3D vacuum suction shrinkage equipment and silica gel vamp processing method

A processing method and vacuum technology, which can be applied to household appliances, other household appliances, household components, etc., can solve problems such as cumbersome procedures, affecting the appearance, and seams on the upper, and achieve the effect of simplifying procedures and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

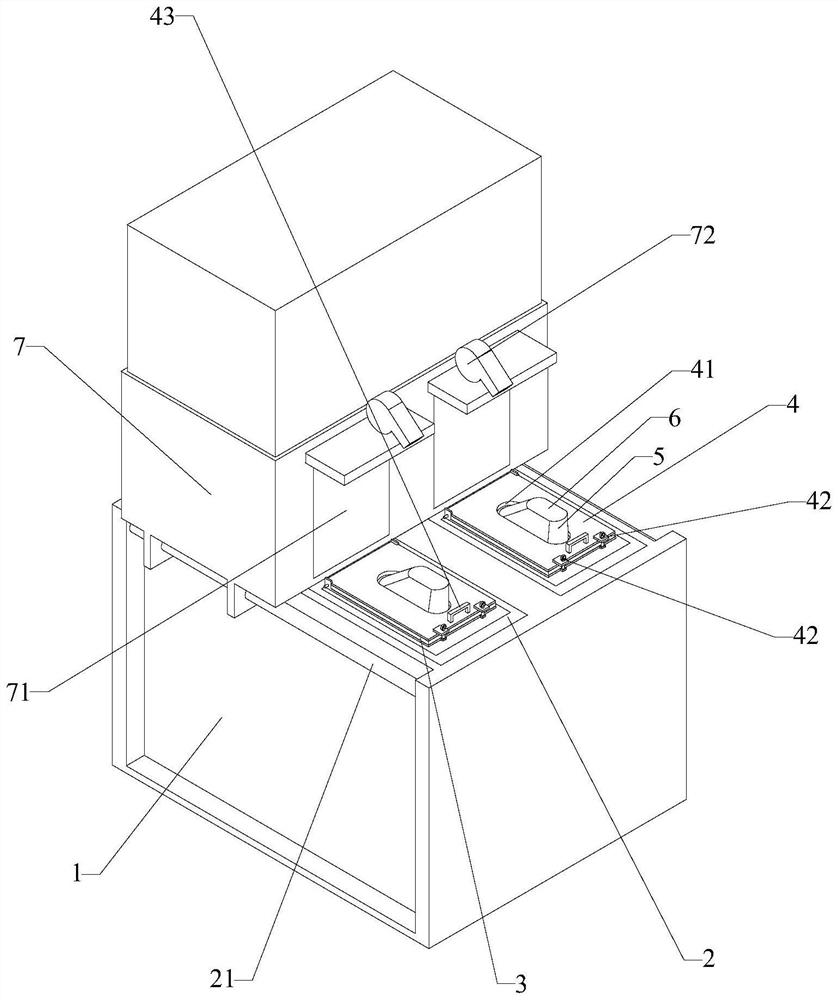

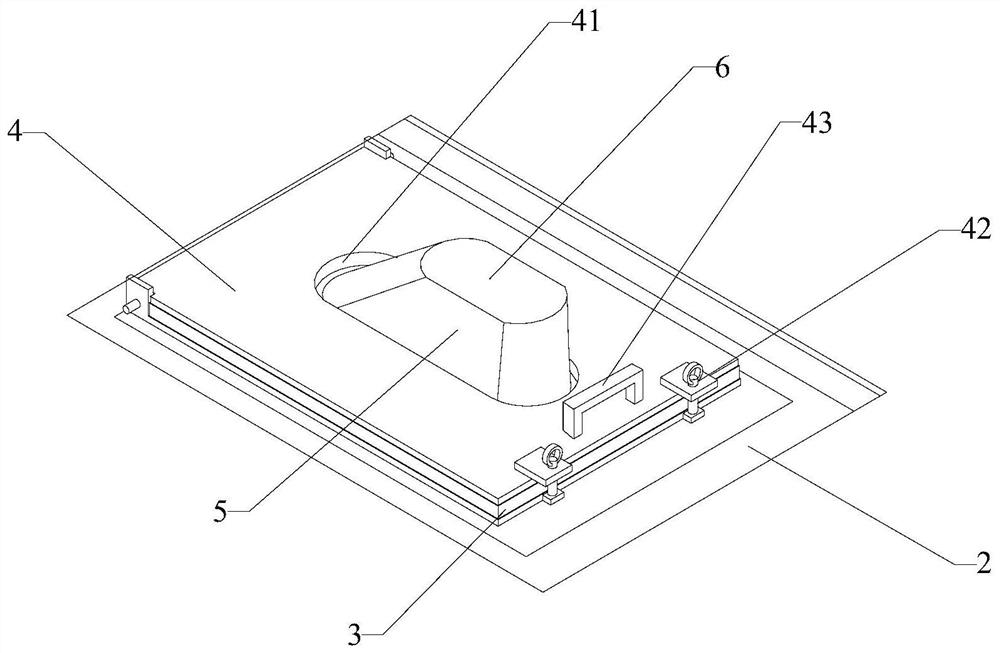

[0051] A 3D vacuum shrinking device, including a shrinking assembly and a thermal fixing assembly; the shrinking assembly includes a base 1, a suction table 2, an elastic pad 3, a pressure plate 4 and a vacuum pump; the suction table 2 is located on the top of the base 1 , the shrinking table 2 is provided with a ventilation hole, the vacuum pump is arranged under the shrinking table 2, and is used to suck the air on the shrinking table 2 downward through the through hole 41, and the elastic pad 3 is located on the shrinking table 2. The upper part of the pressing plate 4 is movably covered on the upper part of the elastic pad 3. The pressing plate 4 is provided with a handle 43. The middle part of the pressing plate 4 is provided with a through hole 41 in the shape of a shoe sole. The through hole 41 is placed with a shoe The shoe body 5 of the last 6, the surface of the shoe body 5 is covered with a silicone sleeve, and the edge of the silicone sleeve is pressed between the p...

Embodiment 2

[0053] A method for processing a silicone shoe upper, comprising the following steps:

[0054] Step 1: Put the shoe last into the shoe body, and lay elastic pads on the suction table;

[0055] Step 2: Place the shoe body with the last on the upper part of the elastic pad;

[0056] Step 3: Cover the silicone film on the surface of the shoe body so that the edge of the silicone film extends to the upper part of the elastic sleeve;

[0057] Step 4: Press the pressure plate on the upper part of the elastic sleeve, so that the edge of the silicone film is completely sealed and fit between the elastic sleeve and the pressure plate;

[0058] Step 5: The vacuum pump draws out the air in the upper part of the vent hole, so that the silicone film and the surface of the shoe body are vacuum bonded;

[0059] Step 6: Control the heating box to slide horizontally relative to the shrinking platform, so that the shoe body enters the heating box, so that the silicone film is bonded to the th...

Embodiment 3

[0065] In the method for processing silicone shoe uppers in Example 2, the heating temperature in the heating box is 250° C., the vacuum pumping time is 35 s, and the time for the shoe body to enter the heating box is 20 minutes.

[0066] To sum up, the 3D vacuum shrinking equipment provided by the present invention is a special equipment designed based on the three-dimensional bonding of the silicone film on the surface of the shoe body, which can complete the three-dimensional vamp bonding of the silicone film at one time. The silicone film is absorbed and shaped by the 2D mold alone, and then assembled and attached to the surface of the shoe body, which simplifies the process and greatly improves work efficiency, and the 3D vacuum shrinking equipment makes the silicone film perfectly fit on the surface of the shoe body to avoid misalignment And the fitting seam affects the appearance of the shoe body, realizing the seamless fit of the silicone membrane. The rotatable struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com