Threshing grass-expelling conveyor of head-feed reaper

A conveying device and harvester technology, which is applied in the fields of harvesters, agricultural machinery and implements, applications, etc., can solve the problems of high manufacturing precision requirements, restricting the miniaturization of semi-feeding combine harvesters, and complex transmission structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

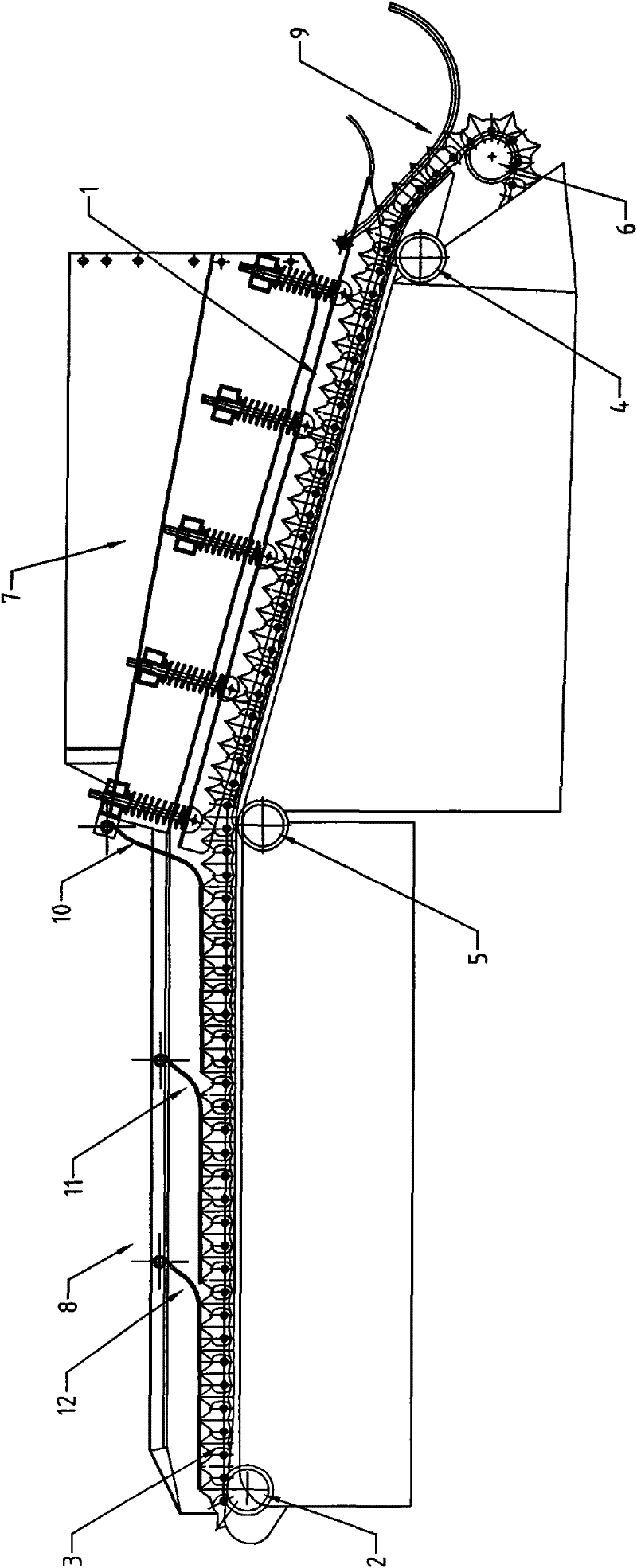

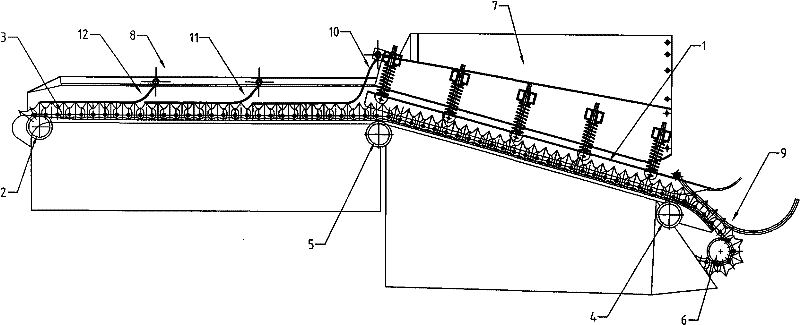

[0012] attached figure 1 Shown is a threshing and grass-discharging conveying device of a semi-feeding harvester, which is mainly composed of a spring pressure plate 1, a pressure spring, a driving sprocket 2 and a clamping chain 3; the clamping chain 3 is set on the driving sprocket 2. On the support wheel 4 and the support wheel 5, the above-mentioned driving sprocket 2 is located at the tail of the grass discharge area 8; the whole route of the clamping chain 3 spans the harvester threshing area 7 and the grass discharge area 8; Tensioning parts 6 are arranged on the clamping chain at the front lower part; there is a first compression spring 9 attached to the clamping chain roller at the leading end of the threshing area 7, and there is a spring 9 corresponding to the upper part of the clamping chain roller in the entire threshing area 7. The contact spring pressing plate 1 has the second compression spring 10, the third compression spring 11 and the fourth compression spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com