A kind of preparation method of seamless splicing honeycomb core material

A technology of honeycomb core material and seamless splicing, which is applied in the field of honeycomb manufacturing, can solve the problems of excessively thick honeycomb glued edges, affecting noise reduction and wave absorption performance, etc., so as to improve the overall appearance and avoid the decline of overall performance, and the method is simple and easy to implement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Select a glass cloth honeycomb with a cell side length of 2mm;

[0046] (2) Epoxy core strip glue is selected as the node glue material, the grade of the node glue is J-80B epoxy resin (product of Heilongjiang Petrochemical Institute), and ethyl acetate is used as a solvent to prepare a node glue solution with a concentration of 10%;

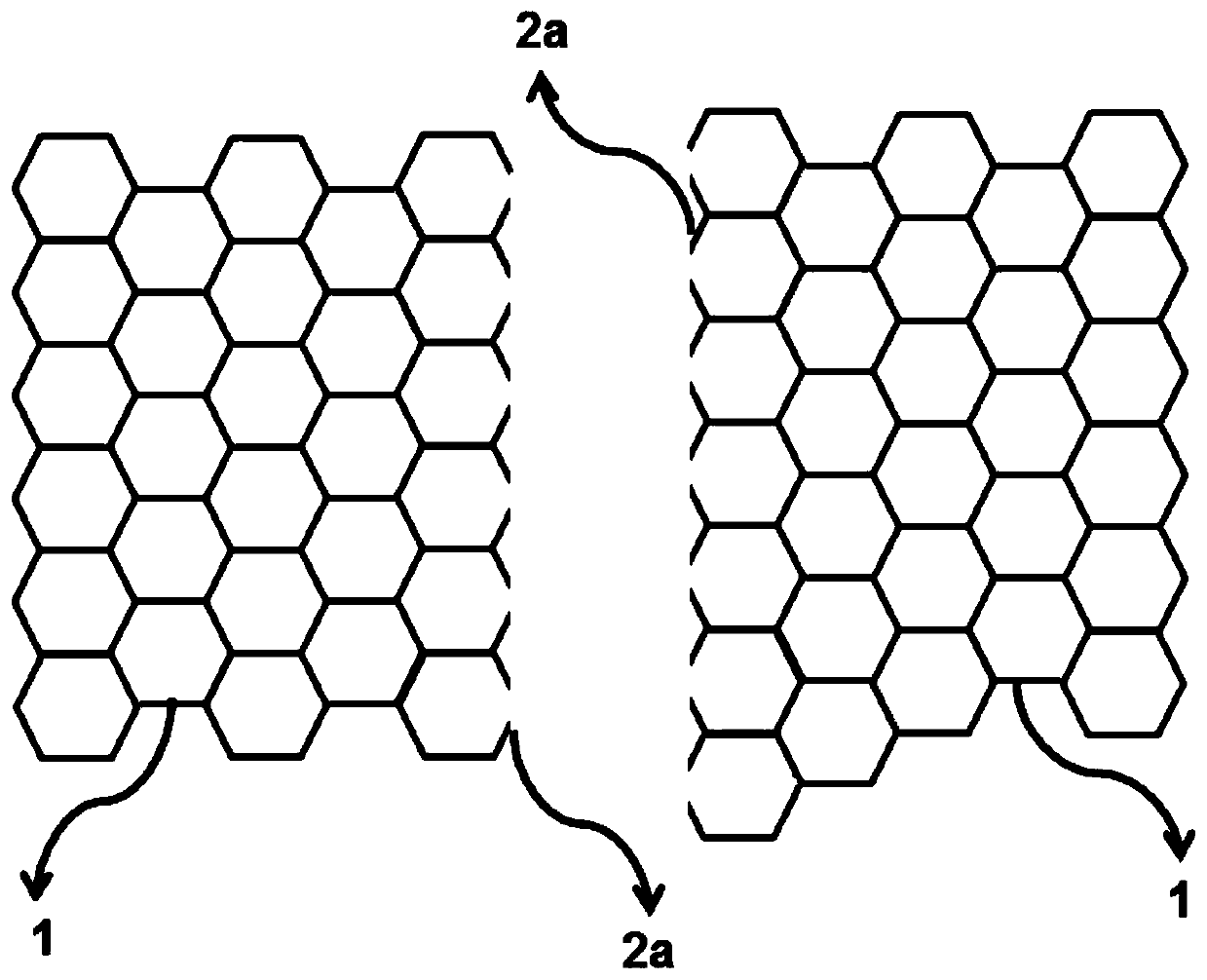

[0047] (3) The honeycomb core material to be spliced is trimmed along the W direction to obtain the spliced edge 2a in the W direction (such as figure 1 ), the splicing edge length is 1.6mm;

[0048] (4) The prepared node glue solution is coated on the W-to-splice edge 2a of the spliced honeycomb respectively to obtain the coated node glue W-to-splice edge 3a (such as Figure 4 );

[0049] (5) Use the geometric characteristics of the honeycomb cell to complete the embedded splicing of the splicing edge, and use the metal wire 6 to fix it along the direction perpendicular to the coated node glue W to the splicing edge 3a, so th...

Embodiment 2

[0053] (1) Its main difference with embodiment 1 is, select the plant fiber honeycomb that cell side length is 10mm;

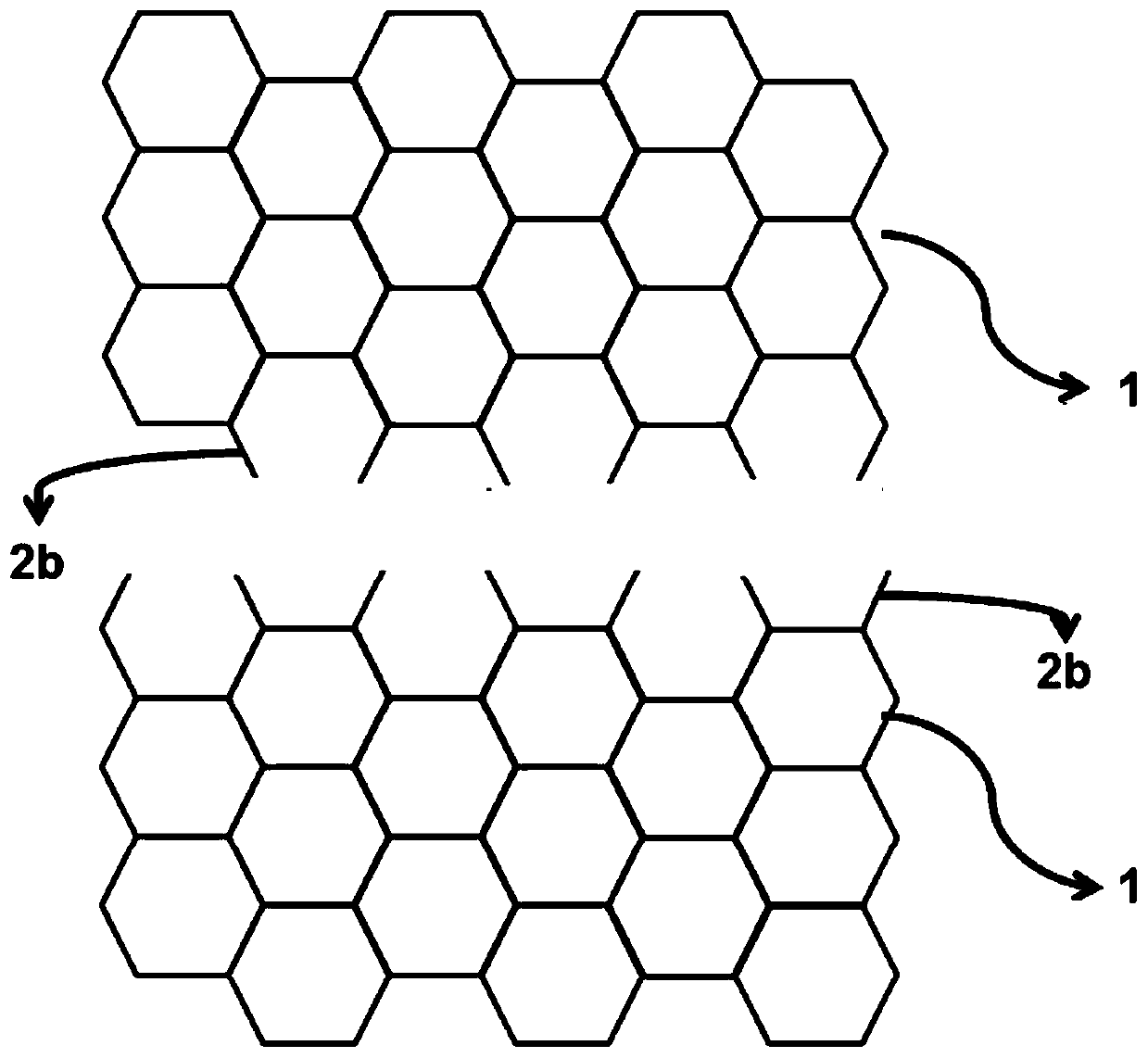

[0054] (2) The inner wall of the honeycomb core material to be spliced is trimmed along the L direction to obtain the spliced edge 2b in the L direction (such as figure 2 ), the splicing side length is 9.5mm;

[0055] (3) The prepared node glue solution is coated on the L-to-splice edge 2b of the spliced honeycomb respectively to obtain the coated node glue L-to-splice edge 3b (such as Figure 5 );

[0056] (4) Use the geometric characteristics of the honeycomb cell to complete the embedded splicing of the splicing edge, and use the metal wire 6 to fix it along the direction perpendicular to the coated node glue L to the splicing edge 3b, so that after sticking, the L will seamlessly splice edge 4b tight fit (such as Figure 8 );

[0057] (5) According to the requirements of the instruction manual of epoxy resin J-80B, the temperature is raised to t...

Embodiment 3

[0060] (1) Its main difference with embodiment 1 and embodiment 2 is that the selection cell side length is 5mm aramid paper honeycomb;

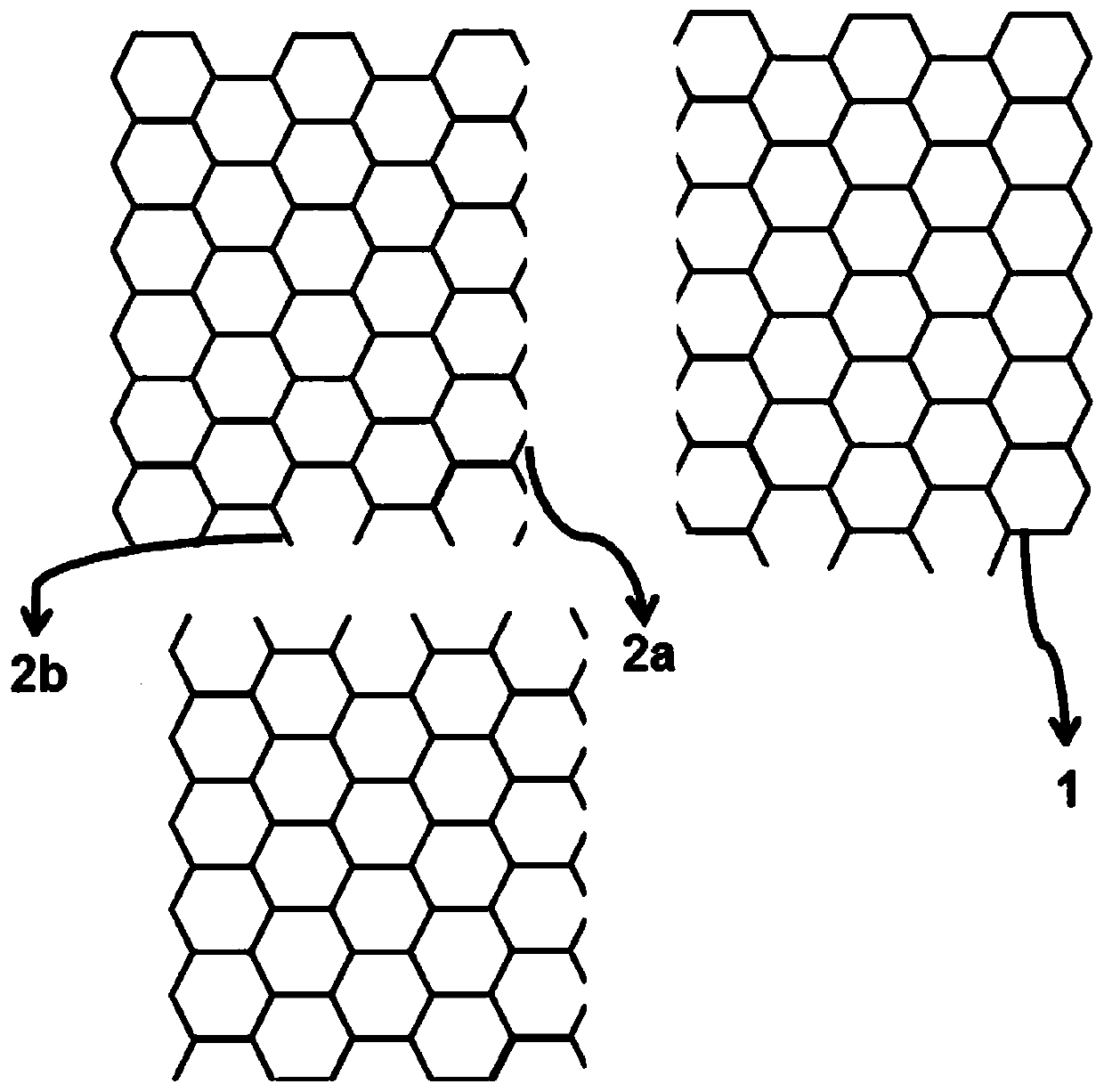

[0061] (2) the honeycomb core material to be spliced carries out inwall trimming along W and L, obtains W and L to splicing edge 2a, 2b (as image 3 ), the splicing side length is 4mm;

[0062] (3) the joint glue liquid of preparation is coated on the W of splicing honeycomb and L to splicing edge 2a, 2b respectively, obtains coating node glue W and L to splicing edge 3a, 3b (such as Figure 6 );

[0063] (4) Use the geometric characteristics of the honeycomb cell to complete the embedded splicing of the splicing edge, and use the metal wire 6 to fix along the direction perpendicular to the coated node glue W and L to the splicing edge 3a, 3b, so that after sticking W and L Closely fit to the seamless splicing edge 4a, 4b (such as Figure 9 );

[0064] (5) According to the requirements of the instruction manual of epoxy resin J-80B, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com