Tap for pressurised gas cylinder

A technology for high-pressure gas cylinders and cylinder valves, which is applied in the direction of lifting valves, valve devices, thin material processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

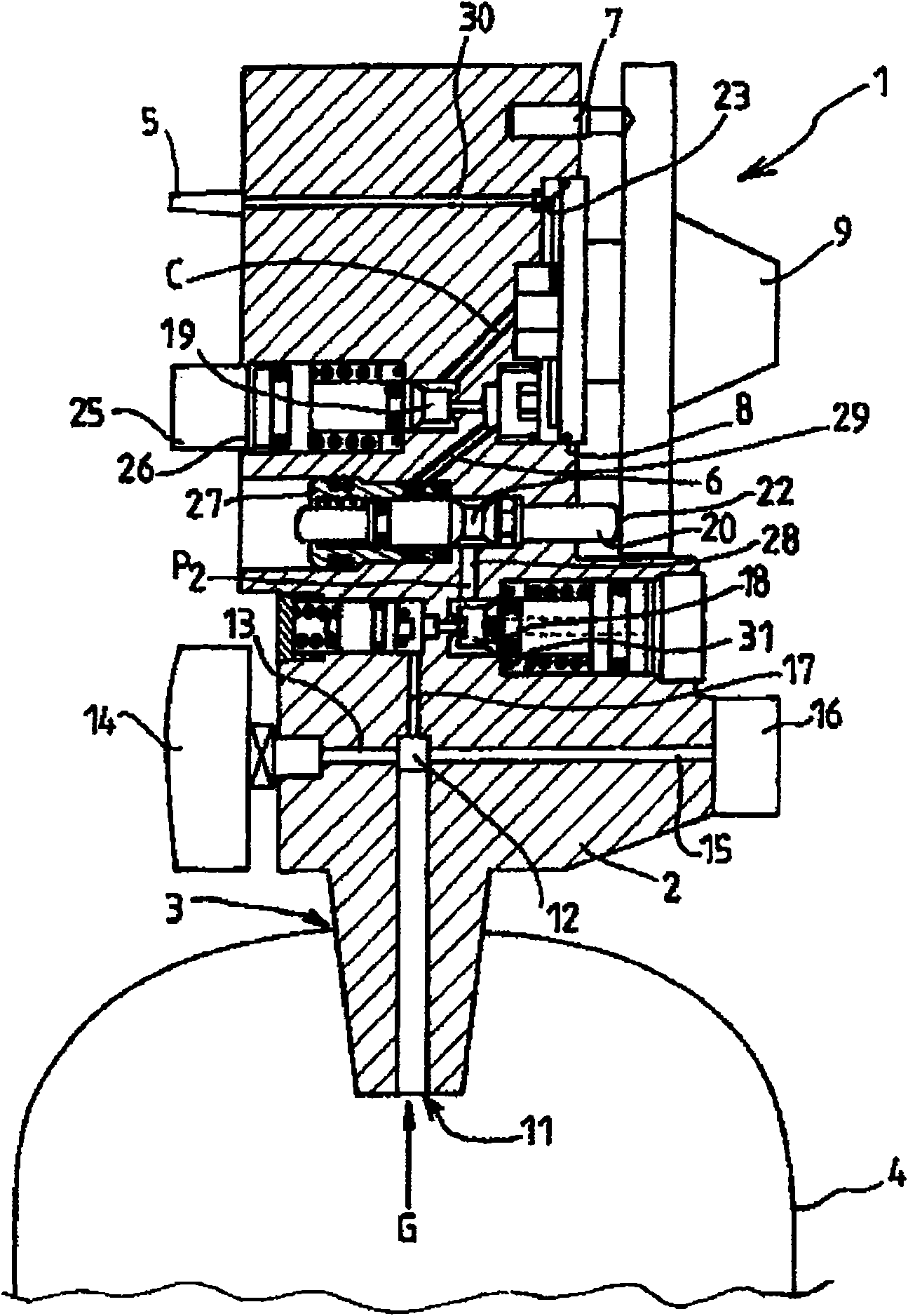

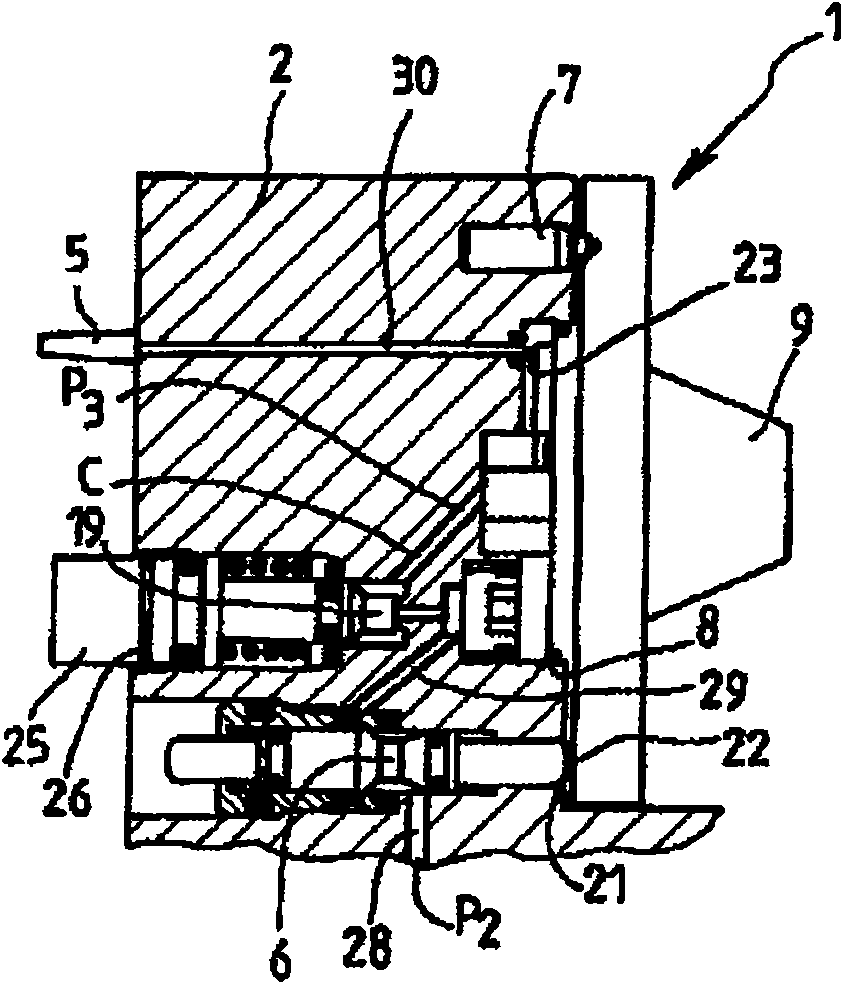

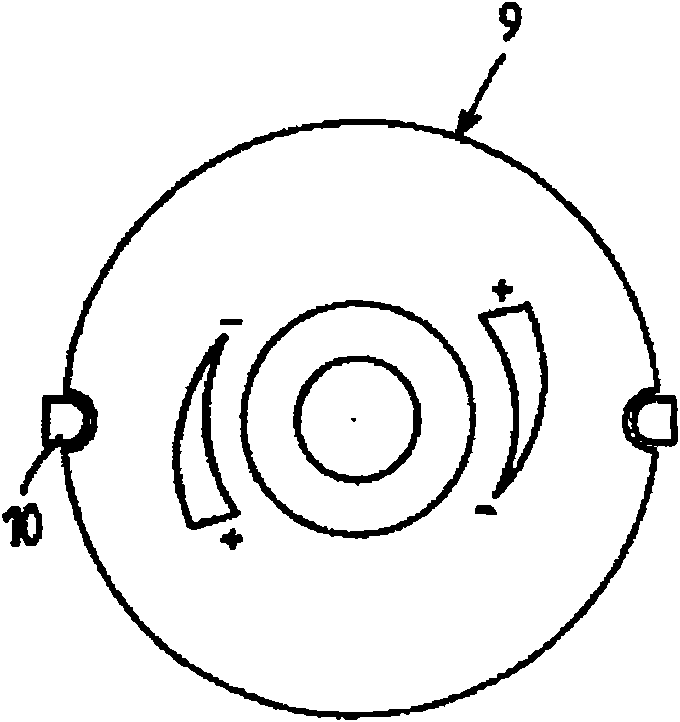

[0033] figure 1 The cylinder valve 1 shown comprises a body 2 connected to an outlet orifice 3 for gas G to flow out of a cylinder 4 .

[0034] An extraction circuit C for extracting gas G is formed in the body 2 in order to connect a gas inlet 11 for gas G connected inside the cylinder 4 to at least one gas release outlet 5 , 25 . Such as figure 1 As shown, a filter 12 may be provided downstream of the inlet 11 . Downstream of the filter 12, the circuit C is divided into a plurality of pipes. The first pipe 13 communicates with a pressure gauge 14 mounted on the body 2 . The second tube 15 is connected to a filling connector 16 . A third pipe 17 or pressure relief channel conveys gas towards one or more outlets 5 , 25 . Downstream of the filter 12, the pressure relief line 17 of the circuit C comprises a safety relief valve 31 for protecting the downstream components from high pressure in the event of accidental leakage. In this way, the mechanical design described abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com