Quick joint of corrugated pipe for gas

A corrugated pipe and gas technology, applied in the direction of pipe/pipe joint/pipe fitting, sealing surface connection, sleeve/socket connection, etc., can solve the problems of poor sealing effect, troublesome installation, not fast enough, etc., and achieve simple structure and improved Sealing, fast installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

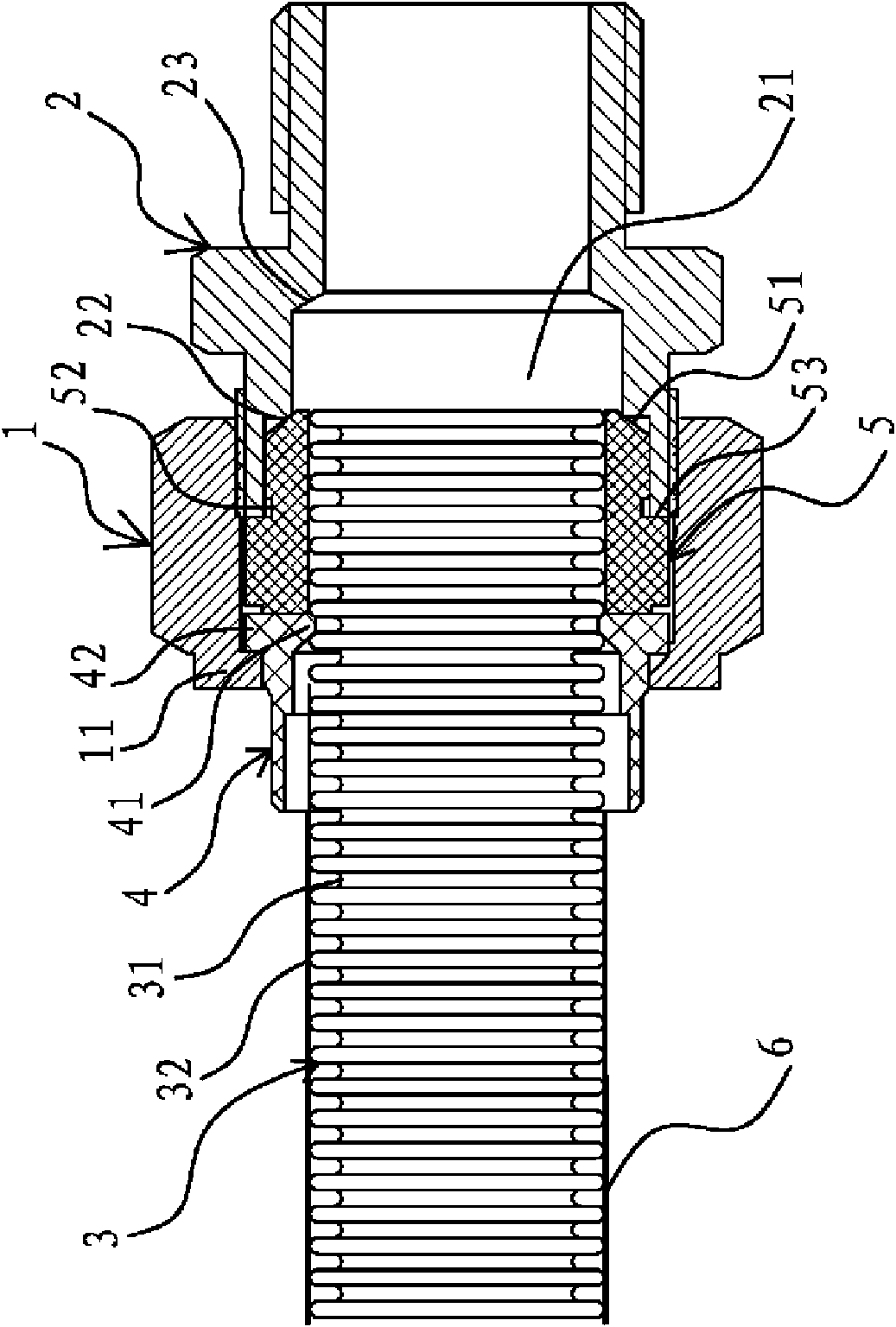

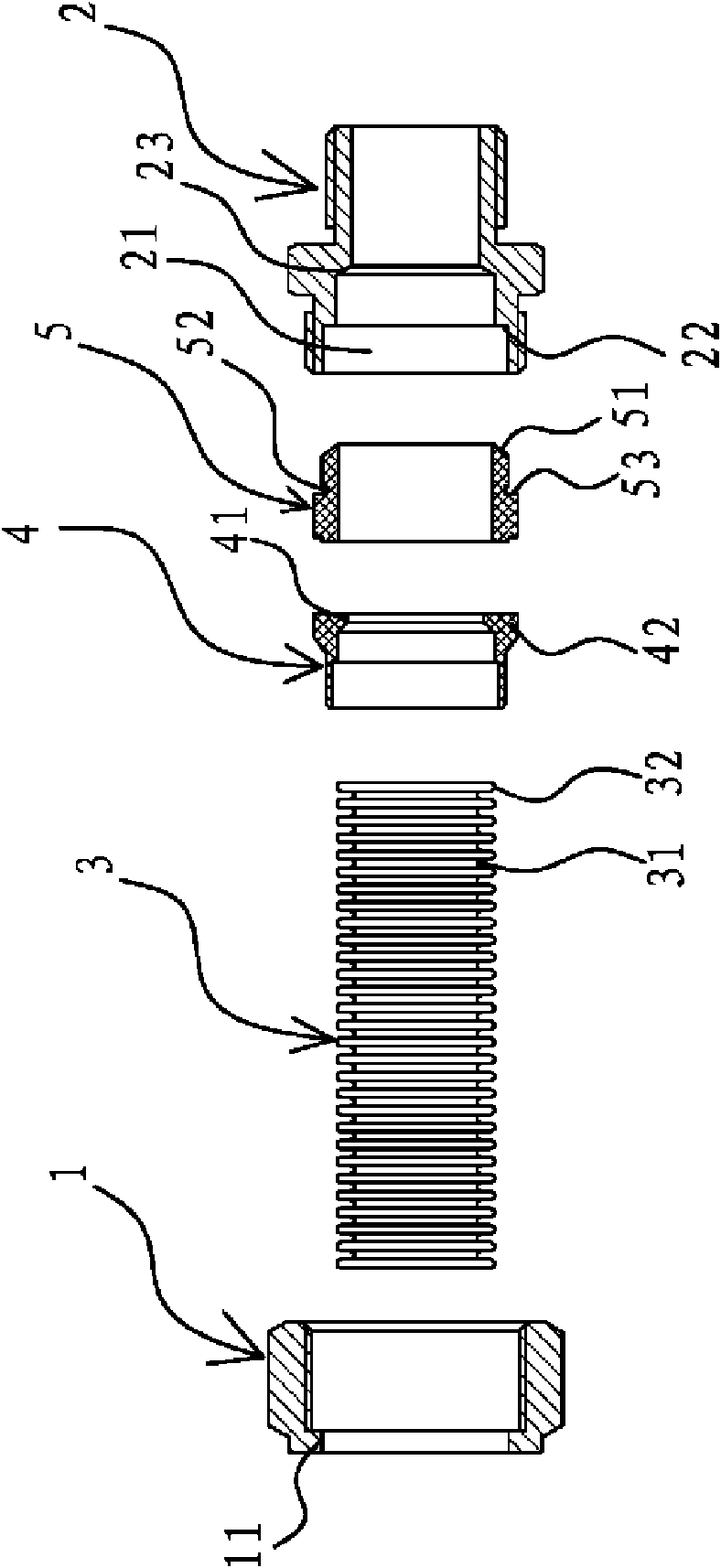

[0028] Such as figure 1 and 2 As shown, the gas bellows quick connector includes a lock nut 1, a bellows 3, a clamping sleeve 4, a sealing washer 5 and a joint 2 with a connection hole 21, and one end of the lock nut 1 is provided with an inwardly protruding A retaining edge 11, a pressure ring 41 is provided on the inner wall of the clamping sleeve 4 and an outwardly protruding retaining edge 42 is provided at the end close to the sealing gasket 5 . The inner end of the sealing gasket 5 is provided with a slope 51, and its outer peripheral surface is provided with a step 2 53 and an annular groove 52. The annular groove 52 is located between the step 2 53 and the slope 51 and is adjacent to the step 2 53. The connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com