Quick indexing hydraulic indexing clamping device

A clamping device and indexing technology, used in precision positioning equipment, metal processing mechanical parts, metal processing equipment, etc., can solve the problems of inability to rotate with motion, complex structure, unavailability, etc., to achieve compact structure and improve processing efficiency. , use reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

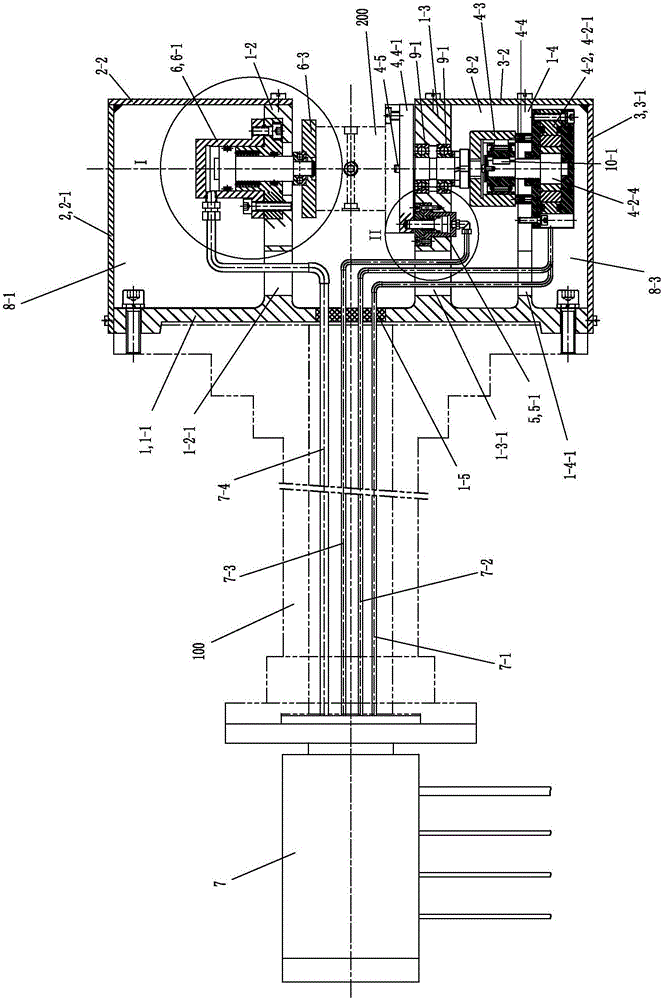

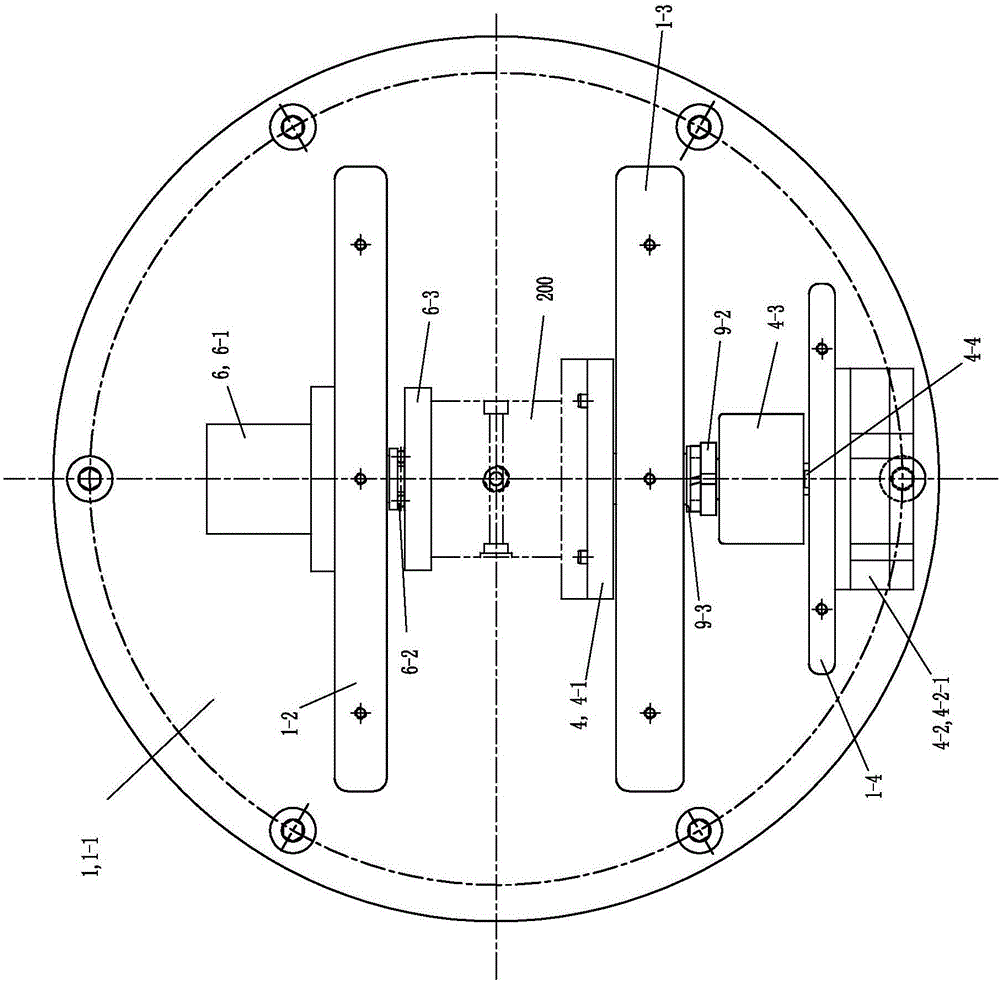

[0070] See figure 1 with figure 2 , The rapid indexing hydraulic indexing clamping device of the present invention includes a fixed base 1 , an upper cover assembly 2 , a lower cover assembly 3 , a rotating assembly 4 , a positioning assembly 5 , a pressing assembly 6 and a hydraulic rotary joint 7 .

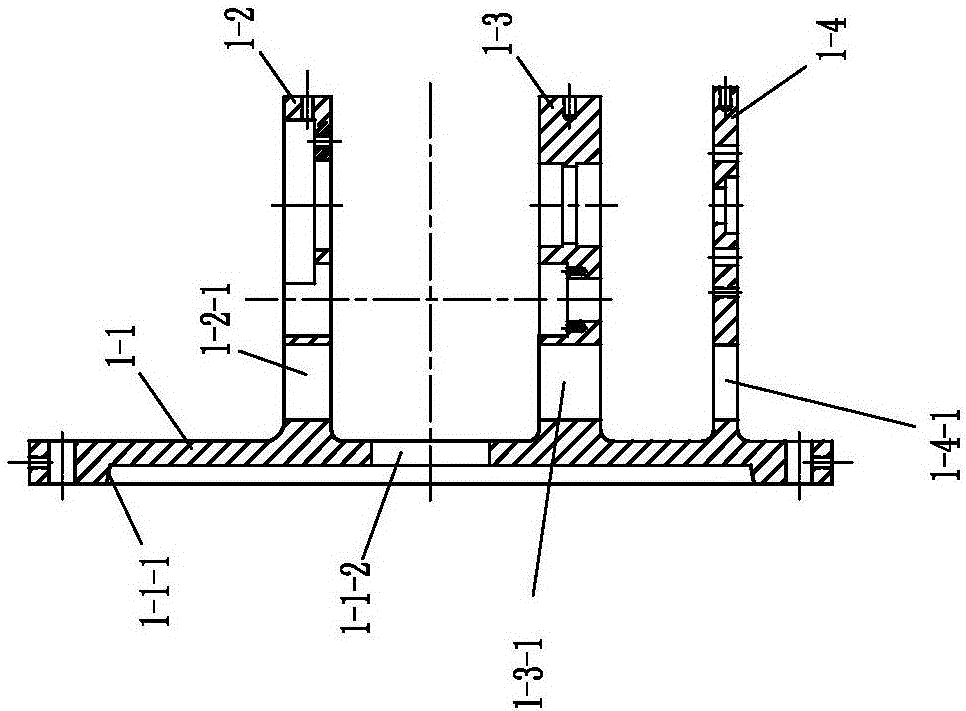

[0071] See Figure 1 to Figure 4 , The fixed seat 1 is a steel integral piece. The fixed seat 1 includes a disc connecting portion 1-1, an upper seat plate 1-2, a middle seat plate 1-3 and a lower seat plate 1-4. The axis of the disc connection part 1-1 is arranged horizontally along the left and right directions. The disk connecting portion 1-1 is provided with a positioning taper hole 1-1-1 opening to the left. A first oil pipe hole 1-1-2 runs through the left and right sides of the disk connecting portion 1-1. A dust-proof rubber ring 1-5 is arranged in the first oil pipe hole 1-1-2. The upper seat plate 1-2 is horizontally arranged on the upper right side of the disk ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com