Production technology of delayed bonding prestressed tendon

A technology of slow bonding prestressing and prestressing ribs, which is applied to the device and coating of the surface coating liquid, which can solve the problems of unguaranteed product quality, high labor intensity, and low production efficiency, and achieve product quality. Guarantee, low labor intensity and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

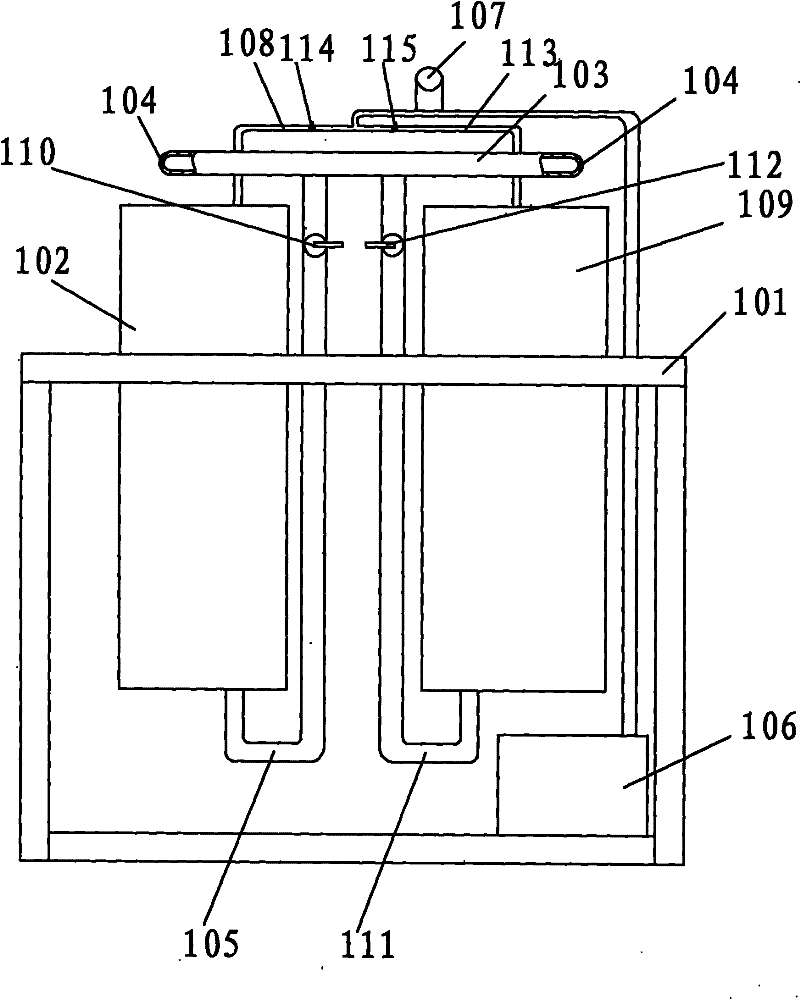

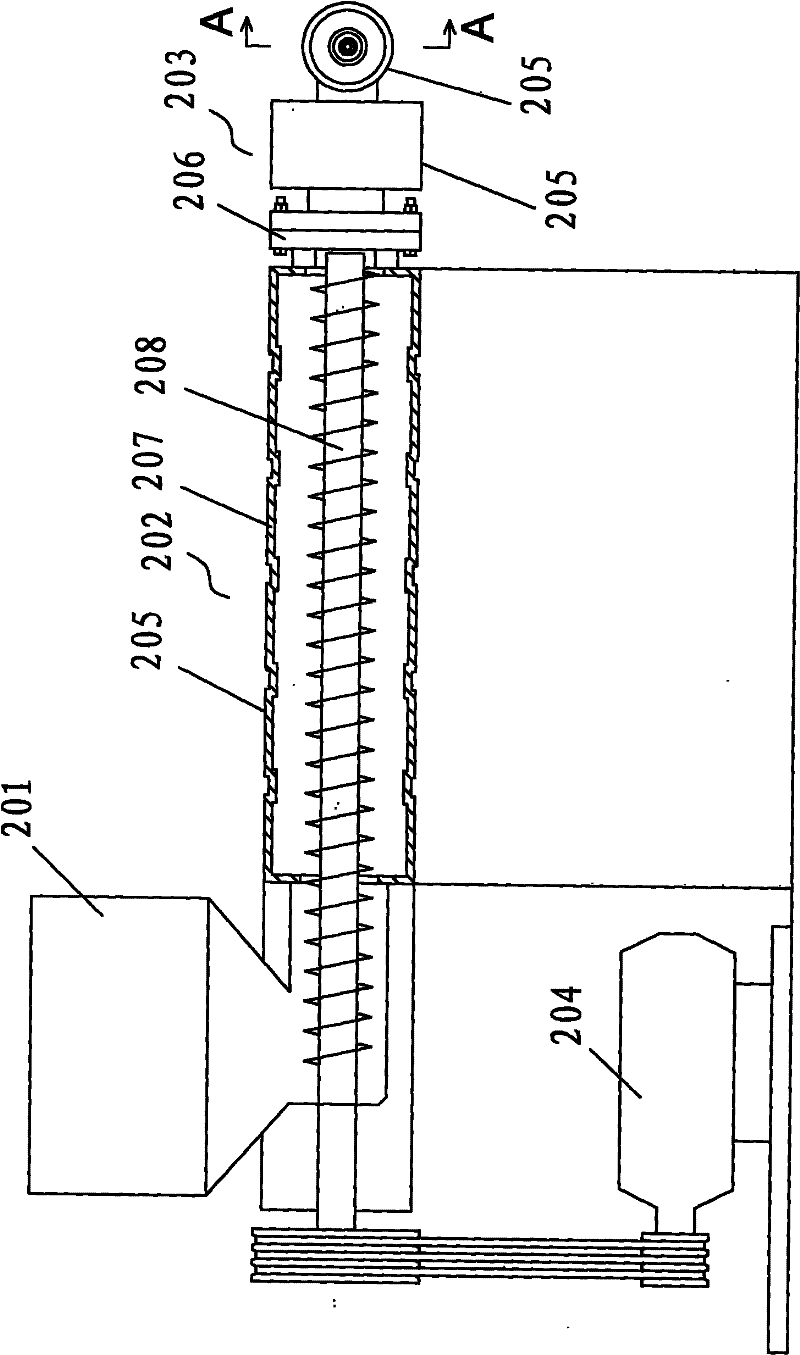

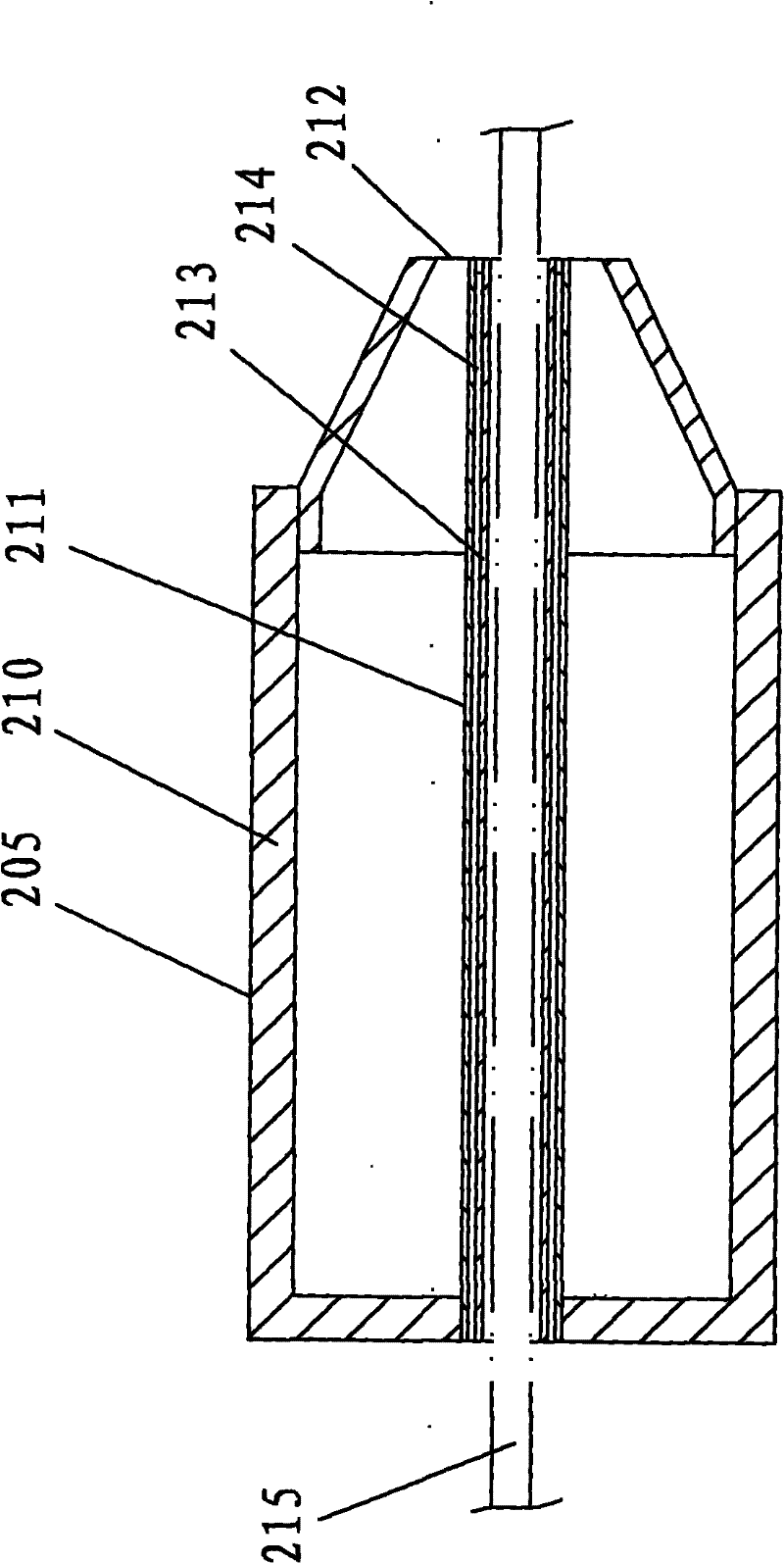

[0028] For the convenience of further understanding the purpose means of the present invention, hereby attach preferred embodiment figure to describe in detail as follows:

[0029] The invention relates to a production process for slow-bonded prestressed tendons, in which the prestressed tendons pass through a slow gel adhesive coating device, an outsourcing sheath extrusion molding machine, an outsourcing sheath creasing machine and a cooling device sequentially under the drive of a tractor; The retarding adhesive coating device coats the outer surface of the prestressed tendon with a retarding adhesive coating to form a prestressed tendon with a retarding adhesive coating; The prestressed tendon is covered with a plastic sheath to form a prestressed tendon with a plastic sheath; the outer sheath indentation machine presses the plastic sheath of the prestressed tendon with a plastic sheath into a corrugated indentation , forming prestressed tendons with indented plastic sheat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com