PCBA calibration clamp and calibration method thereof

A fixture and radio frequency head technology, which is applied in the field of PCBA calibration fixture and its calibration, can solve the problems of wasting labor costs and production costs, and achieve the effect of improving production efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

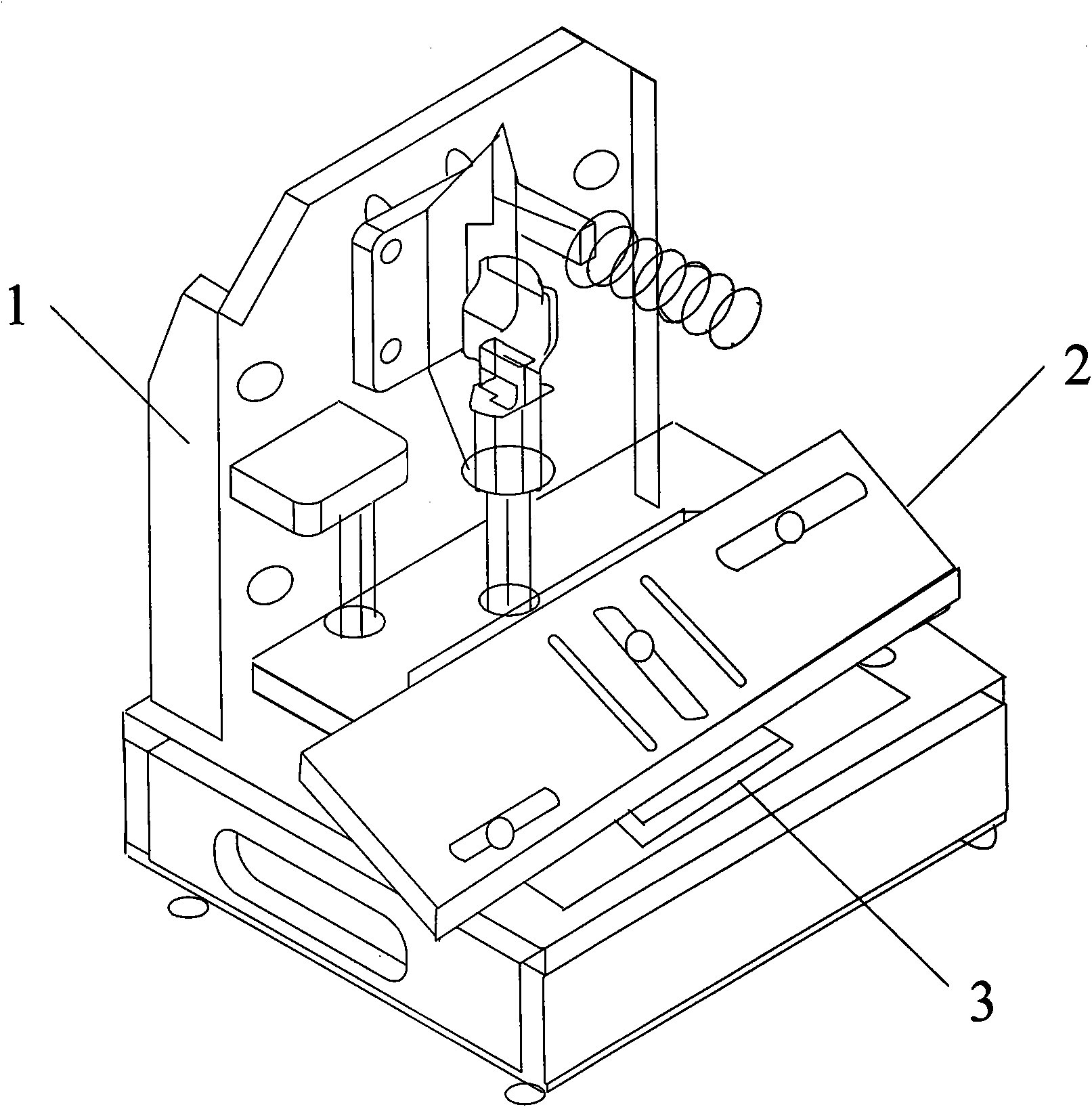

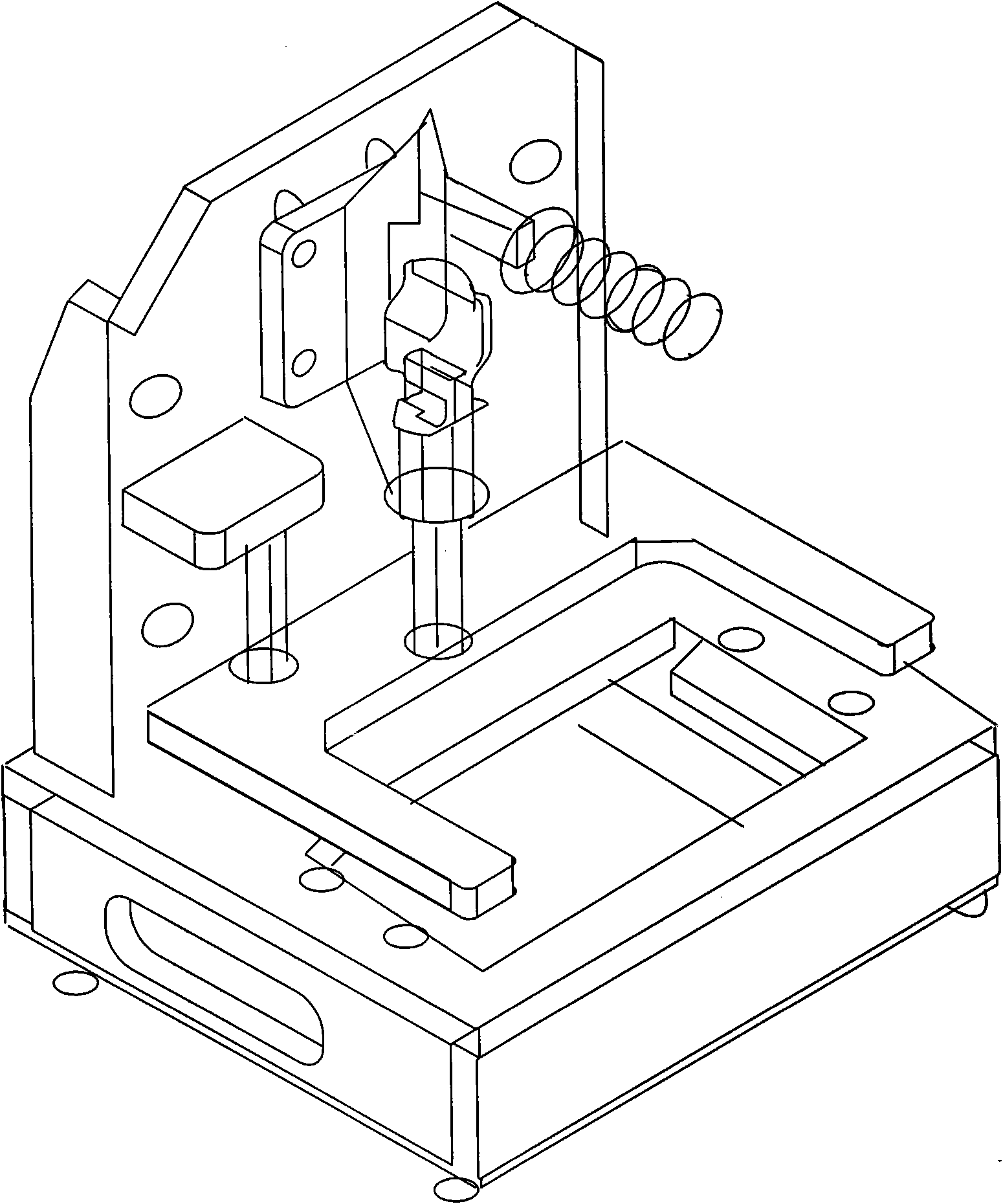

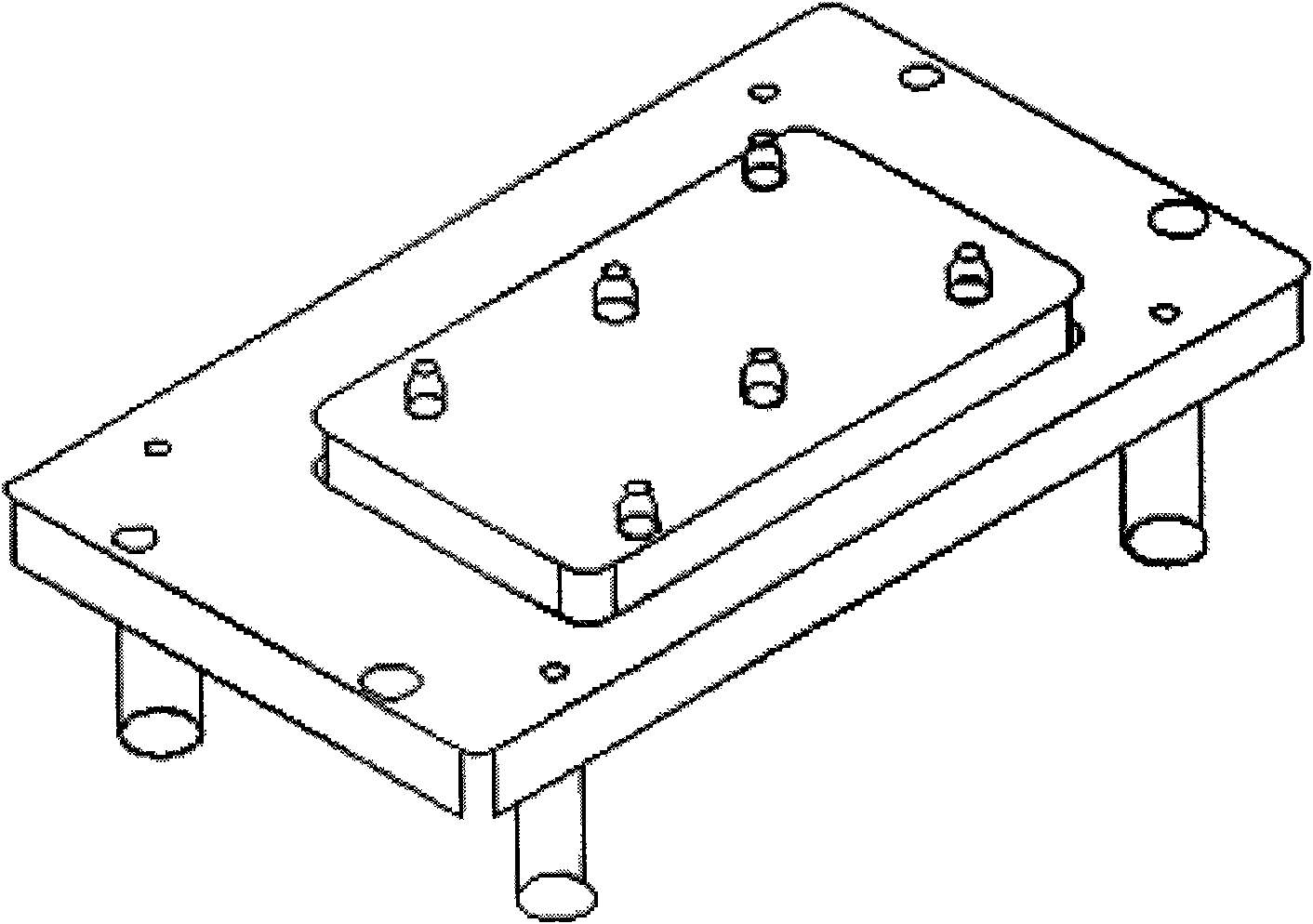

[0016] like figure 1 As shown, the PCBA calibration fixture of the present invention includes: a fixture frame 1, a radio frequency head adjustment board 2, a PCBA size adjustment board 3, a comprehensive tester, a radio frequency head and its radio frequency line, and the like. like figure 2 As shown, the fixture frame is the frame seat of the fixture, which is used to load the PCBA size adjustment board and the RF head adjustment board. In addition, the PCBA size adjustment board can also be replaced according to the PCBA of the special project; image 3 As shown, the PCBA size adjustment plate is used to adjust the size of the PCBA and fix the PCBA; Figure 4 As shown, the RF head adjustment board is used to adjust the RF head to correspond to the RF test socket of the PCBA; Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com