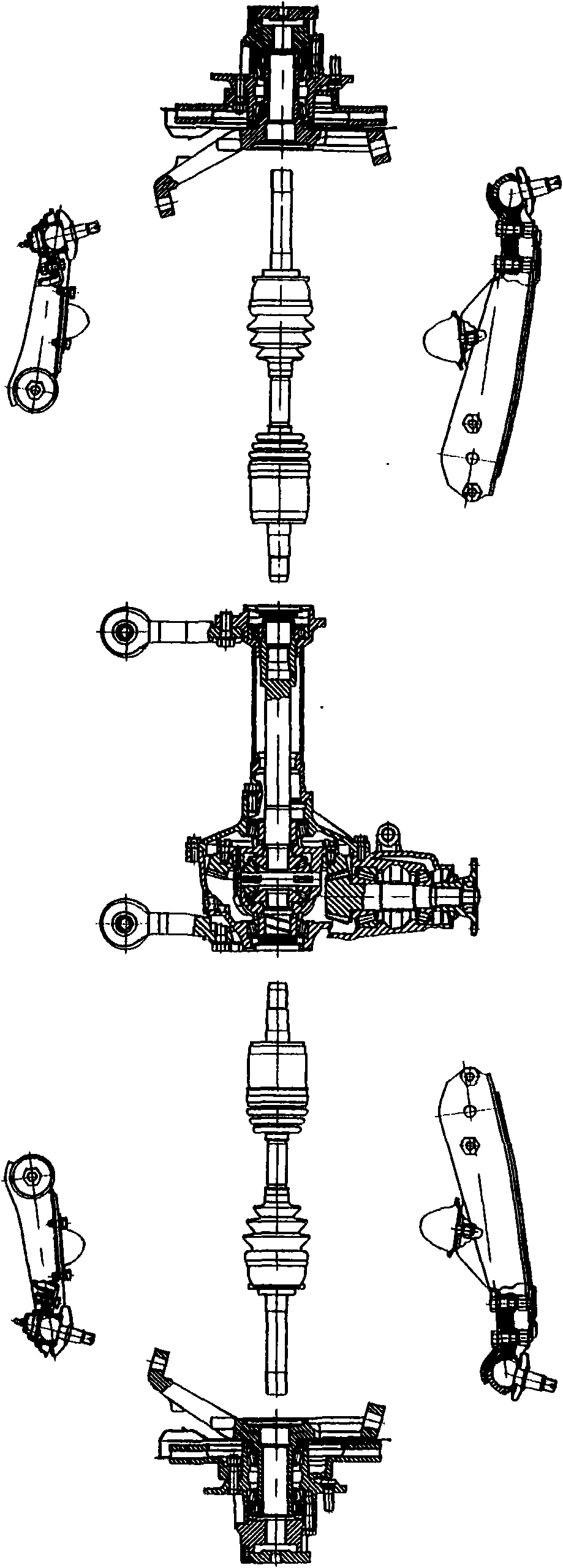

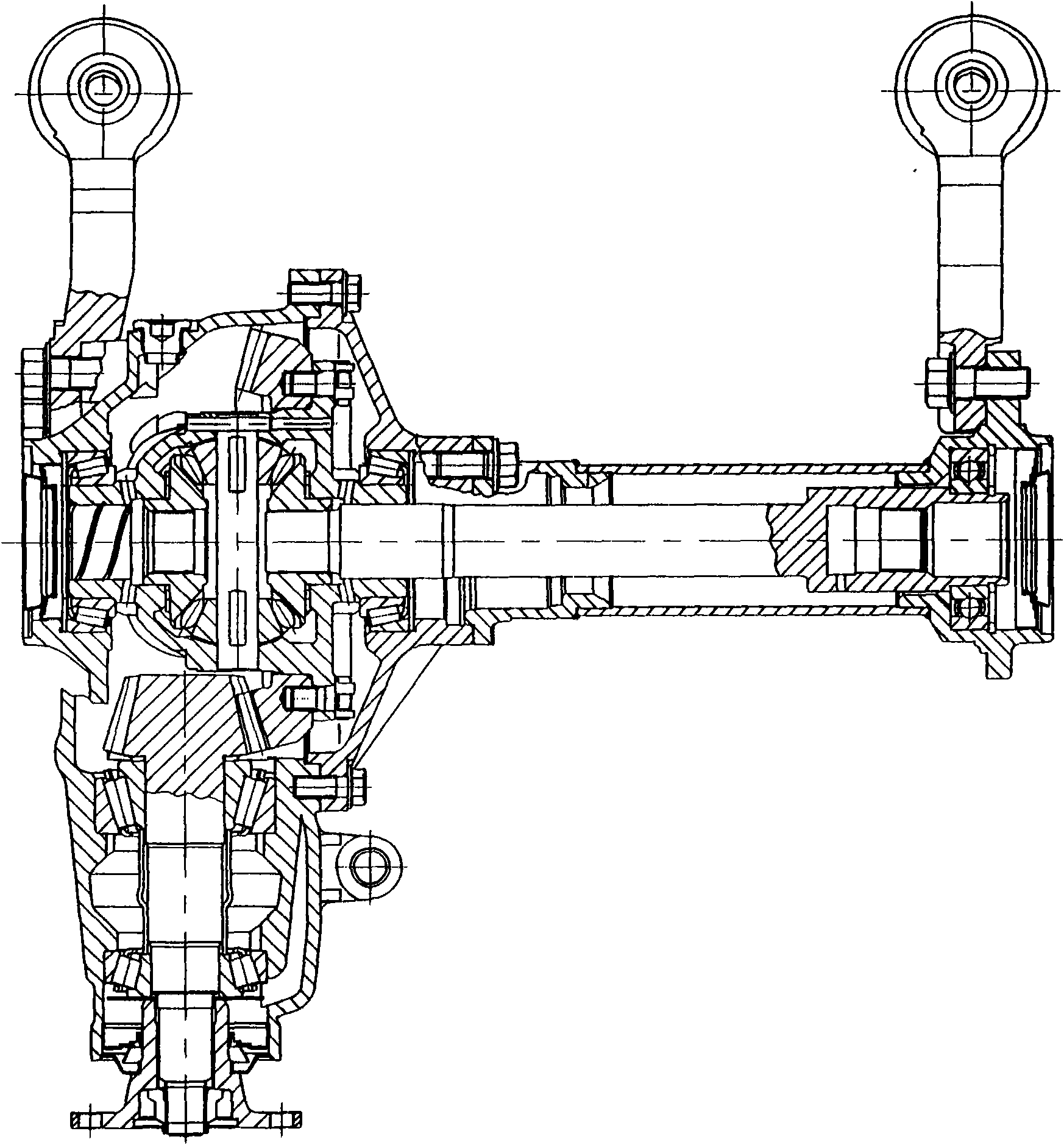

System and method for measuring and selecting differential bearing gasket of divided steering drive axle assembly

A technology for steering drive axles and differentials, which is applied in the direction of machine gear/transmission mechanism testing, instruments, measuring devices, etc., can solve the problem of improper selection of differential bearing pre-tightening torque adjustment washer value, damage to the surface accuracy of parts matching, Assembly quality control and production efficiency are difficult to meet the needs of the production of disconnected steering drive axle assemblies and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

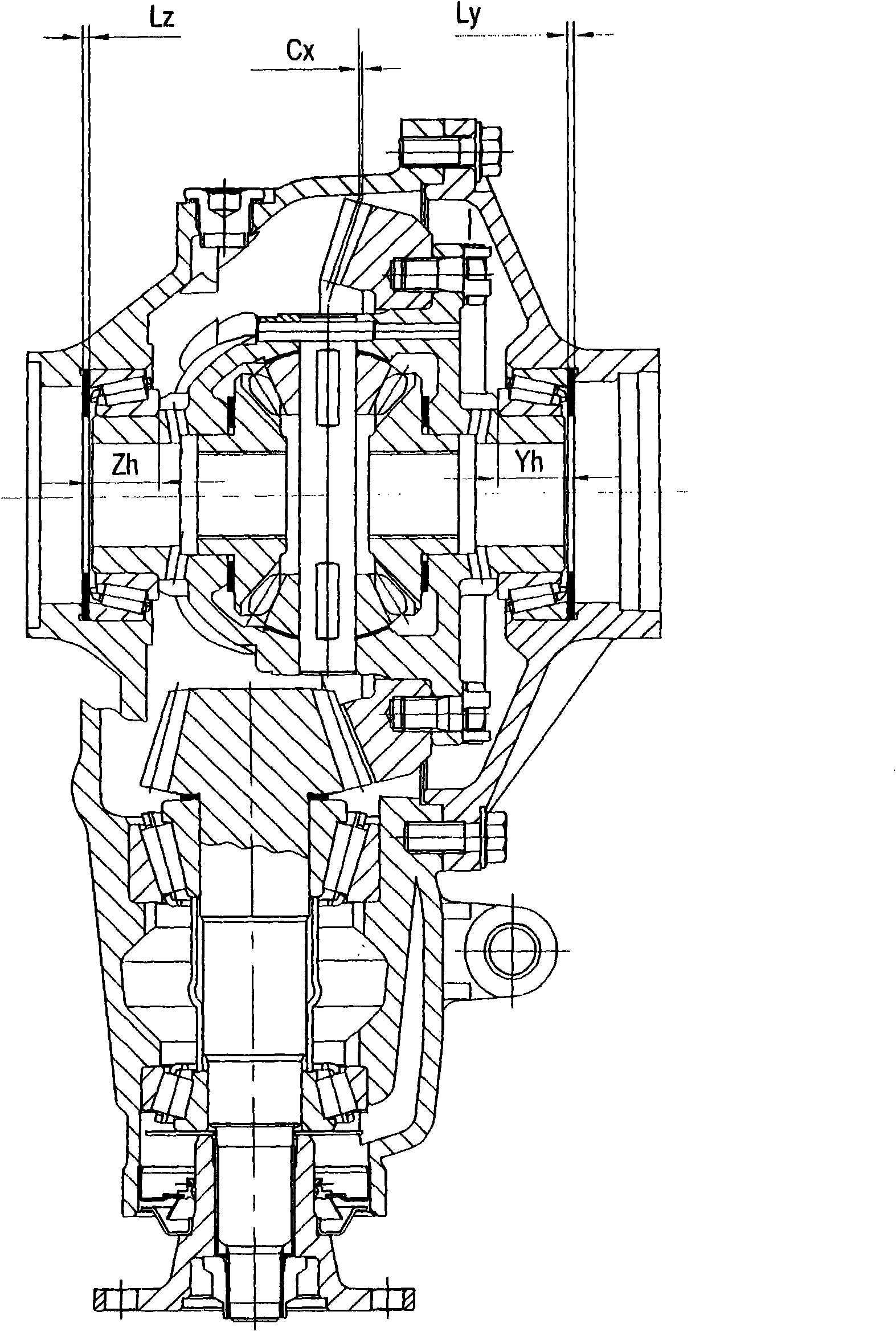

[0016] The test and selection system for the differential bearing washer of the disconnected steering drive axle assembly includes an electronic control unit and a test platform. Such as Figure 4 As shown, the detection platform 1 is provided with the positioning and locking mechanism of the main reducer housing placed vertically with the axis of the driven gear, the driving mechanism for driving the rotation of the driving gear, the lower guide driving mechanism of the lower reference measuring block 2, and the positioning and locking mechanism of the upper reference measuring block 3. Scale adjustable pressure head 78 and its upper guide drive mechanism. The positioning and locking mechanism of the main reducer housing is a planar three-point support mechanism surrounding the main reducer housing, and each support point is composed of an adjustable support block 10 fixed on the upper end of the support body 11 laterally. In the upper reference measuring block 3, the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com