Slow bonding prestressed tendon outer coated sheath indenting machine

A slow-bonding prestressing and indentation machine technology, which is applied in the field of slow-bonding prestressed tendon sheath creasing machines, can solve the problems of insignificant indentation, poor bonding effect, easy recovery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] For the convenience of further understanding the purpose means of the present invention, hereby attach preferred embodiment figure to describe in detail as follows:

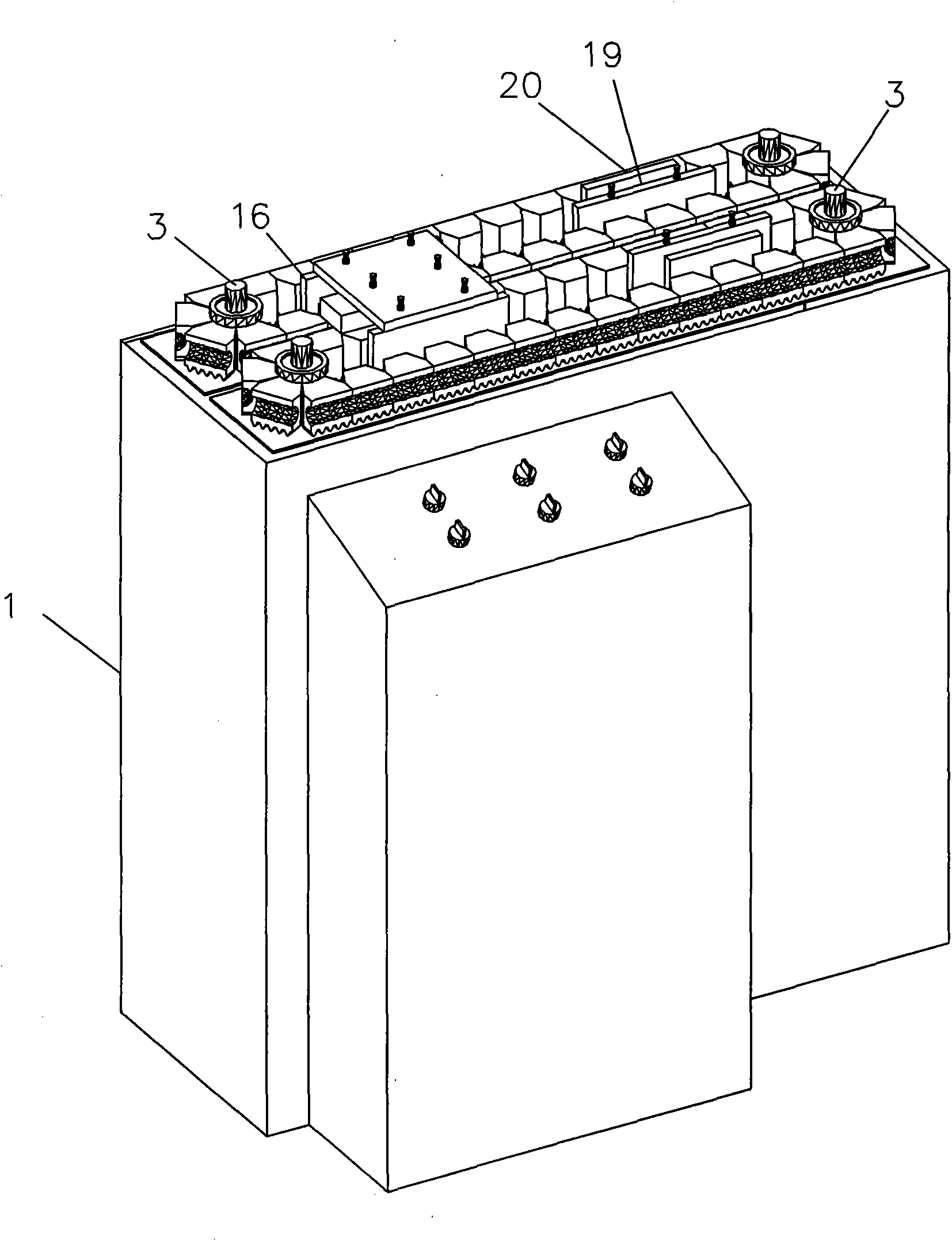

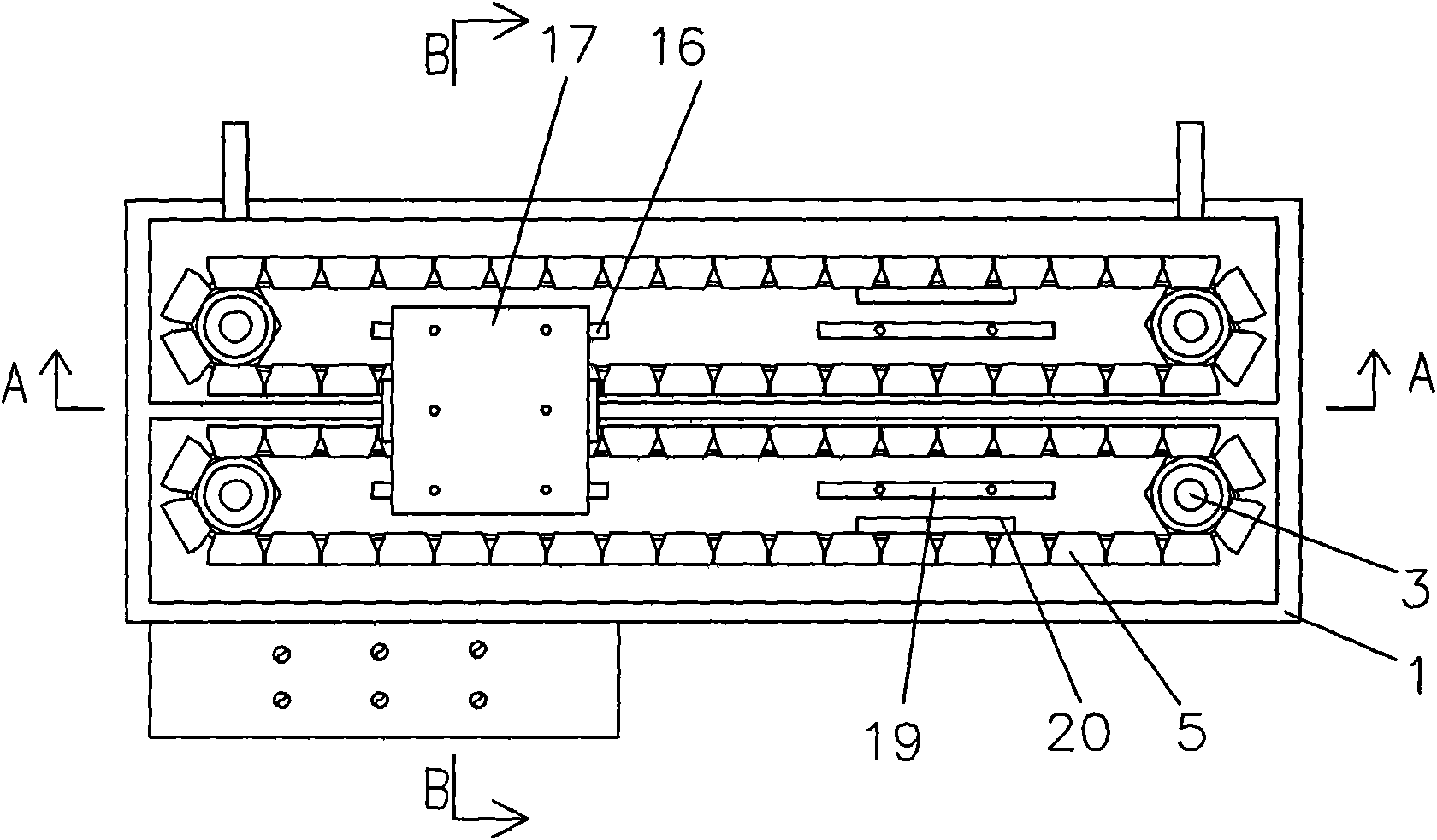

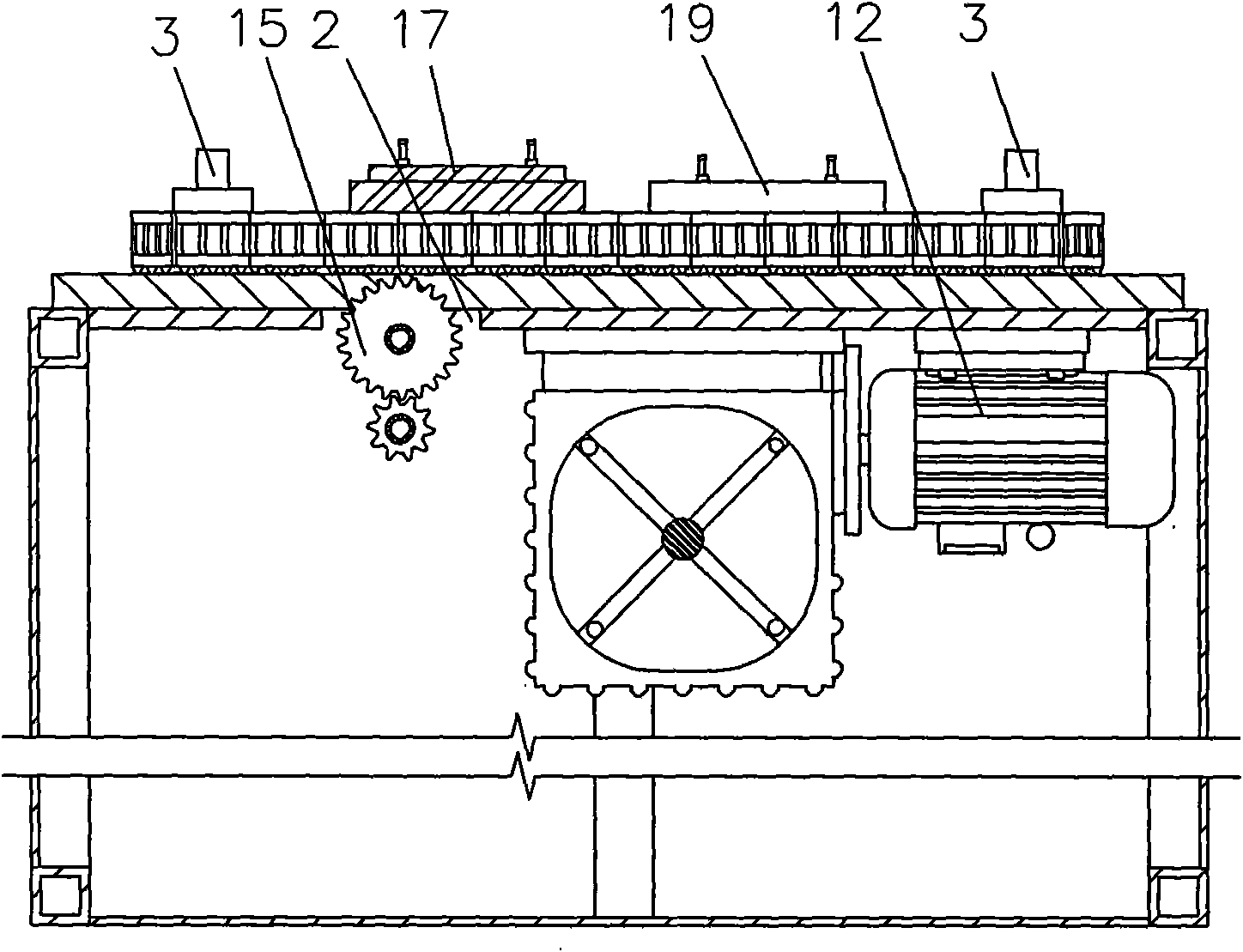

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 Shown, the present invention slow bonding prestressed tendons outsourcing sheath creasing machine, it comprises body 1, rack driving device and molding device;

[0028] The top of the machine body 1 is a horizontal work surface, and there is a longitudinal slot 2 on the horizontal work surface;

[0029] The molding device includes: four fixed shafts 3 arranged in a rectangular shape fixed on the horizontal working table of the machine body 1, regular hexagonal prisms 4 connected to the fixed shafts 3 through bearings, and regular hexagonal prisms 4 on every two fixed shafts 3 are connected There is a horizontal ring-shaped module chain located on the horizontal workbench of the body 1. The module chain includes several...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com