Method for processing small cover shell of automobile parts

A technology for auto parts and processing methods, applied in the field of auto parts, can solve the problems that affect the production, operation and development of enterprises, affect product quality, and the requirements for coaxiality, verticality, and position cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

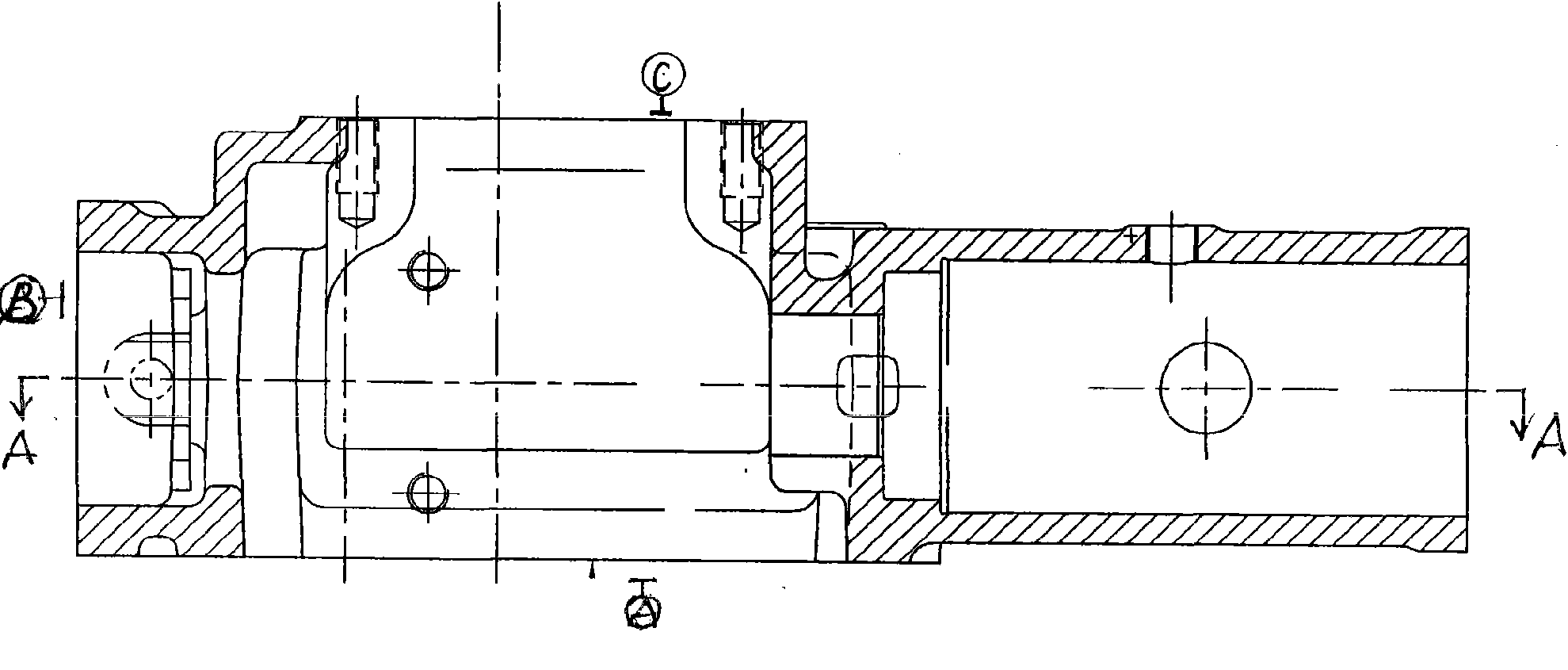

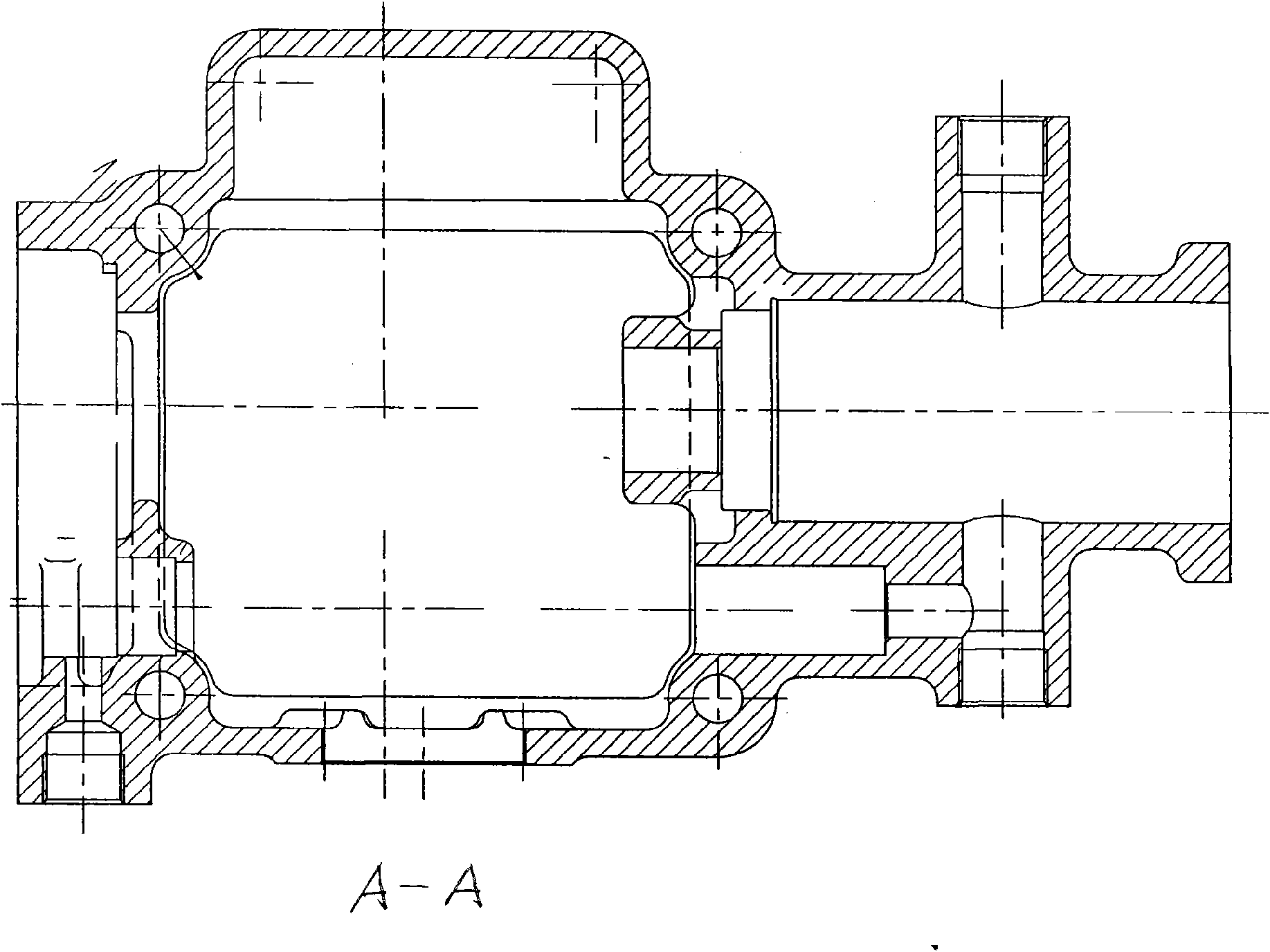

[0006] Below in conjunction with accompanying drawing, the present invention will be further described;

[0007] exist figure 1 , figure 2 Among them, the processing method of the small cover shell of auto parts is characterized by: milling A surface: positioning with a large plane support nail, pressing the side with a positioning platen, milling the plane to ensure the size of the center line, drilling, expanding, and drilling according to the requirements of the drawing Ream the holes on surface A, and ensure the accuracy requirements of each position; mill surface B, position it with the machined plane, and press it tightly, mill the plane, ensure the dimensions according to the requirements of the drawing, drill 12- 6.7 holes, hole depth 20, to ensure the center distance of the four holes on three sides, drilling and reaming 16.5 deep 16 and other drilling and reaming according to the requirements of the drawing, fine boring the inner hole on the left to the size of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com