Manufacturing method of surface light source of notebook computer

A technology of surface light source and manufacturing method, which is applied in the field of electronics, can solve the problems of few varieties, achieve product diversification, and increase the effect of practical progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

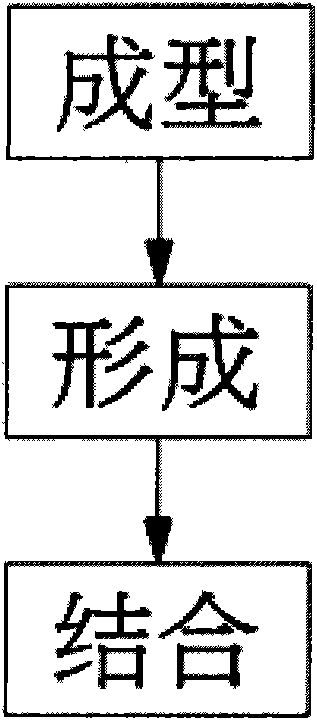

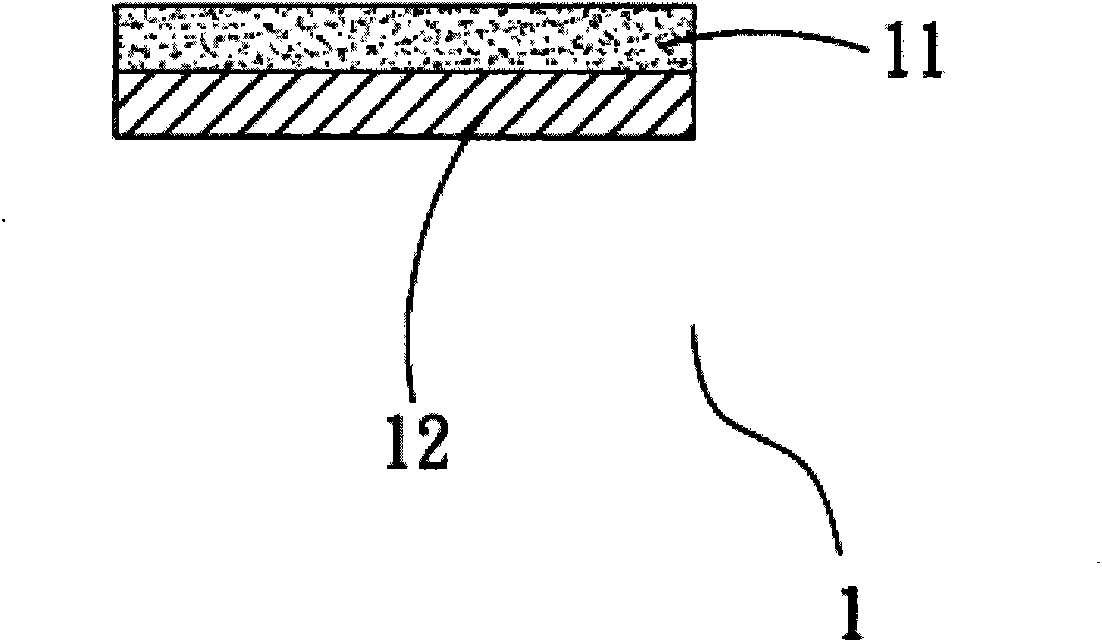

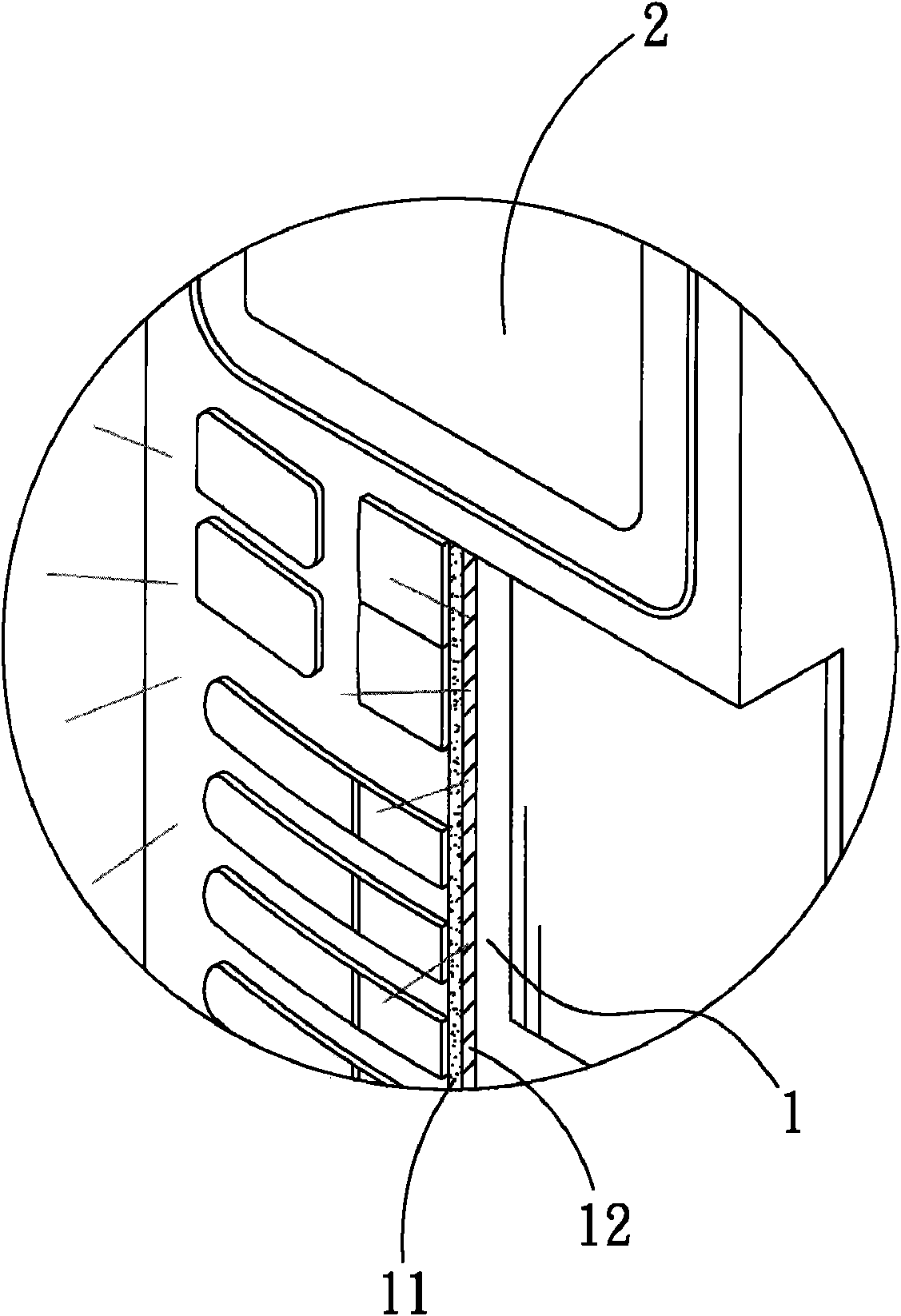

[0019] as attached figure 1 with attached figure 2 As shown, it is a flow chart and a cross-sectional view of a preferred embodiment of the present invention. It can be clearly seen from the figure that the notebook computer light source device 1 of the present invention is carried out according to the following steps:

[0020] In the molding step, a plastic substrate 11 is injection-molded using a preset mold. The plastic substrate 11 can be made of a transparent material or a translucent material, and the mold can be an optical mold, an embossed mold or an IMD mold;

[0021] The forming step is to form a light emitting source into a thin film light emitting layer 12. The light emitting source can be conductive luminescent ink, conductive luminescent paint, electronic power supply device, light emitting diode, cold light plate, fluorescent paint, temperature sensitive luminescent paint or light emitting component processing product;

[0022] In the combining step, the plas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com