Design method of building block multi-single-chip microcomputer control system with preset programs

A single-chip microcomputer control and system design technology, applied in the direction of program control, general control system, control/adjustment system, etc., can solve the obstacles to the intelligent process of the control system and motor drive mechanical equipment, frequent main program failures, long programming time and Debugging time and other issues, to achieve the effect of benefiting the development of intelligence, reducing failures and accidents, and facilitating technical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

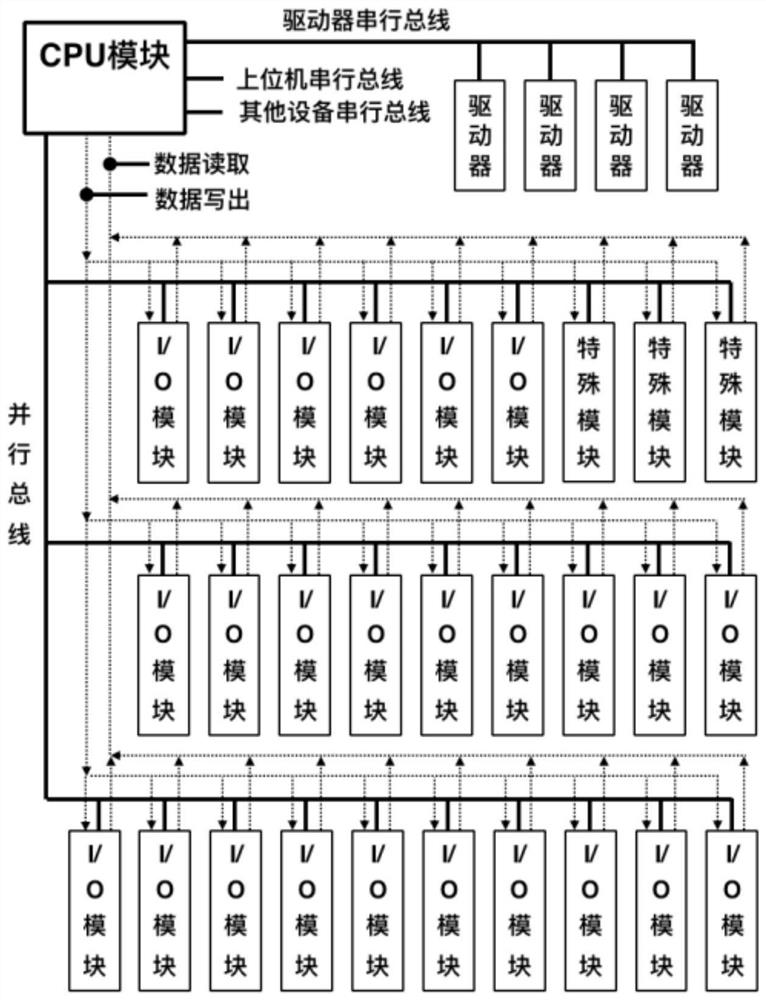

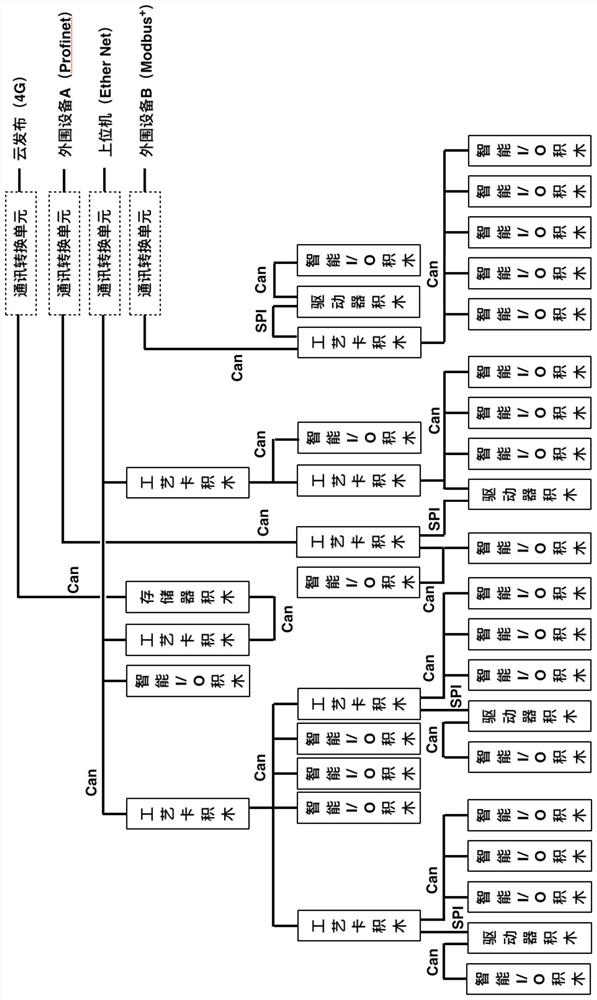

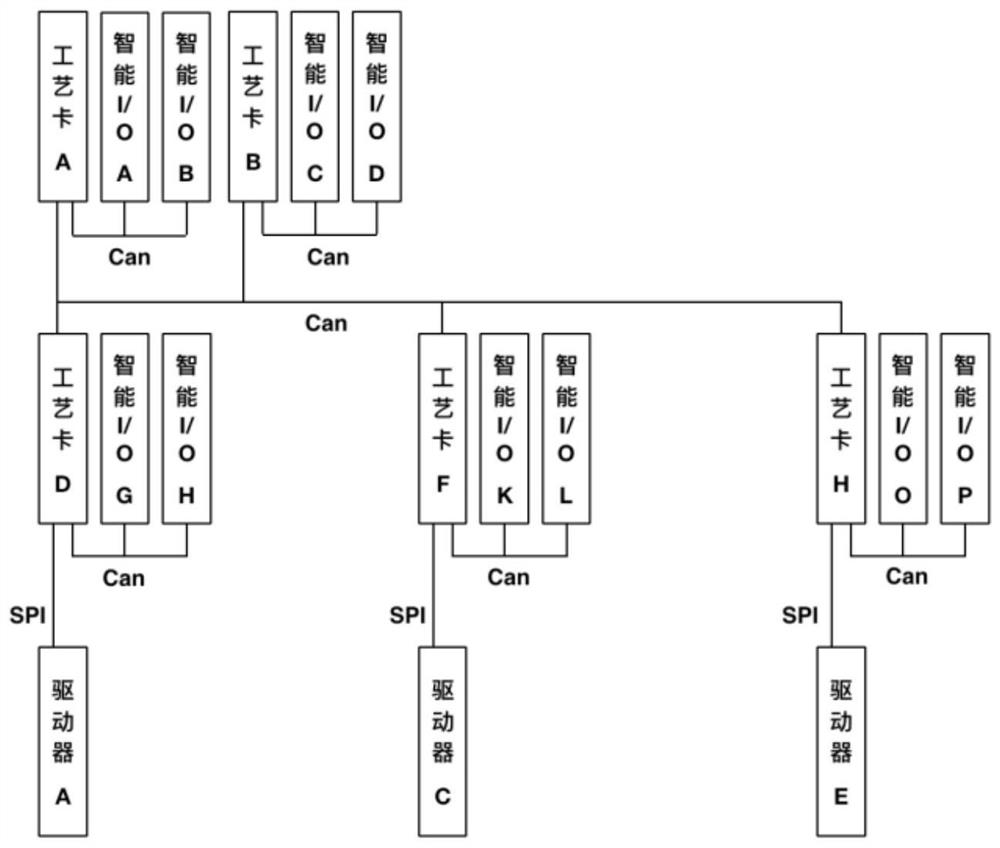

[0031] MSPPS intelligentizes the I / O module of PLC to form an intelligent I / O building block with preset software, so that it can preprocess the I / O data read and written and the received function code, and directly complete it locally The realization of local functions, and convert simple I / O data into simple function codes and send them to the associated building blocks that need these function codes; MSPPS converts a single CPU (or computer) module (main program module) of PLC and PCbase into many Each process card building block (functional program module) handles different sub-tasks respectively; MSPPS, with the cooperation of senior programmers and industry experts, directly presets software for specific industries and specific applications in the intelligent building blocks, and no longer requires users to carry out PLC Or PCbase programming.

[0032] 1. Design and make building block hardware

[0033] 1) The hardware of building blocks is called "module". The present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com