Tooth-shaped disk, tooth-shaped disk assembly, screw assembly and double-screw assembly

A screw assembly and toothed disk technology, applied in the field of extruders, can solve the problems of dead zone of material accumulation, difficult cleaning of materials, affecting product quality, etc., to avoid dead zone of accumulation of material, improve dispersibility, and improve self-cleaning ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 10

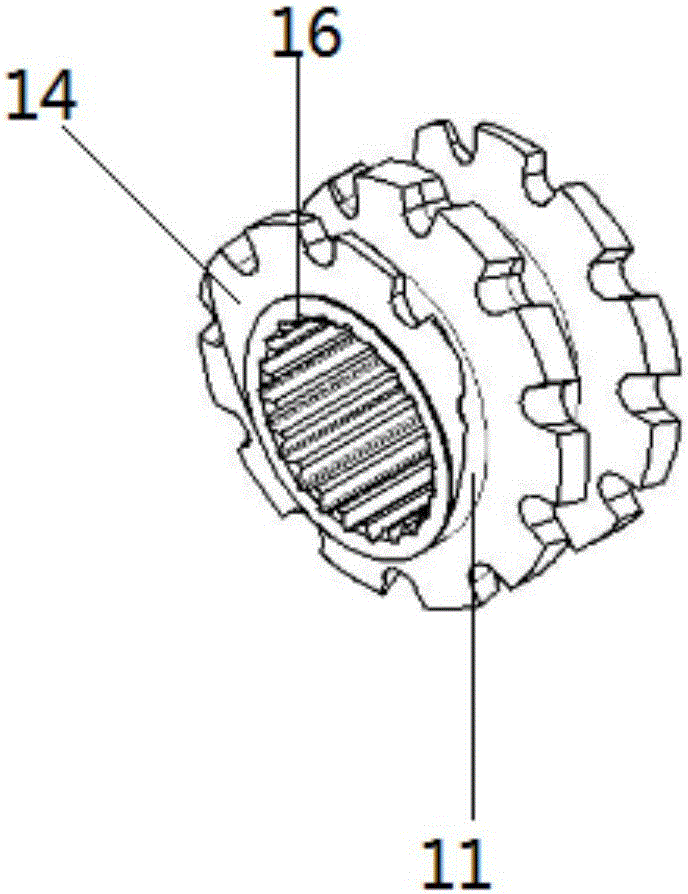

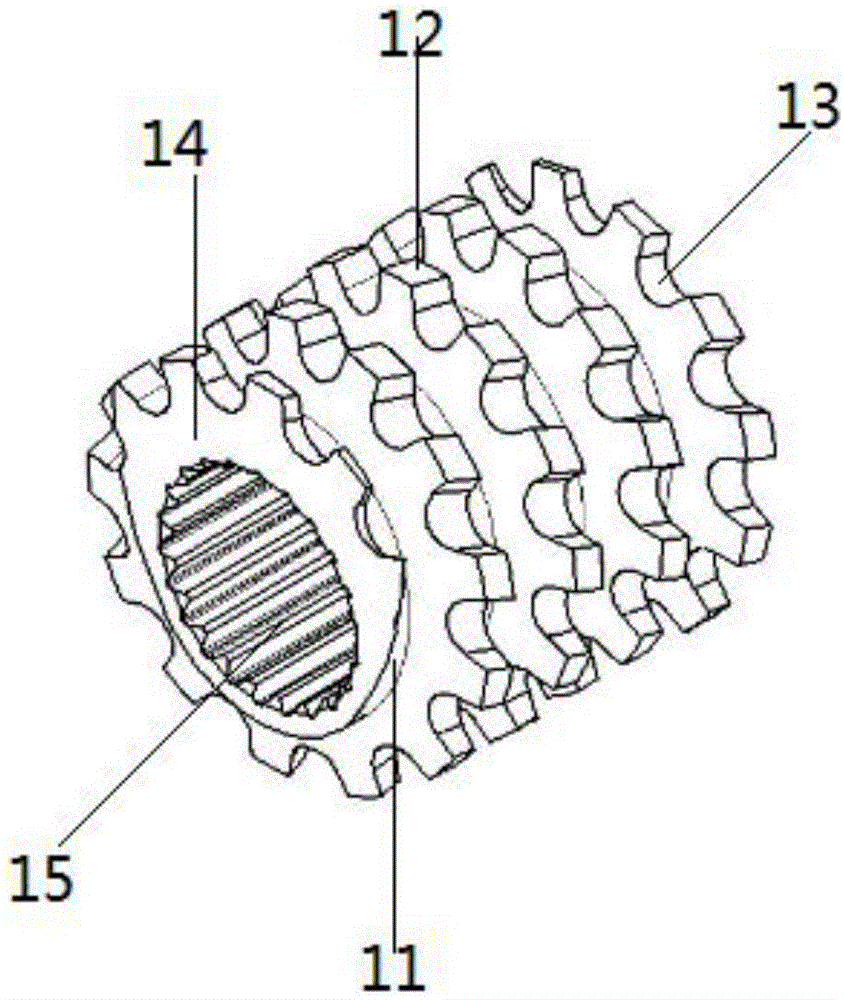

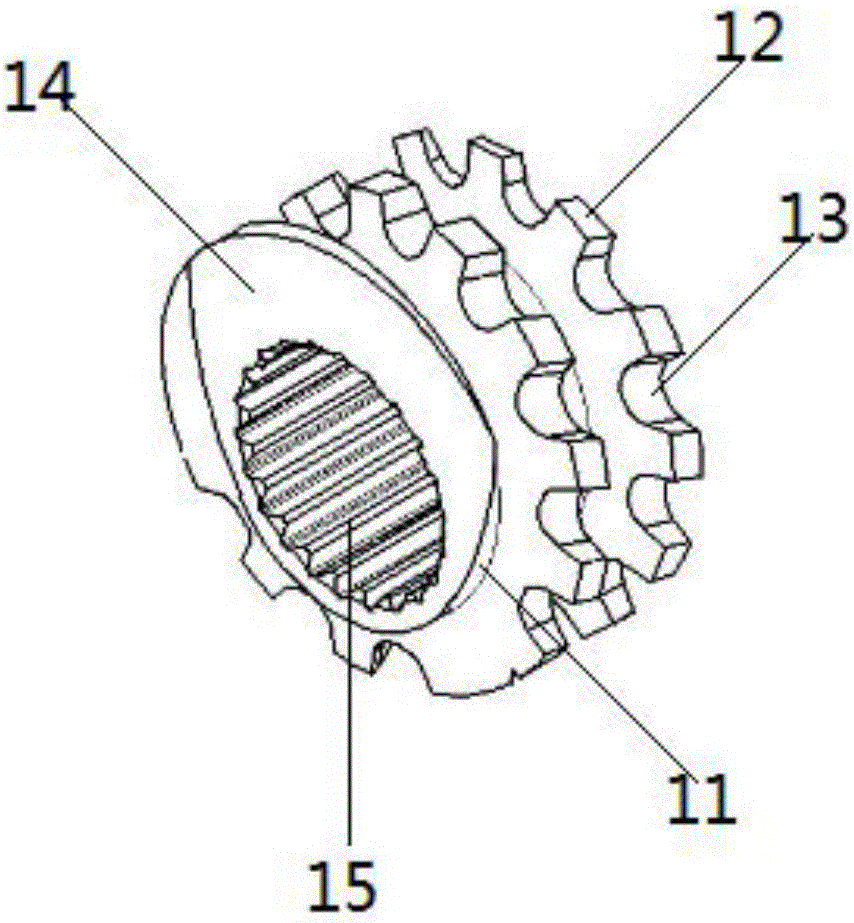

[0041] Such as Figure 4As shown, the toothed disk assembly includes a plurality of the above-described toothed disks, including both the first embodiment 10 of the toothed disks and the second embodiment 20 of the toothed disks. Multiple toothed discs are combined in a queue by end-to-end fit. The two toothed discs at the two ends of the row are the second embodiment 20 of the toothed discs, each second embodiment 20 of the toothed discs has only one helical end face 14 with grooves 13 . In addition to the second embodiment 20 of the two toothed disks at the two ends of the queue, one or more first embodiments 10 of the toothed disks of the present invention can be arranged in the middle, and the two teeth of the first embodiment 10 of each toothed disk A helical end surface 14 has a groove 13 . Located at the head of the queue is the second embodiment 20 of the toothed disk of the present invention. The second embodiment 20 of the toothed disk does not have the helical end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com