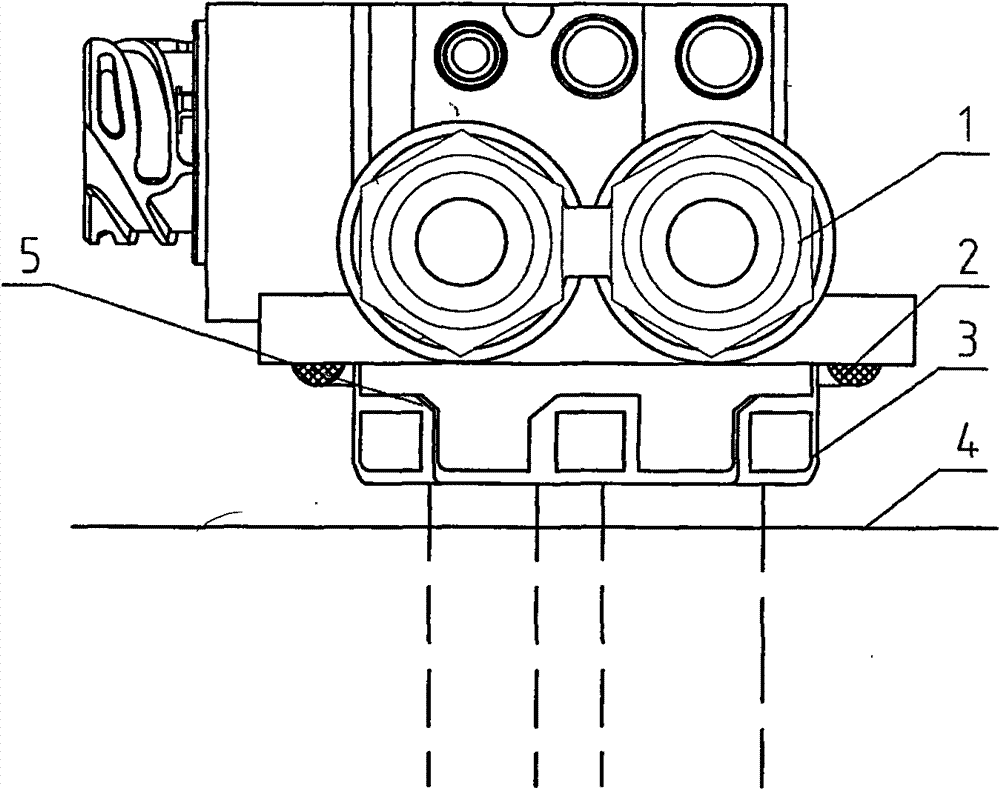

Connecting structure of fuel sensor and fuel tank

A connection structure and sensor technology, applied in the substructure, the layout combined with the fuel supply of the internal combustion engine, the power plant, etc., can solve the problems of easy wear and aging failure of the O-ring seal, oil leakage of the fuel sensor, loose fitting, etc., to avoid problems such as The effect of oil leakage, improving service life and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The following description is only exemplary and does not limit the protection scope of the present invention.

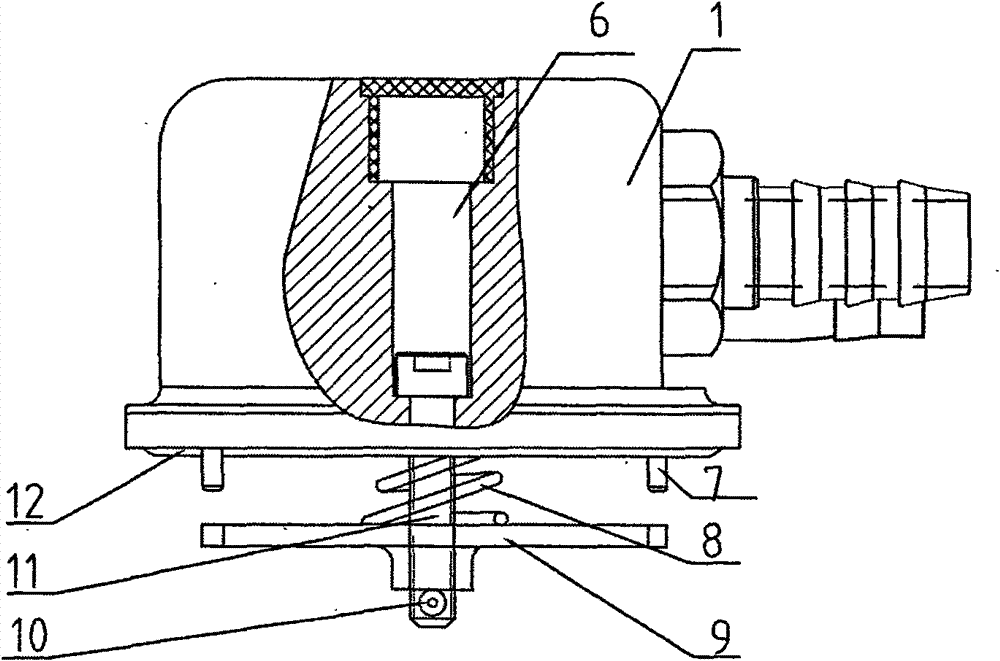

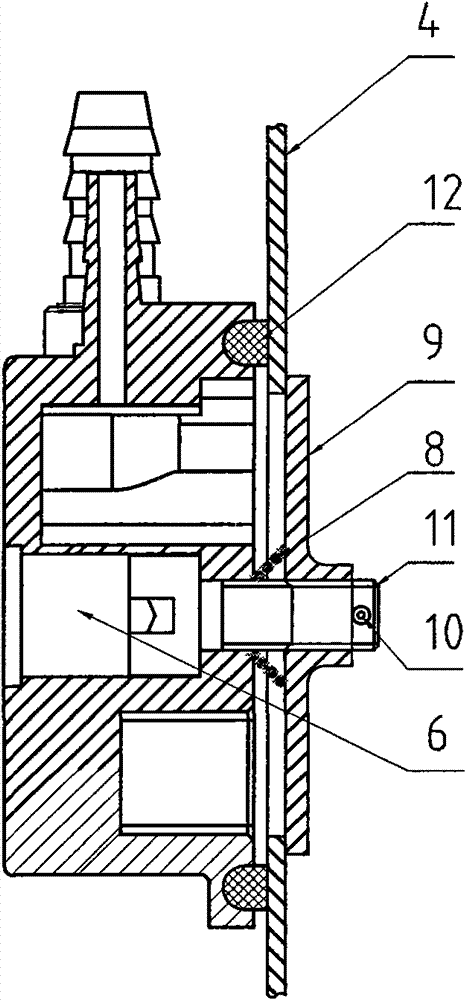

[0031] Such as figure 2 , 3 , a connection structure between a fuel sensor and a fuel tank shown in 4, including a fuel tank port 4 with six protrusions uniformly distributed along the circumference, a locking piece 9 for cooperating with the fuel tank port 4 and pressing the fuel tank port, an axial A stepped mounting hole 6 that runs through the base 1 of the fuel sensor, a hexagon socket bolt 11 and a gasket 12; Figure 4 The locking piece shown is provided with a central hole 13 with an internal thread, and six protrusions are evenly distributed in the circumferential direction, and the width of the protrusions is smaller than the distance between adjacent protrusions. corresponding; such as figure 2 , 3 The shown he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com