Stelmor cooling control technique

A process method and process technology, applied in the field of Stelmore controlled cooling process, can solve problems such as unsatisfactory application effect, achieve excellent drawing performance and improve the effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The process route for producing SWRH82A wire rod for Φ11mm rope-making steel wire is as follows: 100-ton top-bottom double-blown converter—LF refining outside the furnace—continuous casting billet—high wire rolling—Styermore controlled cooling process. Chemical composition of wire rod: C 0.79-0.86%, Mn0.30-0.60%, Si 0.15-0.35%, wire rod start rolling temperature: 950-1100°C, finish rolling temperature: 900-1050°C.

[0022] Embodiment 1 of the Stelmore controlled cooling process of the present invention includes an air cooling process and a water cooling process.

[0023] In the water cooling process:

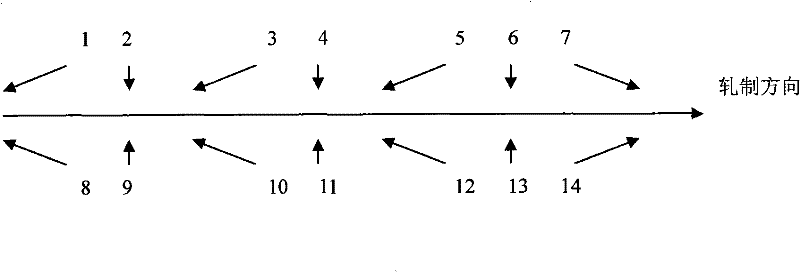

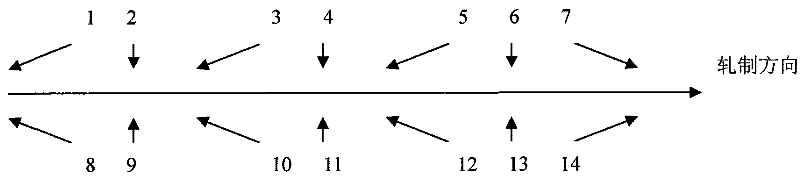

[0024] Such as figure 1 As shown, 1-14 in the figure is No. 1-14 water spray nozzle, and the direction of the arrow is the water spray direction and the wire rod running direction (rolling direction).

[0025] No. 1-7 water spray nozzles spray water from the top of the cooling roller table to the wire rod walking on the cooling roller table, and No. 8-14 water spray noz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com