Feeding and clamping oil cylinder mechanism for processing spherical surface roller

A technology of spherical roller processing and clamping oil cylinder, which is applied in metal processing and other directions, can solve problems such as poor wear resistance and frequent maintenance, and achieve the effects of long service life, enhanced stability, and simplified partial structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

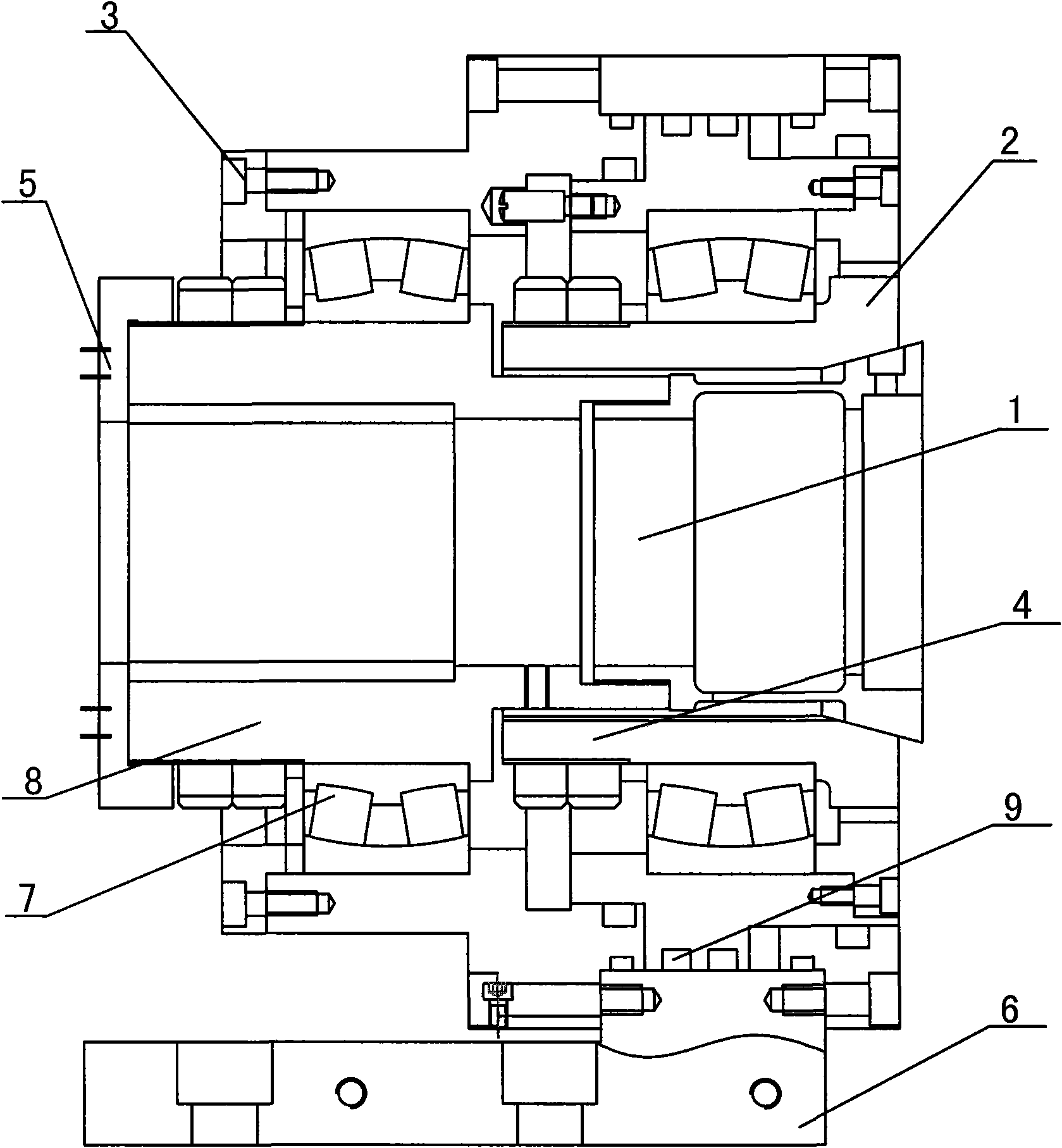

[0011] like figure 1 As shown, the feeding and clamping oil cylinder mechanism for spherical roller processing according to the present invention includes a main shaft mechanism 1, an upper sliding body 2, and a chuck fixture 8. The upper part of the main shaft mechanism 1 is provided with an upper sliding body 2, The upper sliding body 2 is fixed on the support frame 4 by the limit bolt 3; the end of the main shaft mechanism 1 is connected with the ferrule 5, and the bottom of the support frame 4 is provided with an oil cylinder base 6, and the oil cylinder base 6 is connected with the support frame Several washers 9 are arranged between 4, and the front end of described support frame 4 is installed chuck fixture 8, and the bottom of described chuck fixture 8 is provided with movable slider 7. During work, the feeding and clamping oil cylinder mechanism is driven by the hydraulic oil cylinder to move the upper sliding body 2 to realize the forward and backward movements.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap