Patents

Literature

31results about How to "For a seamless fit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

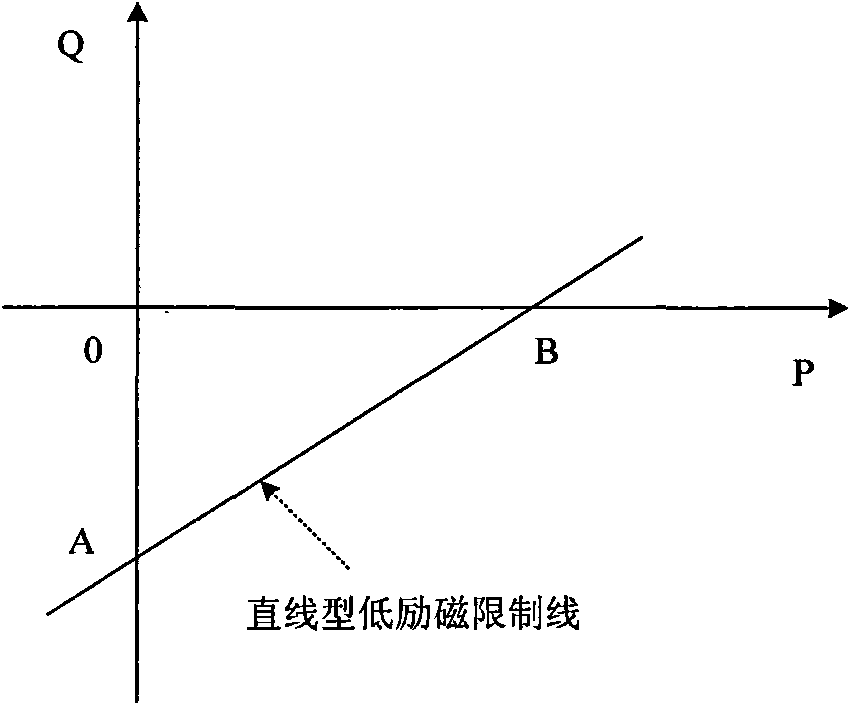

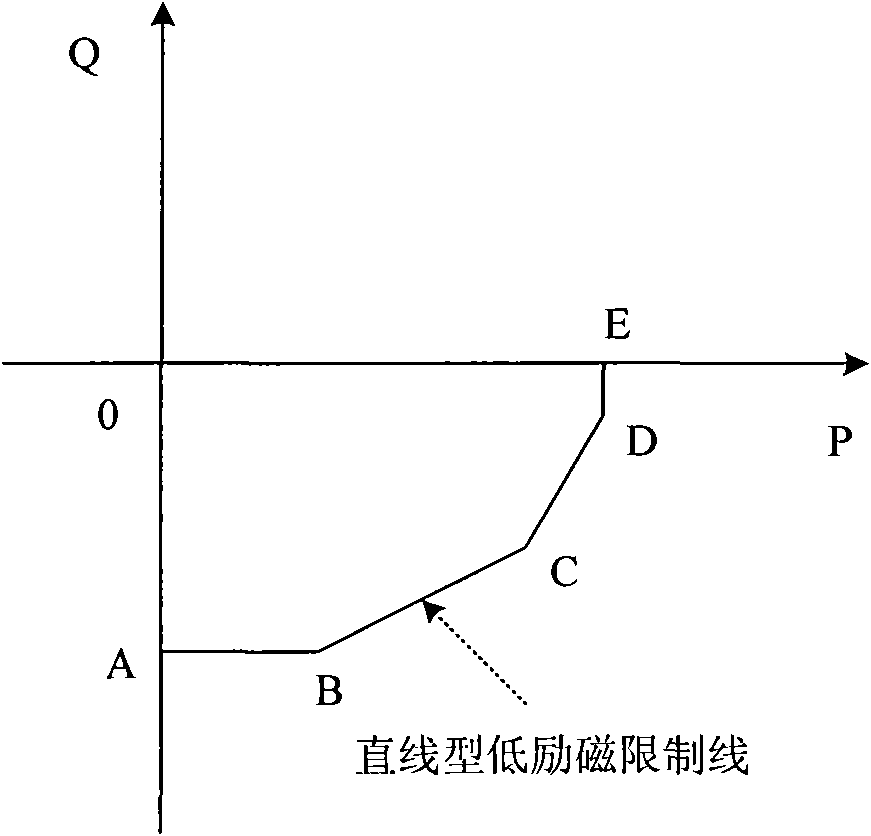

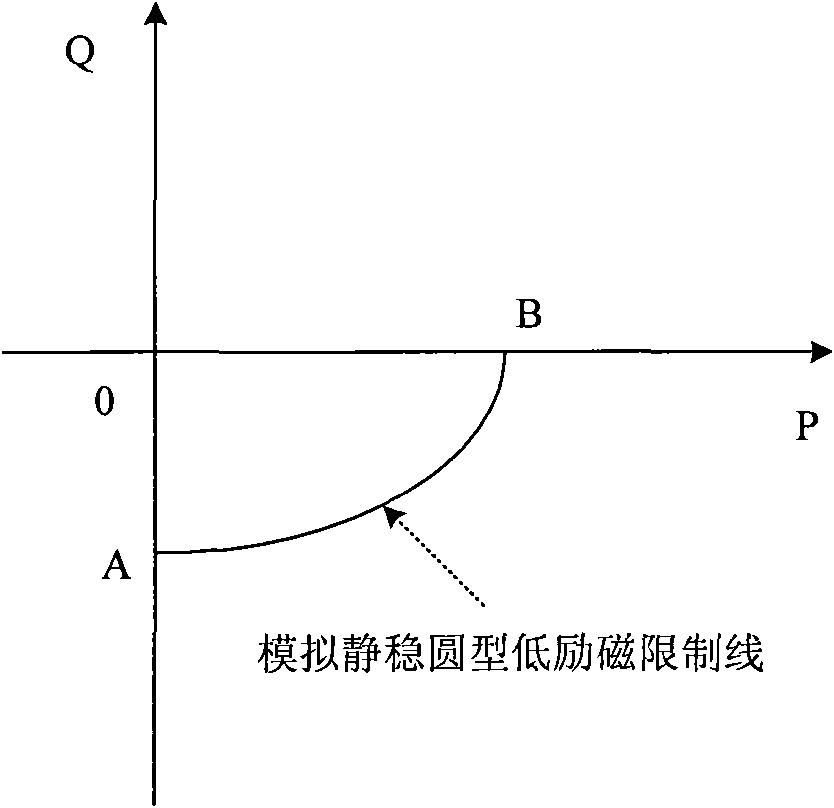

Method of limiting low excitation

ActiveCN101588153AFor a seamless fitPrevent accidental tripGenerator control by field variationTerminal voltageExcitation current

Method of limiting low excitation, calculating measured impedance of generator terminal by detecting generator terminal voltage and terminal current, when the measured impedance entering low excitation limited impedance circle, the low excitation limits prolong action of 40-60 ms on amplifying excitation current to maintain generator in stable operation situation, the low excitation limited impedance impedance circle covers static stable loss of excitation protection impedance circle to implement seamless connection with generator loss of excitation protection impedance criterion, and prevent the generator in low excitation operation, the low excitation is limited lagging behind the loss of excitation protection action, thereby generator error jump is caused. The invention is used in generator excitation regulation, comparing with former low extitation limiting method, the invention is more visualized, the loss of excitation protection and low excitation are all R-X impedance plane coordinate description and easy to cooperate with each other.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +2

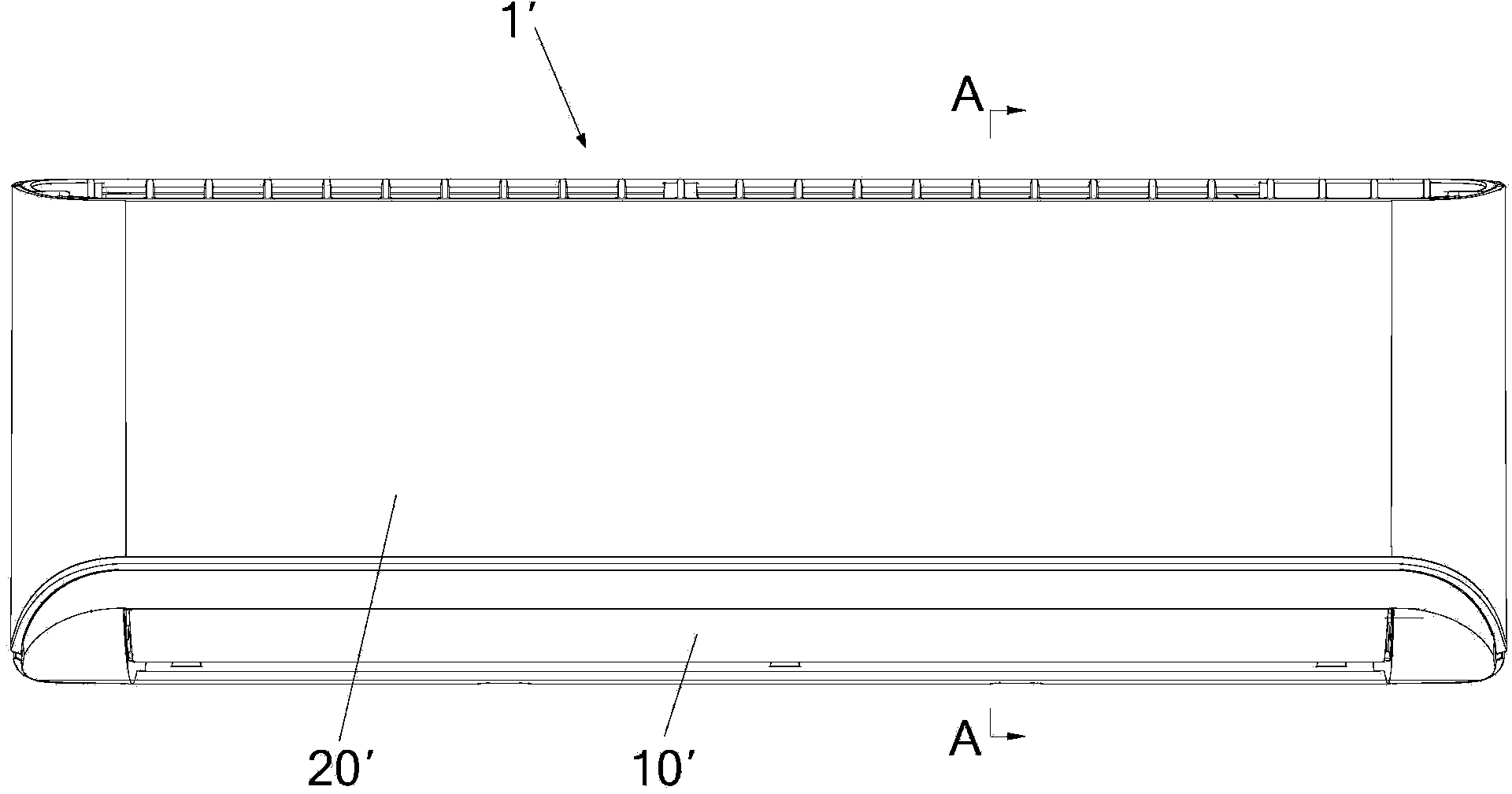

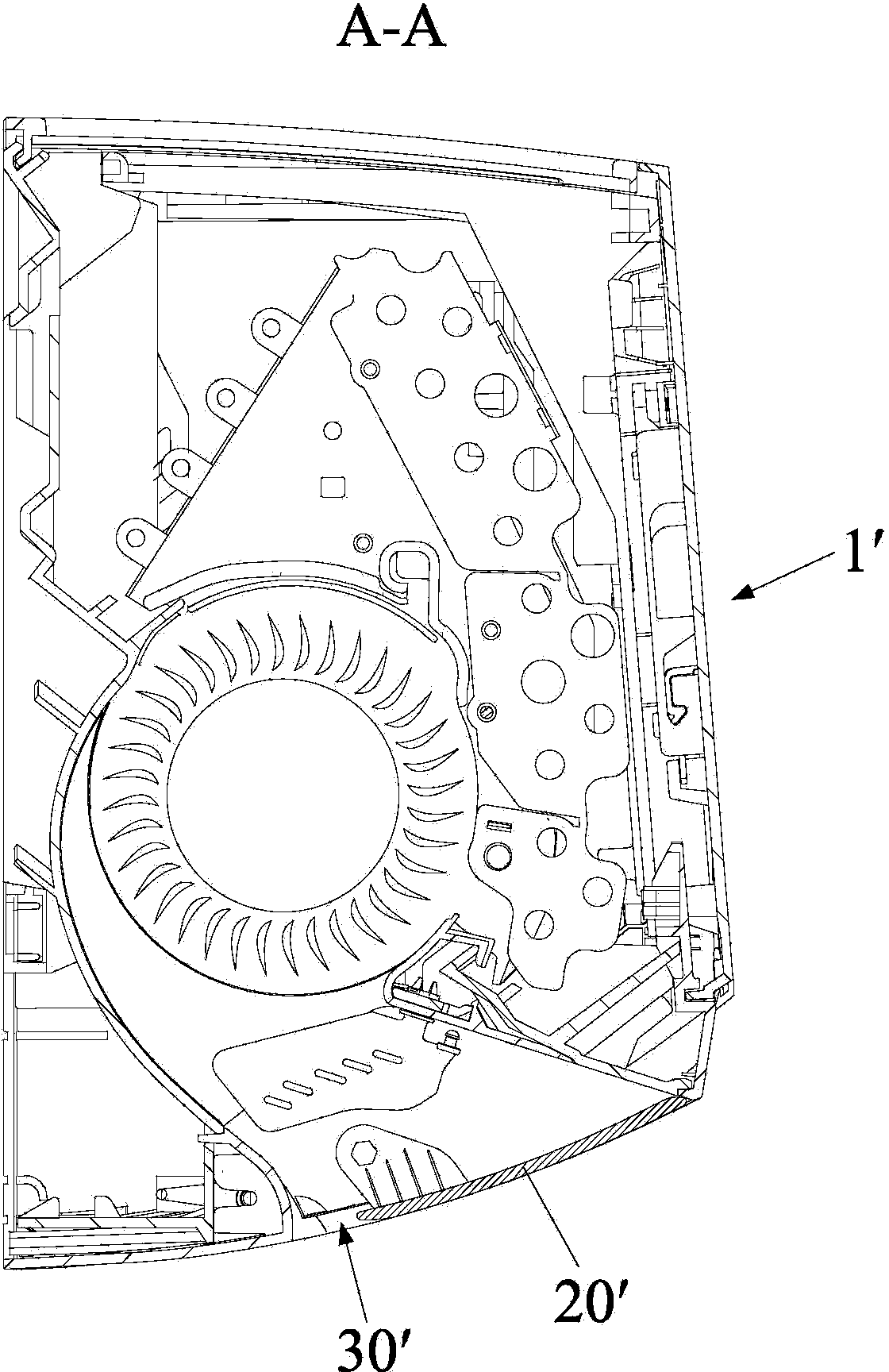

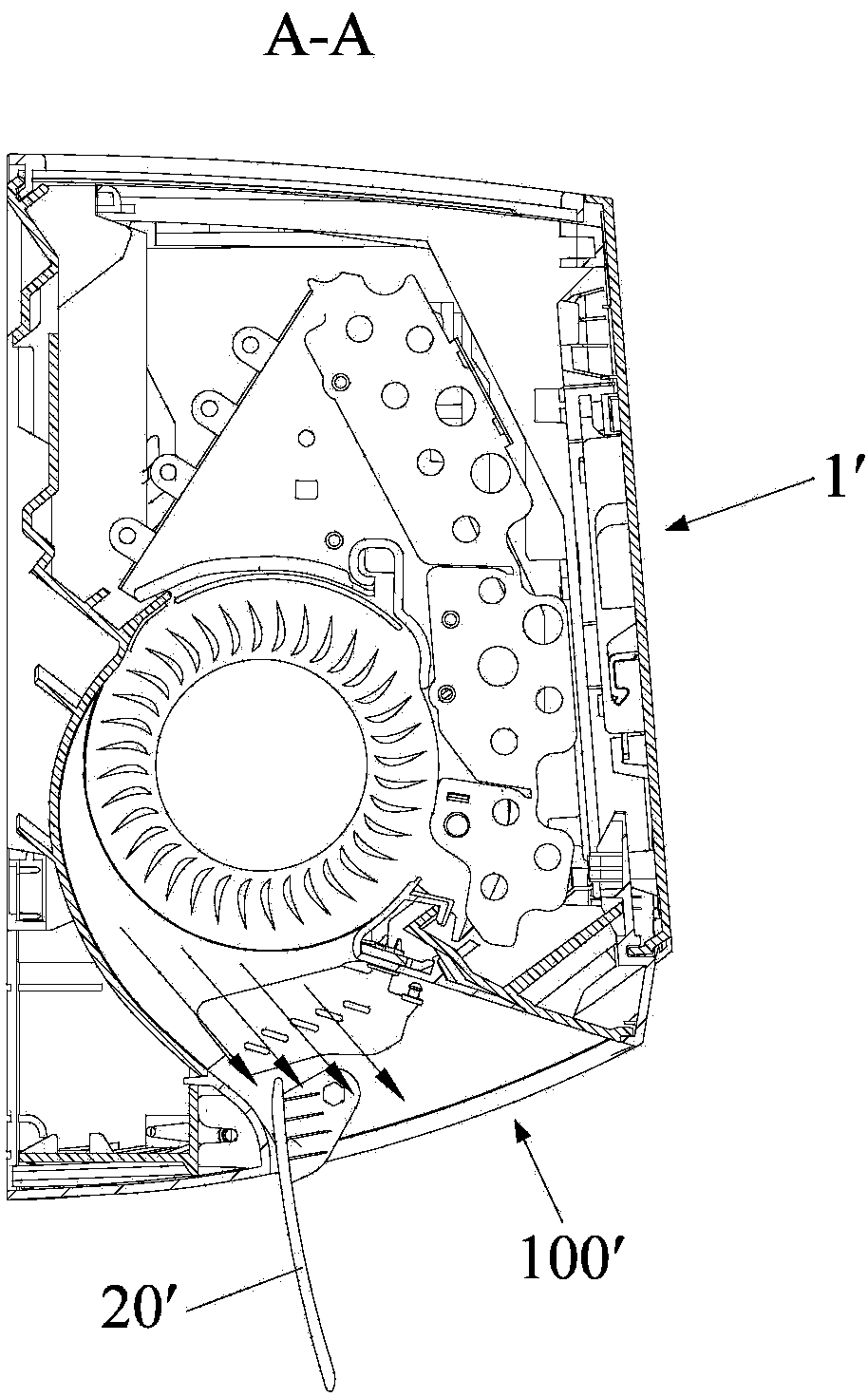

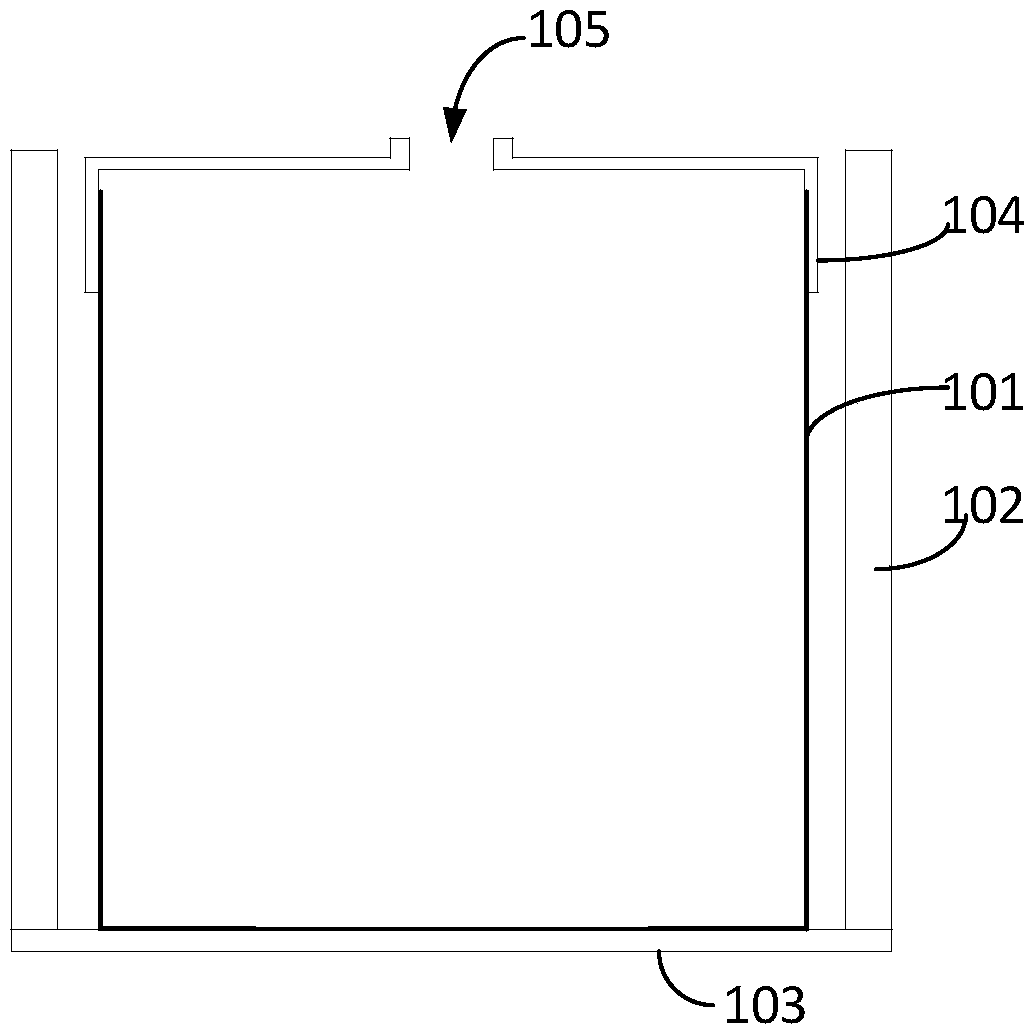

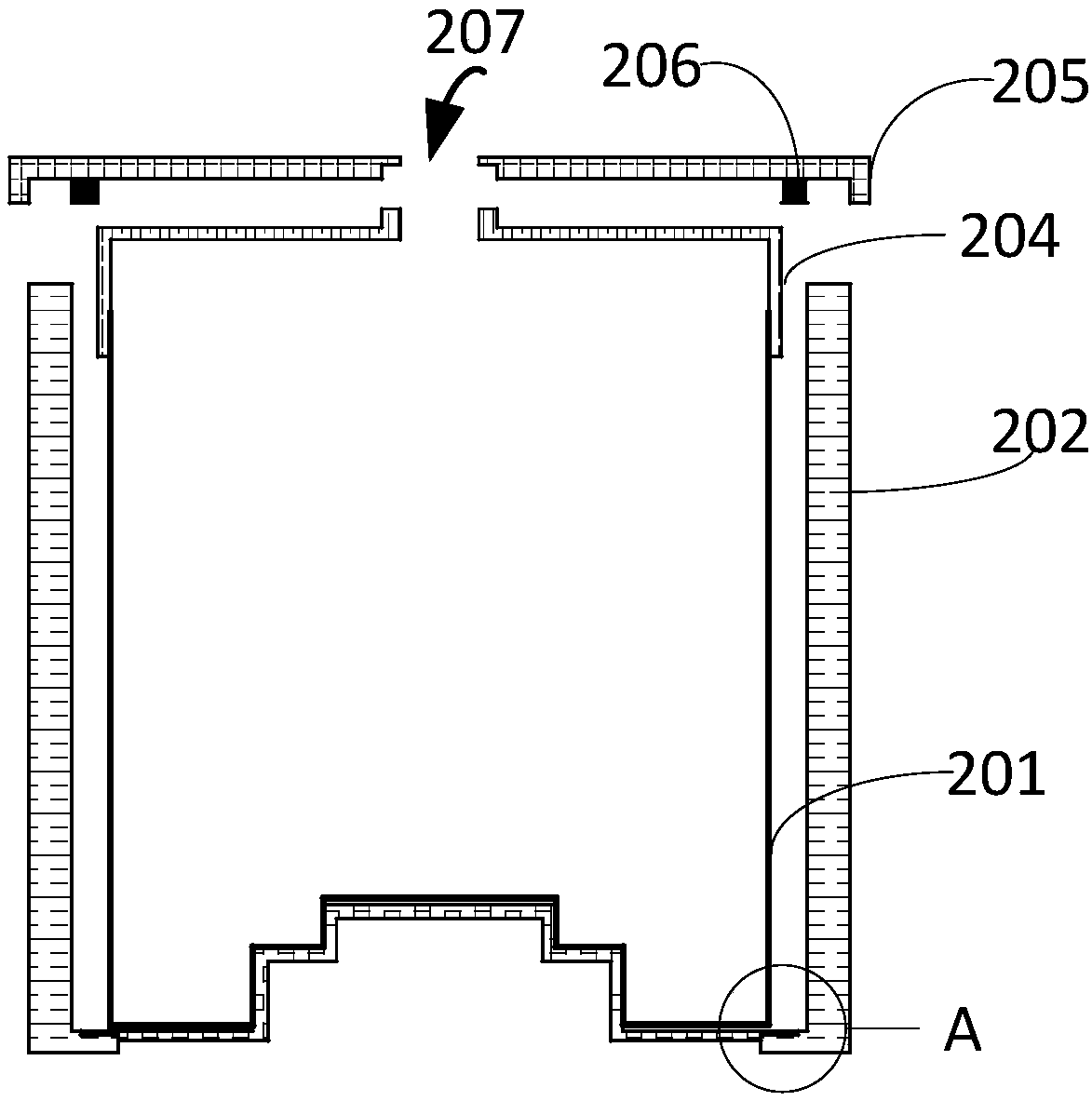

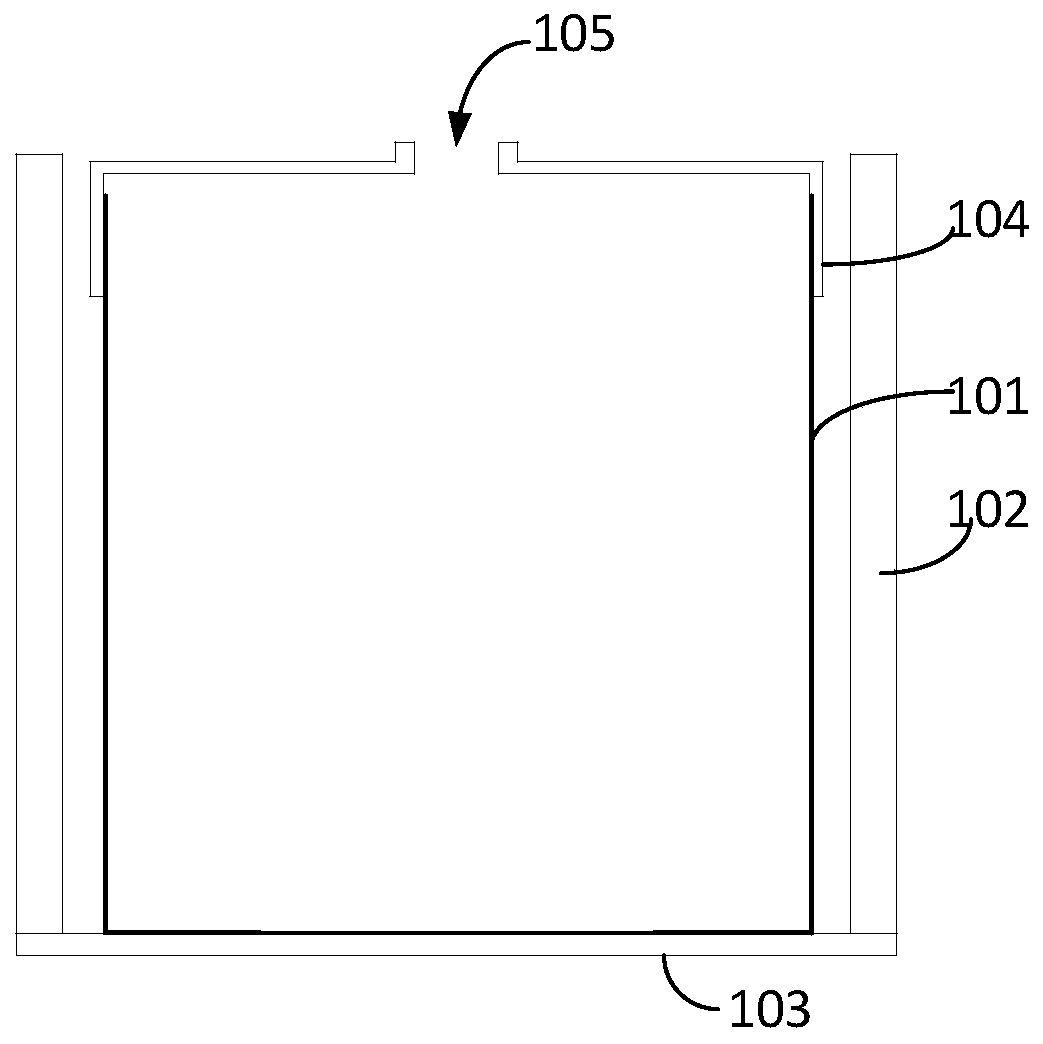

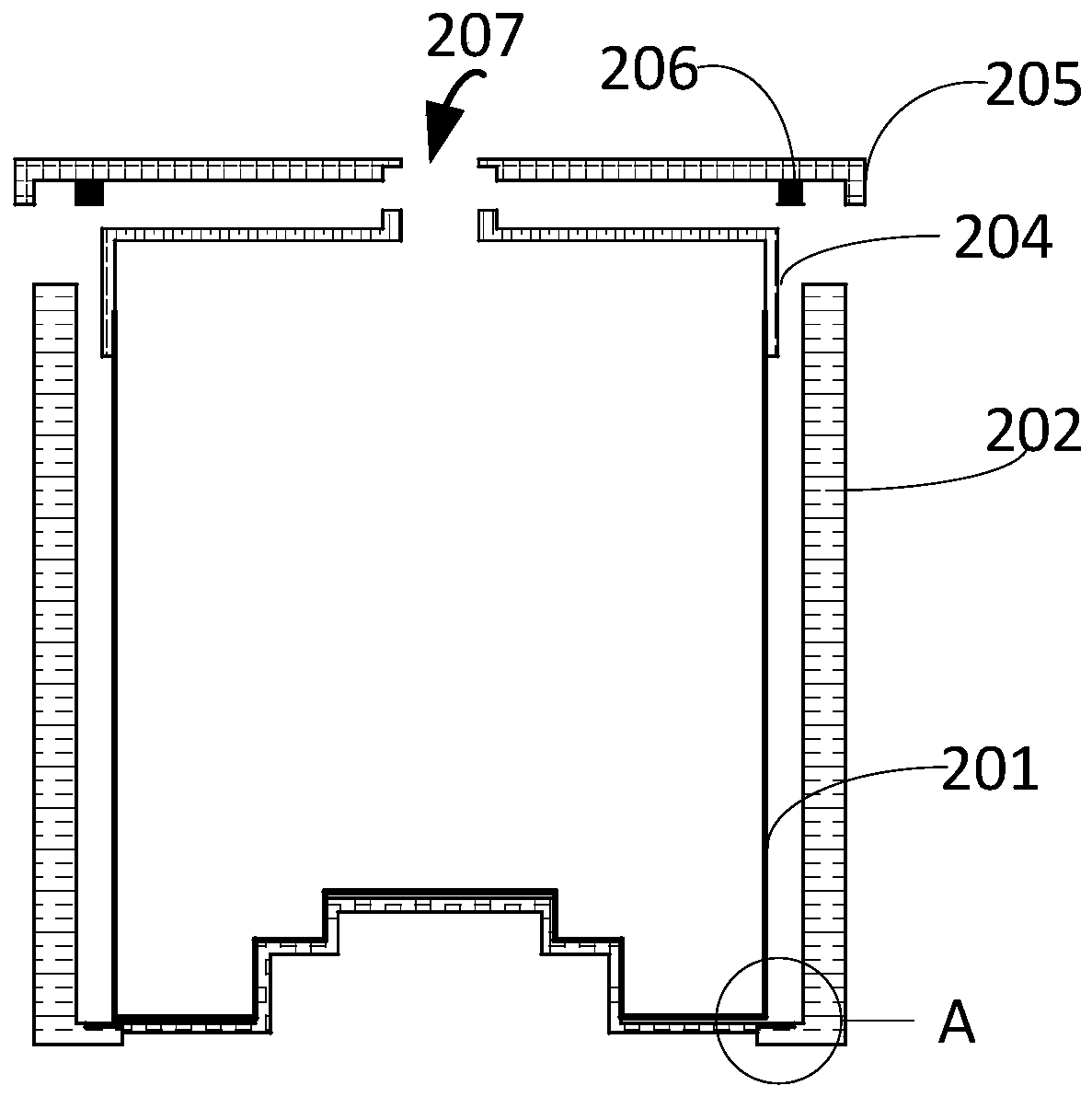

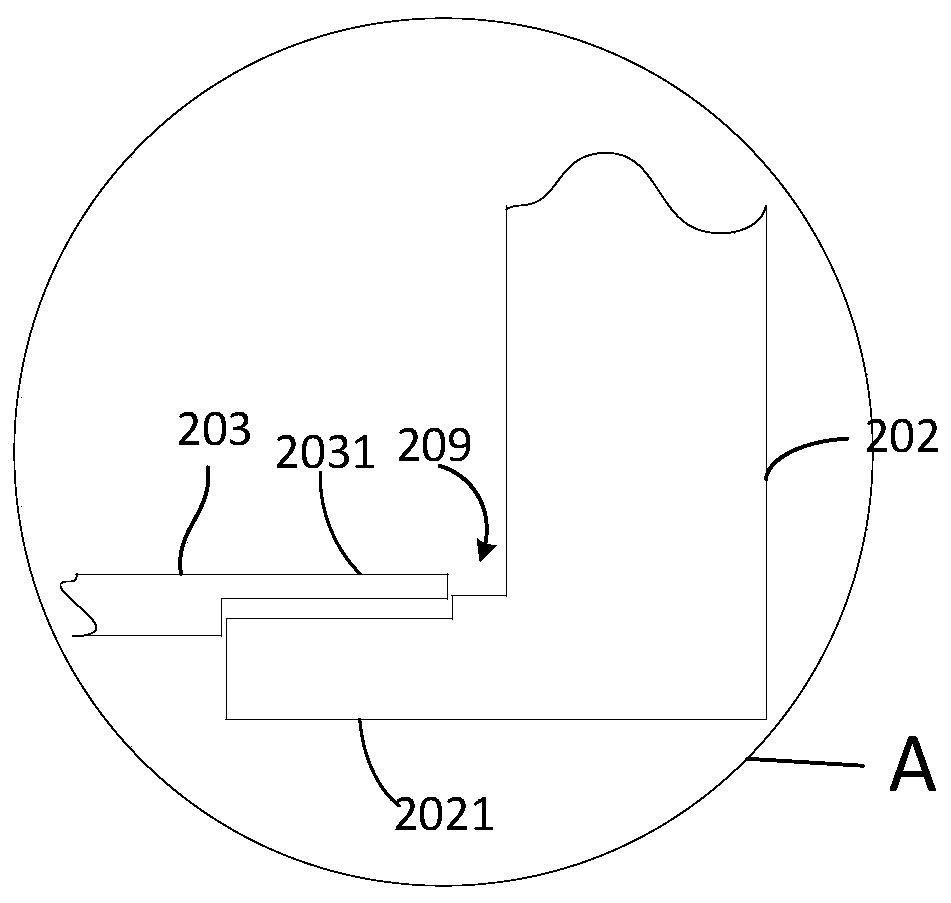

Air-conditioner indoor unit

ActiveCN103940068ABeautiful appearanceIncrease air volumeHeating and ventilation casings/coversAir-flow control membersPollutionElectrical and Electronics engineering

The invention provides an air-conditioner indoor unit which comprises a case and a first air guide plate. One end of the first air guide plate is installed on the case in a rotating mode and can open or close an air outlet of the case. The case is provided with a first protruding portion. The rotating connection end of the first air guide plate is provided with a second protruding portion. When the first air guide plate closes the air outlet, the first protruding portion makes contact with the second protruding portion. According to the air-conditioner indoor unit, the case is provided with the first protruding portion, the rotating connection end of the first air guide plate is provided with the second protruding portion, when the first air guide plate closes the air outlet, the first protruding portion makes contact with the second protruding portion, and therefore the first air guide plate and the case can be matched in a seamless mode, and the problems that due to the fact that a gap is reserved between the air guide plate and the case, the appearance of the air-conditioner indoor unit is poor in attractiveness and dust enters the case from the gap and causes pollution in the prior art can be solved.

Owner:WUHAN REFRIGERATION EQUIP OF MIDEA GROUP

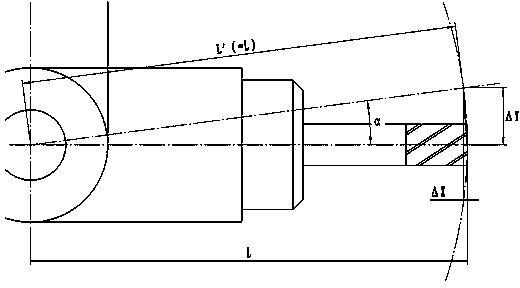

Universal angular milling head virtual axis numerical control programming method

InactiveCN104281097AFor a seamless fitAccurate work performanceProgramme controlComputer controlNumerical controlTool bit

The invention provides a universal angular milling head virtual axis numerical control programming method and relates to a milling head programming method. The method aims at solving the problem that machining can not be achieved by a machine tool through a numerical control programmed program because of the adoption of the principal axis direction which can not be achieved or defined by the machine tool in the use process of a universal angular milling head. The method specifically includes the following steps that the theoretical position of the virtual axis of the milling head is set, the theoretical deflection position of a tool is determined, a gap between a tool bit and a workpiece is calculated, tool length compensation is conducted, the program is executed, and the tool starts to work. The method is applied to a numerical control milling machine which can not achieve special angle machining, four-axis machining can be achieved by a three-axis machine tool, five-axis machining can be achieved by a four-axis machine tool, numerical control programming application problems of the universal angular milling head are solved, and the use range of the machine tool is expanded.

Owner:航天科工哈尔滨风华有限公司

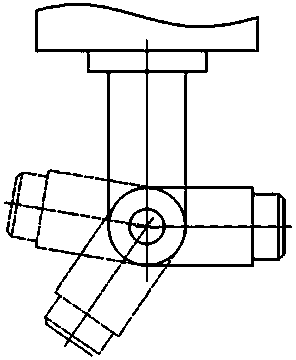

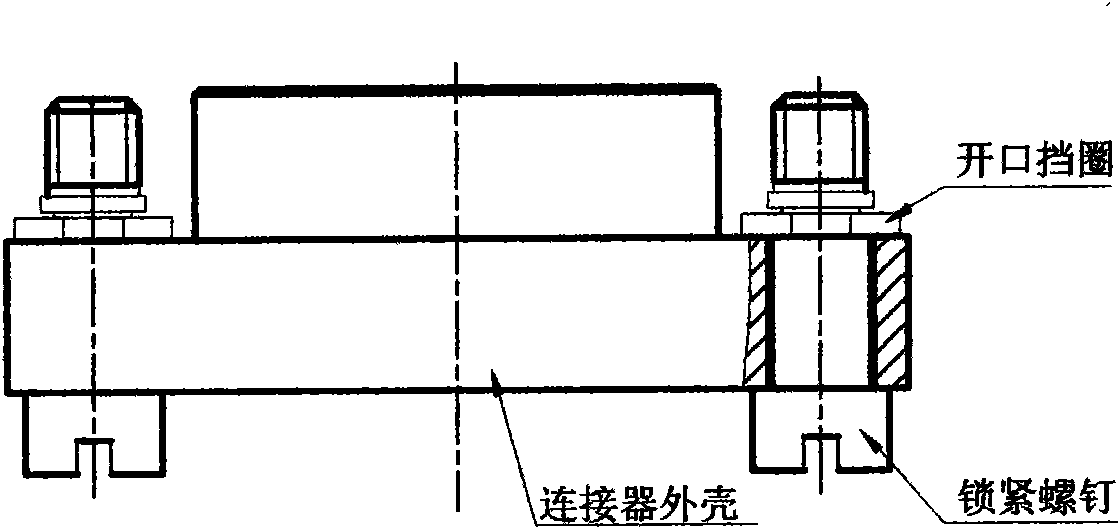

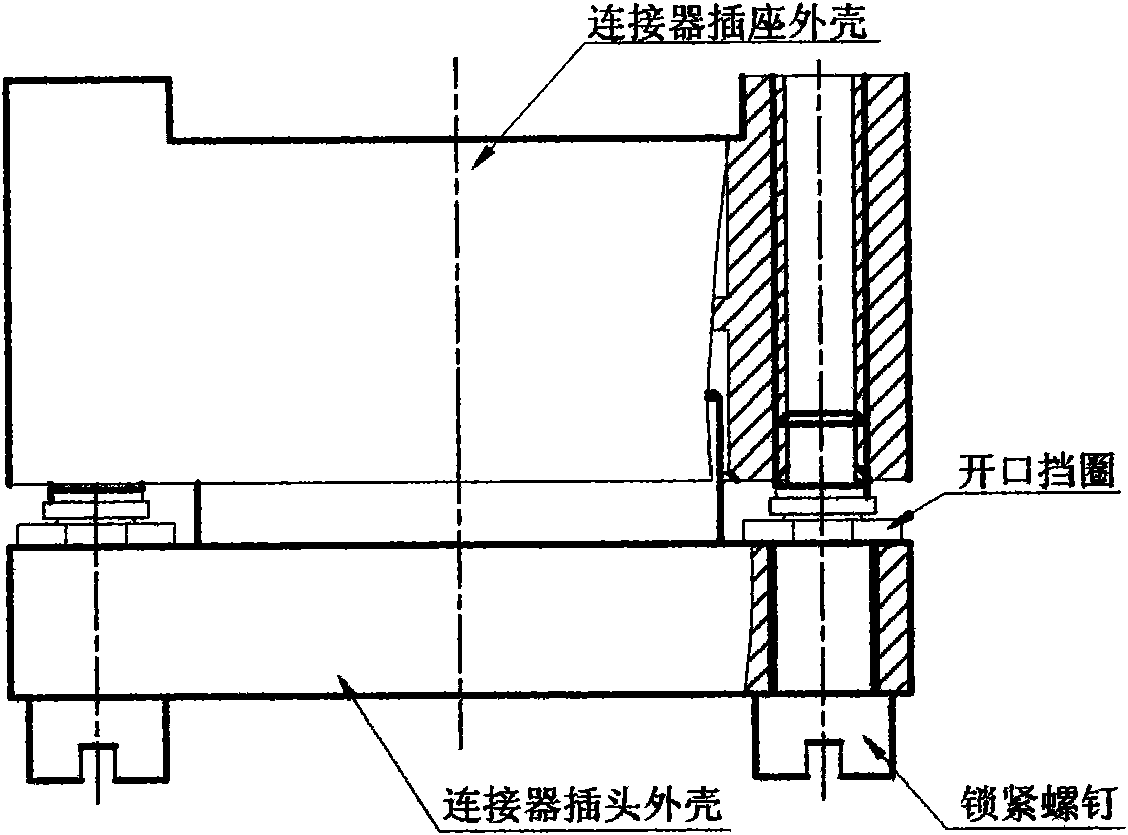

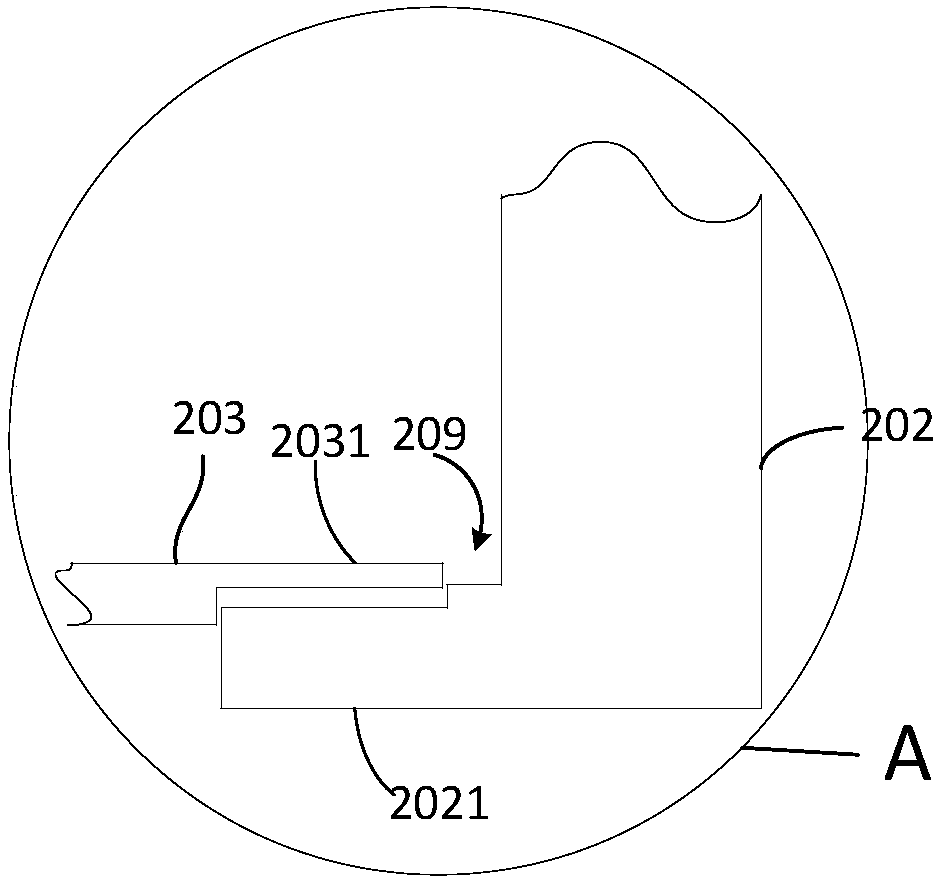

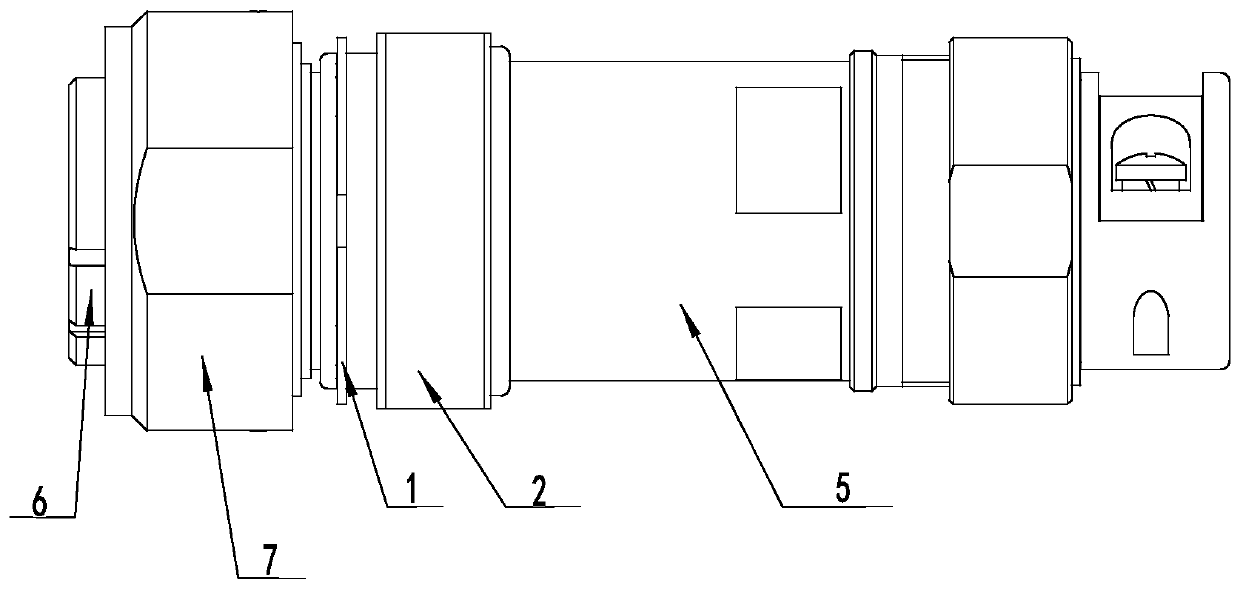

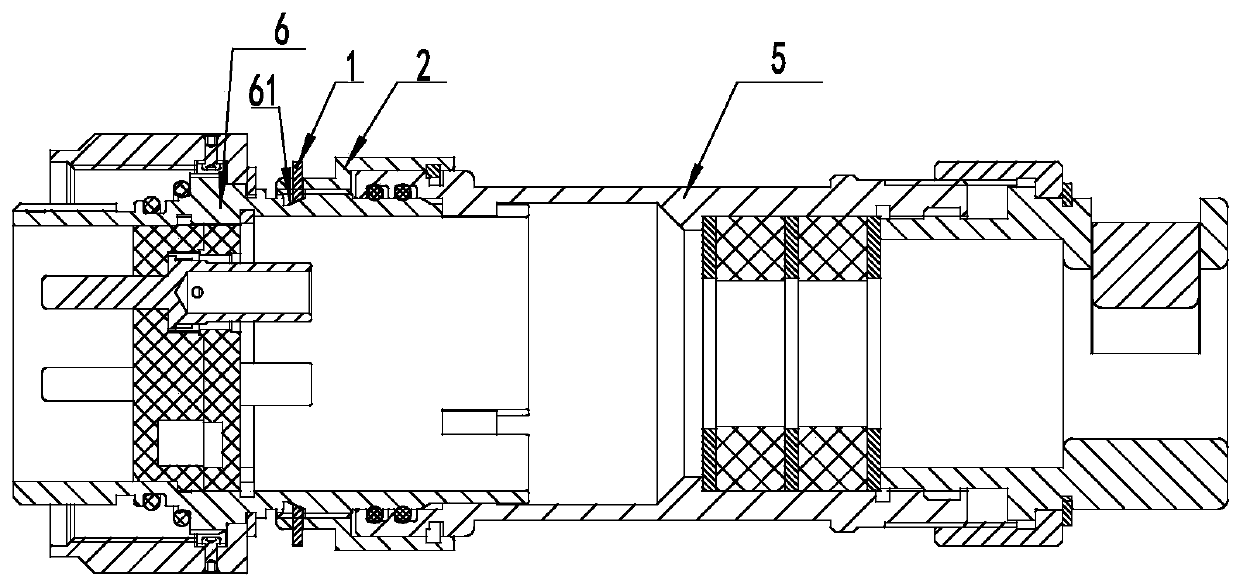

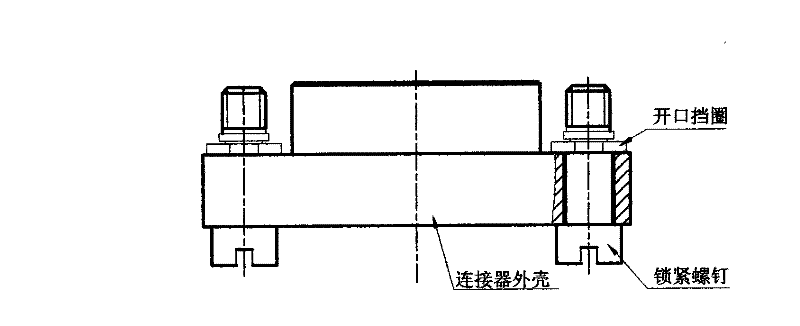

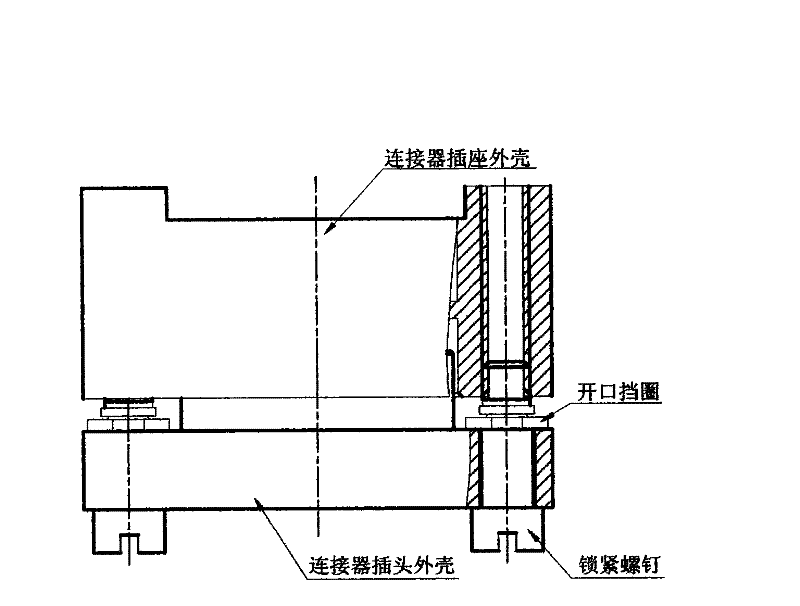

Locking mechanism of miniature electric connector

InactiveCN101635409AMiniaturizationFor a seamless fitCoupling device detailsLocking mechanismEngineering

The invention relates to a locking mechanism of a miniature electric connector. The locking mechanism comprises a necking sleeve and a locking screw which is provided with a circular groove; a chamfer angle is arranged at one end of the circular groove, and a taper angle is arranged at the other end; the necking sleeve is in a step structure and comprises a conical thin wall part and a round thick wall part; the conical thin wall part is mounted in the circular groove of the locking screw and in a step fixed hole corresponding to an outer shell of the electric connector; and the abutting part of the locking screw, which is exposed out of the outer shell of the electric connector, is a full thread. The locking mechanism of the miniature electric connector occupies small space, can obtain a smaller center distance of the electric connector, be beneficial to the miniaturized development and realize the seamless attachment of a plug and a socket outer shell after being spliced.

Owner:GUIZHOU SPACE APPLIANCE CO LTD

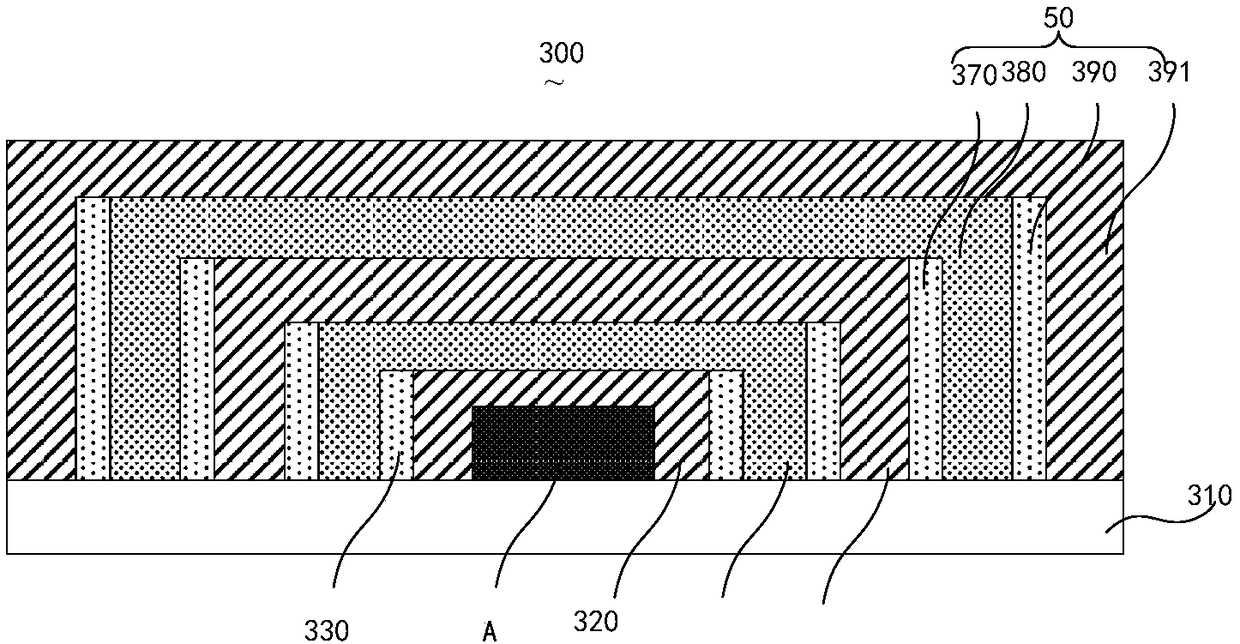

Evaporation coating device

ActiveCN107805782AEasy to replaceHeating evenlyVacuum evaporation coatingSolid-state devicesCrucibleEvaporation

The invention relates to an evaporation coating device which comprises a crucible main body, a side surface heating device and a bottom heating device, wherein the side surface heating device is arranged around the crucible main body, and the bottom heating device is arranged under the crucible main body. The bottom heating device can move up and down in the height direction of the side surface heating device and support the crucible main body to rise to a position which is higher than the side surface heating device. According to the evaporation coating device, by means of the arrangement ofthe heating device on the bottom of the crucible main body, the crucible main body is made to be capable of moving up and down, the maintenance efficiency is improved, the maintenance time is shortened, and unnecessary procedures are reduced.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

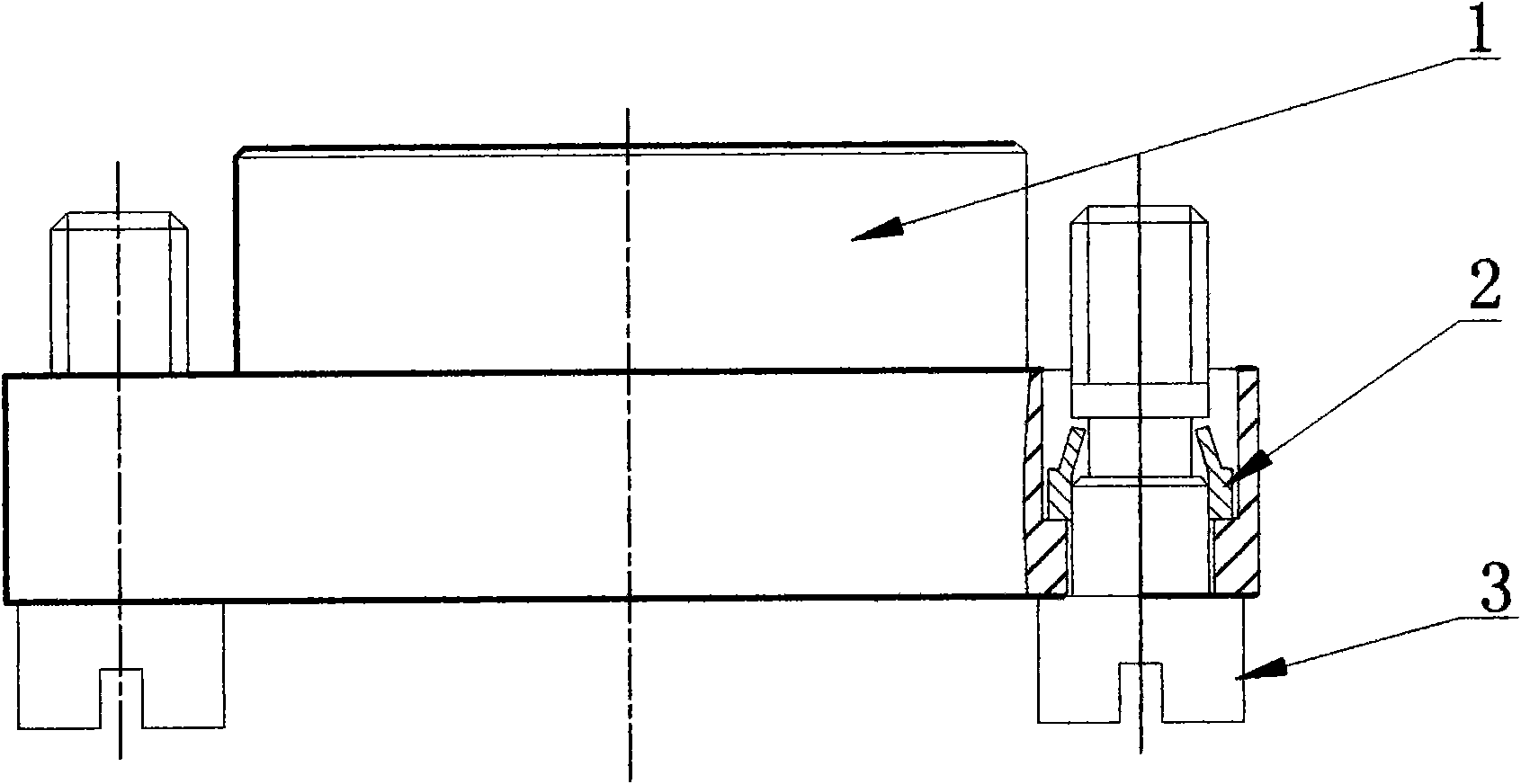

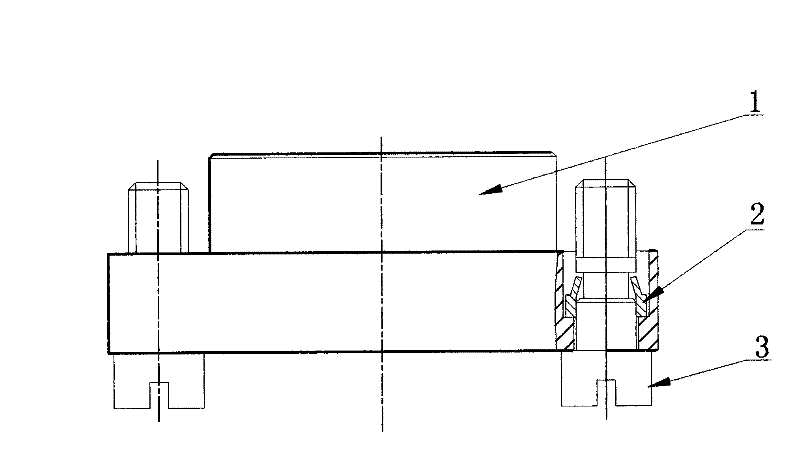

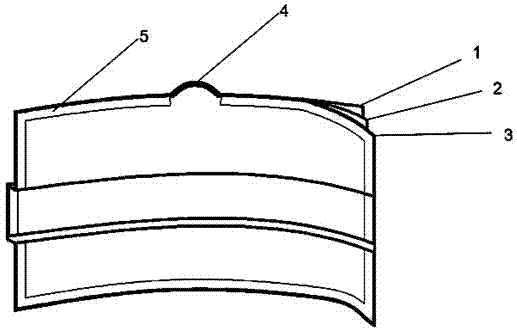

Anti-loosening snap spring, anti-loosening structure, and in-position anti-loosening connector

PendingCN109980415AIncrease frictionObstructed movementEngagement/disengagement of coupling partsLeaf springsEngineeringMechanical engineering

The invention relates to an in-position anti-loosening connector including a first connecting member and a second connecting member that are connected to each other through the front ends thereof. Ananti-loosening structure for preventing the separation of the two connecting members is fixed to the front end of the first connecting member. The second connecting member housing is provided with ananti-loosening contact surface matching the anti-loosening structure. The anti-loosening structure comprises a connecting nut provided with an annular anti-loosening groove. The anti-loosening grooveis provided with a plurality of through engagement slots. The anti-loosening table of an anti-loosening snap spring passes through the through engagement slots. The anti-loosening surface of the anti-loosening table and the anti-loosening contact surface of the second connecting member housing are seamlessly attached to each other and maintain a certain tension. In addition, other parts except theanti-loosening table are trapped in the anti-loosening groove to achieve axial positioning.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

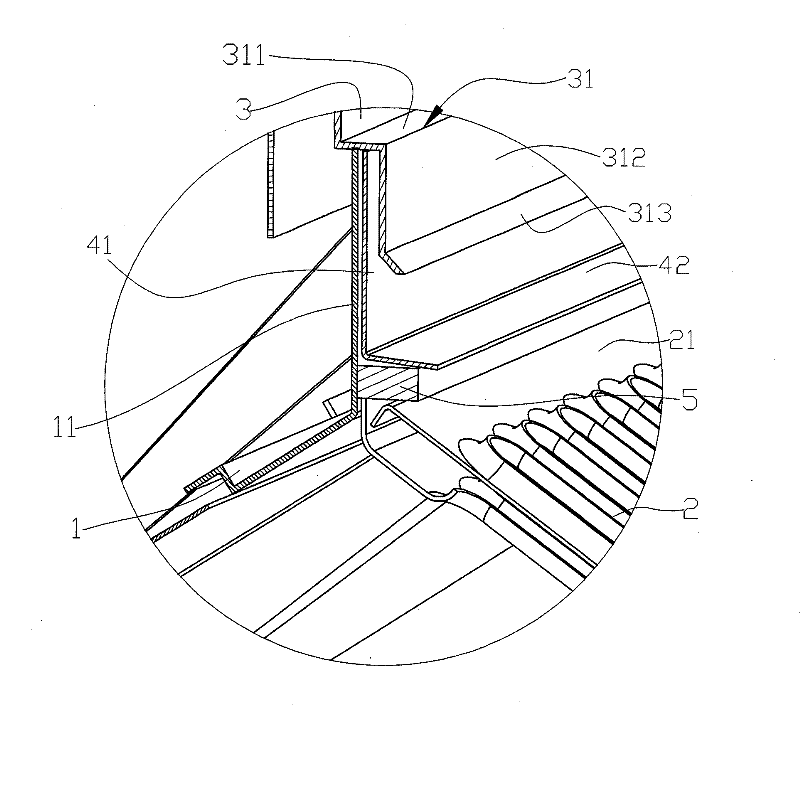

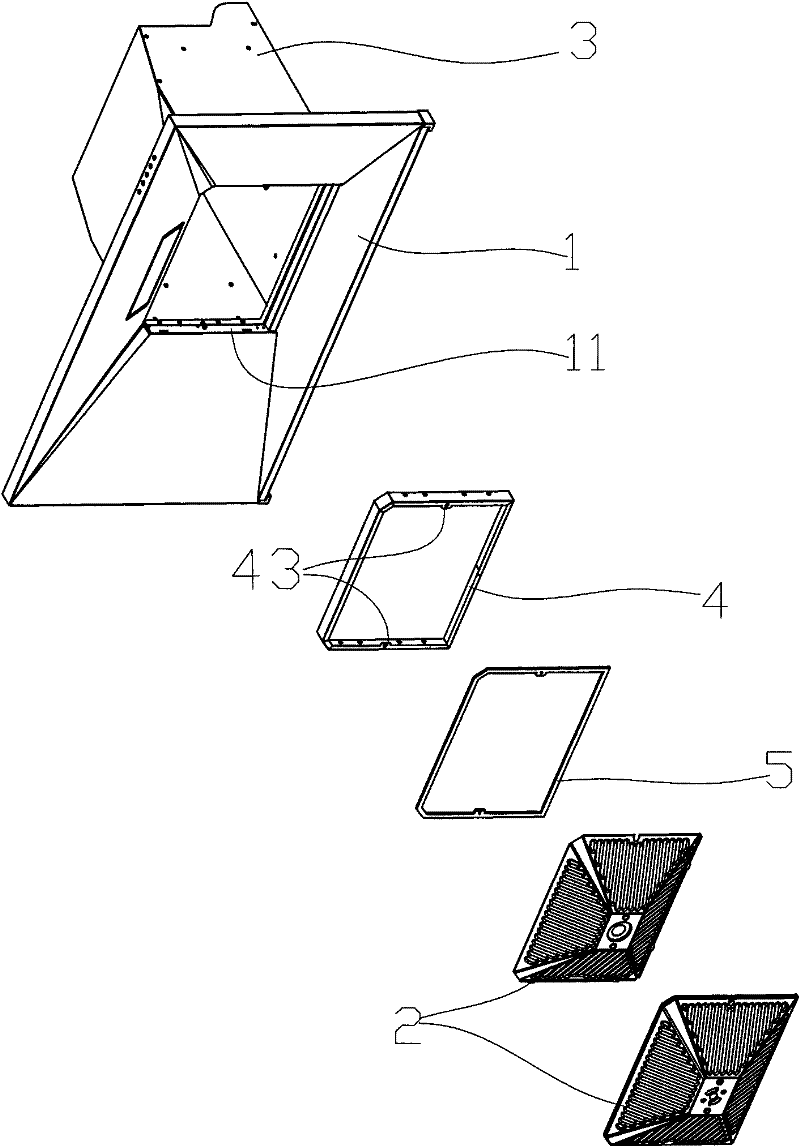

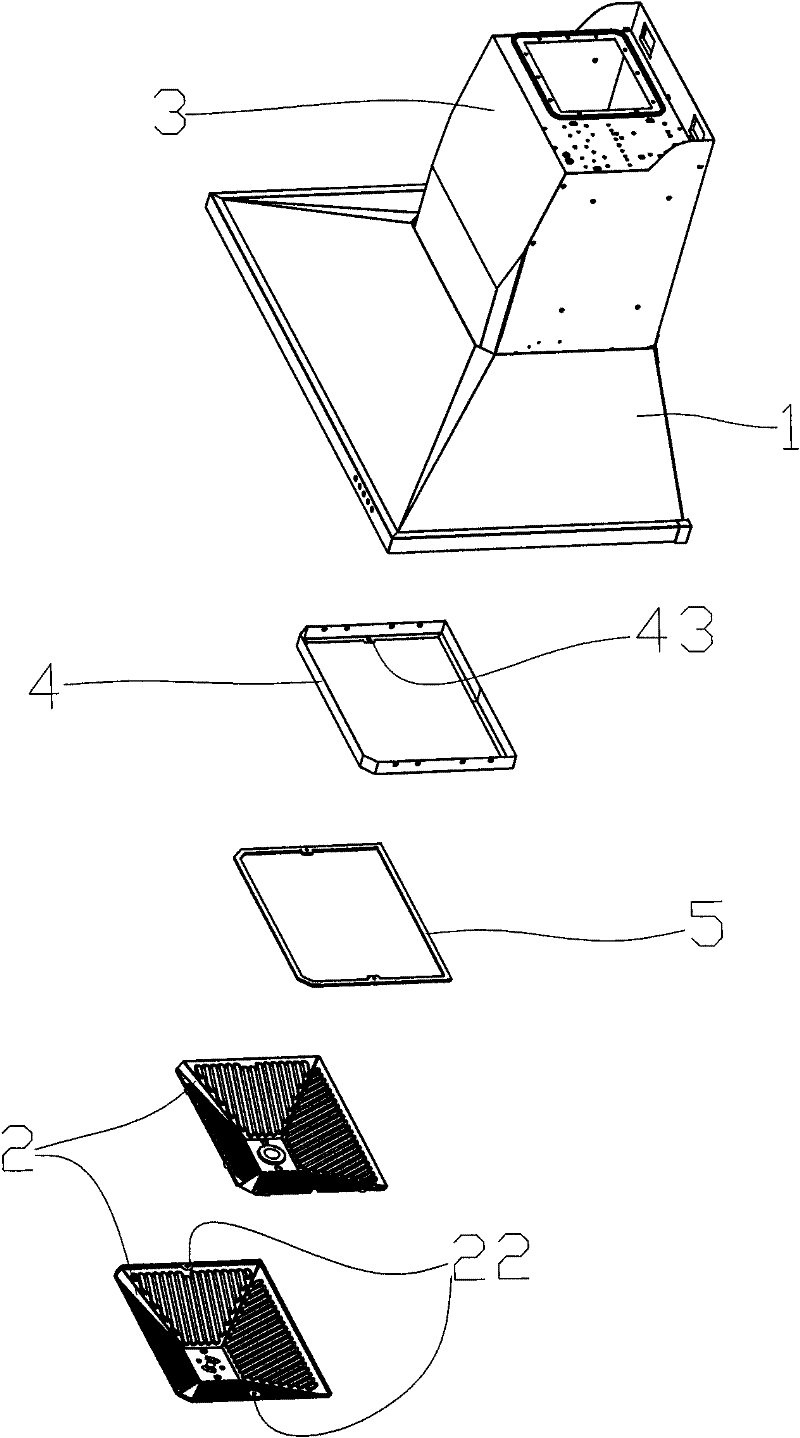

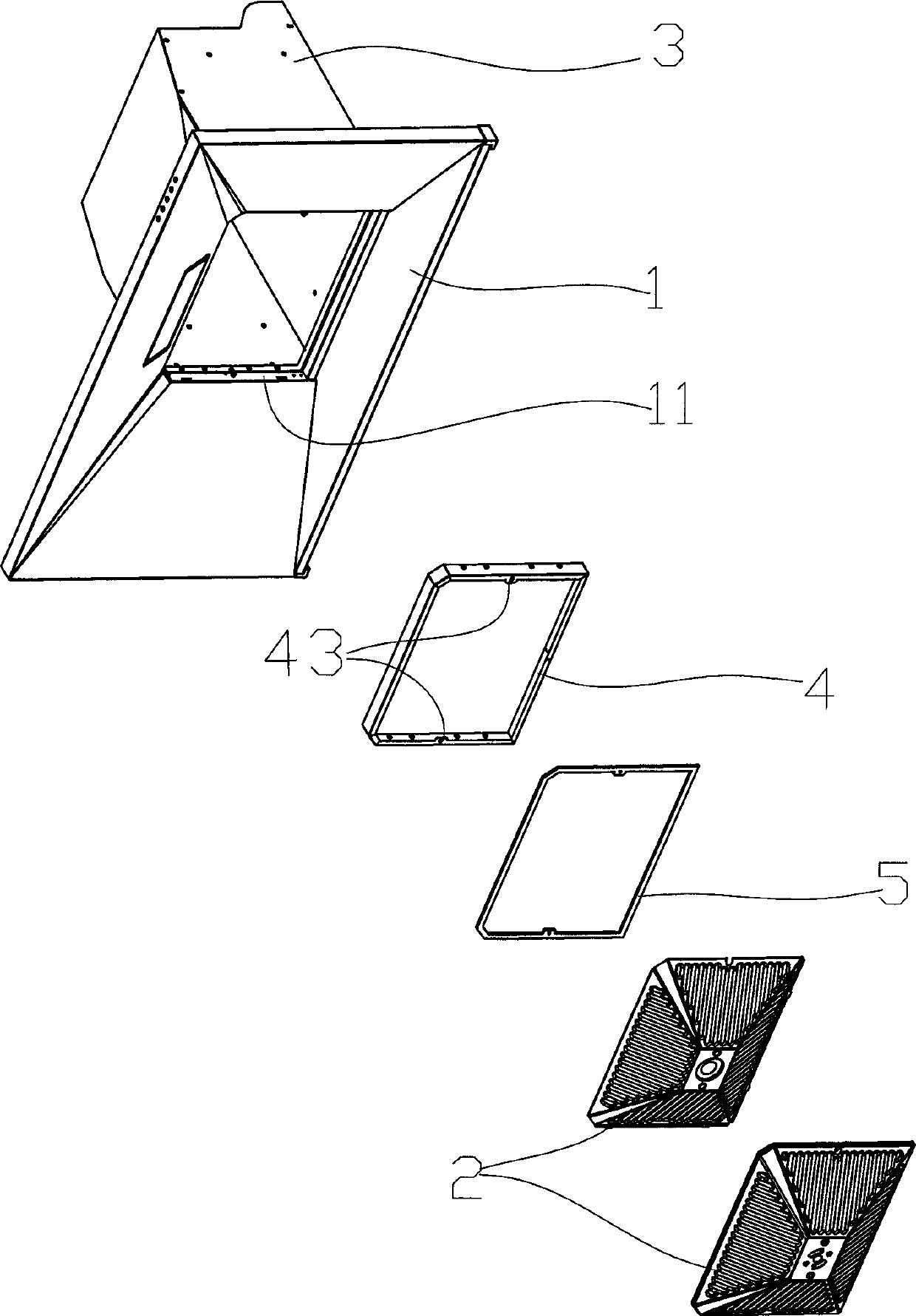

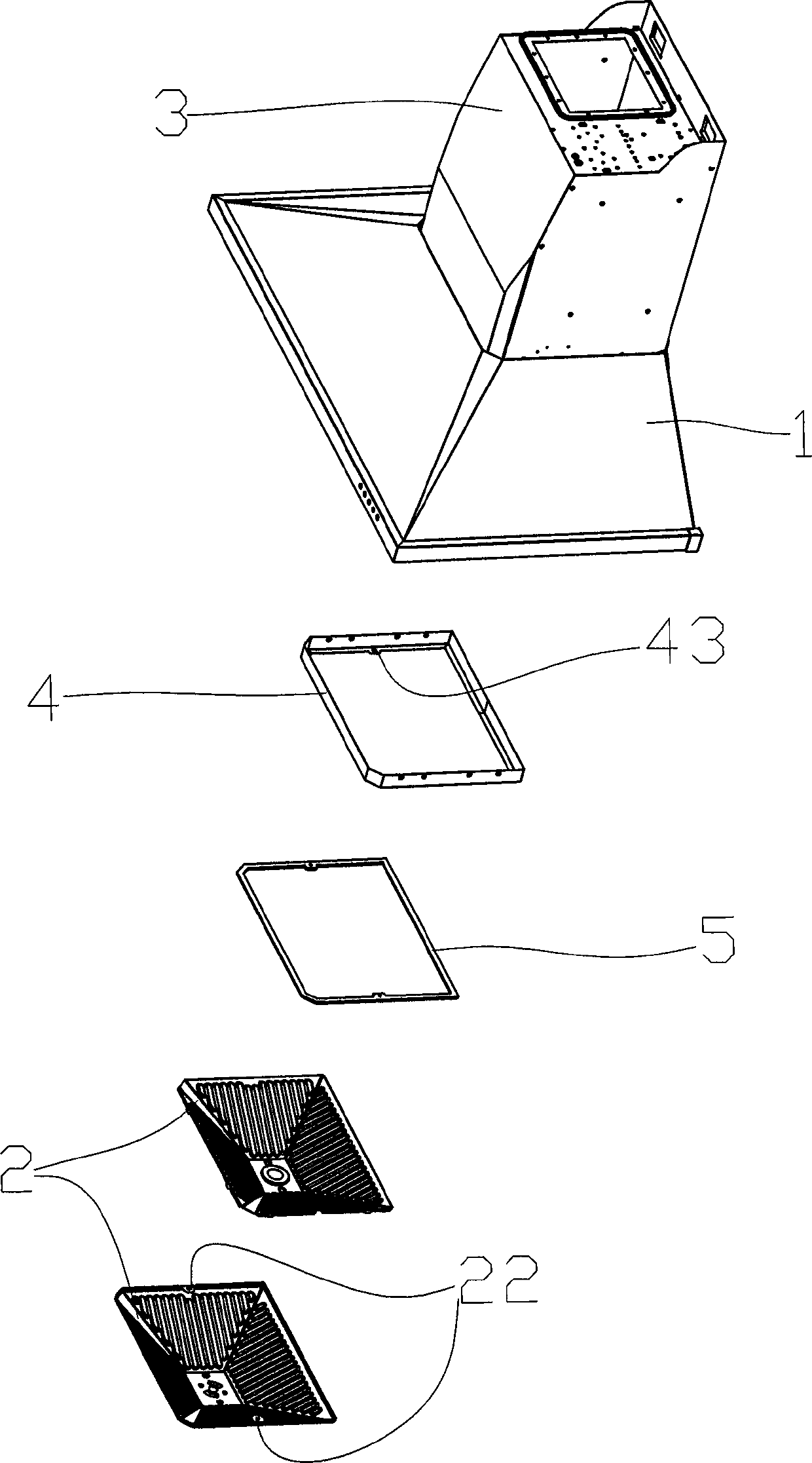

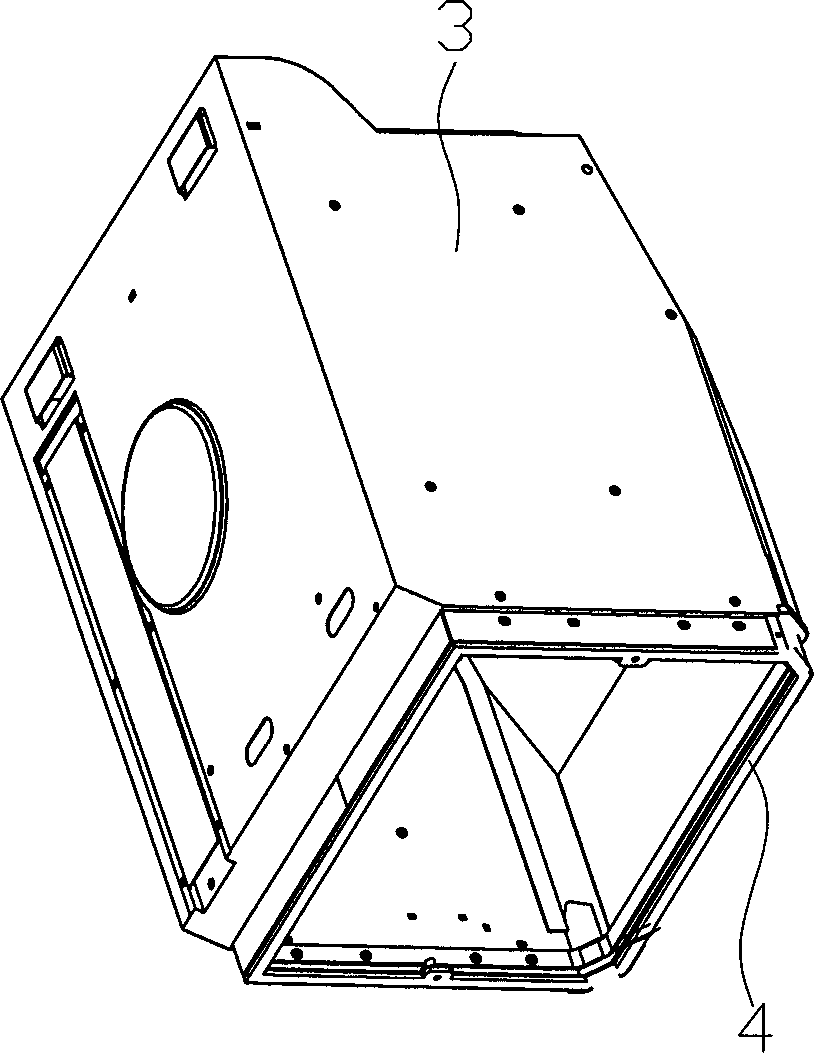

A connection structure for preventing oil dripping and leakage of range hood

ActiveCN102287859ASimple structureEasy to makeDomestic stoves or rangesLighting and heating apparatusPetroleum engineeringAirflow

The invention provides a connecting structure for preventing oil dripping and leakage of an oil and smoke exhauster, which comprises a smoke-collecting hood, an oil net, a machine box and an oil-guiding surrounding frame, wherein the oil-guiding surrounding frame comprises a first hem and a second hem, the first hem is closely bonded with the outer side at the lower part of the machine box, the second hem is closely bonded with the upper side at the periphery of the oil net, and the oil net is installed on the oil-guiding surrounding frame. The connecting structure has a simple and reasonablestructure, and the conception of blocking clearance airflows is mainly adopted, thereby the seamless matching among the smoke-collecting hood, the oil net and the machine box of the oil and smoke exhauster is realized; after oil and smoke are pumped into a space between the oil net and the machine box by a fan of the oil and smoke exhauster, the oil and the smoke can not outwards overflow from aninstalling gap between the oil net and the machine box, thereby the problem of oil leakage, oil flow or oil dripping of the oil and smoke exhauster is prevented; and moreover, the oil-guiding surrounding frame is simple to manufacture and convenient to assemble and unassembled, so that the oil net and the machine box can be directly connected, thereby the installing mode of the oil net is greatlysimplified.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

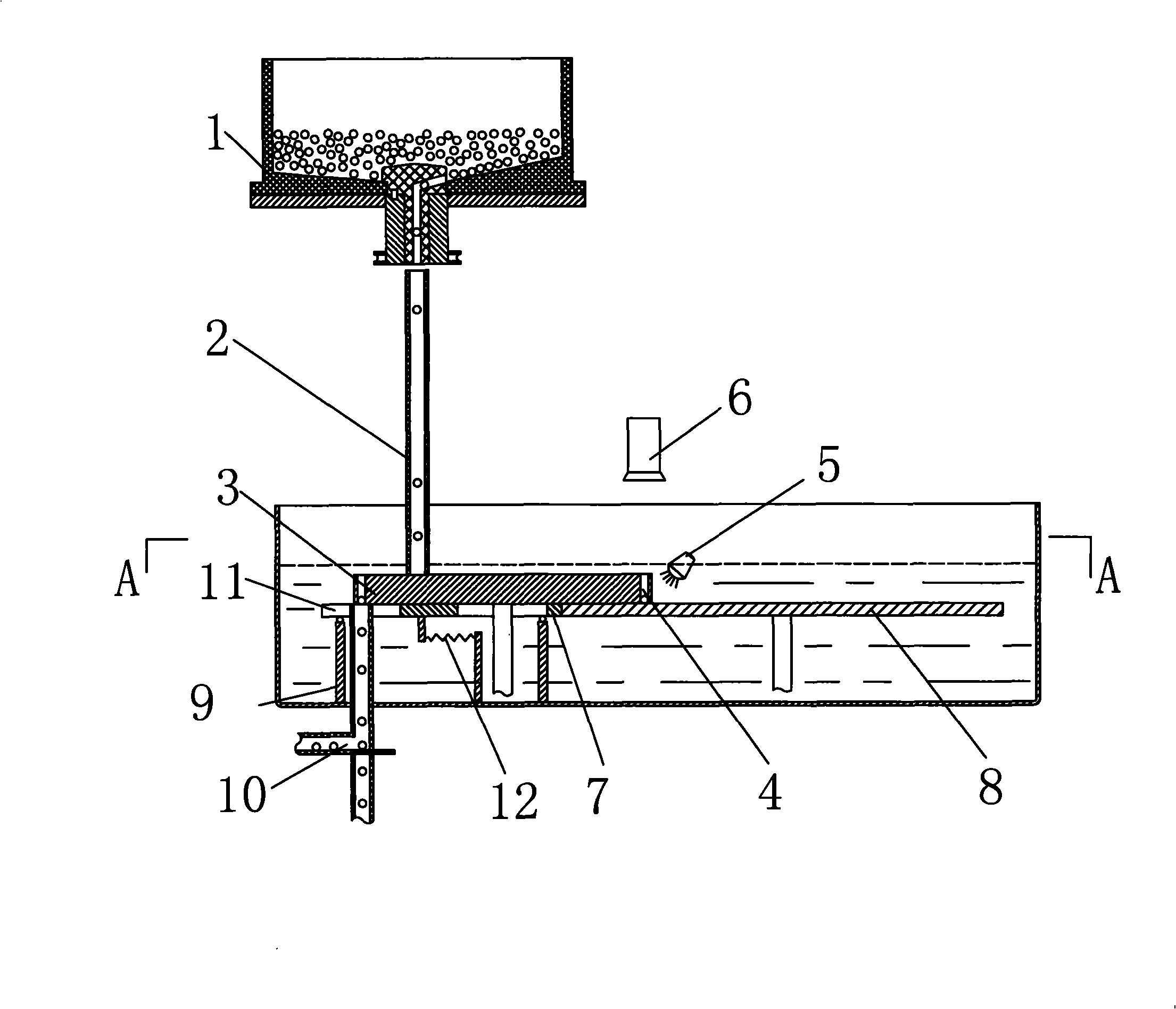

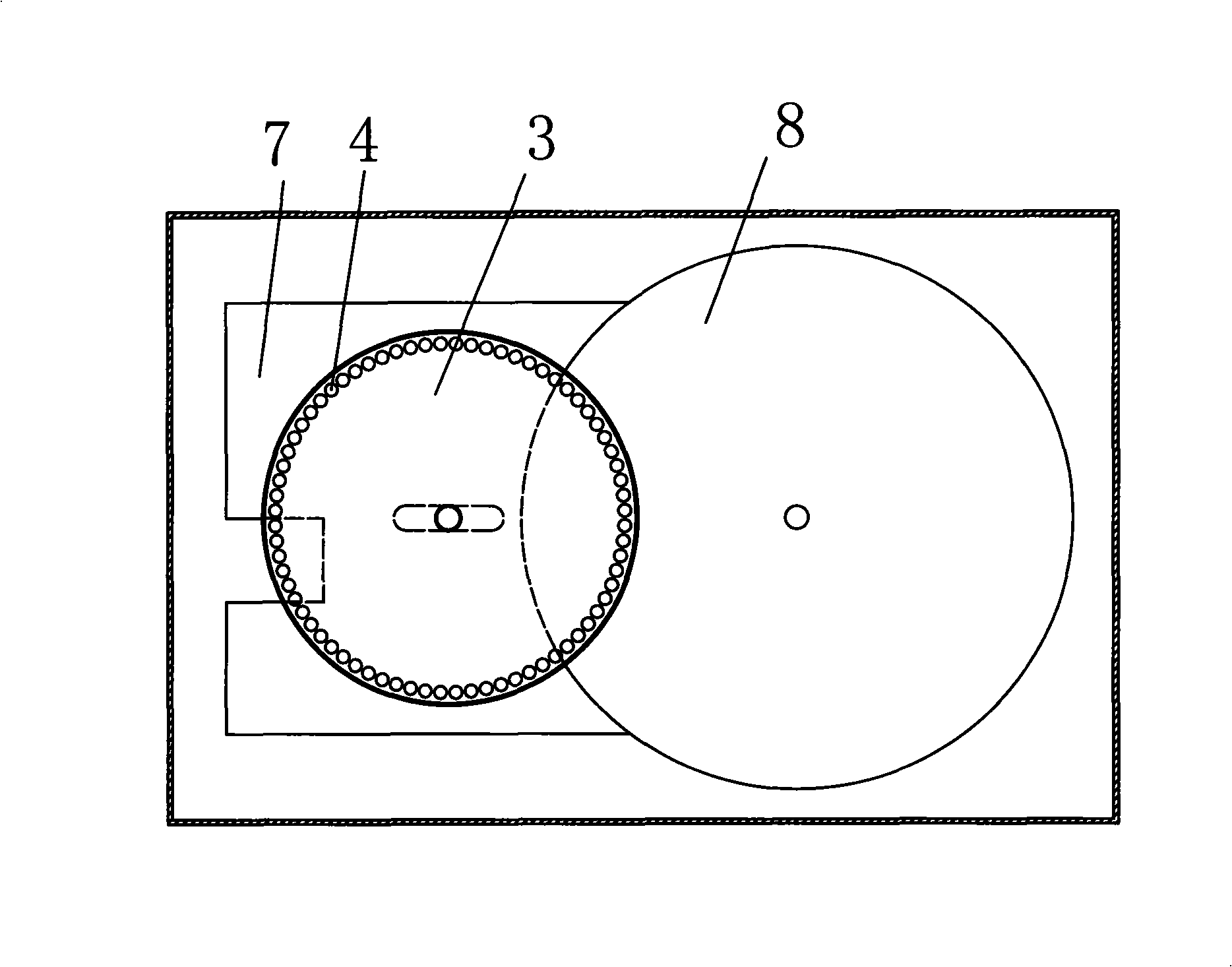

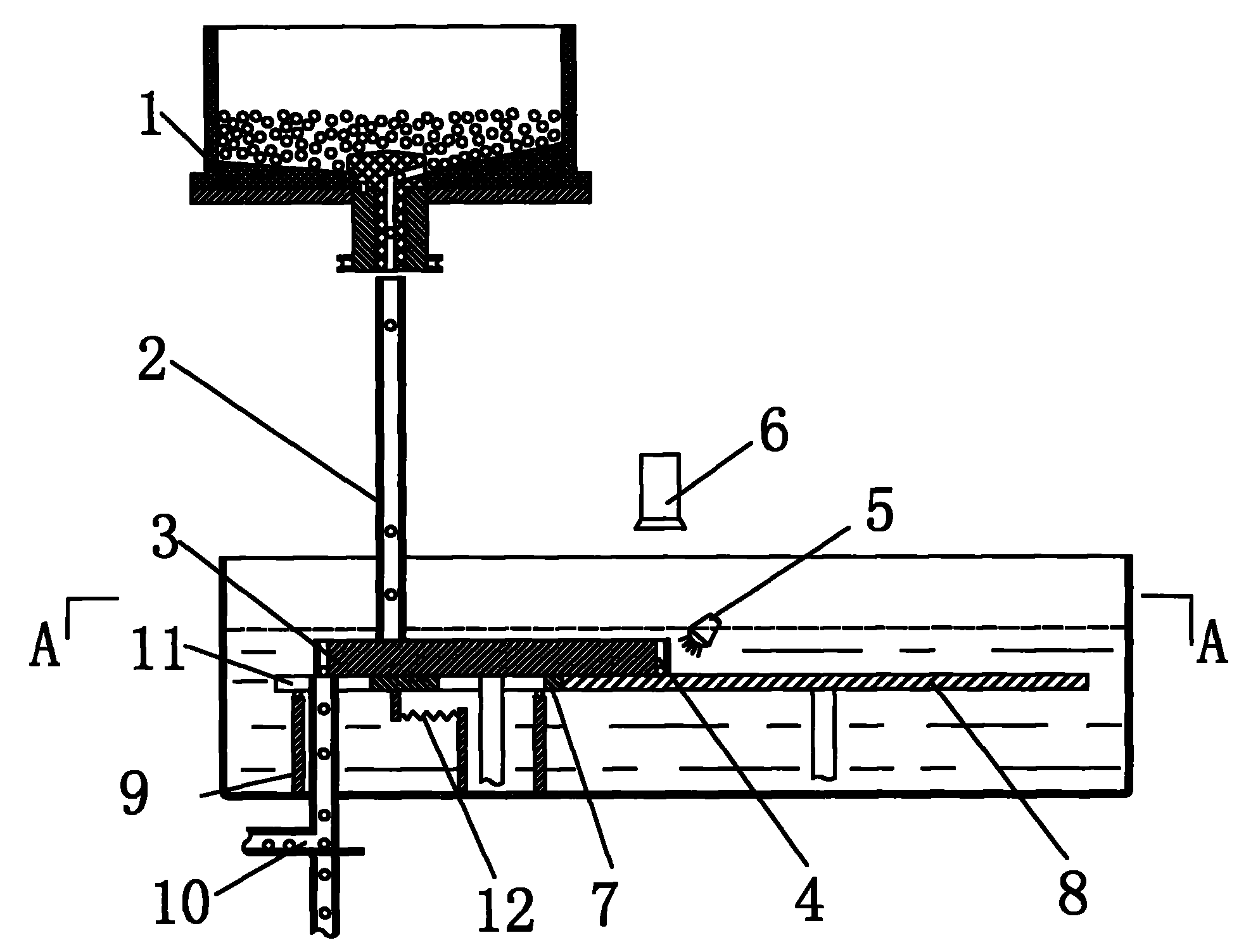

Steel ball surface defect detection apparatus

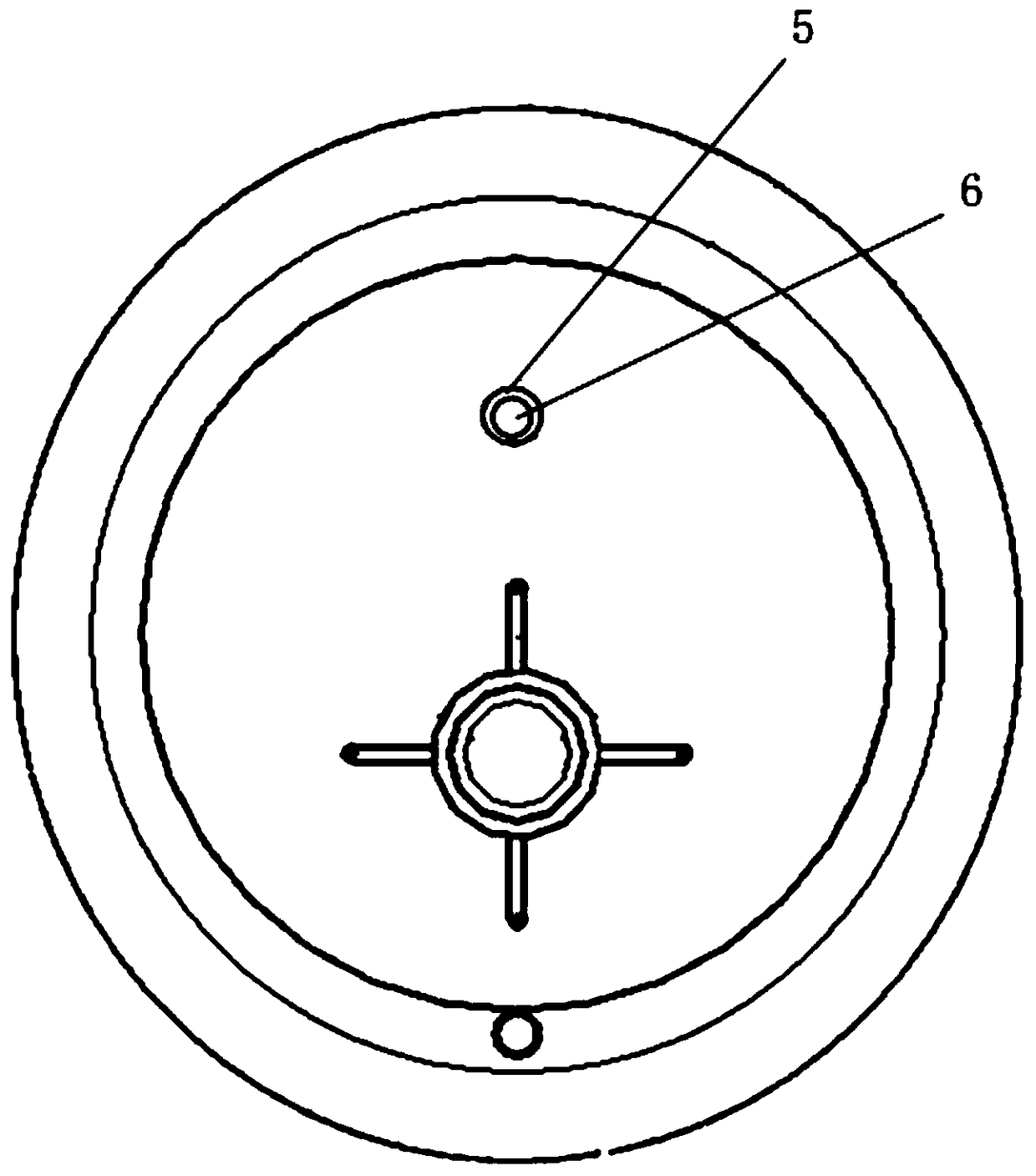

InactiveCN101430290BOvercoming the defects of gapsTo overcome the defect that the thickness must be smaller than the radius of the steel ballMaterial analysis by optical meansEngineeringSteel ball

The invention discloses a device for detecting the surface damage of a steel ball. A feeding mechanism is connected with a feeding turnplate by a feeding passage. A plurality of detection cavities are arranged at the circle of the feeding turnplate. The position of the detection cavities is provided with a detection light source which provides illumination for the steel ball to be detected. A camera is arranged above the detection cavities. A salver and an unfolded turnplate are arranged below the feeding turnplate. The upper surfaces of the salver and the unfolded turnplate are flush. The middle part of the salver is provided with a guiding slot. A rotating shaft of the feeding turnplate penetrates the guiding slot of the salver to be connected with a stepping device. A salver support isarranged below the salver, the lower part of the salver support is fixed at the bottom of a detection slot. The top of the salver support is used for arranging the salver, and a tourelle is arranged between the salver support and the salver. A discharge hole is arranged on the salver and is communicated with a discharging mechanism. The discharging mechanism penetrates the bottom of the detectionslot. The unfolded turnplate is connected with a swing rotary drive set by a rotating shaft. The inside of the detection slot is provided with a swing mechanism which is connected with the salver fixedly. The device can detect the steel ball with any diameter and has high detection accuracy and efficiency.

Owner:南京尊莱科技有限公司

Locking mechanism of miniature electric connector

InactiveCN101635409BMiniaturizationFor a seamless fitCoupling device detailsLocking mechanismThick wall

Owner:GUIZHOU SPACE APPLIANCE CO LTD

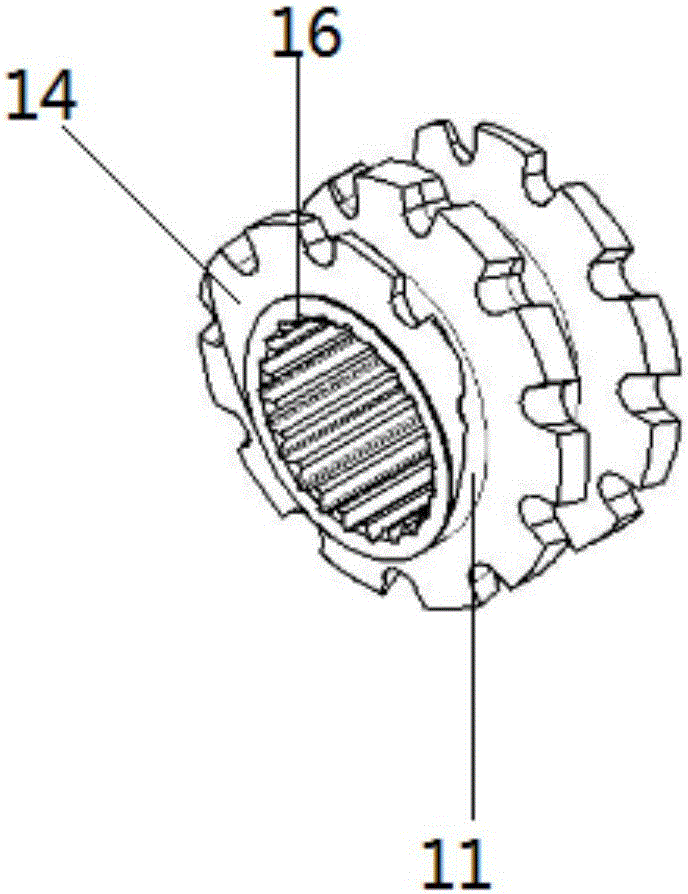

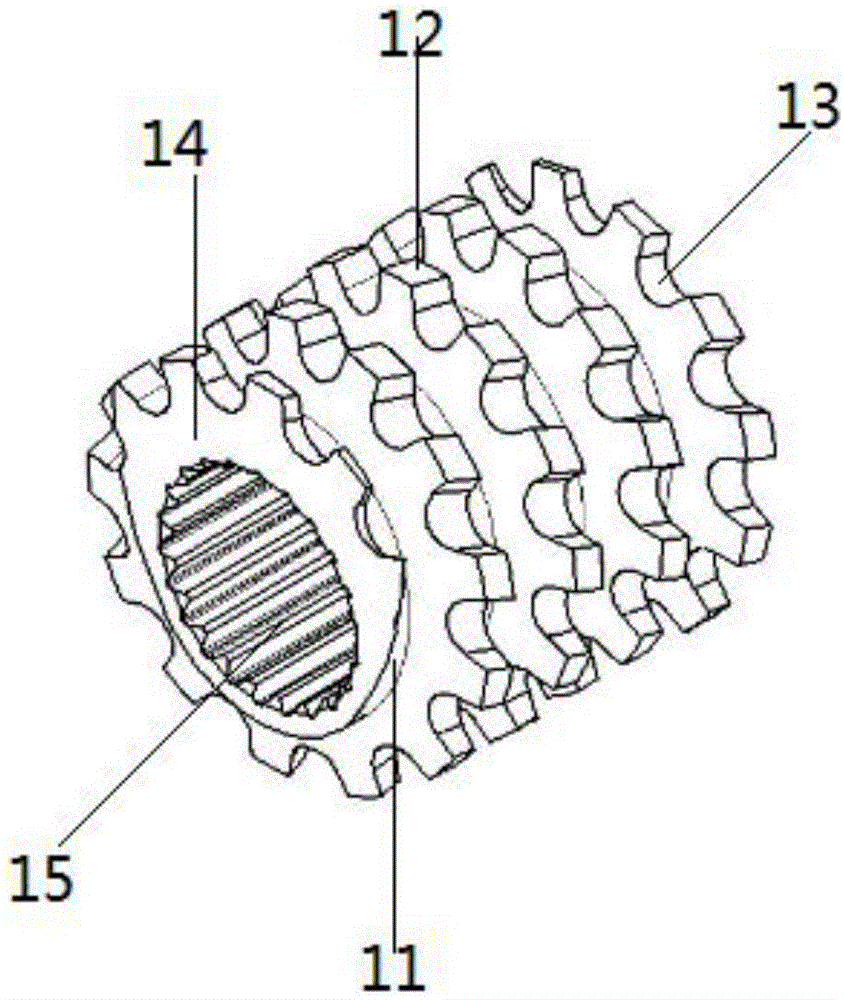

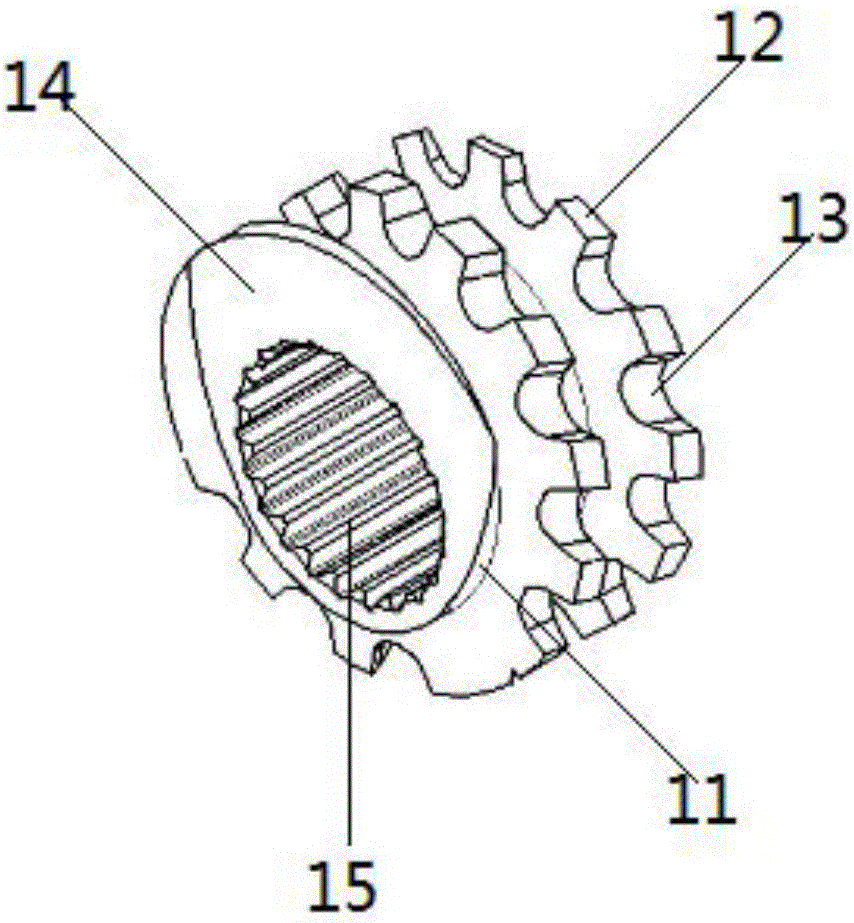

Tooth-shaped disk, tooth-shaped disk assembly, screw assembly and double-screw assembly

The embodiment of the invention discloses a tooth-shaped disk. The tooth-shaped disk is arranged between two adjacent screws of an extruding machine. The tooth-shaped disk comprises a cylinder body. The outer wall of the cylinder body is provided with a spiral thread. The spiral thread circles around the surface of the outer wall of the cylinder body and extends to the other end of the cylinder body from one end of the cylinder body. The spiral thread is provided with grooves sunken from the top to the bottom of the spiral thread every preset distances. The two ends, extending to the cylinder body, of the spiral thread are each provided with one spiral end face. Each spiral end face and the end face, where the spiral end face is located, of the cylinder body are located in the same plane. By means of the tooth-shaped disk, seamless fitting between tooth-shaped disks or between the tooth-shaped disk and other elements is achieved, a material accumulation dead area formed between the end faces of the tooth-shaped disks or between the end face of the tooth-shaped disk and the end faces of the other elements is avoided, the self-clearing ability of materials is improved, and thus the product quality is improved.

Owner:SICHUAN ADVANCE TECH CO LTD

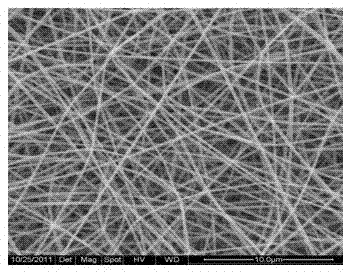

Safe rope-free mask

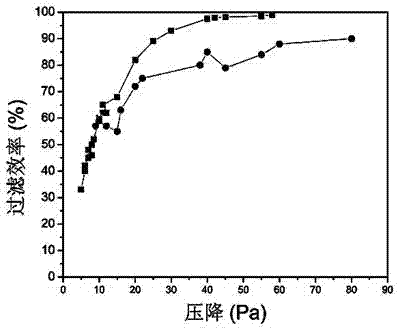

InactiveCN105433472AImprove filtration efficiencyImprove filtering effectProtective garmentSpecial outerwear garmentsFiberEngineering

The invention discloses a safe rope-free mask. The problems that an existing mask is inconvenient to wear and low in air pollutant filtering efficiency are solved. The safe rope-free mask comprises mask cloth, a mask nose clamp and a mask rubber ring. The mask cloth is used for covering the face contour of the human body and purifying air and comprises a primary filtering supporting layer, a nanofiltration layer and a protection layer which are sequentially overlapped together from outside to inside. The nanofiltration layer is of an interlayer structure and comprises two layers of nonfiber nets and micron fiber felt which is clamped between the two layers of nonfiber nets and manufactured by a chitosan solution through an electrostatic spinning process. The mask nose clamp is arranged at the upper end of the mask cloth. The mask rubber ring is arranged on the edge of the protection layer. The safe rope-free mask is convenient to wear, comfortable and safe, multi-layer structural design is adopted, then the characteristics of a chitosan material and the electrostatic spinning process are ingeniously combined, and therefore the filter effect of the mask on air pollutants is greatly optimized, and the effect of purifying the air is enhanced.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

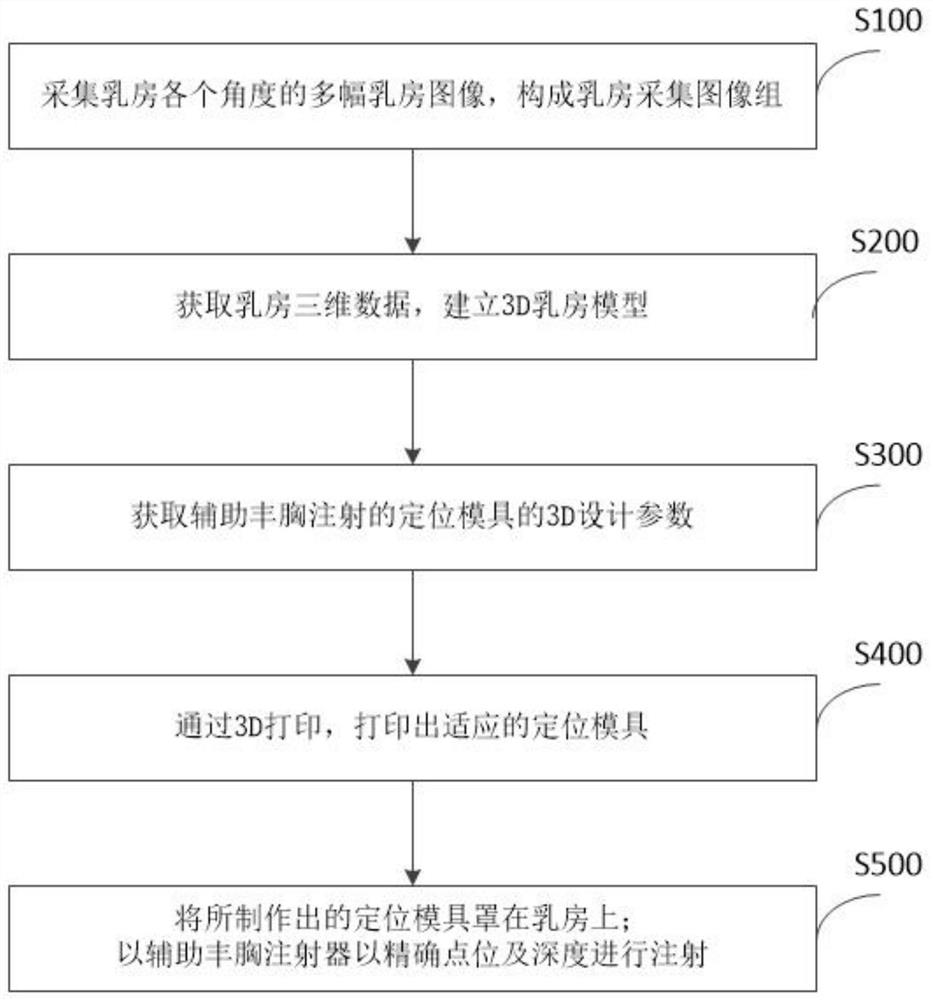

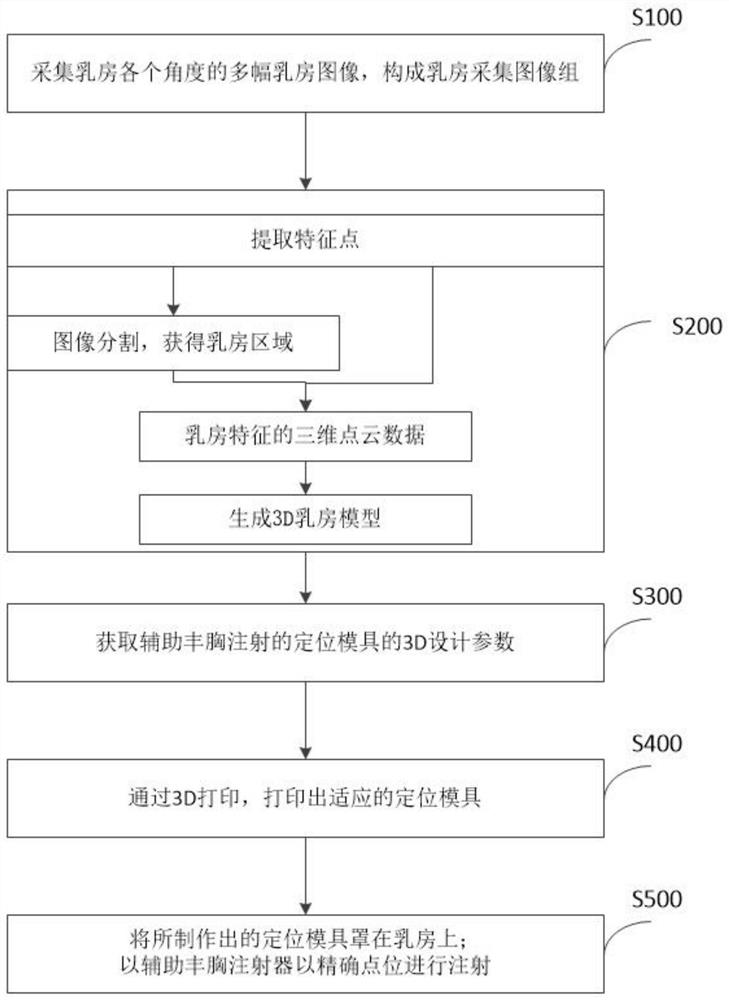

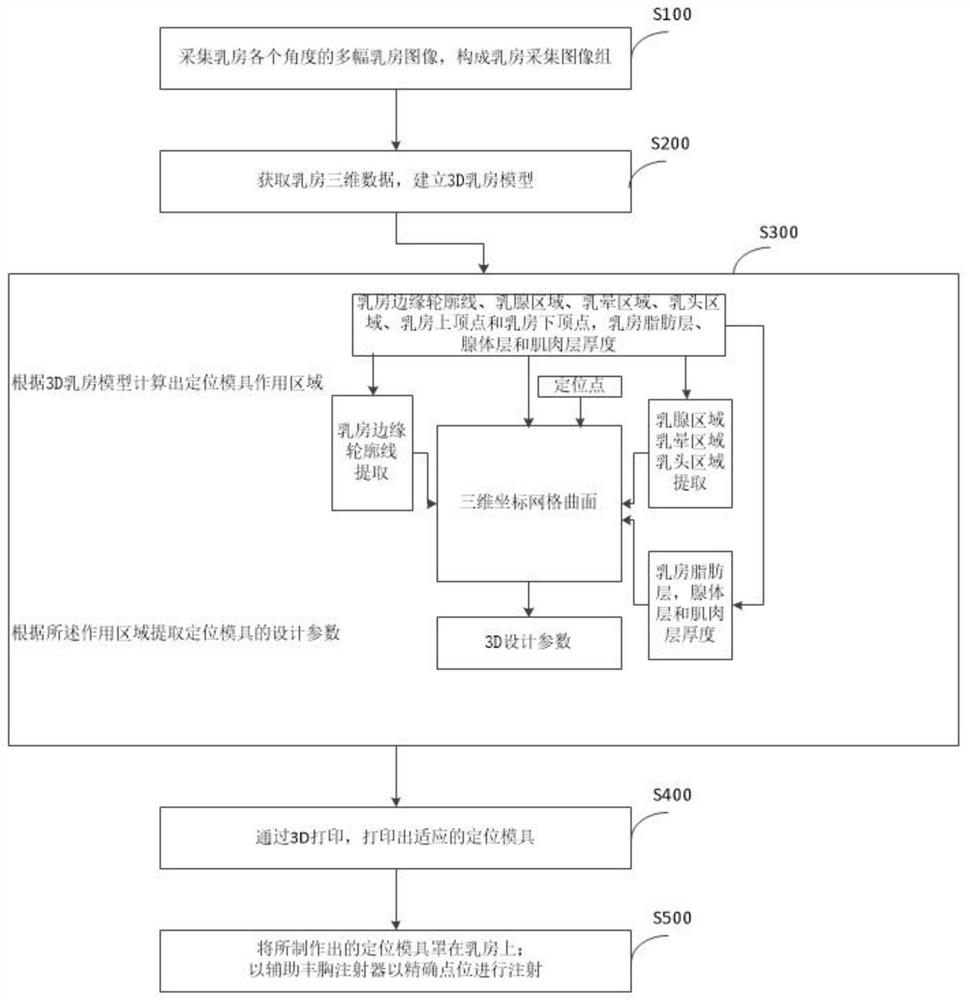

Breast augmentation injection positioning model acquisition method based on 3D modeling printing

PendingCN111887907AFor a seamless fitAccurate injection locationAdditive manufacturing apparatusDiagnostic markers3d designRadiology

The invention discloses a breast augmentation injection positioning model acquisition method based on 3D modeling printing. The method comprises the steps: collecting a plurality of breast images of different angles of a breast, and forming a breast collection image group; acquiring breast three-dimensional data by utilizing the breast collection image group, and establishing a 3D breast model; according to the 3D breast model, acquiring 3D design parameters of a positioning mold assisting in breast augmentation injection in combination with breast augmentation shape requirements; printing a suitable positioning mold through 3D printing by using the 3D design parameters of the positioning mold; and covering the manufactured positioning mold on the breast so as to assist a breast augmentation injector to inject at accurate point positions and levels. The precise positioning mold assisting in breast augmentation injection can be obtained, seamless attachment of the positioning mold is achieved, the injection position and depth are precisely determined, safety risks and adverse effects caused by individual differences are effectively avoided, and the breast augmentation injection process is safer and more precise.

Owner:喻堃

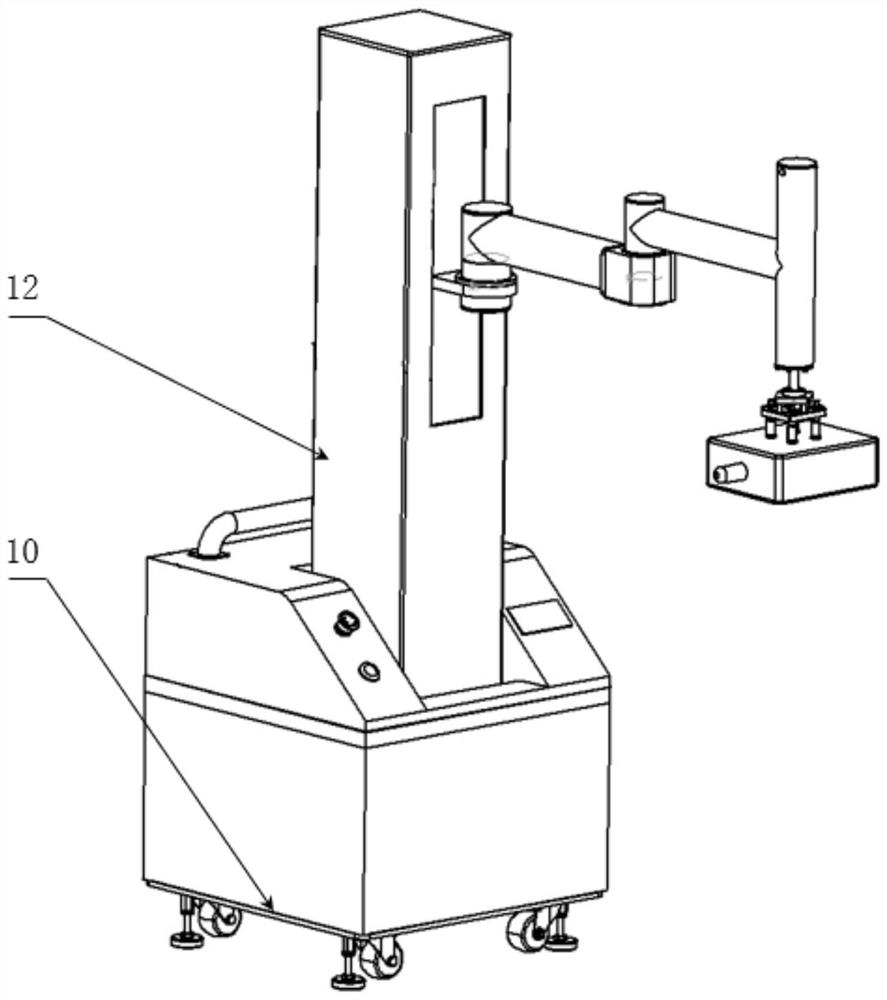

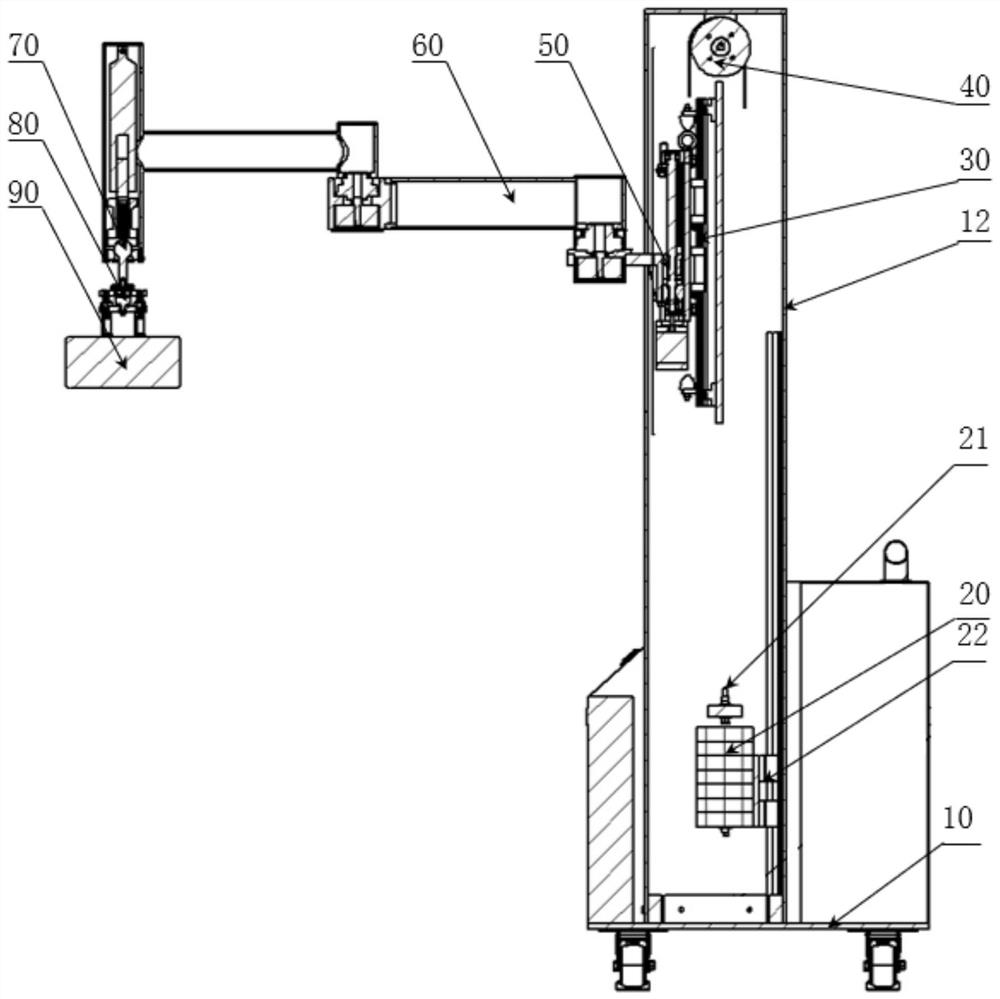

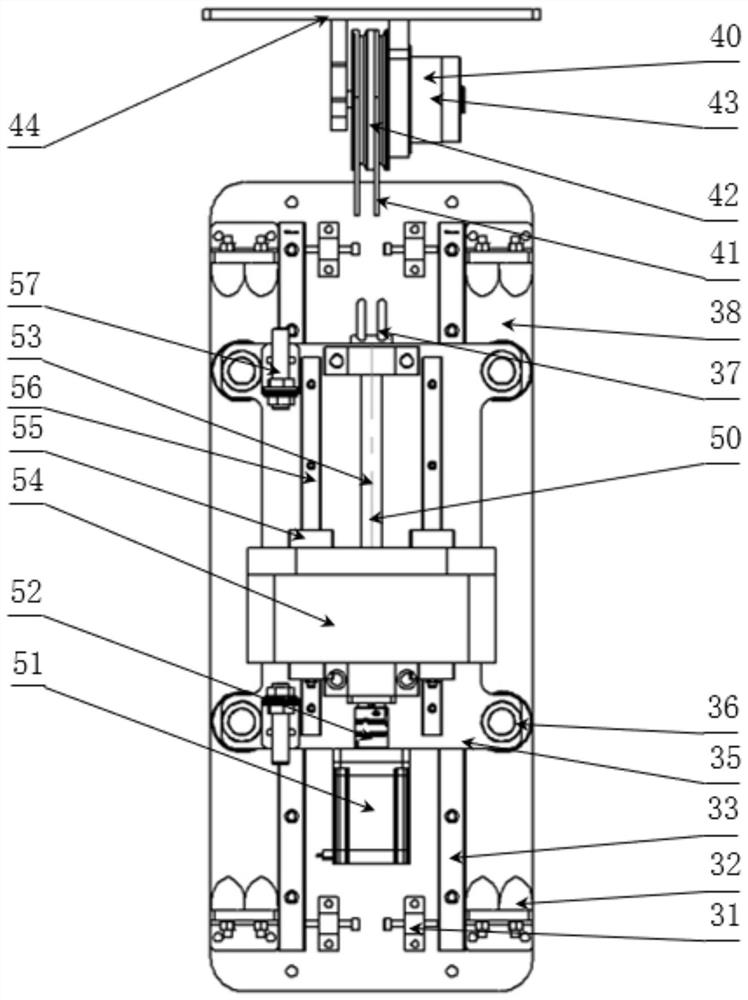

An ultrasonic non-destructive testing device

ActiveCN107991389BHigh degree of automationHigh precisionAnalysing solids using sonic/ultrasonic/infrasonic wavesControl systemEngineering

The invention discloses an ultrasonic non-destructive testing device, which includes a mobile platform, a column, a rotating arm, a pressure sensor, an ultrasonic transducer and a control system. The column is installed on the mobile platform, and a lifting device is installed in the column mechanism and a lifting counterweight module, one end of the rotating arm is connected to the lifting mechanism, and the lifting mechanism controls the rotating arm to lift and pressurize, and the other end of the rotating arm is provided with a self-control locking ball hinge , the pressure sensor is connected to the bottom of the self-control locking ball hinge, the ultrasonic transducer is connected to the pressure sensor through a spring guide post connection mechanism, and the control system controls the action of each executive part of the entire detection device. The above ultrasonic nondestructive testing device not only has a compact structure, can reduce manual intervention in the ultrasonic testing process, reduce labor intensity of testing personnel, but also improve the accuracy and reliability of ultrasonic testing results.

Owner:HUST WUXI RES INST

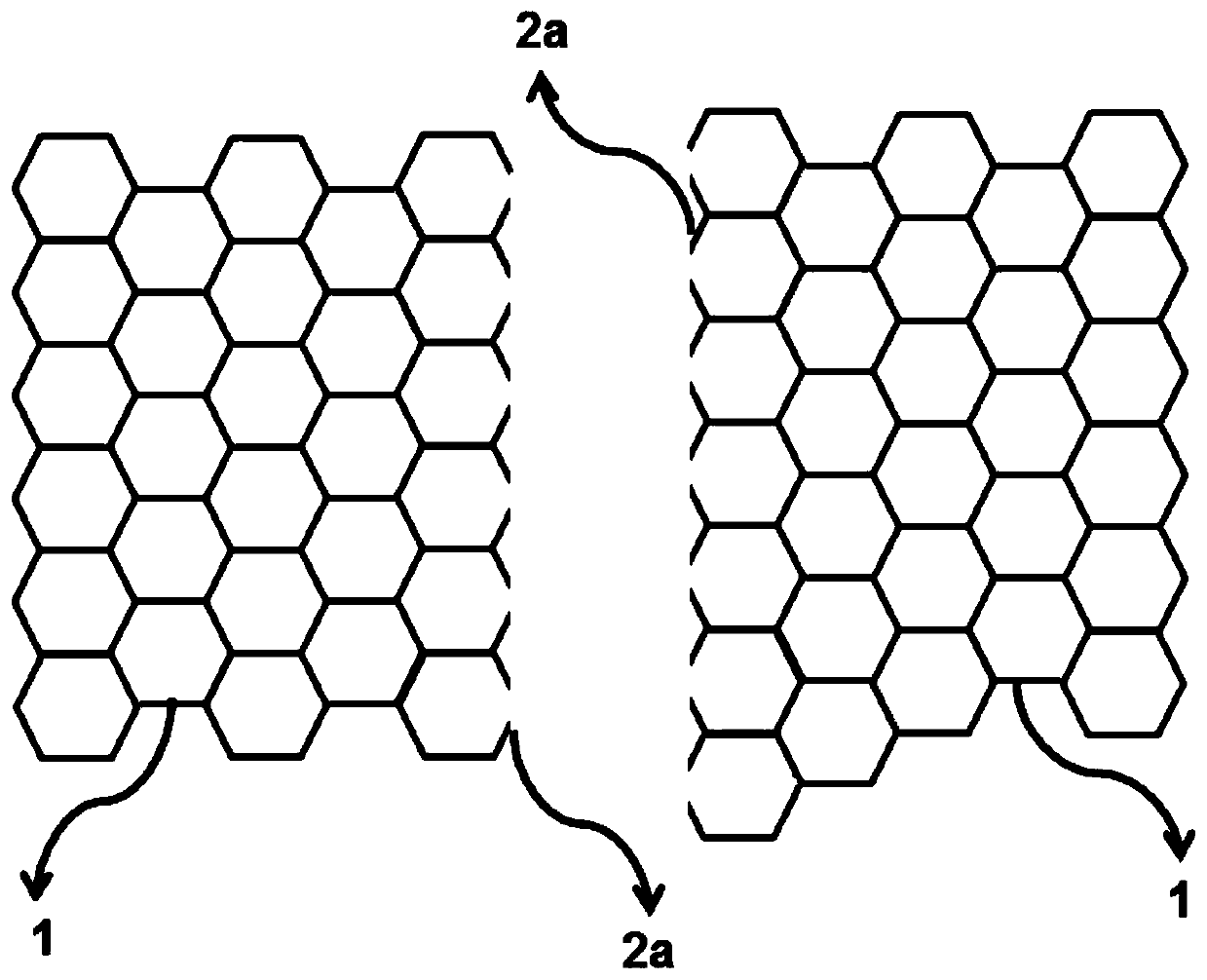

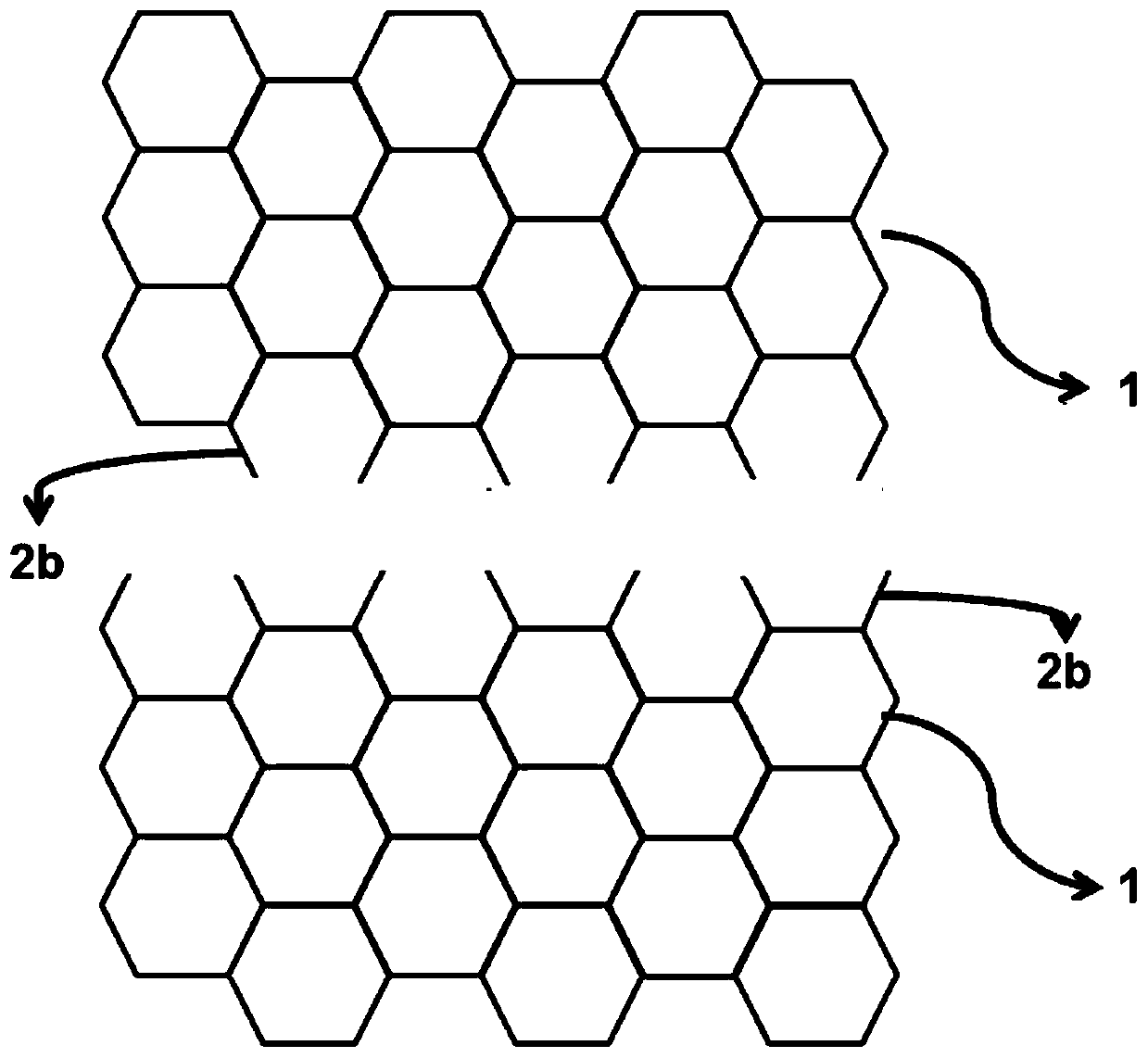

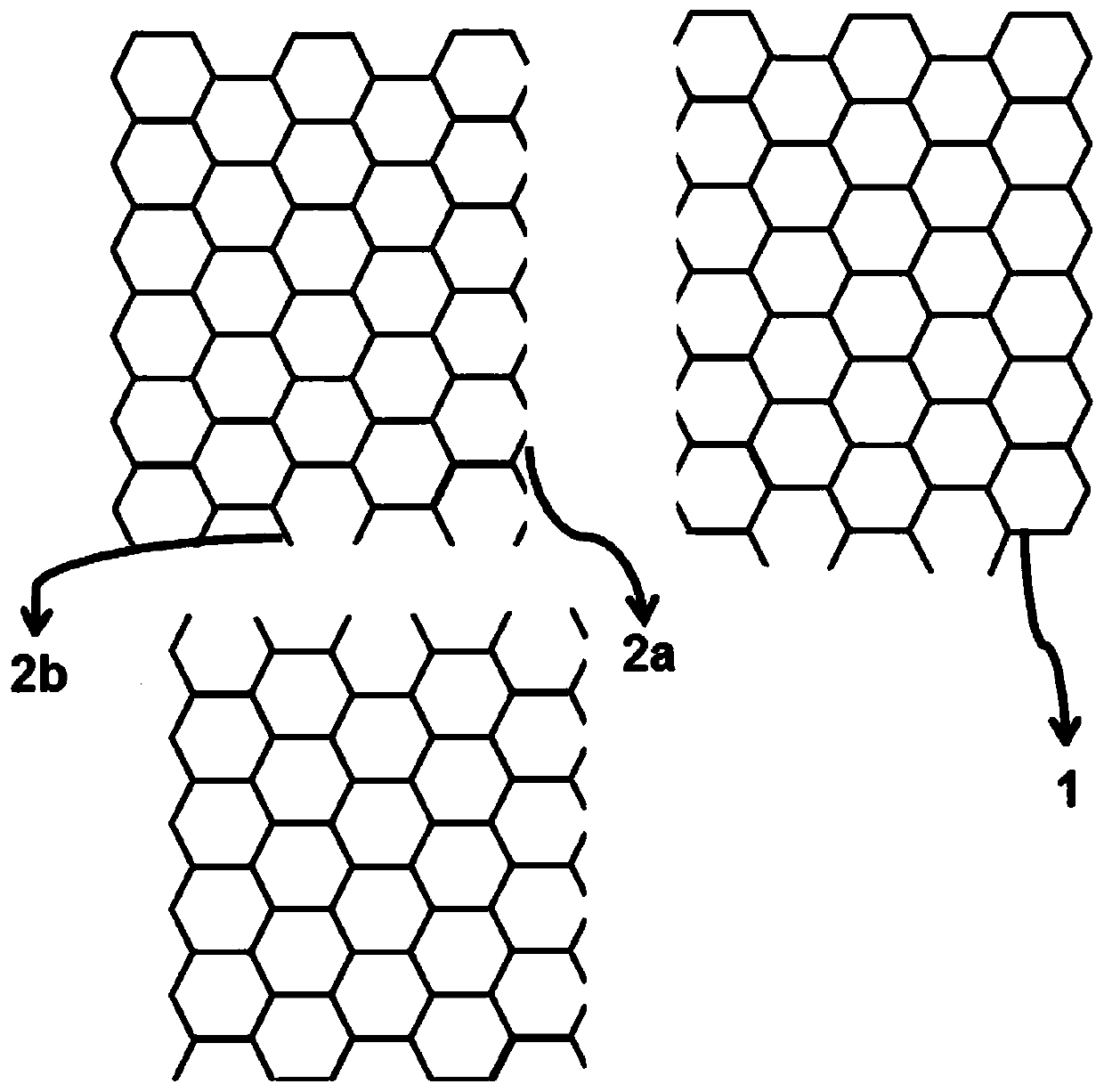

A kind of preparation method of seamless splicing honeycomb core material

ActiveCN107639884BMaintain continuous functional performanceKeep the lookPaper/cardboard articlesDomestic articlesHoneycombRoom temperature

Owner:AVIC BASIC TECH RES INST

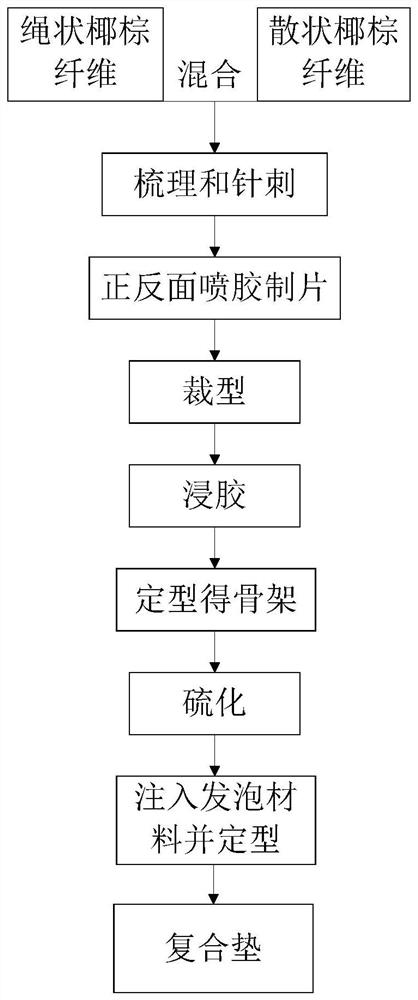

Production process of composite pad

InactiveCN112497802ASimple production processModerate hardnessDomestic articlesRettingIndustrial engineering

The invention discloses a production process of a composite pad. The production process of the composite pad comprises the following steps of carding and needling coconut fibers by using a needling machine; spraying glue on the front surface and the back surface of the coconut fibers by using a flaking machine for flaking to obtain a coconut fiber sheet; cutting the coconut fiber sheet according to requirements; putting the cut coconut fiber sheet into a gum dipping box to be integrally dipped with gum; putting the gum-dipped coconut fiber sheet into a first mold for shaping to obtain a skeleton of the composite pad; putting the framework into a vulcanization box for vulcanization; putting the vulcanized skeleton into a second mold, and injecting a foaming material into the second mold; and removing the second mold to obtain the composite pad. The coconut fiber is moderate in hardness; and the foaming material has high resilience and can be well matched with the curve of a human body,so that seamless fitting is realized. According to the composite pad, the framework is made of the coconut fibers and is wrapped with the foaming material, so that the use strength and the air permeability of the composite pad are guaranteed, and the comfort of fitting with a user is also guaranteed.

Owner:CHANGCHUN FAW SIHUAN ASSEMBLY WELFARE PACKING

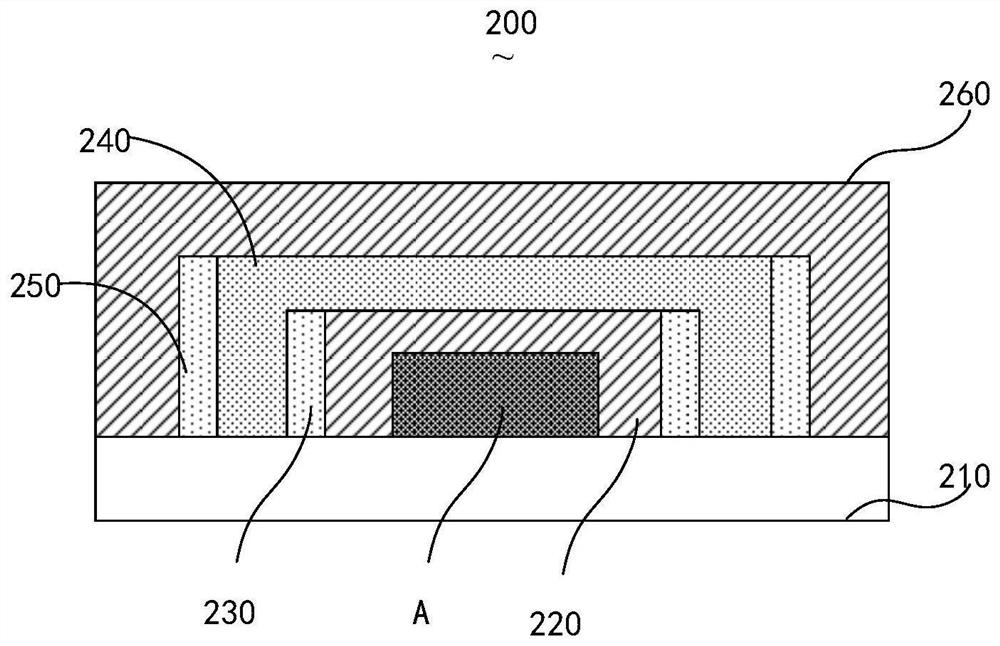

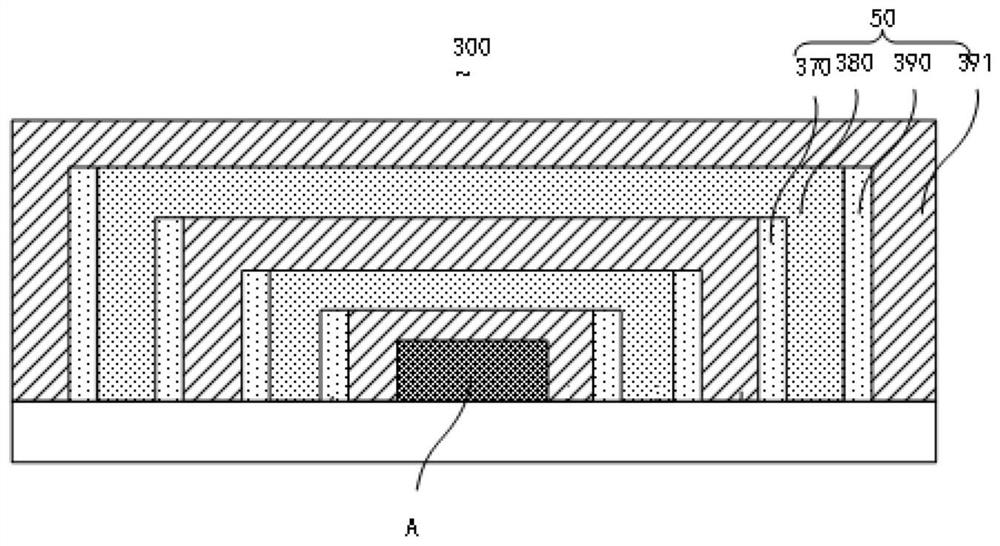

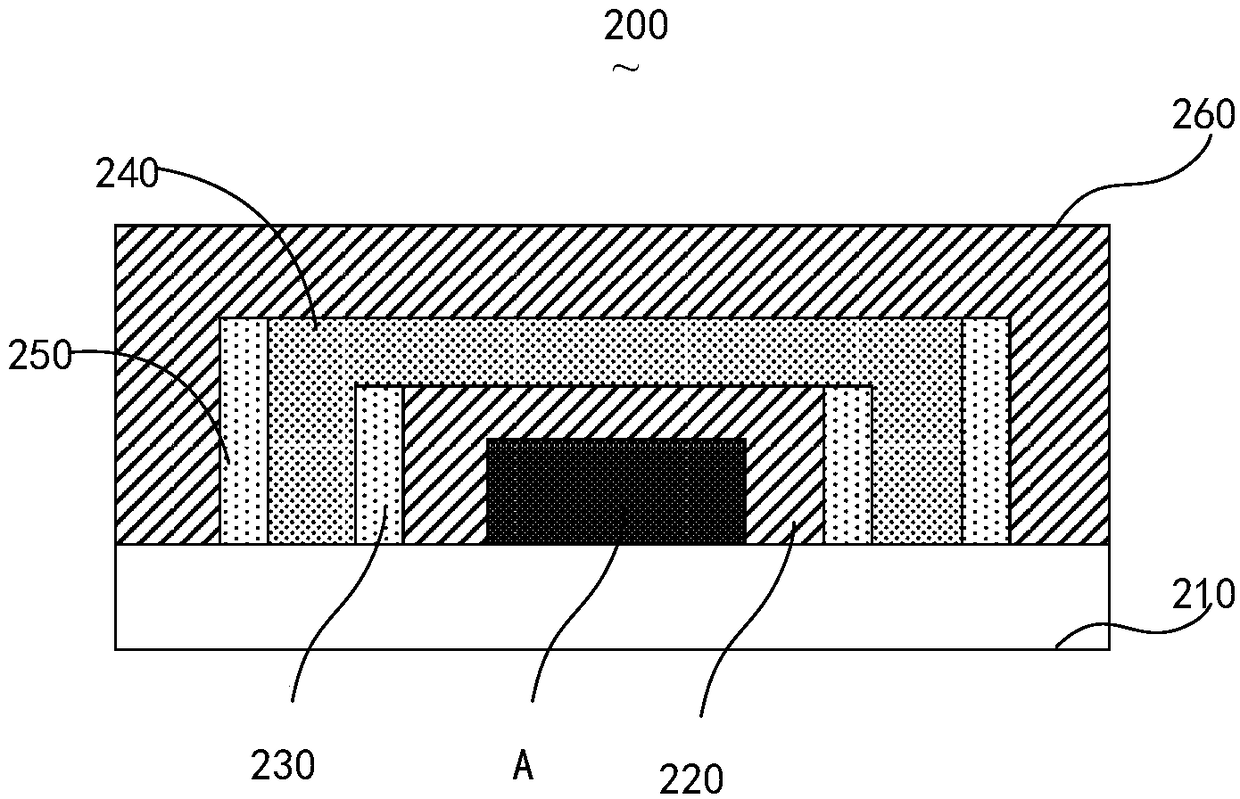

Packaging Structure and Packaging Devices

ActiveCN109461823BImprove bindingReduce sheddingSolid-state devicesSemiconductor/solid-state device manufacturingStructural engineeringMechanical engineering

The present application discloses a packaging structure and a packaging device. The packaging structure includes: a base layer, one side of the base layer is used to form a part to be packaged; a first packaging layer is formed on a side of the part to be packaged facing away from the base layer, And cover the side wall of the component to be packaged; the first buffer layer is arranged around the periphery of the first packaging layer and pasted on the side wall of the first packaging layer; the second packaging layer is formed on a side of the first packaging layer facing away from the base layer side, and cover the sidewall of the first buffer layer. Through the above method, the present application can enhance the bonding force between the film layers, reduce the possibility of the film layer falling off and enhance the ability of the packaging device to block water and oxygen, so as to realize the seamless bonding between the film layers.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

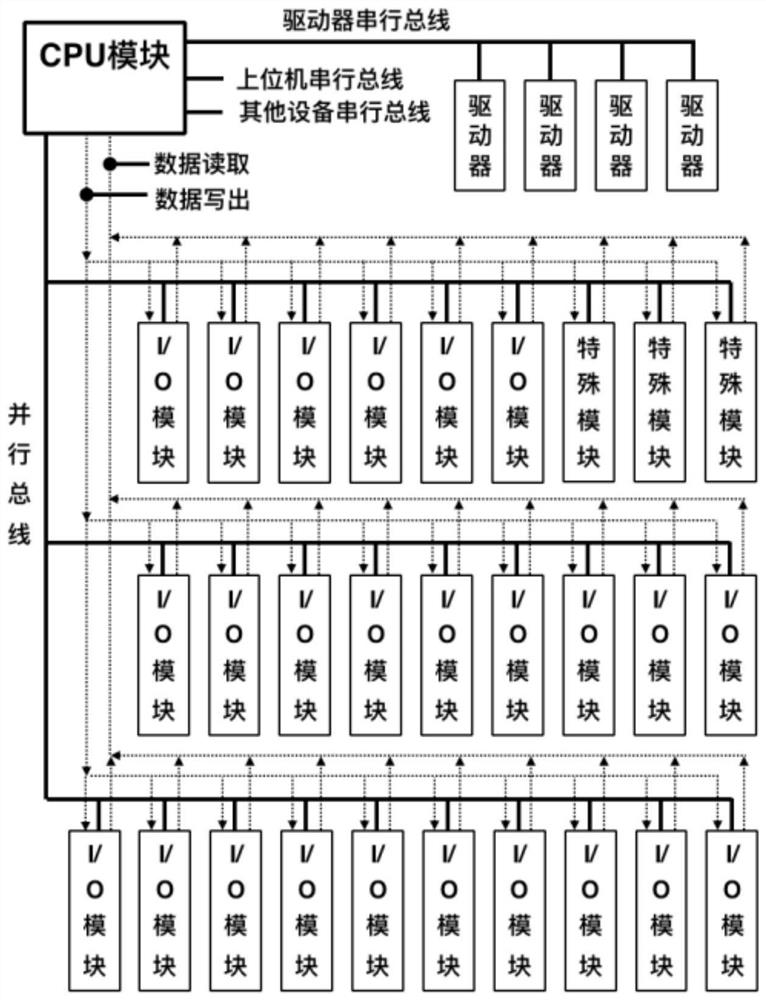

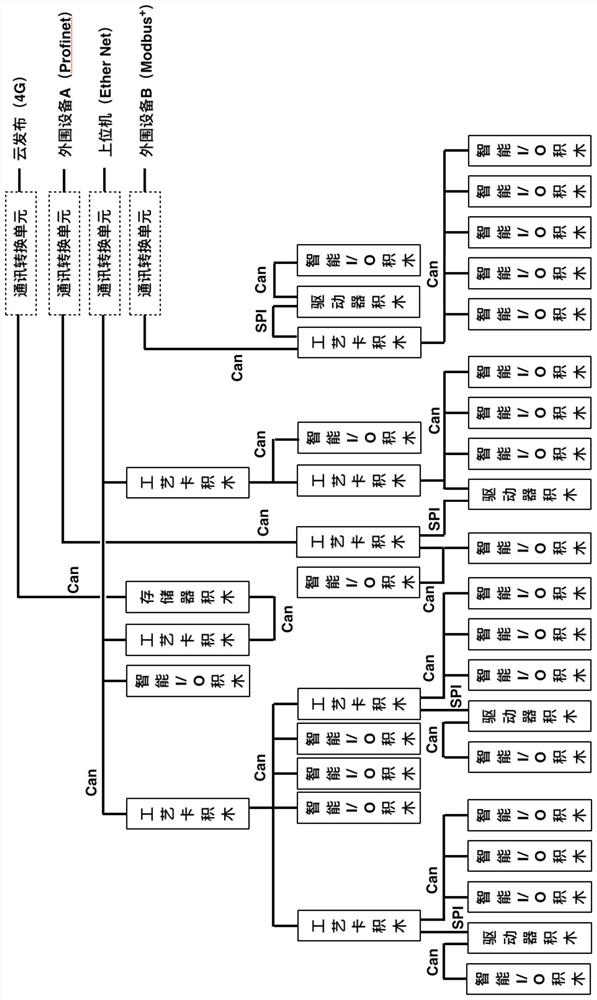

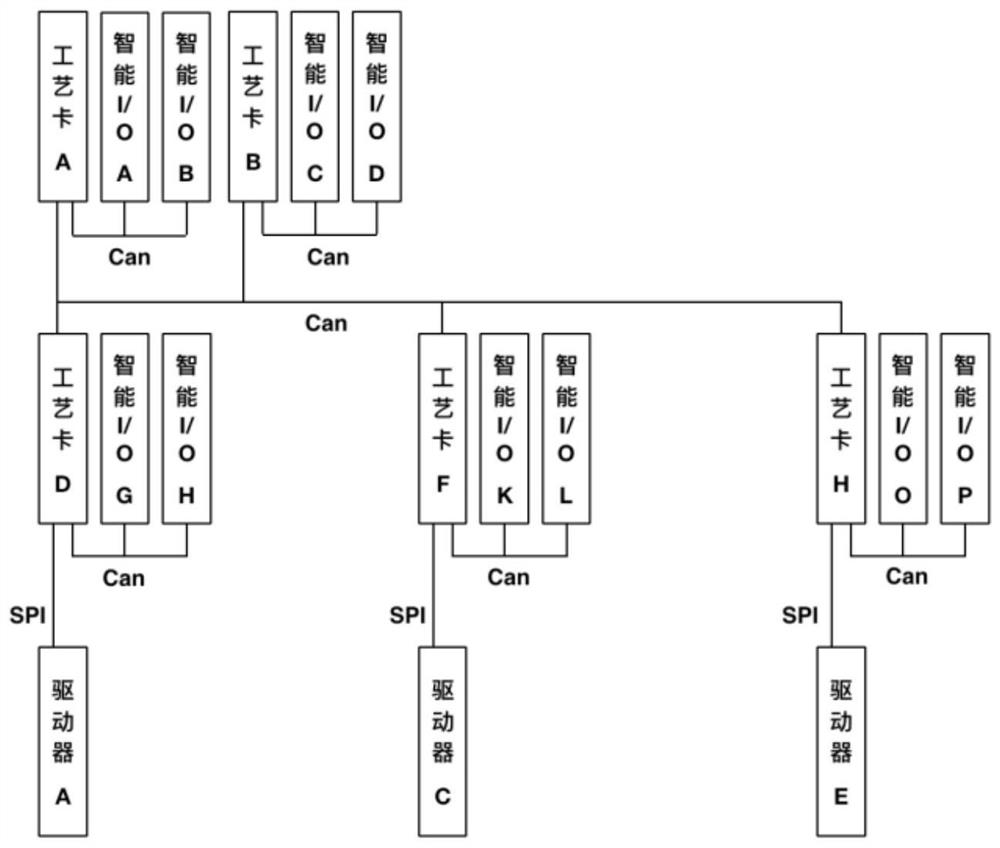

Design method of building block multi-single-chip microcomputer control system with preset programs

ActiveCN110262350BFor a seamless fitPromote intelligent developmentProgramme controlComputer controlCommunication interfaceControl system

The invention relates to a design method of a building block multi-single-chip microcomputer control system with preset programs. Designers add single-chip microcomputers, practical software and communication interfaces to the conventional module form of the control system to form building blocks with different functions for different industries and different equipment. According to the functional requirements, select the building blocks, and connect each building block through the serial bus network to realize the complete function of the control system. The program of each building block is simple, easy to modify, fast to execute, and not prone to bugs; adopting the serial bus mode can better realize distributed control, reduce system size, shorten wiring, and reduce interference; users no longer need programming, You only need to set parameters, and the debugging workload is greatly reduced. That is, the user burden is reduced, and failures or even accidents caused by improper user programming are avoided. Treat the motor driver as a building block and a part of the control system to make it seamlessly connected and make the intelligence of mechanical equipment more convenient.

Owner:王旭

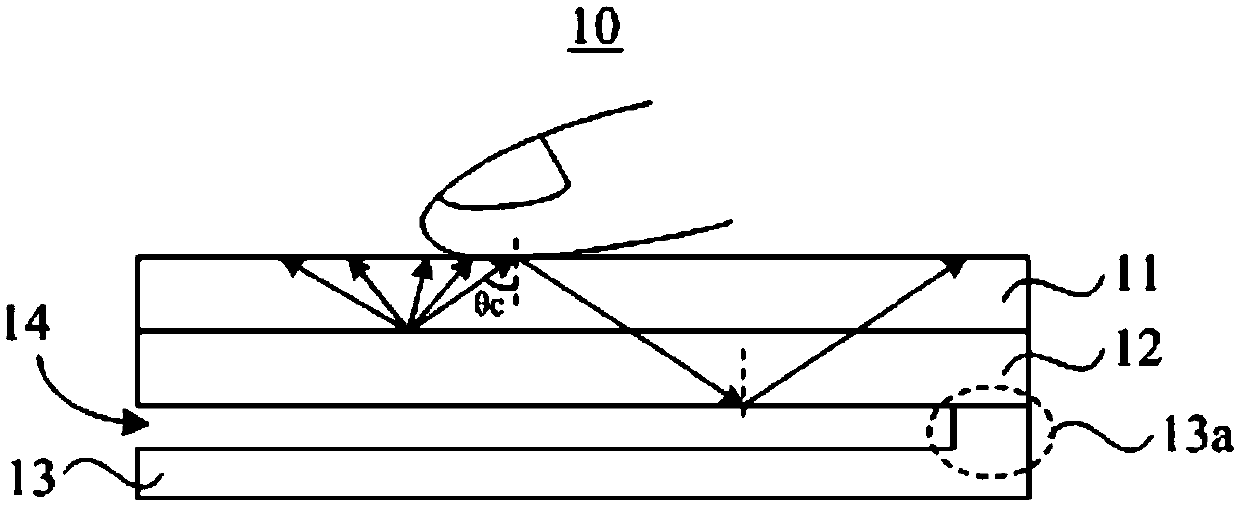

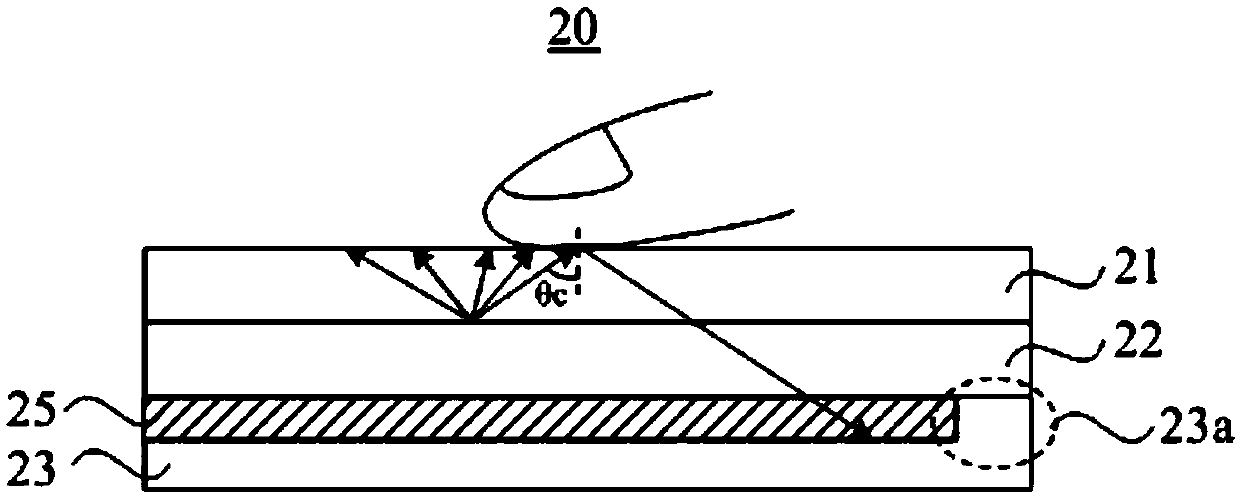

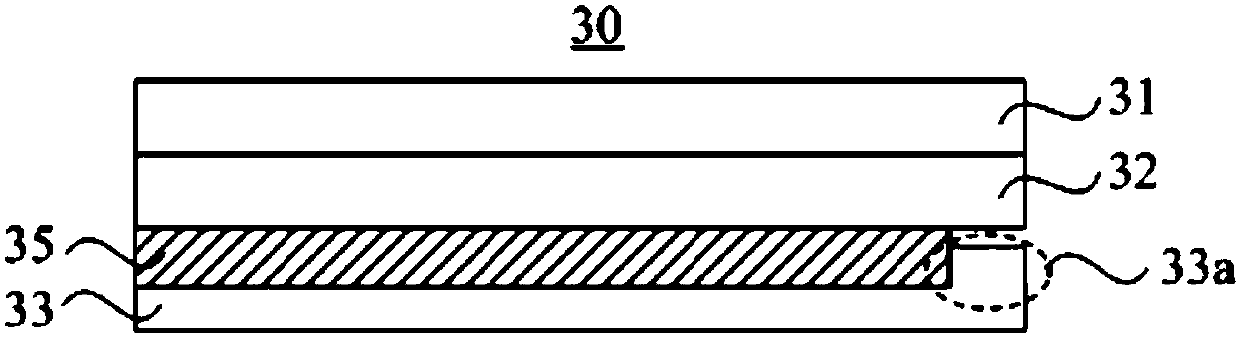

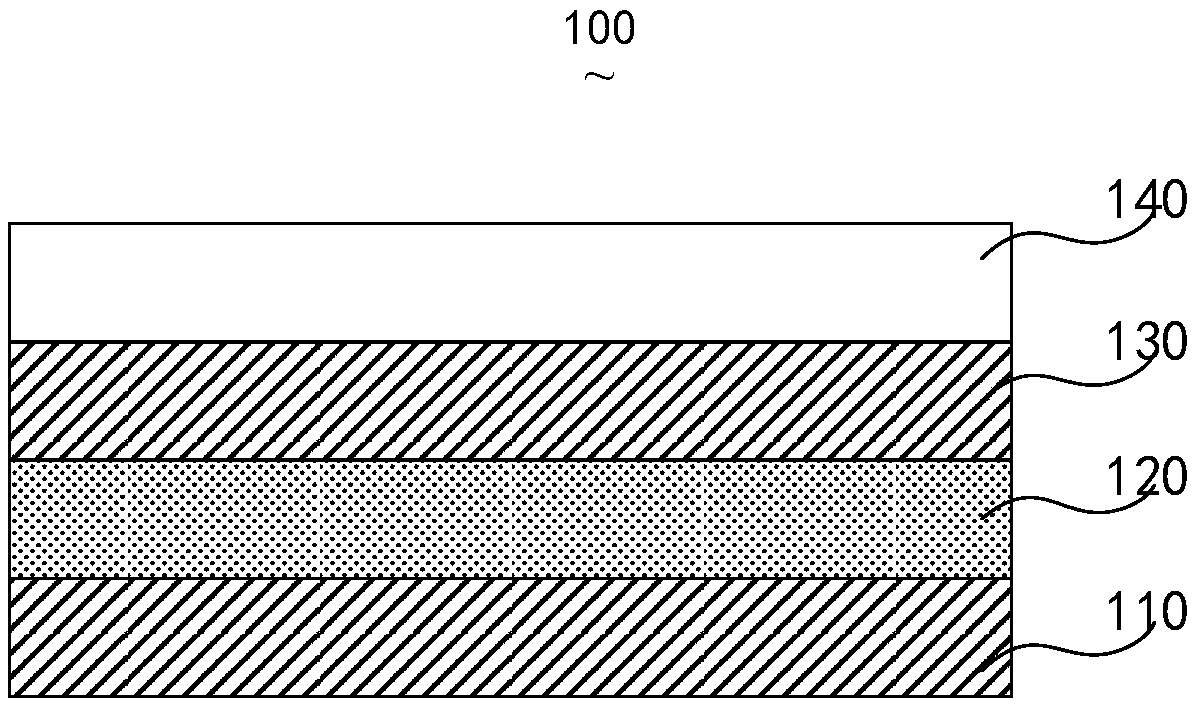

Fingerprint acquisition device and manufacturing method thereof

PendingCN111209785AImprove stabilitySolve the noiseCharacter and pattern recognitionDielectricRefractive index

The invention provides a fingerprint acquisition device and a manufacturing method thereof. The fingerprint acquisition device comprises a light-transmitting cover plate, a display layer, a dielectricfilm and a sensing module, wherein the light-transmitting cover plate is provided with a first surface for contacting a fingerprint; the display layer is arranged on the second surface of the light-transmitting cover plate and comprises a pixel array for displaying; the first surface of the sensing module is provided with a protruding part;the dielectric film is filled between the display layer and the area, not provided with the protruding part, of the first surface of the sensing module, the two surfaces of the dielectric film in the thickness direction are attached to the display layer andthe sensing module respectively, the dielectric film is pervious to light, and the difference value between the refractive index of the dielectric film and the refractive index of the display layer is within a preset range. According to the fingerprint acquisition device and the manufacturing method thereof provided by the embodiment of the invention, a gap between the display layer and the sensing module due to the existence of the convex part can be avoided, the normal reception of fingerprint reflection light rays by the sensing module is ensured, the noise is reduced, and the stability isimproved.

Owner:SHANGHAI HARVEST INTELLIGENCE TECH CO LTD

Air conditioner indoor unit

ActiveCN103940068BBeautiful appearanceIncrease air volumeHeating and ventilation casings/coversAir-flow control membersPollutionElectrical and Electronics engineering

Owner:WUHAN REFRIGERATION EQUIP OF MIDEA GROUP

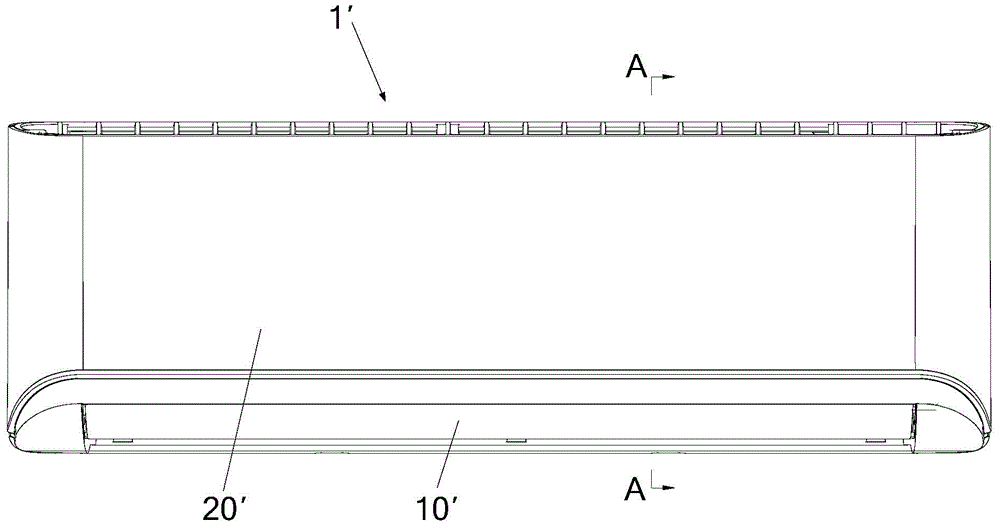

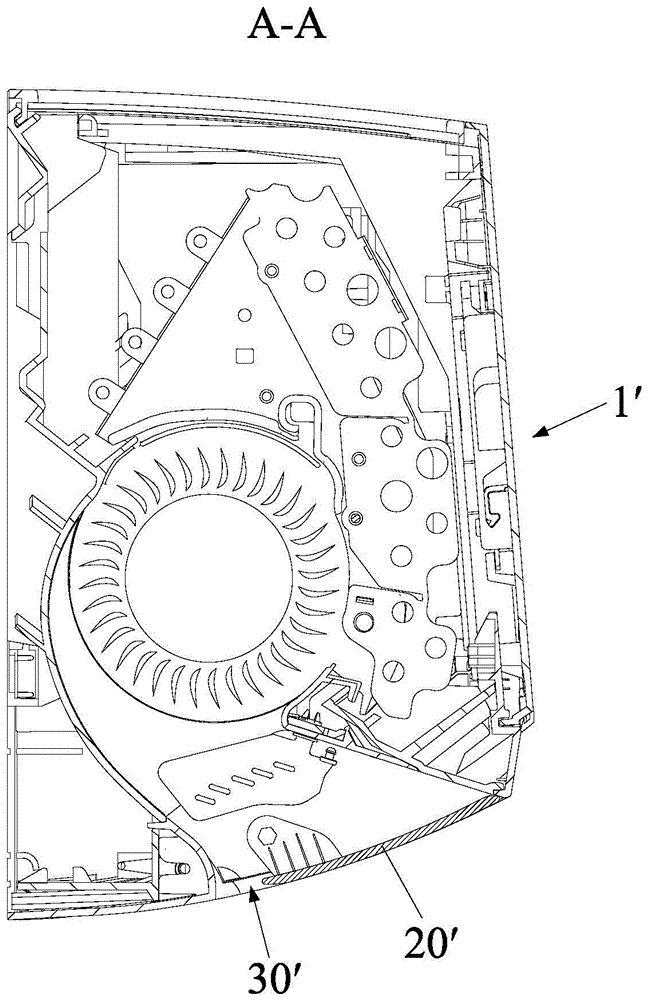

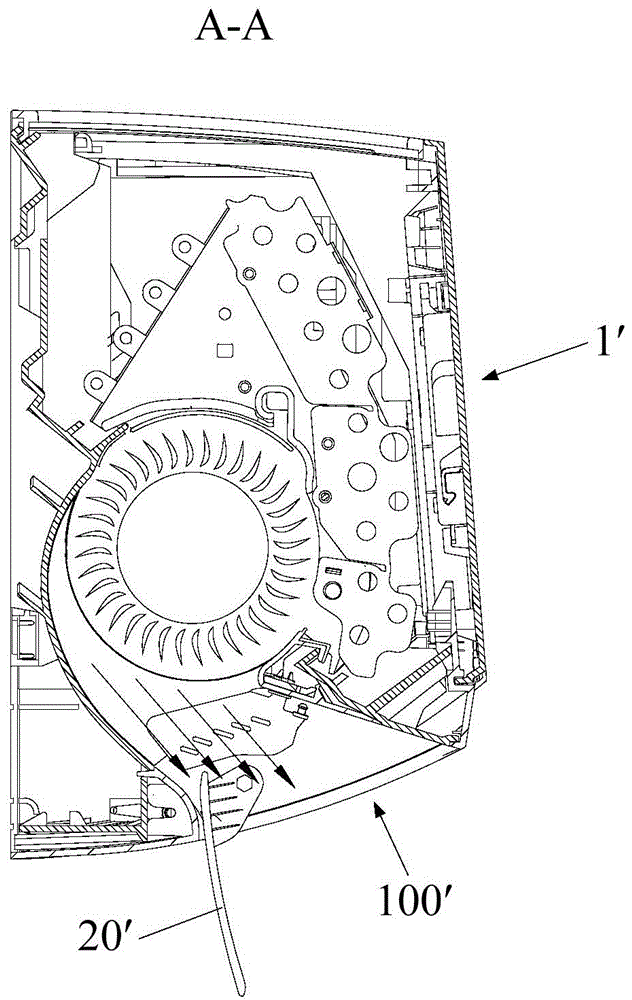

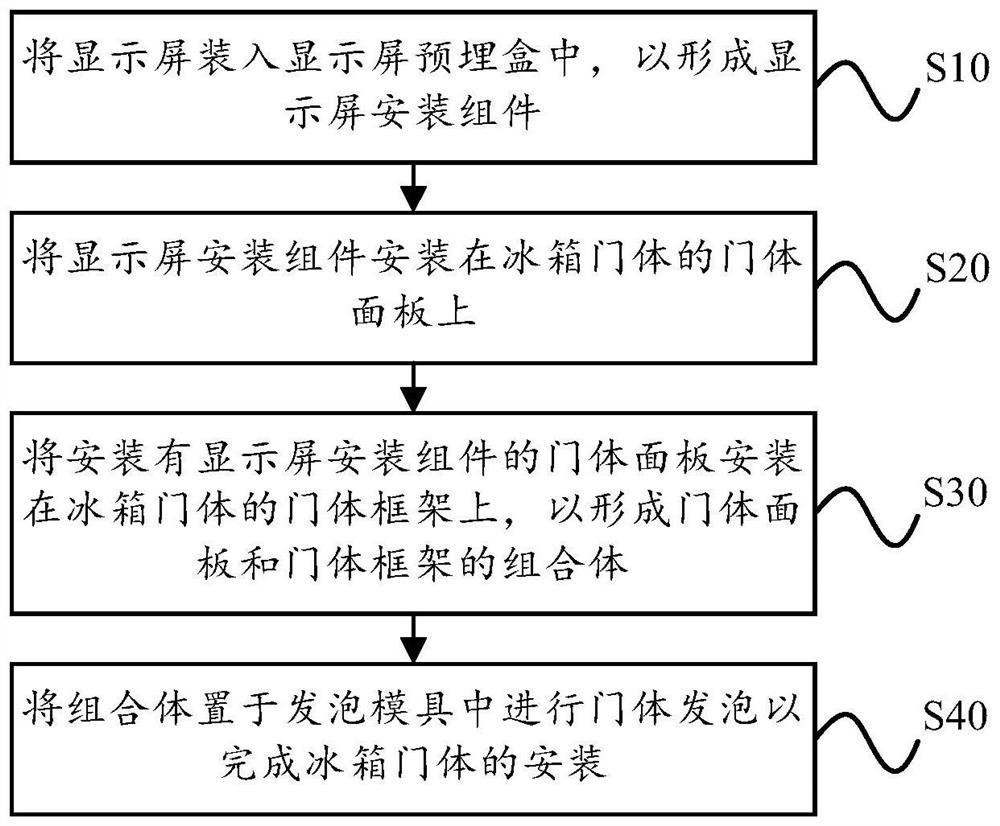

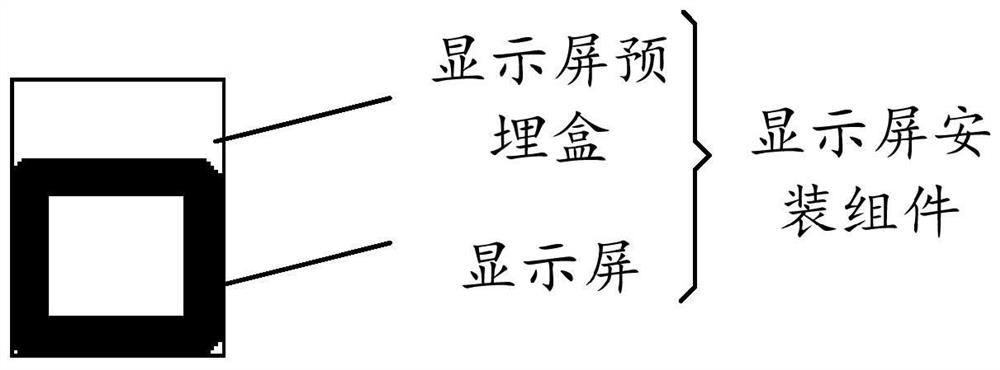

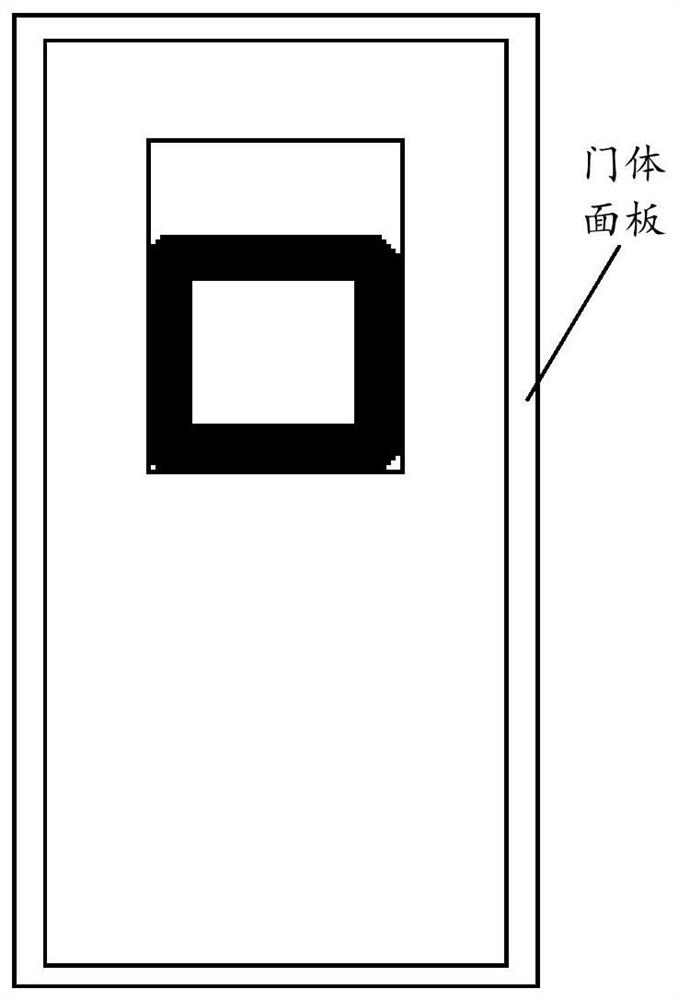

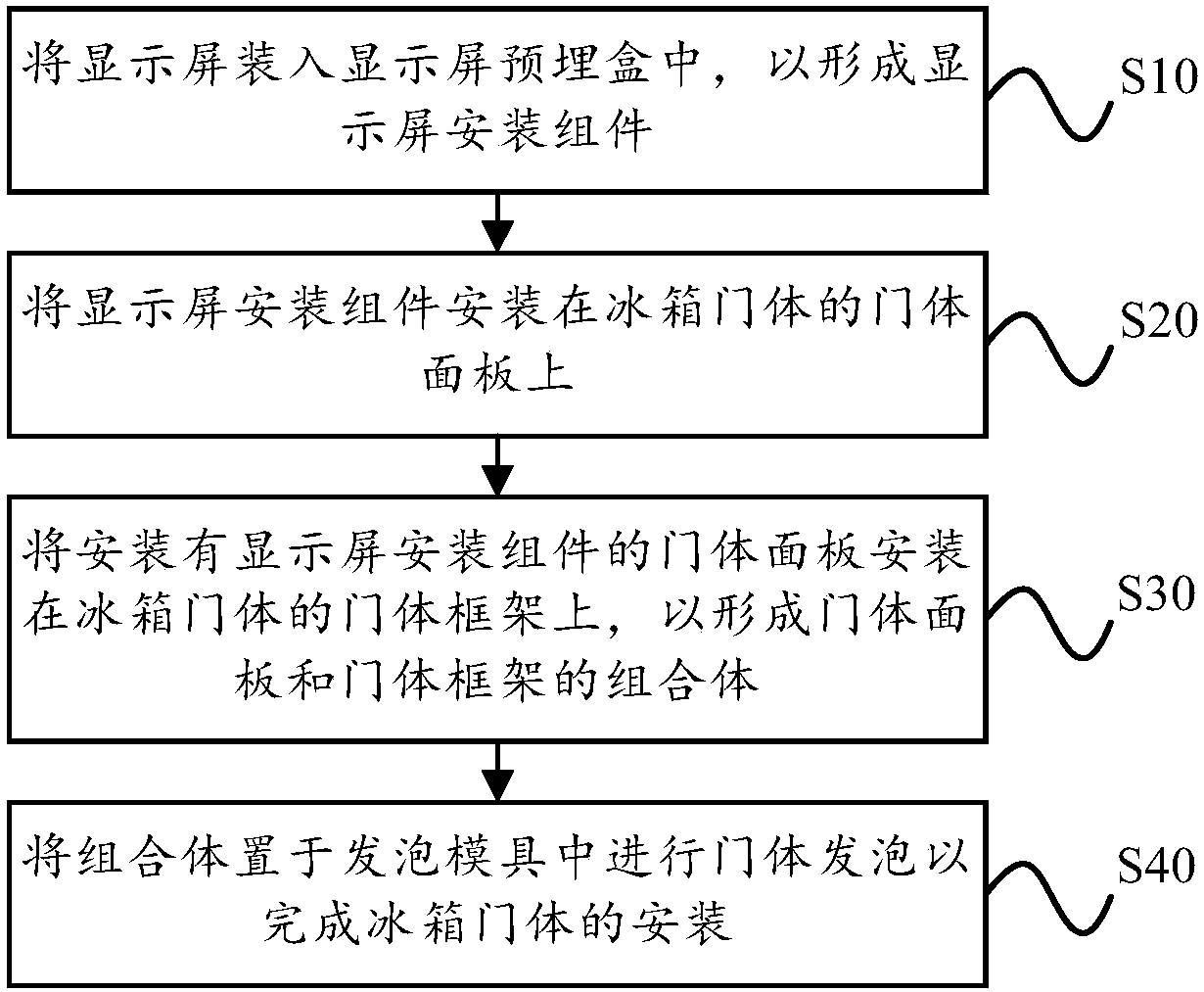

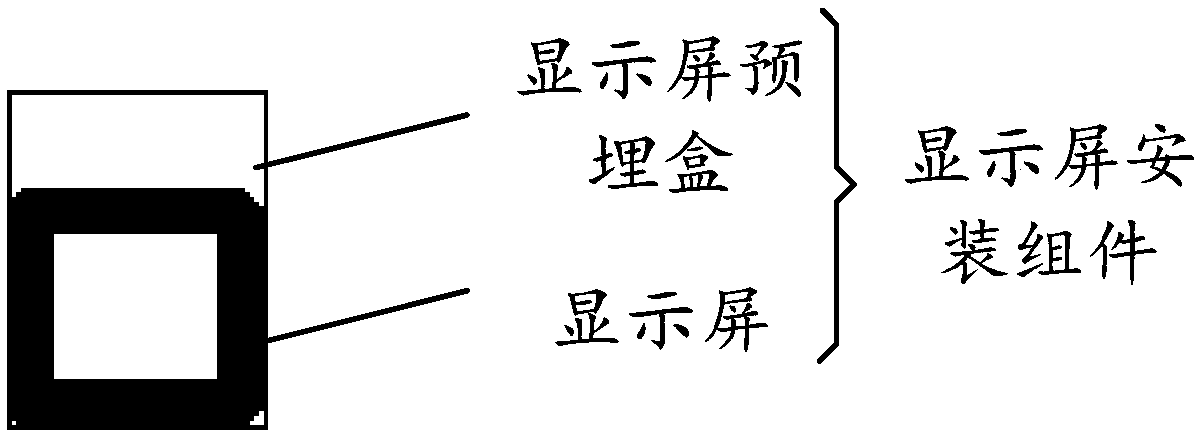

Installation method of refrigerator door body, refrigerator door body and refrigerator

ActiveCN107677036BSimplify the installation processImprove installation efficiencyLighting and heating apparatusCooling fluid circulationIceboxStructural engineering

The invention provides an installation method for a refrigerator door body, and further provides the refrigerator door body assembled adopting the installation method and a refrigerator with the refrigerator door body accordingly. The installation method comprises the steps that a display screen is loaded into a display-screen embedded box to form a display-screen installation component; the display-screen installation component is installed on a door body panel of the refrigerator door body; the door body panel provided with the display-screen installation component is installed on a door body frame of the refrigerator door body to form a combination body of the door body panel and the door body frame; and the combination body is placed into a foaming mould to be subjected to door body foaming to complete the installation of the refrigerator door body. According to the installation method for the refrigerator door body, the refrigerator door body assembled adopting the installation method and the refrigerator with the refrigerator door body, by means of the manner that the display screen is placed into the display-screen embedded box before the door body foaming procedure is performed, thus the procedure of installation and disassembly of foaming tooling in related technologies is omitted, the installation procedure of the refrigerator door body is simplified, and dirty hard to clean generated on the display screen is further effectively avoided and the possibility of scratching the door body panel is eliminated.

Owner:HEFEI MIDEA INTELLIGENT TECH CO LTD

Ventilated saccule mask for assisting painless bronchoscopy

The invention relates to a ventilated saccule mask for assisting painless bronchoscopy. The ventilated saccule mask comprises a mask shell, a crash pad, an airbag inflation connector, a positive pressure ventilation connector and a bronchoscopy catheter connector; the crash pad is arranged at the inner side of the mask shell; the airbag inflation connector is arranged at the outer side of the maskshell, and the airbag inflation connector is communicated with an inner cavity of the crash pad; the positive pressure ventilation connector and the bronchoscopy catheter connector are formed above the airbag inflation connector in sequence; the outer side of the positive pressure ventilation connector is provided with a fixing mechanism; and the bronchoscopy catheter connector is internally provided with a sealing ring. The ventilated saccule mask for assisting the painless bronchoscopy has the advantages that not only can a nasal catheter be used for oxygen inhalation during examination andtreatment, but also a breathing saccule can provide positive pressure ventilation, so that oxygenation of a patient during the examination and treatment is maintained, oxygen inhalation of the patient can be combined during painless bronchoscopy, and hypoxemia is not caused.

Owner:太仓市中医医院

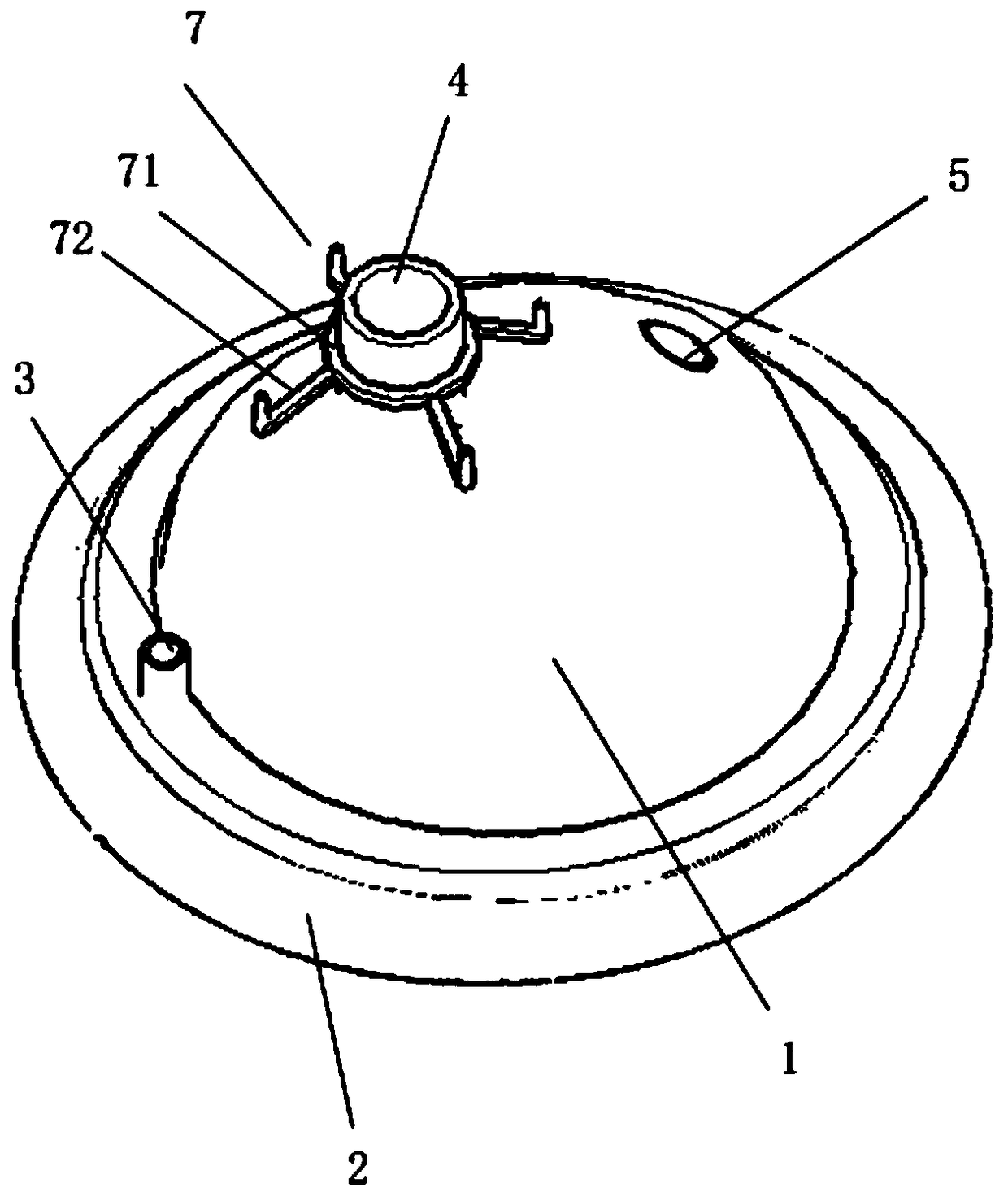

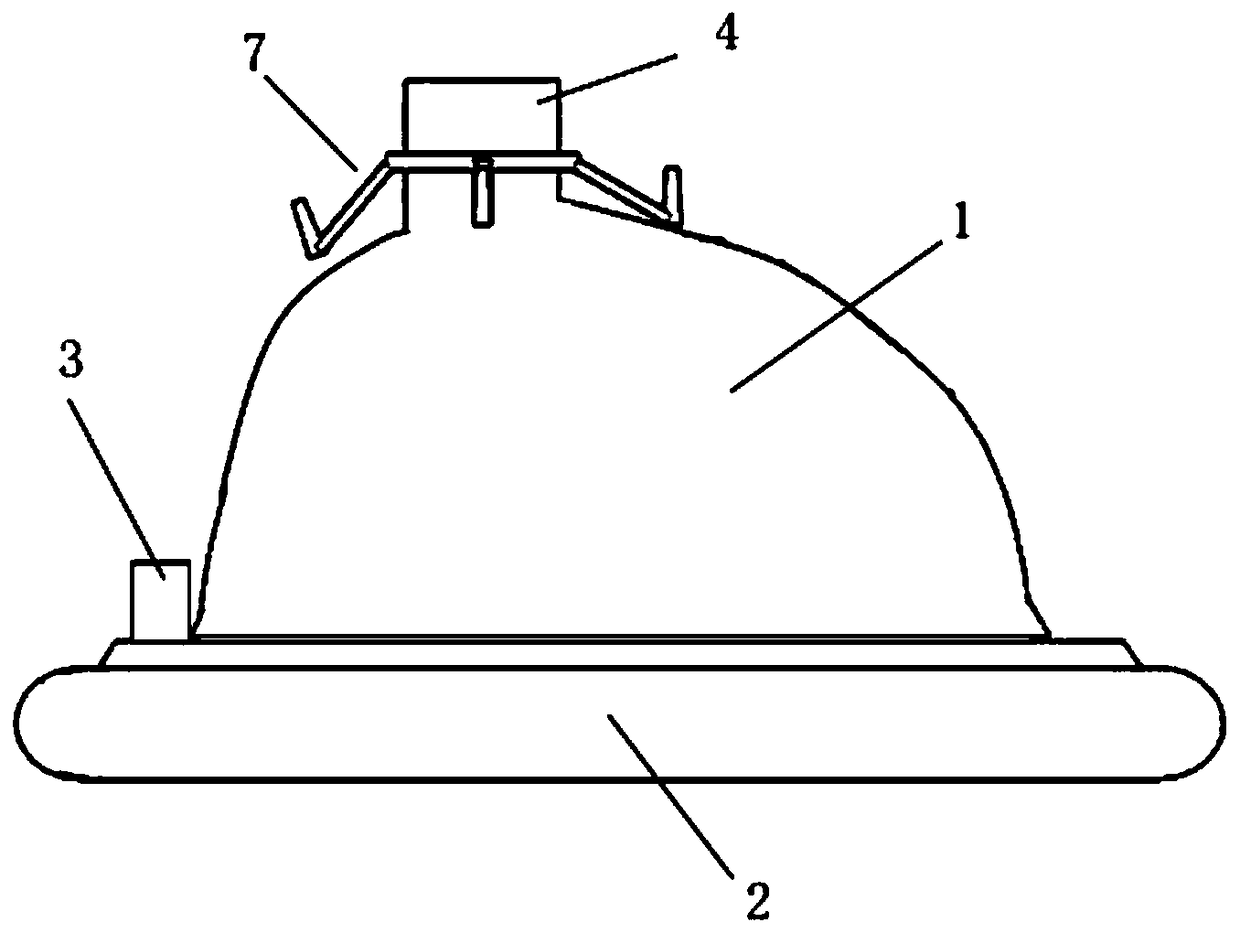

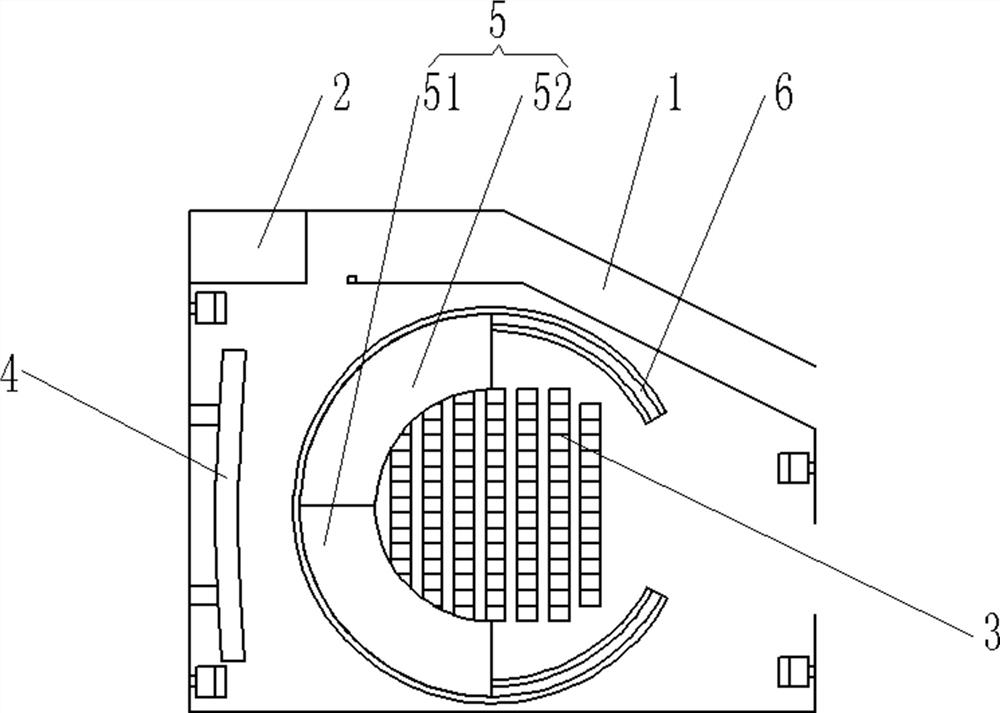

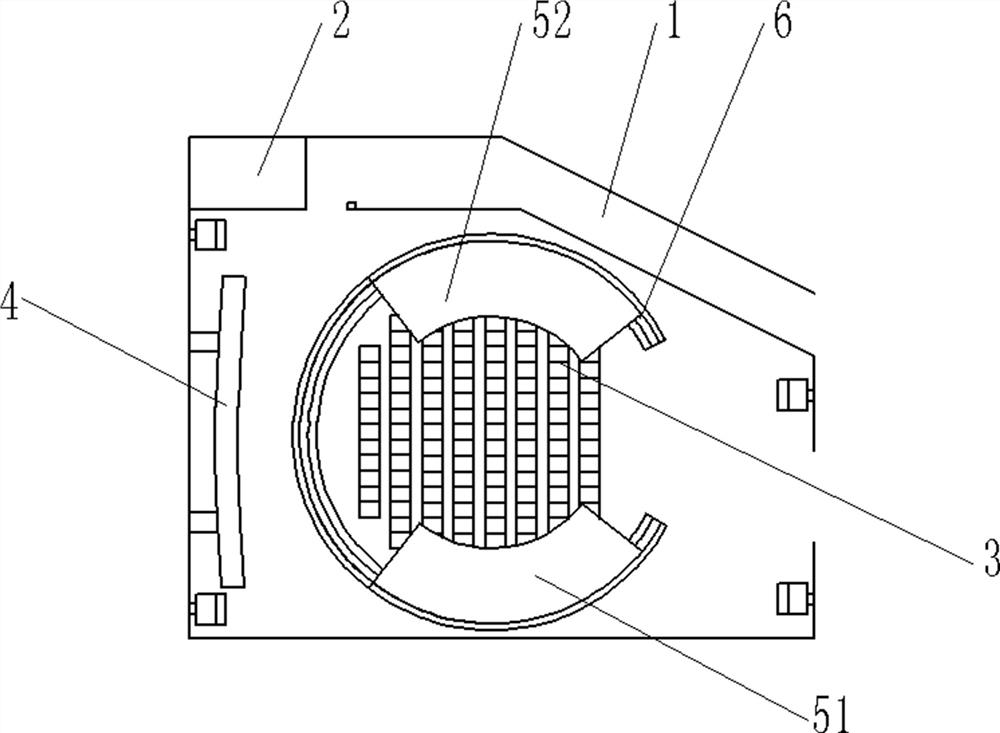

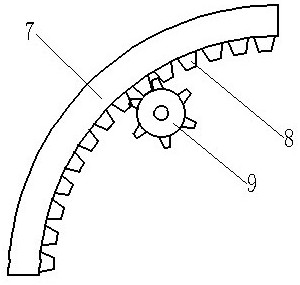

Open-close type spherical screen and huge screen integrated cinema and screening method

PendingCN111734175AIncrease diversityImprove viewing effectCinema apparatusTheatresGear wheelLarge screen

The invention discloses an open-close type spherical screen and huge screen integrated cinema and a screening method. The integrated cinema comprises a cinema hall, wherein the cinema hall comprises an access way, a control room, seats, a huge screen and a spherical screen, the spherical screen is an open-close type spherical screen and comprises a first hemispherical screen and a second hemispherical screen, a ground track is arranged on the indoor ground of the cinema hall, the ground track is in a circular arc shape, a first sliding plate seat and a second sliding plate seat are arranged inthe ground track, a first hemisphere curtain and a second hemisphere curtain are installed on the first sliding plate seat and the second sliding plate seat respectively, gear tooth structures are arranged on the inner sides of plate bodies, located below the ground track, of the first sliding plate seat and the second sliding plate seat, motors are arranged below the indoor ground of the cinemahall, gears are horizontally installed on output rotating shafts of the motors, the number of the motors and the number of the gears are both two, and the two gears are engaged with the gear tooth structures of the first sliding plate seat and the second sliding plate seat respectively. The large screen and the spherical screen are arranged, so that the diversity of screening and film watching isimproved, and the film watching effect is improved.

Owner:内蒙古自然博物馆

Connecting structure for preventing oil dripping and leakage of oil and smoke exhauster

ActiveCN102287859BSimple structureEasy to makeDomestic stoves or rangesLighting and heating apparatusPetroleum engineeringAirflow

The invention provides a connecting structure for preventing oil dripping and leakage of an oil and smoke exhauster, which comprises a smoke-collecting hood, an oil net, a machine box and an oil-guiding surrounding frame, wherein the oil-guiding surrounding frame comprises a first hem and a second hem, the first hem is closely bonded with the outer side at the lower part of the machine box, the second hem is closely bonded with the upper side at the periphery of the oil net, and the oil net is installed on the oil-guiding surrounding frame. The connecting structure has a simple and reasonablestructure, and the conception of blocking clearance airflows is mainly adopted, thereby the seamless matching among the smoke-collecting hood, the oil net and the machine box of the oil and smoke exhauster is realized; after oil and smoke are pumped into a space between the oil net and the machine box by a fan of the oil and smoke exhauster, the oil and the smoke can not outwards overflow from aninstalling gap between the oil net and the machine box, thereby the problem of oil leakage, oil flow or oil dripping of the oil and smoke exhauster is prevented; and moreover, the oil-guiding surrounding frame is simple to manufacture and convenient to assemble and unassembled, so that the oil net and the machine box can be directly connected, thereby the installing mode of the oil net is greatlysimplified.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

An evaporation device

ActiveCN107805782BEasy to replaceHeating evenlyVacuum evaporation coatingSolid-state devicesThermodynamicsCrucible

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

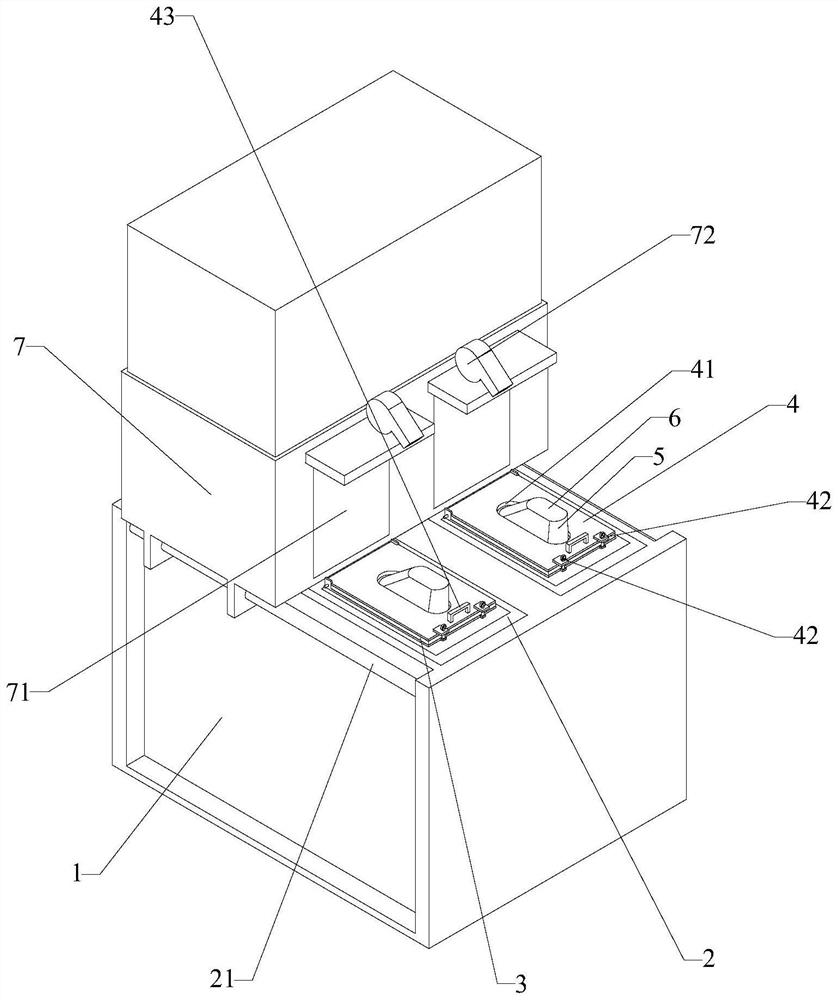

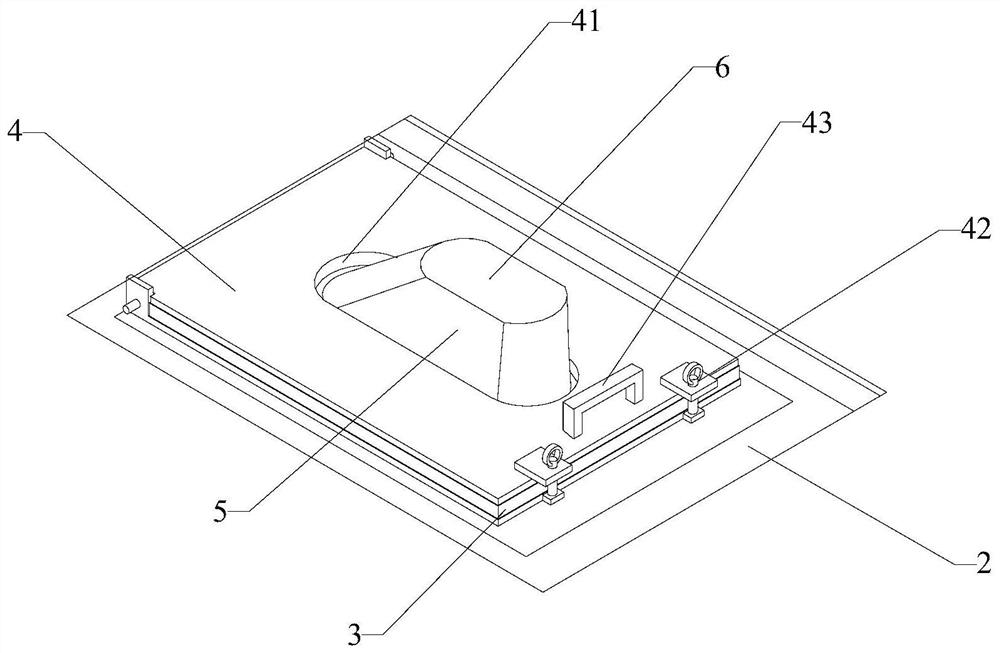

3D vacuum suction shrinkage equipment and silica gel vamp processing method

ActiveCN111941820AAffect the appearanceFor a seamless fitDomestic articlesSilicone membraneSilica gel

The invention relates to the technical field of shoe production, in particular to 3D vacuum suction shrinkage equipment and a silica gel vamp processing method. The equipment comprises a suction shrinkage assembly and a heat fixing assembly; the suction shrinkage assembly comprises a base, a suction shrinkage table top, an elastic cushion, a pressing plate and a vacuum pump; the suction shrinkagetable top is located on the upper portion of the base, the suction shrinkage table top is provided with a vent hole, the vacuum pump is arranged below the suction shrinkage table top and used for sucking air on the suction shrinkage table top downwards through the through hole, the elastic cushion is located on the upper portion of the suction shrinkage table top, the pressing plate movably coversthe upper portion of the elastic cushion, and a sole-shaped through hole is formed in the middle of the pressing plate; and a shoe body sleeved with a shoe tree is placed at the through hole, the surface of the shoe body is covered with a silica gel sleeve, and the edge of the silica gel sleeve is pressed between the pressing plate and the elastic cushion. According to the special equipment designed on the basis of the shoe body surface three-dimensional silica gel film laminating process, three-dimensional vamp silica gel film laminating can be completed at a time.

Owner:福建省莆田市双源鞋业有限公司

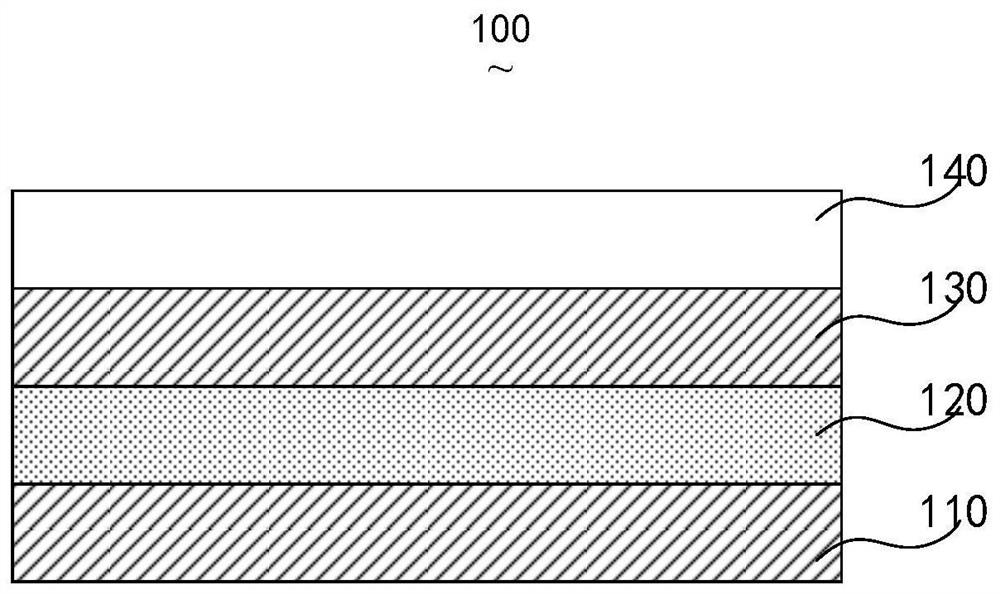

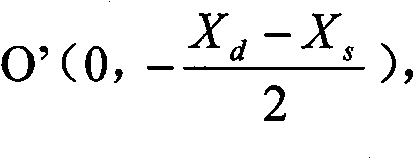

Packaging structure and packaging device

ActiveCN109461823AImprove bindingReduce sheddingSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringOxygen

The application discloses a packaging structure and a packaging device. The packaging structure comprises a base layer, a first packaging layer, a first buffer layer and a second packaging layer. Oneside of the base layer is used for forming a to-be-packaged member; the first packaging layer is formed on one side of the to-be-packaged member back to the base layer and covers the side wall of theto-be-packaged member; the first buffer layer is surrounded on the periphery of the first packaging layer and adhered to the side wall of the first packaging layer; the second packaging layer is formed on one side of the first packaging layer back to the base layer and covers the side wall of the first buffer layer. Through the manner, the packaging structure and the packaging device in the application can enhance the binding force between the film layers, thereby reducing the probability of falling of the film layers, enhancing the capability of blocking water oxygen of the packaging device and realizing seamless joint between the film layers.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Method of limiting low excitation

ActiveCN101588153BFor a seamless fitPrevent accidental tripGenerator control by field variationExcitation currentTerminal voltage

Method of limiting low excitation, calculating measured impedance of generator terminal by detecting generator terminal voltage and terminal current, when the measured impedance entering low excitation limited impedance circle, the low excitation limits prolong action of 40-60 ms on amplifying excitation current to maintain generator in stable operation situation, the low excitation limited impedance impedance circle covers static stable loss of excitation protection impedance circle to implement seamless connection with generator loss of excitation protection impedance criterion, and preventthe generator in low excitation operation, the low excitation is limited lagging behind the loss of excitation protection action, thereby generator error jump is caused. The invention is used in generator excitation regulation, comparing with former low extitation limiting method, the invention is more visualized, the loss of excitation protection and low excitation are all R-X impedance plane coordinate description and easy to cooperate with each other.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +2

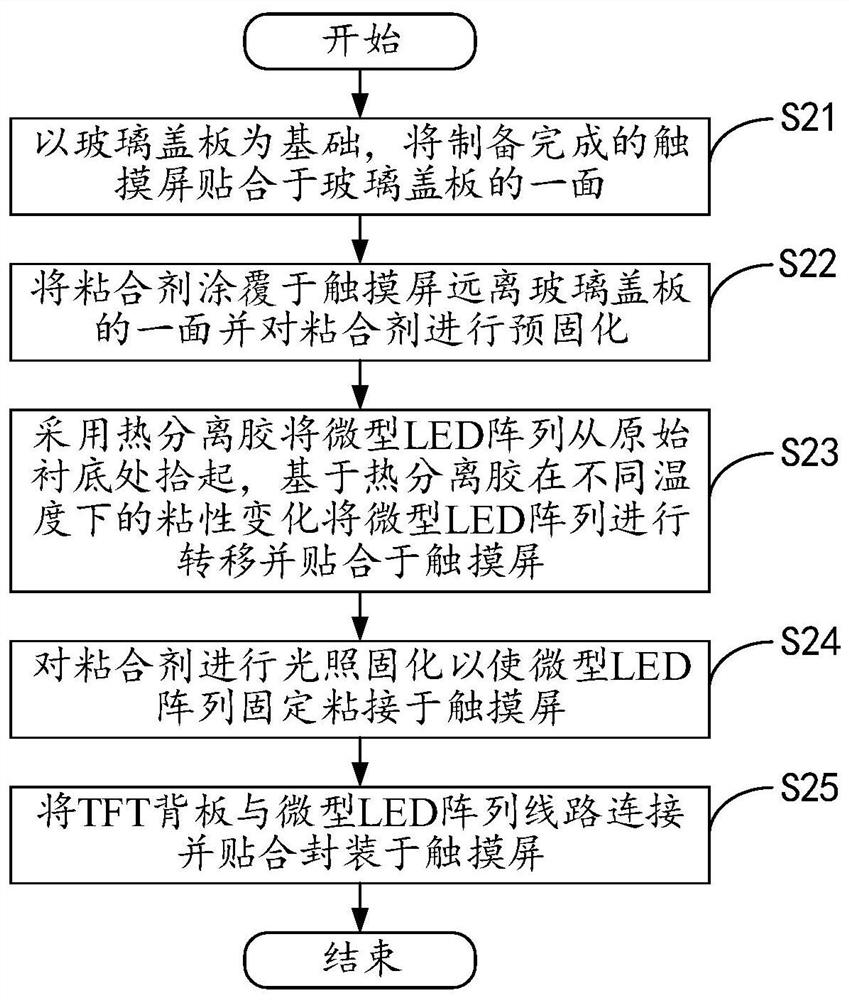

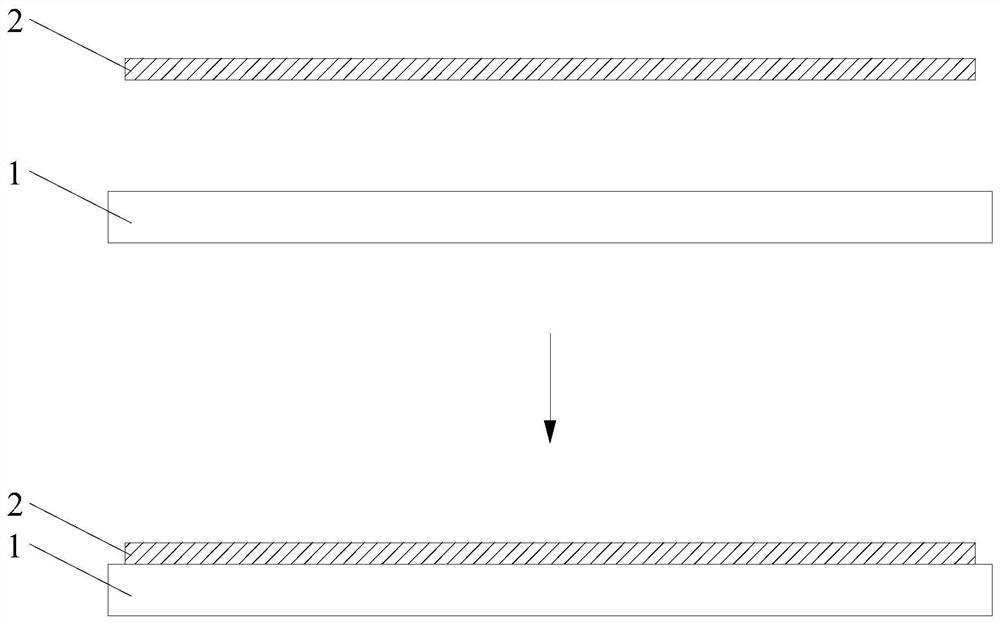

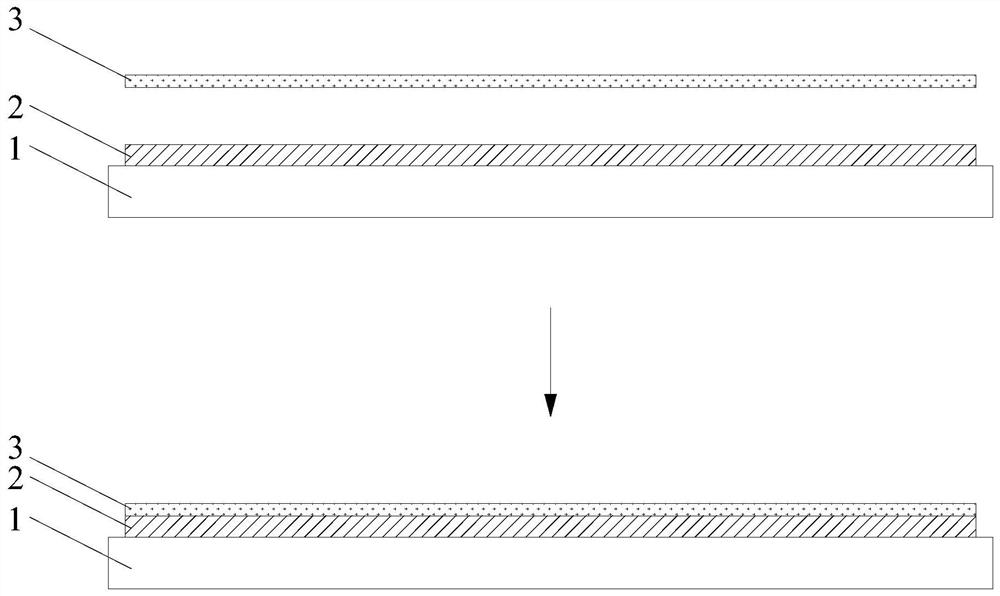

Method for manufacturing a touch display device and touch display device

ActiveCN109753185BImprove the display effectAvoid blurInput/output processes for data processingLed arrayDisplay device

The embodiment of the present invention relates to the technical field of display device manufacturing, and specifically relates to a method for manufacturing a touch display device and a touch display device. The lamination, integration and packaging of the micro-LED array and the thin film transistor backplane can avoid image blur or color distortion caused by light reflection between layers, thus improving the display effect of the touch display device.

Owner:GUANGDONG INST OF SEMICON IND TECH

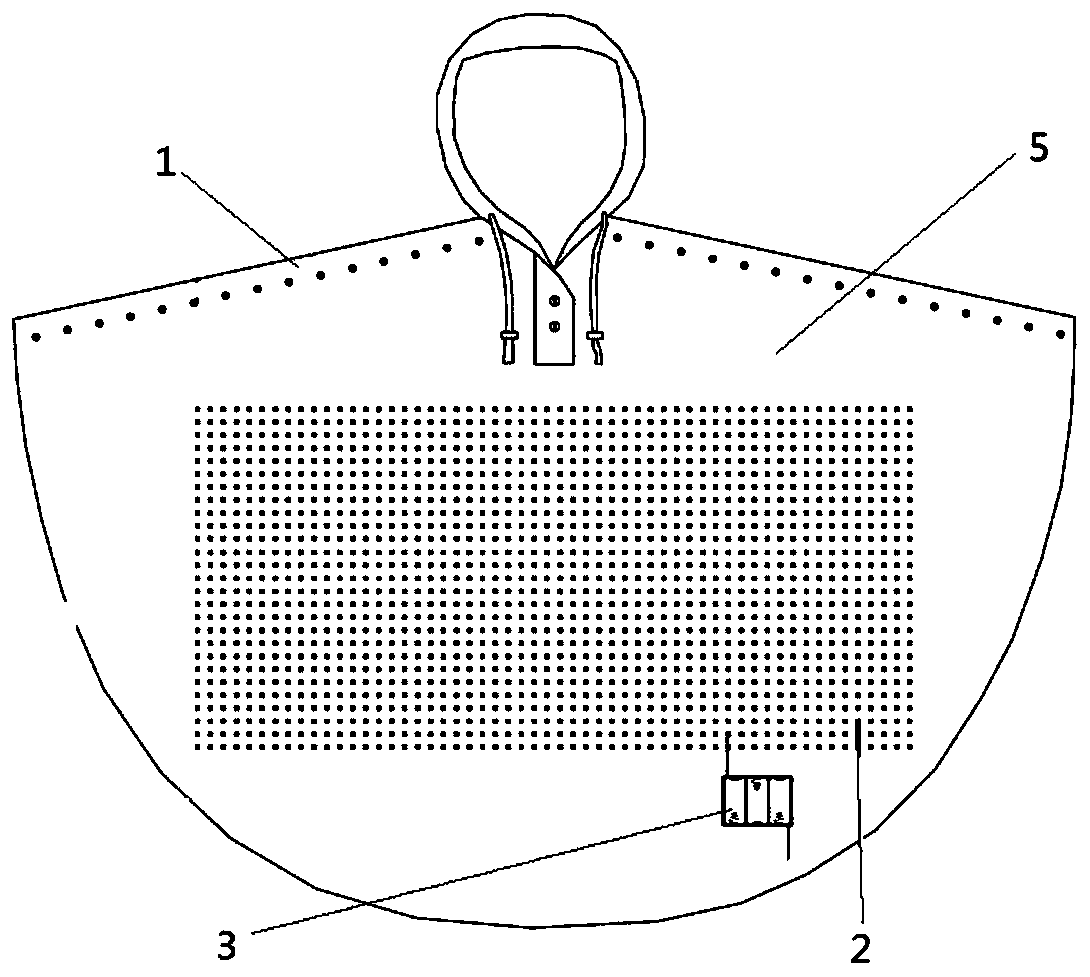

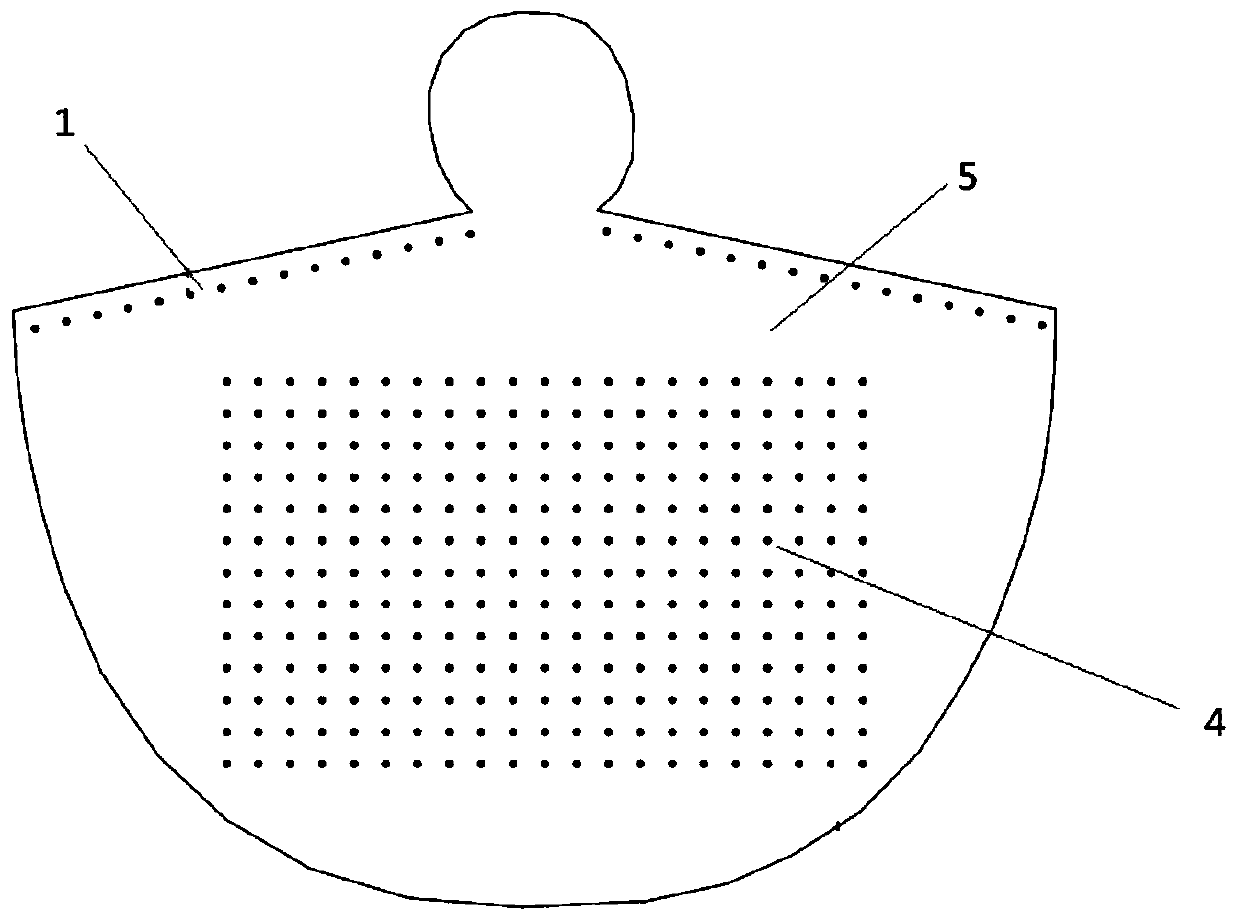

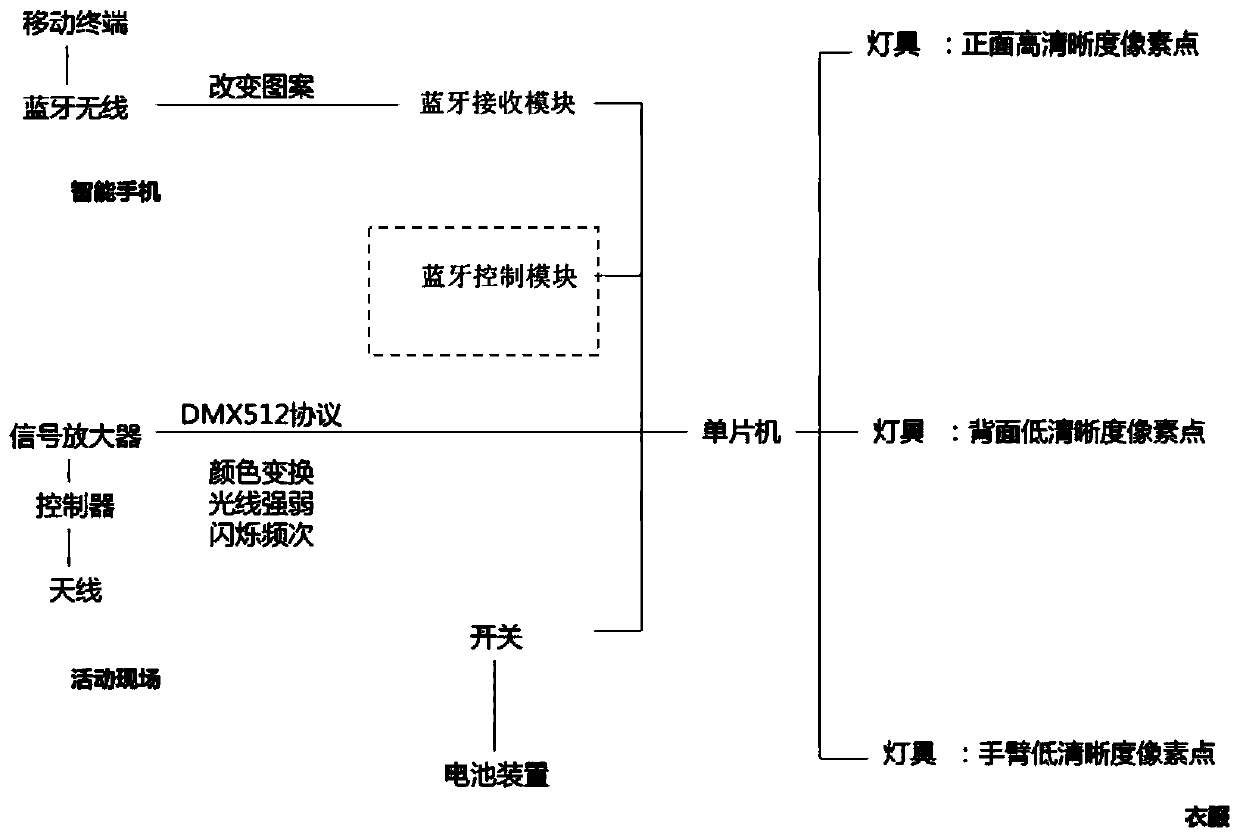

LED garment and LED garment linkage system

PendingCN110638120ARealize linkage controlCreate an immersive interactive performance atmosphereTransmission systemsStatic indicating devicesMicrocomputerMicrocontroller

The invention relates to LED garment. The LED garment comprises a garment body, and a circuit board and an LED lamp that are arranged on the garment body and connected with each other, wherein the circuit board comprises a single chip microcomputer and a Bluetooth receiving module connected with each other; the Bluetooth receiving module receives a signal from a mobile terminal; the circuit boardis connected with a power unit; the circuit board also comprises a wireless control chip connected to the single chip microcomputer; the wireless control chip and a base station are in communication with each other; the Bluetooth receiving module receives an LED lamp pattern control signal of the mobile terminal; and the wireless control chip receives LED lamp color change, brightness intensity and flicker frequency control signals from the base station. Compared with the prior art, the LED garment can achieve linkage control of the garment, and create an immersive interactive performance atmosphere.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

Installation method for refrigerator door body, refrigerator door body and refrigerator

ActiveCN107677036ASimplify the installation processImprove installation efficiencyLighting and heating apparatusCooling fluid circulationRefrigerated temperatureSoftware engineering

The invention provides an installation method for a refrigerator door body, and further provides the refrigerator door body assembled adopting the installation method and a refrigerator with the refrigerator door body accordingly. The installation method comprises the steps that a display screen is loaded into a display-screen embedded box to form a display-screen installation component; the display-screen installation component is installed on a door body panel of the refrigerator door body; the door body panel provided with the display-screen installation component is installed on a door body frame of the refrigerator door body to form a combination body of the door body panel and the door body frame; and the combination body is placed into a foaming mould to be subjected to door body foaming to complete the installation of the refrigerator door body. According to the installation method for the refrigerator door body, the refrigerator door body assembled adopting the installation method and the refrigerator with the refrigerator door body, by means of the manner that the display screen is placed into the display-screen embedded box before the door body foaming procedure is performed, thus the procedure of installation and disassembly of foaming tooling in related technologies is omitted, the installation procedure of the refrigerator door body is simplified, and dirty hard to clean generated on the display screen is further effectively avoided and the possibility of scratching the door body panel is eliminated.

Owner:HEFEI MIDEA INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com