Connecting structure for preventing oil dripping and leakage of oil and smoke exhauster

A connection structure and anti-drip technology, which is applied in the field of household range hoods, can solve problems such as unsatisfactory sealing effect, increased technical difficulty, complicated installation of oil nets, etc., and achieves the effect of simple and reasonable structure, simple manufacture, and convenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

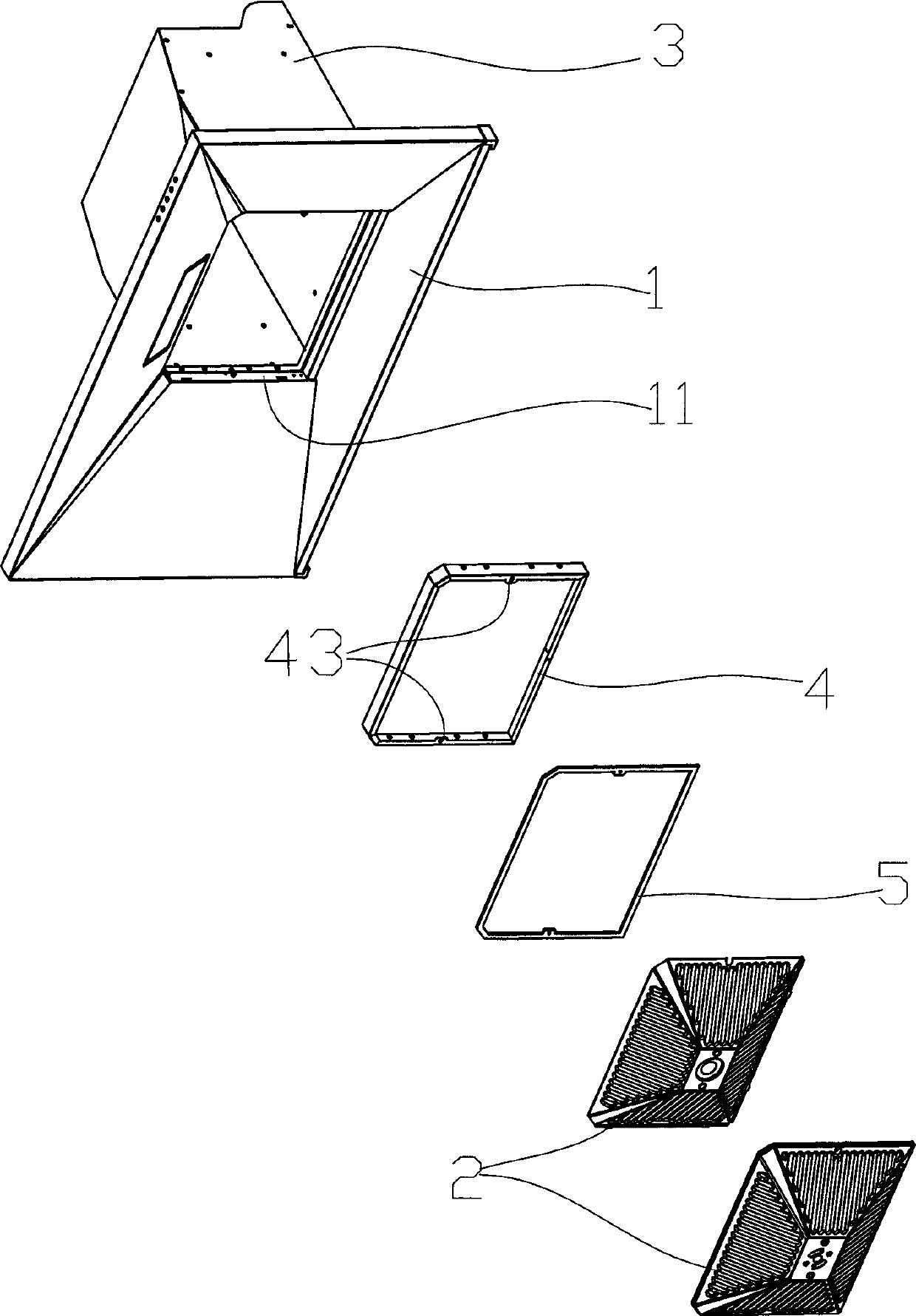

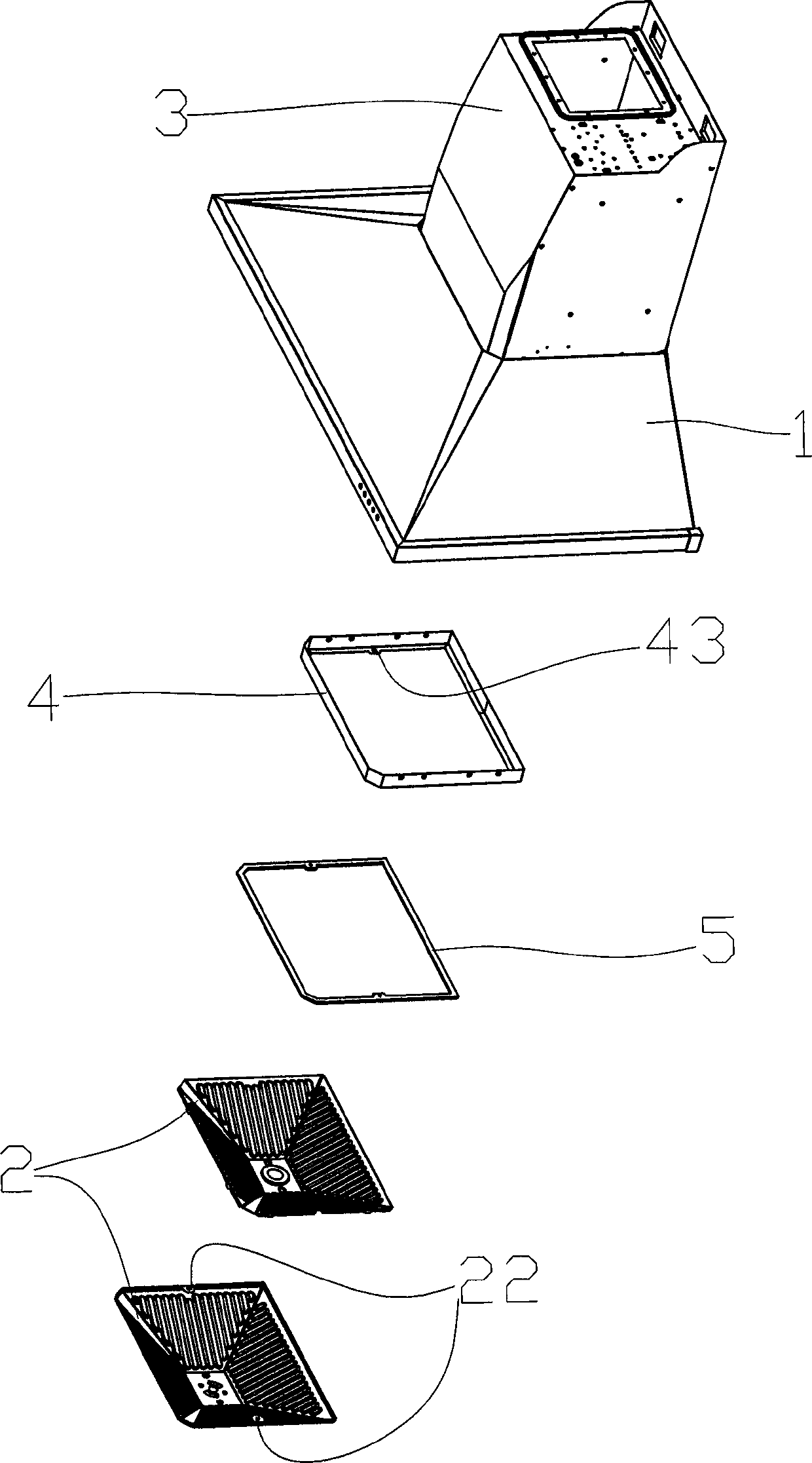

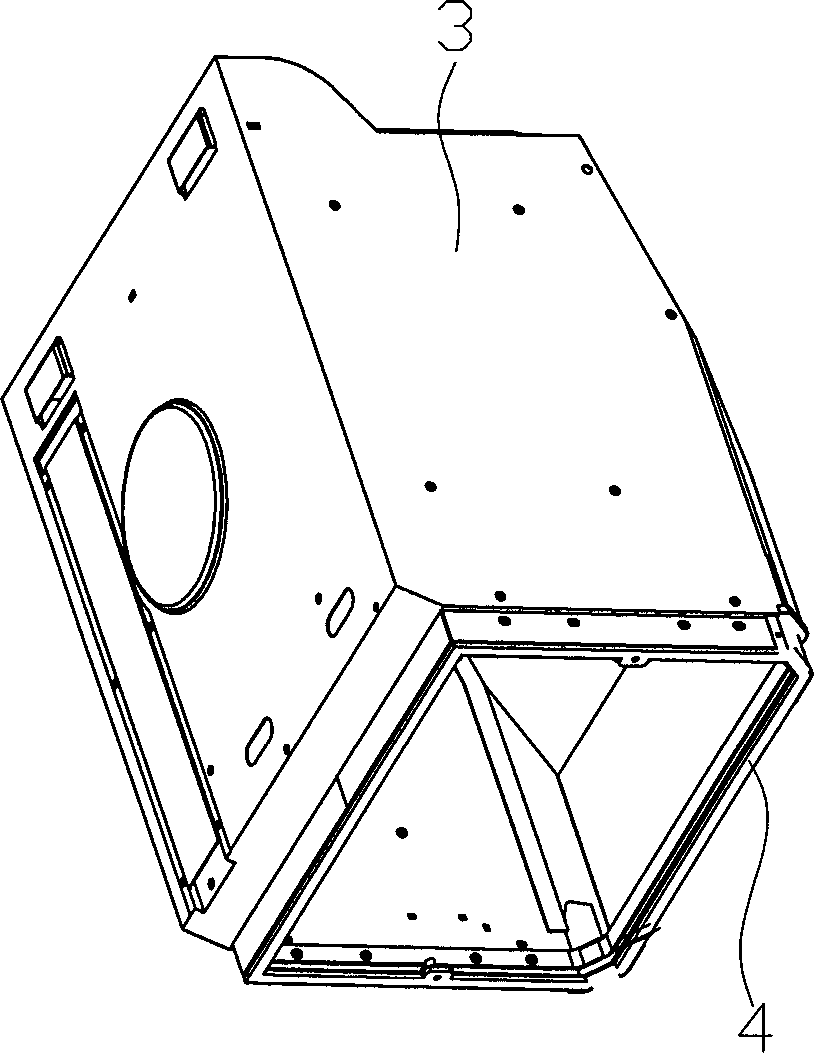

[0018] Example: such as Figure 1 to Figure 5 As shown, the anti-drip oil connection structure of the range hood in this embodiment is mainly used in European-style range hoods. The direction of use is a reference (in this patent, both inside and outside are relative to the range hood as a whole), and the oil screen 2 is arranged below the cabinet 3, and the oil screen is low in the middle and high around the edges. The fume collecting hood 1 is installed on the lower side of the outer wall of the cabinet 3, and plays the role of gathering the oil fume below the range hood. The air duct of the range hood communicates with the space below the range hood through the opening at the center of the fume collecting hood 1, so that the space below can be sucked when the range hood is in use. In this embodiment, in addition to the above-mentioned smoke collecting hood 1, oil screen 2 and cabinet 3, it also includes an oil guide frame 4, whose cross section is roughly L-shaped, and as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com