Locking mechanism of miniature electric connector

A technology of locking mechanism and electrical connector, which is applied in the direction of connection, parts and circuits of connecting devices, etc., which can solve problems such as inability to fit in place and limit the application of locking mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

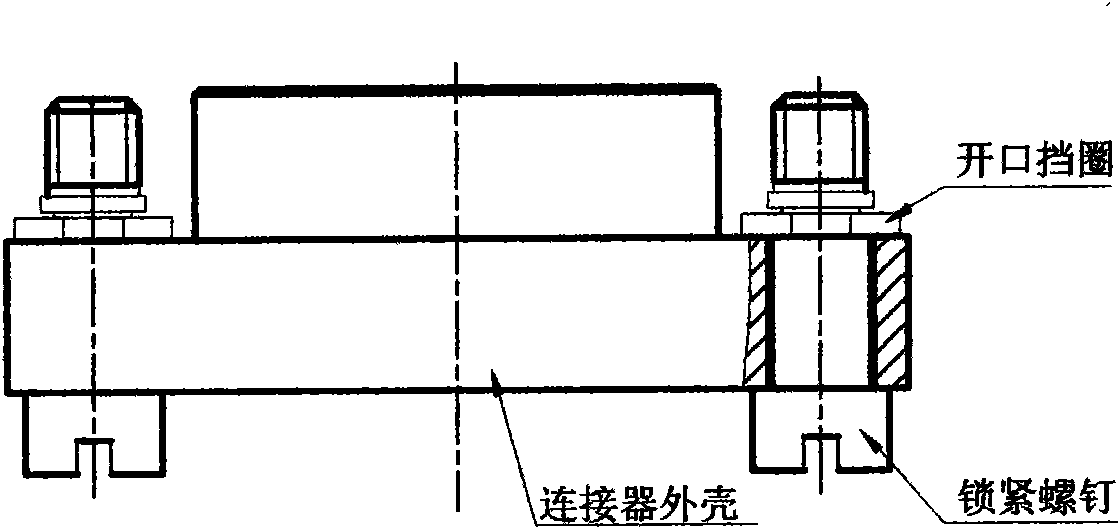

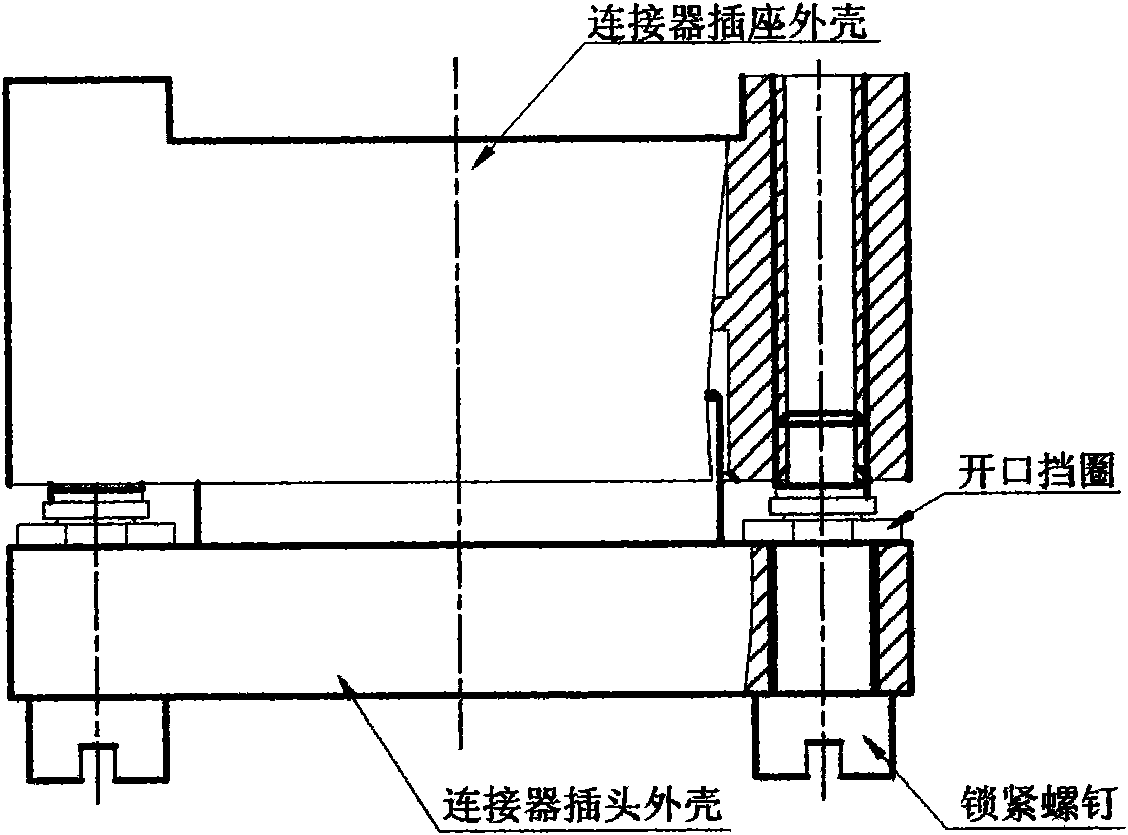

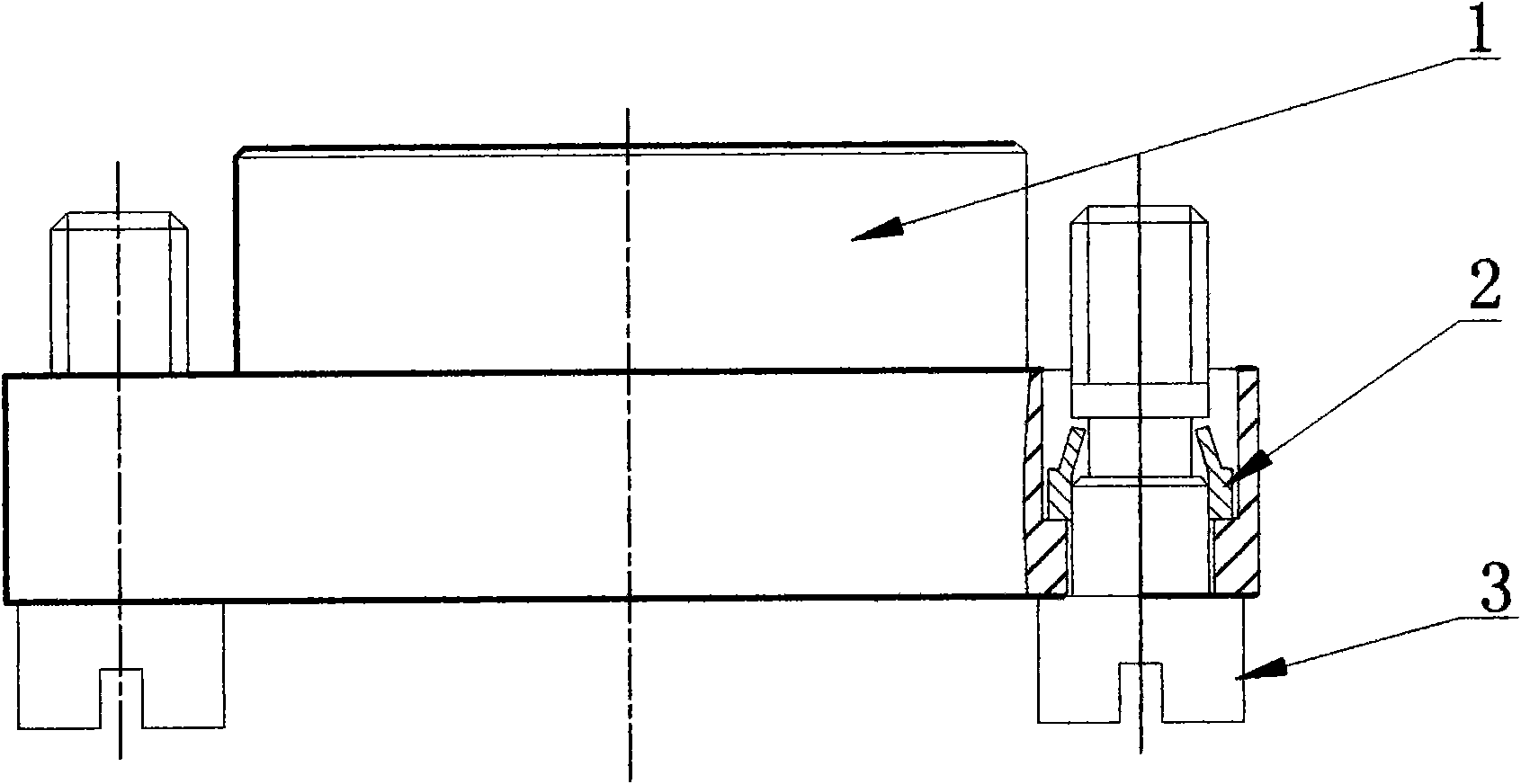

[0010] As shown in the figure, the locking mechanism of the electrical connector of the present invention is composed of a shrinking sleeve 2 and a locking screw 3. The locking screw 3 is provided with an annular groove 4, and one end of the transition between the annular groove 4 and the upper and lower sections is Chamfering, the other end is a right angle, the chamfering structure ensures that the sleeve can be easily put in place, and the right angle structure ensures that the sleeve can reliably block the shrinking sleeve after shrinking. The necking sleeve 2 has a stepped structure, and the strength of the thin-walled part is relatively low. The shrinking can be realized by pressing it with a tapered sleeve. The shrinking sleeve is stuck in the annular groove of the locking screw so that the lock Tighten the screws to fix it on the case. There is a certain gap between the casing, the locking screw and the matching surface of the casing, and there is also a certain gap be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com