Connecting line mechanism of centreless grinder

A centerless grinding machine and connection technology, which is applied in grinding machines, machine tools designed for grinding the rotating surface of workpieces, grinding/polishing equipment, etc., can solve the problems of high labor cost and low processing efficiency of centerless grinding machines, so as to reduce personnel costs. , The effect of eliminating bar collision and improving competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

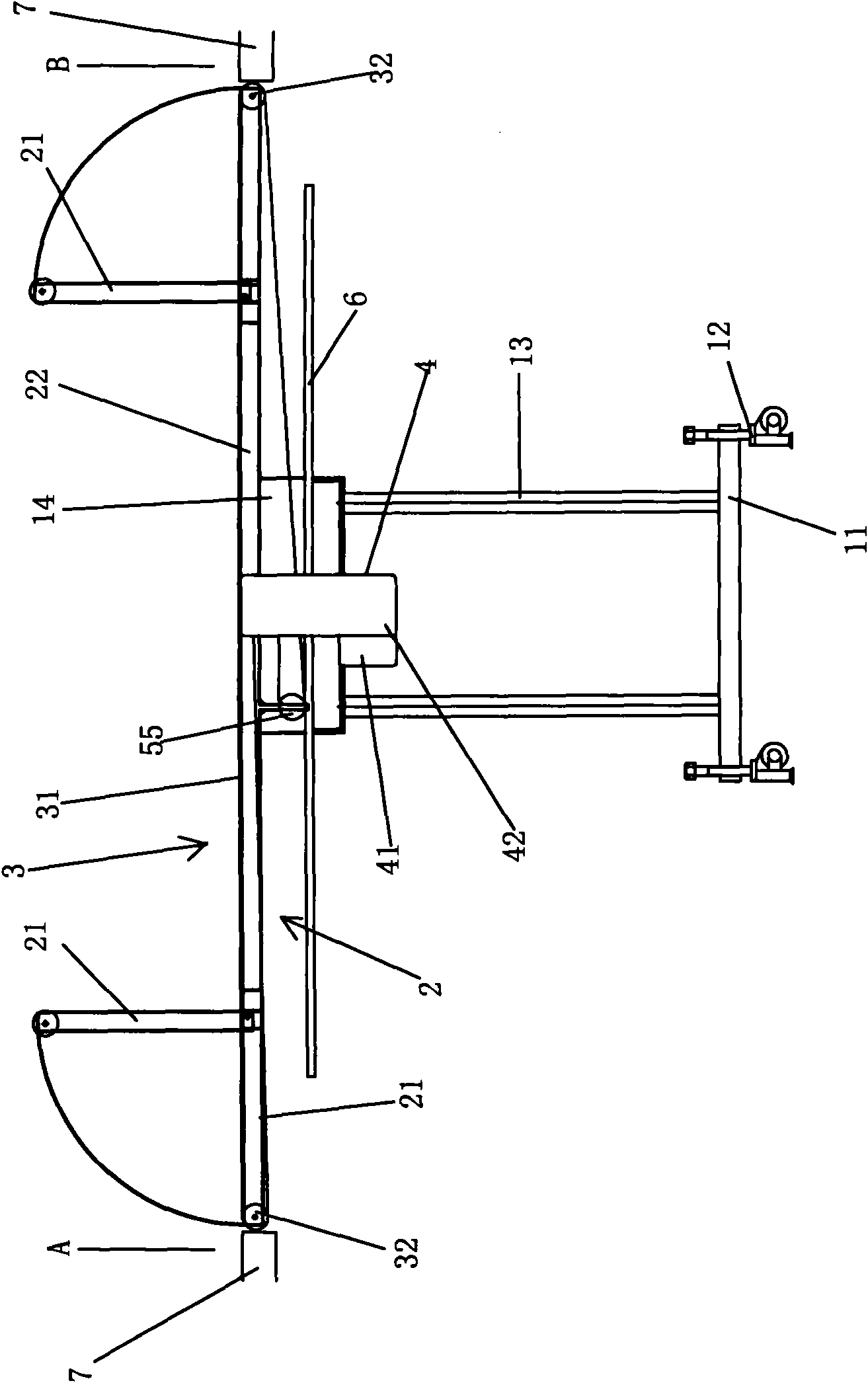

[0057] Such as figure 1 , Figure 6 As shown, a connection mechanism of a centerless grinder, which is connected between the discharge port of the front centerless grinder (A) and the feed port of the rear centerless grinder (B), includes a support unit (1), a guide rail unit (2), a belt unit (3), a motor (4), a transmission unit (5), a water tank (6).

[0058] As shown in Figure 10, the supporting unit (1) includes: a supporting base (11), four adjusting casters (12), two columns (13), and a guide rail fixing plate (14). The supporting base (11) is provided with four threaded holes (111), and the adjusting caster (12) is matched with the threaded holes (111) by screws (121) thereon, and is fixed on the supporting base (11). Because the adjusting caster is fixed on the supporting base through the screw on it and the threaded hole, the screw on it can be adjusted as required, so as to achieve the effect of adjusting the height of the whole connecting mechanism. The lower end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com