Anchoring device of screw pump

A technology for anchors and screw pumps, applied to pumps, machines/engines, pumps with flexible working elements, etc., can solve the problem of no effective structure and function to prevent the stator barrel of screw pumps from rotating, and reduce pump inspection and maintenance Operation, improve work efficiency, reliable function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

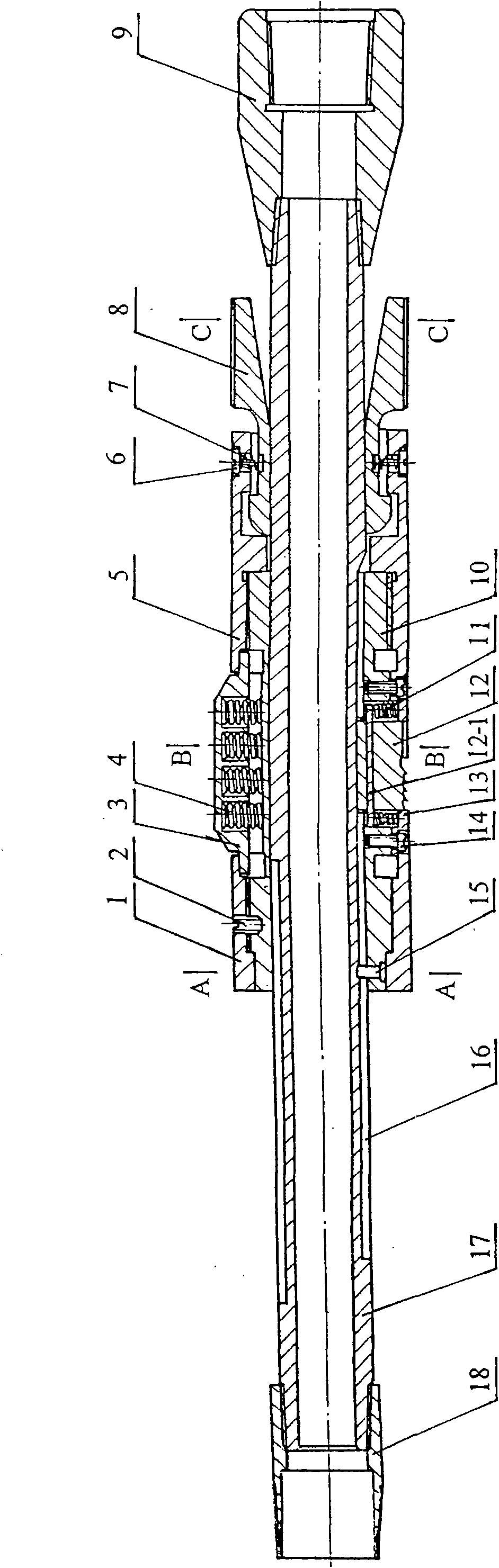

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

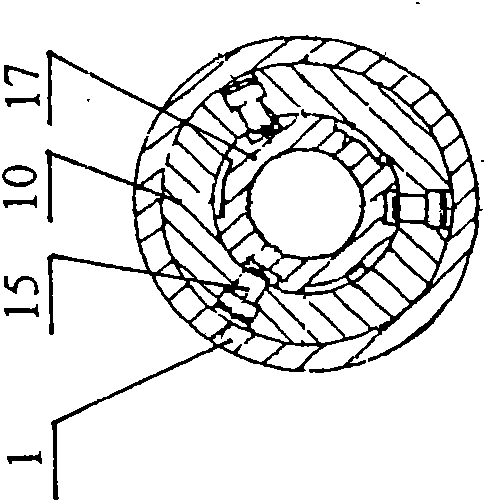

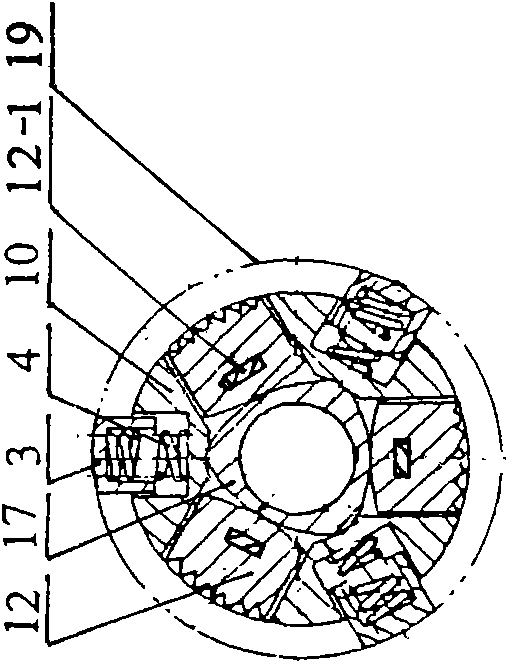

[0018] The main body 10 is a stepped cylindrical shape with a through hole in the middle, and is assembled on the central tube 17 as an anchor base frame structure.

[0019] There are 2 to 3 track grooves 16 (determined by the size of the anchor) evenly distributed on the outer diameter surface of the central tube 17 .

[0020] Track groove 16 is made up of downhole track groove 16-1, setting sealing track groove 16-2 again, as Figure 5 shown.

[0021] The cross-sections at both ends of the central tube 17 are circular with through holes in the middle, and the cross-section of the middle part is a trilateral cam shape with through holes, and the length of the cam-shaped central tube is 2 to 2.5 times the length of the body 10, such as figure 1 , image 3 shown.

[0022] The upper part of the main body 10 is connected with the brace 5 with the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com