Processing technology of corrugated paper

A processing technology and technology for corrugated paper, applied in the field of corrugated paper, can solve the problems of different depths of indentation and affect the quality of corrugated cardboard, and achieve the effect of improving indentation effect, improving safety and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

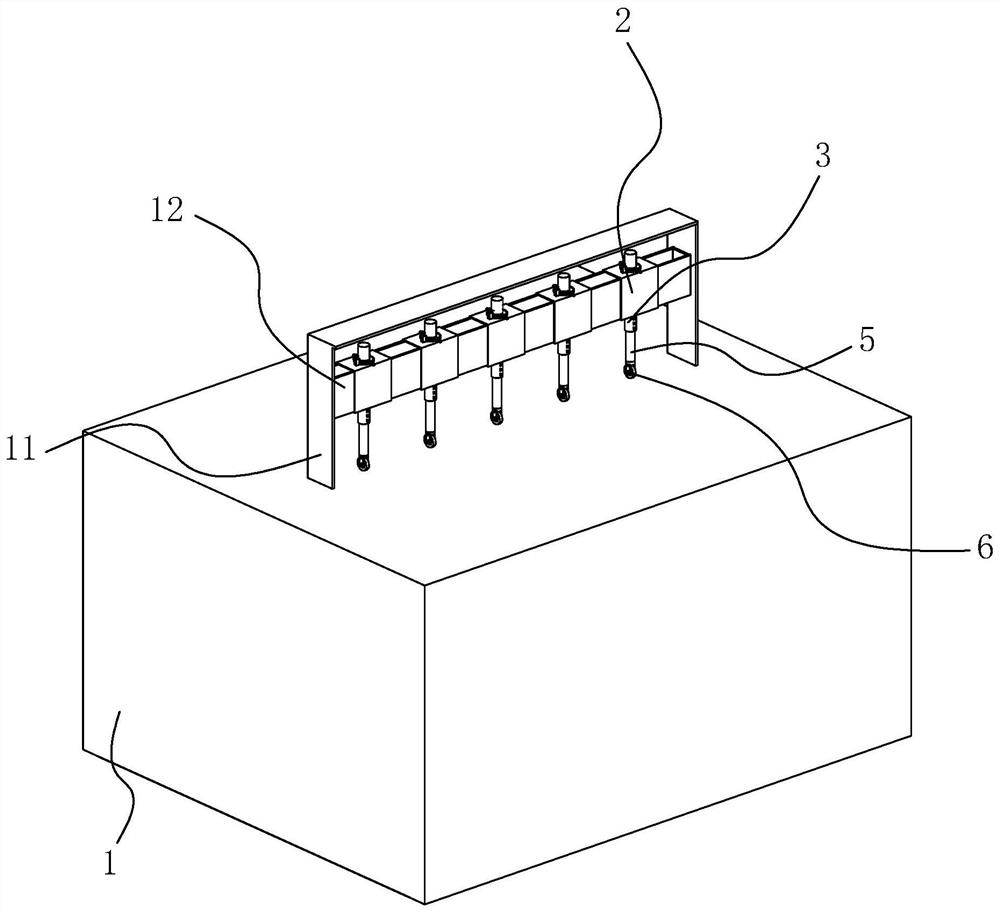

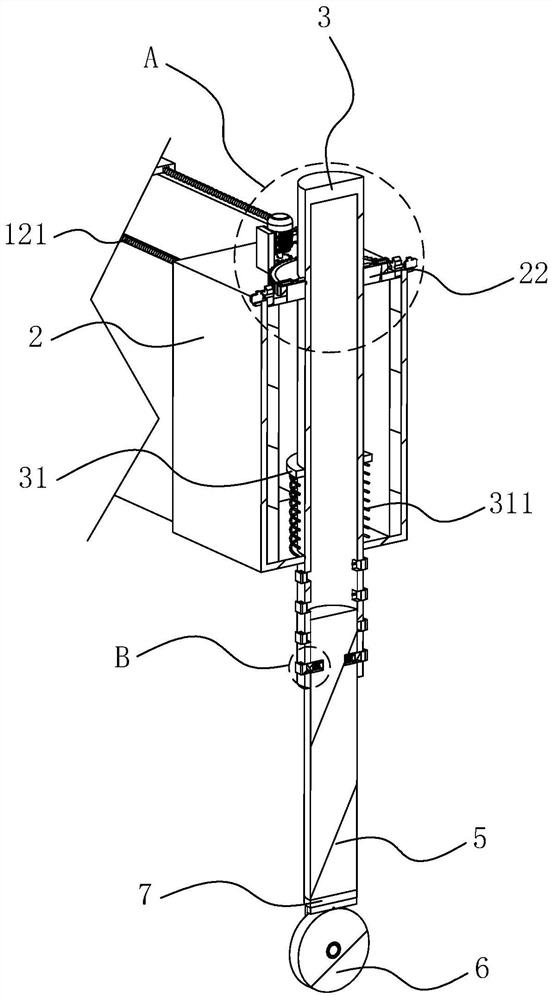

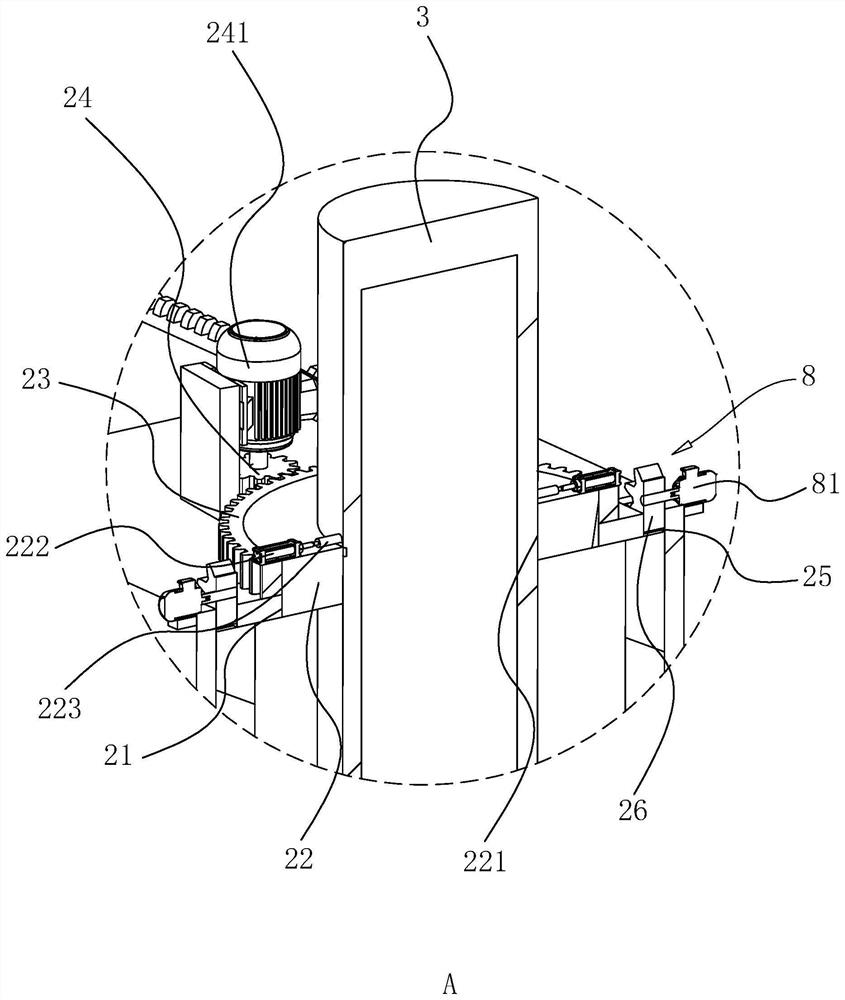

[0047] The following is attached Figure 1-9 The application is described in further detail.

[0048] The embodiment of the application discloses a corrugated paper processing technology. A kind of corrugated paper processing technology comprises the steps:

[0049] S1: Preheating: the corrugated base paper passes through the preheating roller, and the preheating roller preheats the corrugated base paper;

[0050] S2: Bonding: Use a single-facer to press the corrugated base paper. The corrugated base paper is corrugated paper, and the paper-plastic adhesive is coated on the surface of the corrugated paper, and then the first liner paper and the second liner paper are bonded to the corrugated paper. On both sides of the board, so as to be processed into three layers of corrugated cardboard;

[0051] S3: Drying: use a dryer to cure the bonded corrugated cardboard;

[0052] S4: Crease: Use a slitting and creasing machine to creasing the surface of the corrugated cardboard;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com