Hydraulic drive limited-rotating-angle straight rotating actuator

A technology with limited rotation angle and actuator, applied in transmission, fluid transmission, belt/chain/gear, etc., can solve the problems of limited output torque, low reliability, and inapplicability to large torque loads, and achieve simplified transmission. The effect of simple chain and transmission mechanism and short action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to the scope of the described embodiments. All these ideas should be regarded as the content disclosed in this technology and the protection scope of this patent.

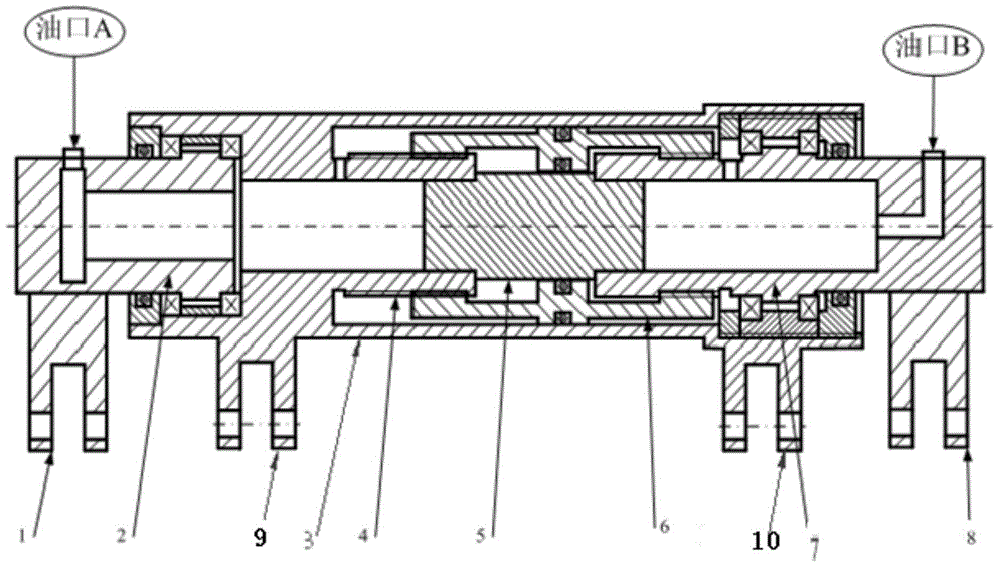

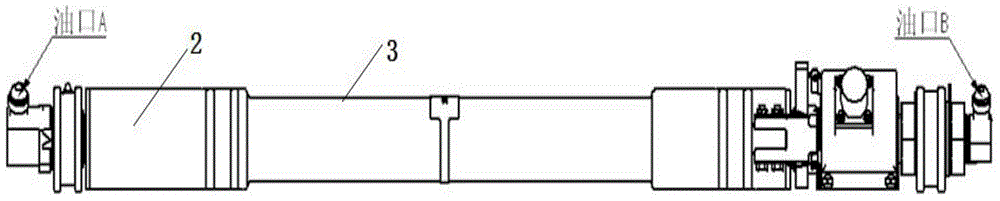

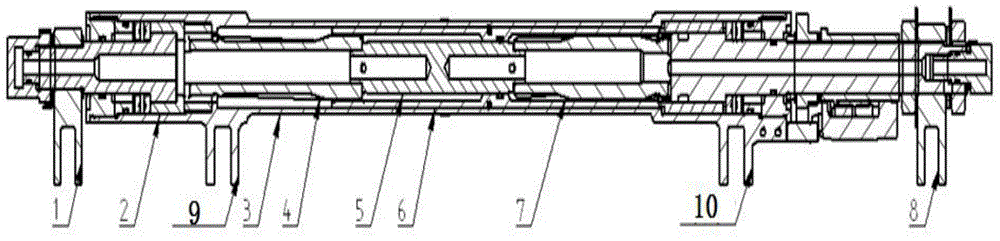

[0014] refer to Figure 1-Figure 3 . The direct rotary actuator with hydraulic drive and limited rotation angle includes an output cylinder 3 with oil port A and oil port B at both ends, a piston rod 4 that moves linearly in the output cylinder 3, a distribution rod 5, and a hollow piston head 6 , fixed rod 7, bearing A1 and bearing B8. The output cylinder 3 is directly used as the rotating shaft of the rotating load, the first lug 9 and the second lug 10 on the output cylinder 3 are used as the load mounting support, and the direct rotation actuator is installed on the fixed bracket through the support A1 and the support B8 superior. Oil port A and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com