Anti-theft lockset

A lock and lock body technology, which is used in construction locks, cylinder pin locks, locks with turning keys, etc., can solve the problems of good anti-theft performance, and locks are easily damaged by force, so as to achieve good anti-theft performance and prevent thieves from destroying the lock. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

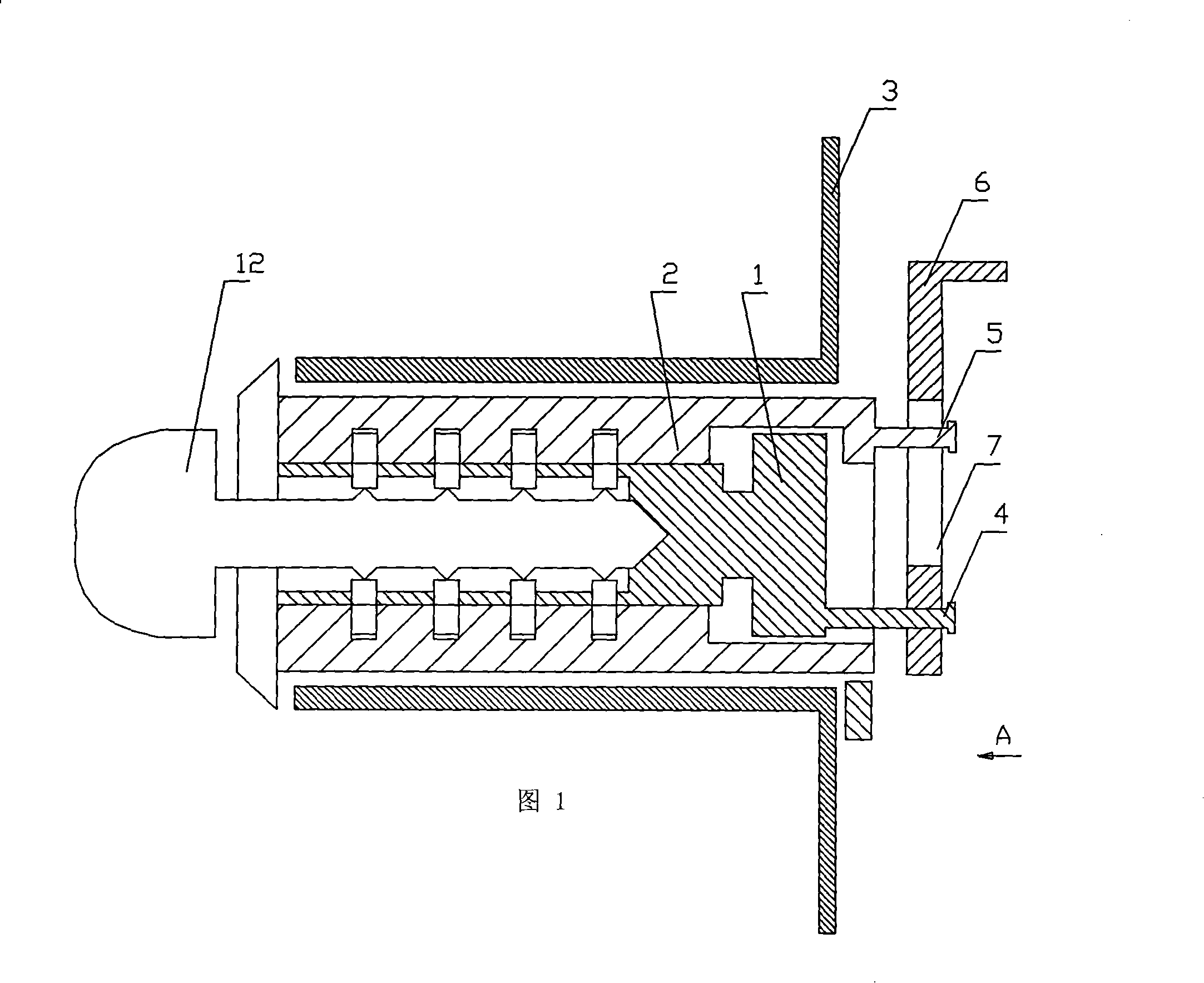

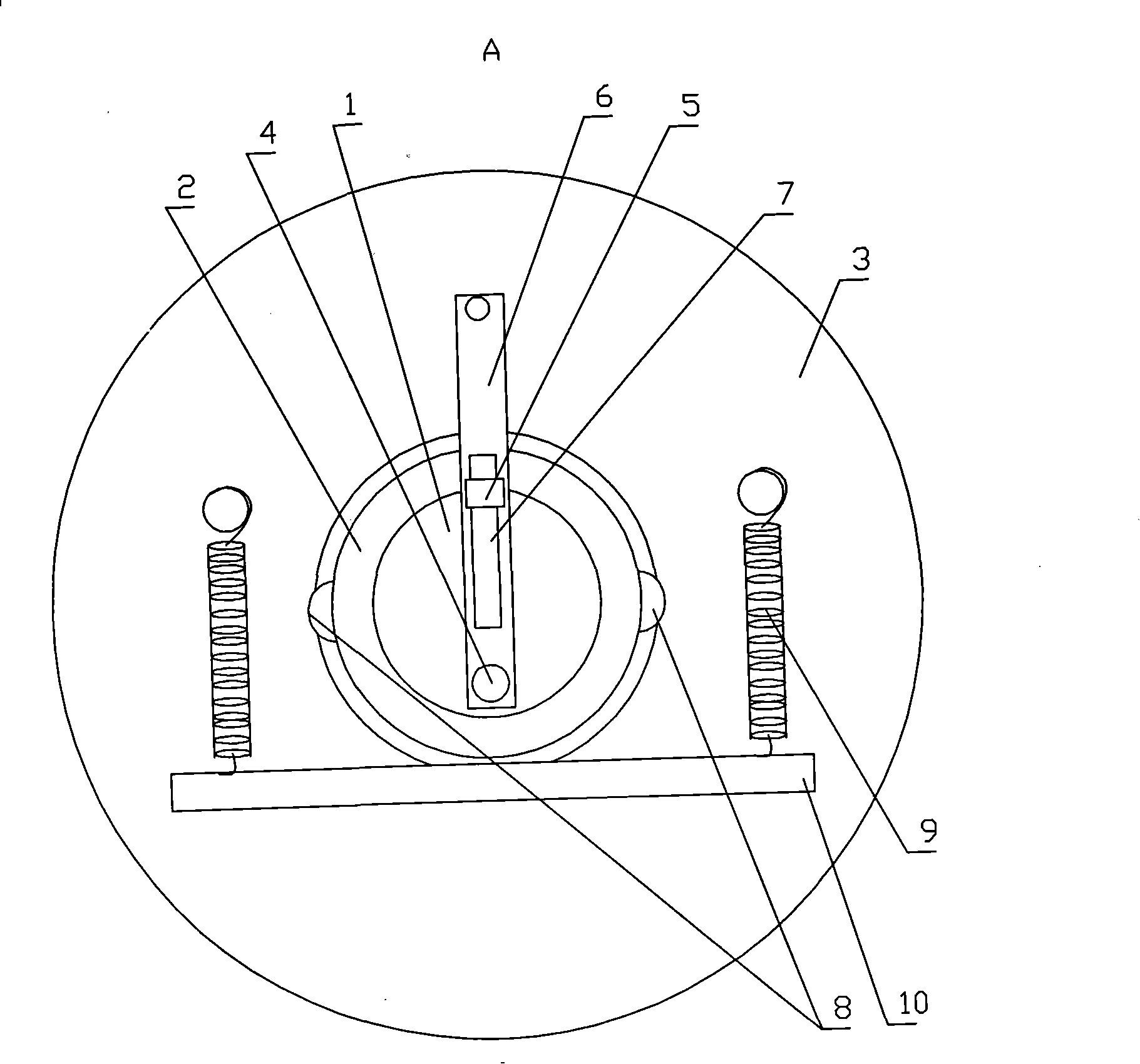

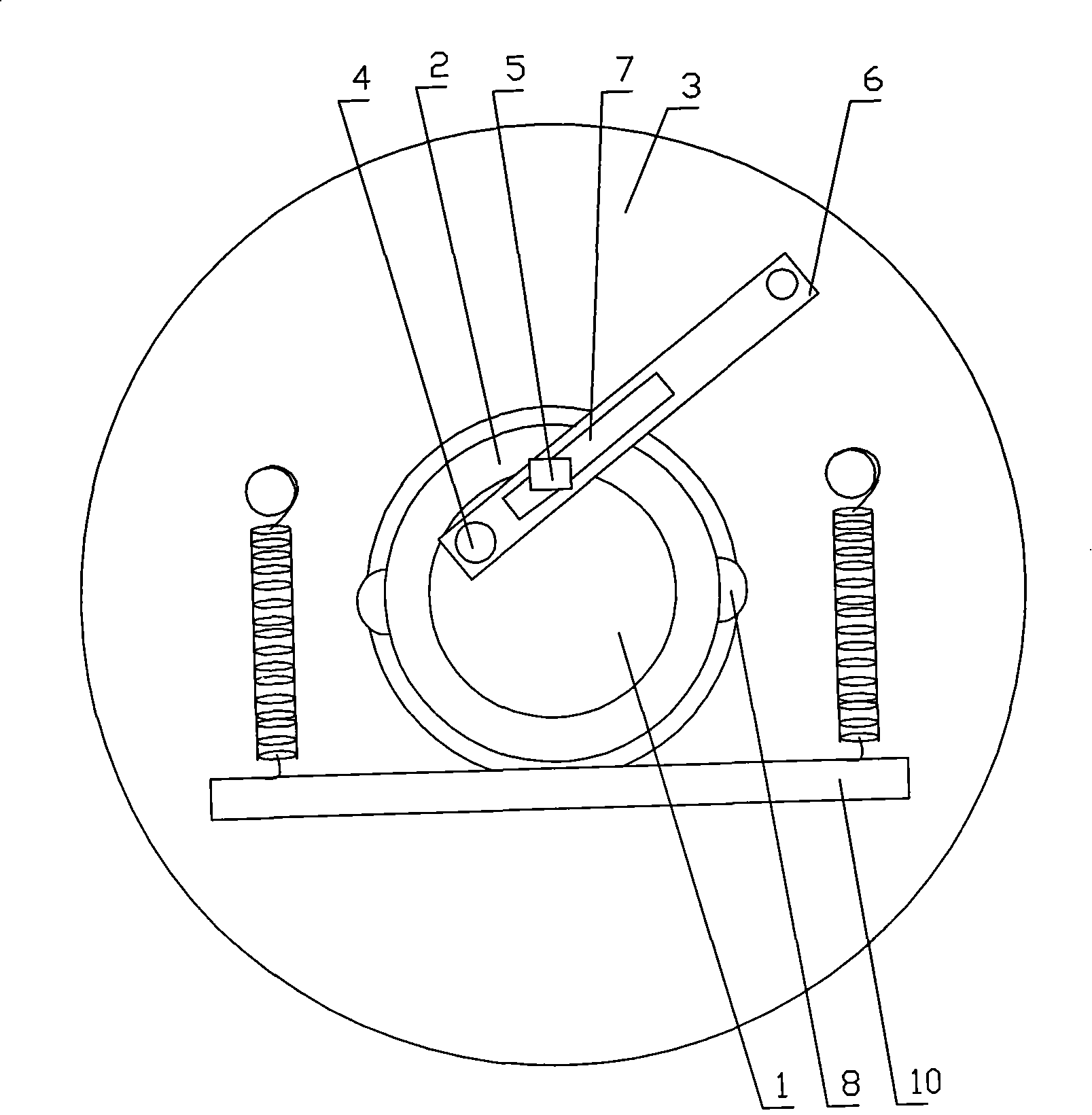

[0018] Embodiment 1: as Figure 1 to Figure 3 As shown, the anti-theft lockset includes a lock core 1, a lock body 2, and a locking mechanism that limits the relative movement of the lock core 1 and the lock body 2. Like a commonly used locking mechanism, the locking mechanism is arranged on the lock core 1 and the lock body 2. It consists of a plurality of sliding holes, a plurality of sliding columns and a return spring, and the lock cylinder is located in the lock body. The internal structure of lock cylinder, lock body is the same with most existing locksets. The lock body 2 is cylindrical, the axes of the lock body 2 and the lock cylinder 1 are the same, the lock body 2 is located in the lock body hole of the shell 3, and the lock body 2 can rotate 360 degrees relative to the shell. A positioning shaft 4 is provided on the distal end surface of the lock core 1 away from the key hole, and the positioning shaft 4 is arranged near the periphery of the distal end surface o...

Embodiment 2

[0020] Embodiment 2: It also includes a movable lock bolt 11, and the lock bolt 11 is provided with bar-shaped teeth; the lock cylinder is inserted with a matching key, and after the lock cylinder and the lock body are rotated in corresponding phases, the bar is pulled to touch the lock on the lock bolt. bar teeth. After the lock core rotates relative to the lock body, the distance between the end of the pulling bar that is far away from the positioning shaft and the axis of the lock core changes, and the distance becomes larger. There is a certain distance between the position and the sliding hole, and the lock cylinder and the lock body cannot produce relative movement in the radial direction, so that the positioning shaft cannot pass over the positioning column, the lock cylinder can no longer rotate relative to the lock body, and the lock cylinder and the lock body rotate at the same time. The deadbolt mechanism can be touched or pulled, at which point the lock can be open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com