Production process of composite pad

A production process and technology of composite pads, which can be used in household appliances, other household appliances, household components, etc., and can solve the problems of insufficient PU foam indentation force, fatigue, and affecting the driving experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

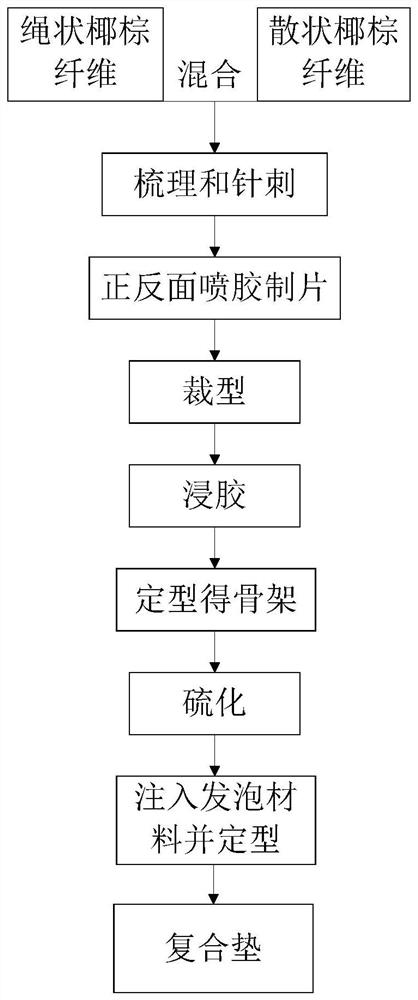

[0028] The core of this specific embodiment is to provide a production process of a composite pad, which improves the composite pad, ensures a good user experience, and solves the current difficulties in this field.

[0029] Hereinafter, the embodiment will be described with reference to the drawings. In addition, the embodiments shown below do not have any limiting effect on the content of the invention described in the claims. In addition, the whole content of the structure shown in the following embodiment is not limited to what is necessary for the solution of the invention described in the claim.

[0030] The production process of the composite mat provided by this specific embodiment includes the steps: step 1, use a needle punching machine to comb and acupuncture the coconut palm fiber; step 2, use a tablet machine to spray glue on both sides of the coconut palm fiber Making the film to obtain the coconut palm fiber sheet; Step 3, cutting the coconut palm fiber sheet a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com