 It is a longitudinal sectional structural diagram of the crankcase of a 4-cylinder in-line engine, figure 2 It is a partial enlarged view of the inter-hole walls 2 and 4.

[0033] Such as figure 1 As shown, a crankshaft 6 is rotatably provided in the crankcase 1, and a first cylinder bore 1a, a second cylinder bore 1b, and a cylinder bore 1 are arranged side by side along the axial direction of the crankshaft 6 from left to right in the figure. No. 3 cylinder bore 1c and No. 4 cylinder bore 1d are provided in each cylinder bore 1a, 1b, 1c, and 1d so as to be slidable in the up and down directions respectively, and are connected to the crankshaft 6 through each connecting rod 8a, 8b, 8c, 8d. The 1st piston 7a, the 2nd piston 7b, the 3rd piston 7c, the 4th piston 7d.

[0034] In this example, the inter-hole wall 2 between the first cylinder hole 1a and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com