An ultrasonic non-destructive testing device

A non-destructive testing and ultrasonic technology, which is used in measuring devices, analyzing solids using sonic/ultrasonic/infrasonic waves, and using sonic/ultrasonic/infrasonic waves for material analysis, etc. Pressure accuracy and other issues, to achieve the effect of simple and compact overall structure, improved automation, and improved labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

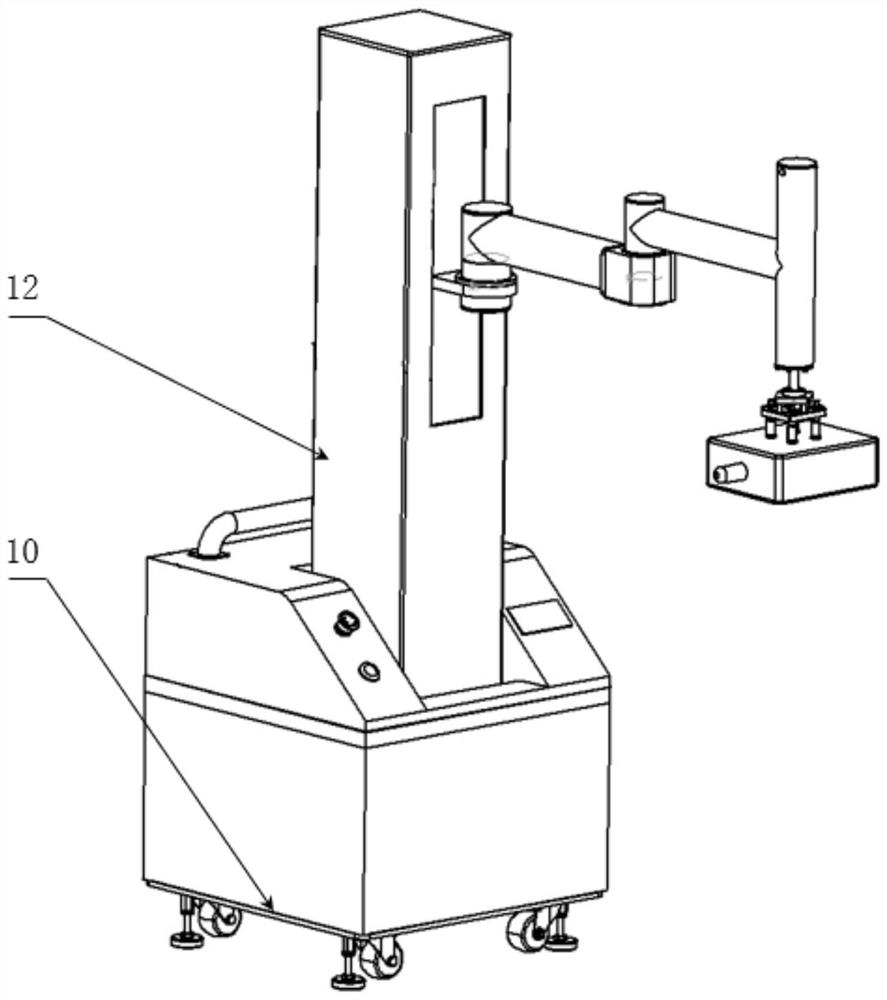

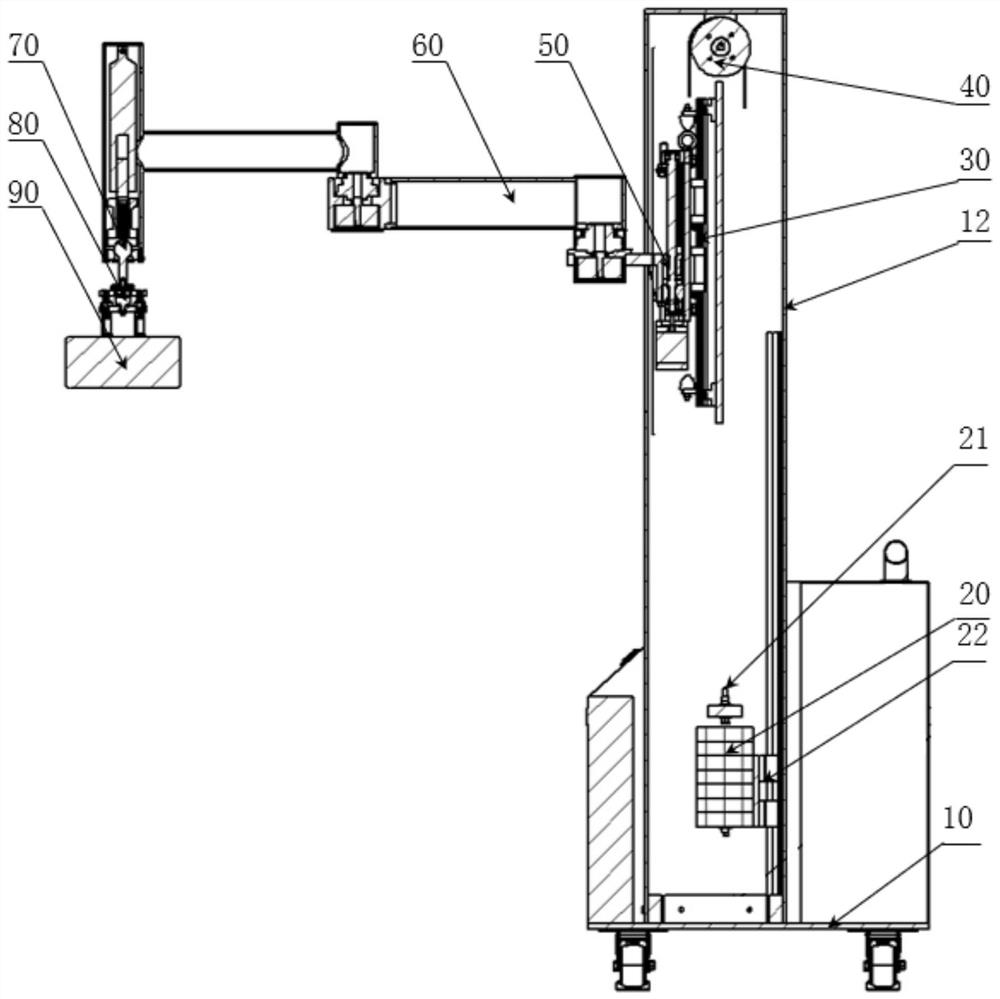

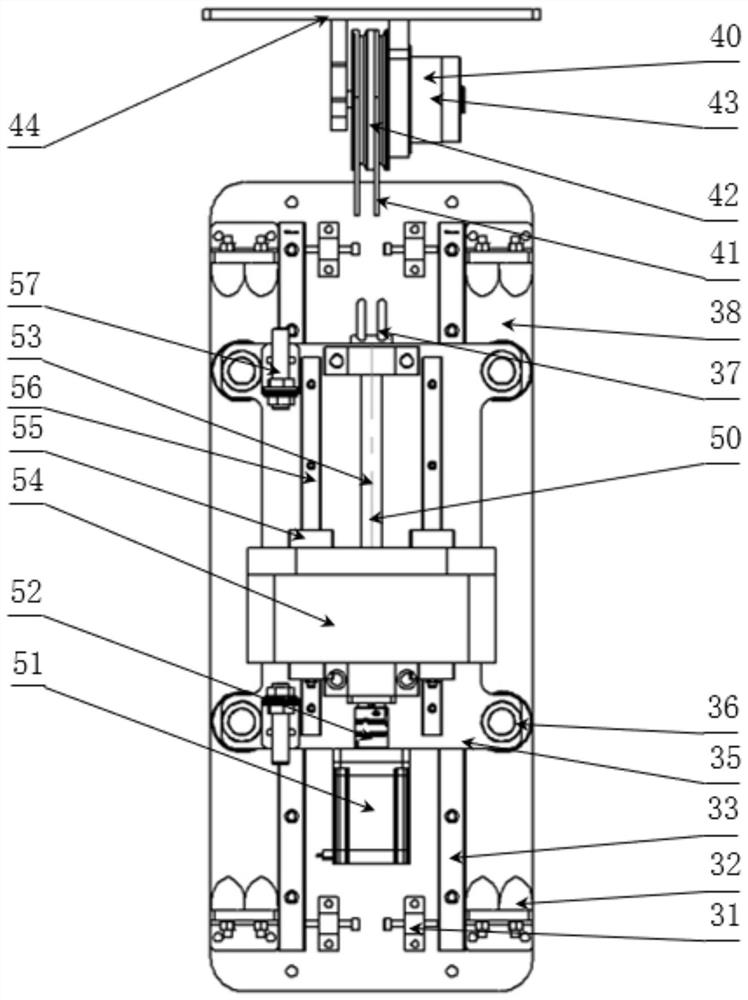

[0029] see Figure 1 to Figure 6 As shown, in this embodiment, an ultrasonic nondestructive testing device includes a mobile platform 10, a lifting mechanism based on a power assist system 40, a lifting counterweight module 20, a rotating arm 60 with a sufficient number of rotating joints and redundant degrees of freedom, and an automatic control lock Tight ball hinge 70, pressure sensor 80, ultrasonic transducer 90 and control system.

[0030] The lifting mechanism is connected to the column 12 through the first base plate 38 , which is used to carry the rotating arm 60 and the ultrasonic transducer 90 . The lifting counterweight module 20 slides on the bearing optical axis mechanism 22 , and the rail optical axis is fixed on the inner surface of the column 12 . The steel wire rope 41 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com