System and method for measuring and selecting driving gear mounting distance adjusting shim of divided steering drive axle assembly

A steering drive axle and driving gear technology, which is applied in the direction of machine gear/transmission mechanism testing, measuring devices, and electrical devices, and can solve the problem of assembly quality control and production efficiency that are difficult to meet the production needs of disconnected steering drive axle assemblies , low production efficiency, difficulty in assembling key components to meet product technical requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

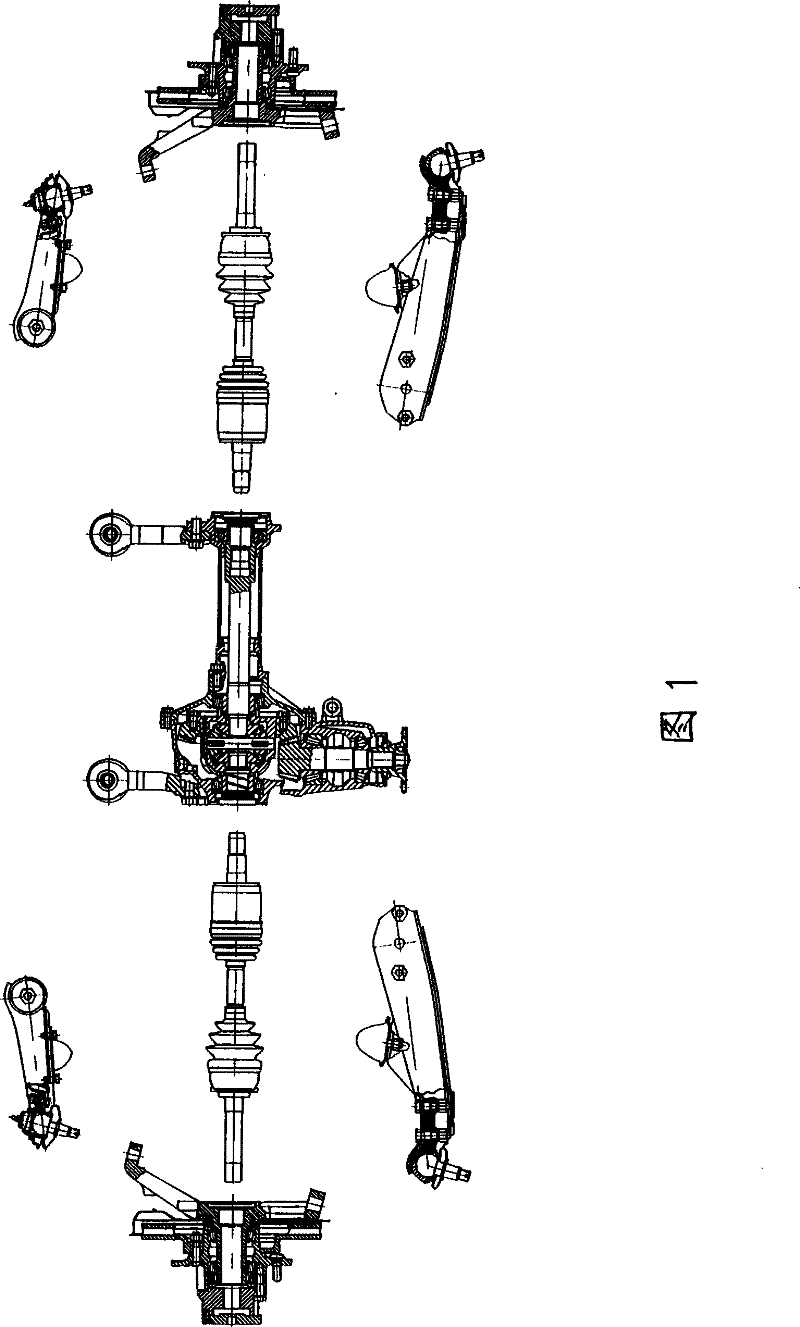

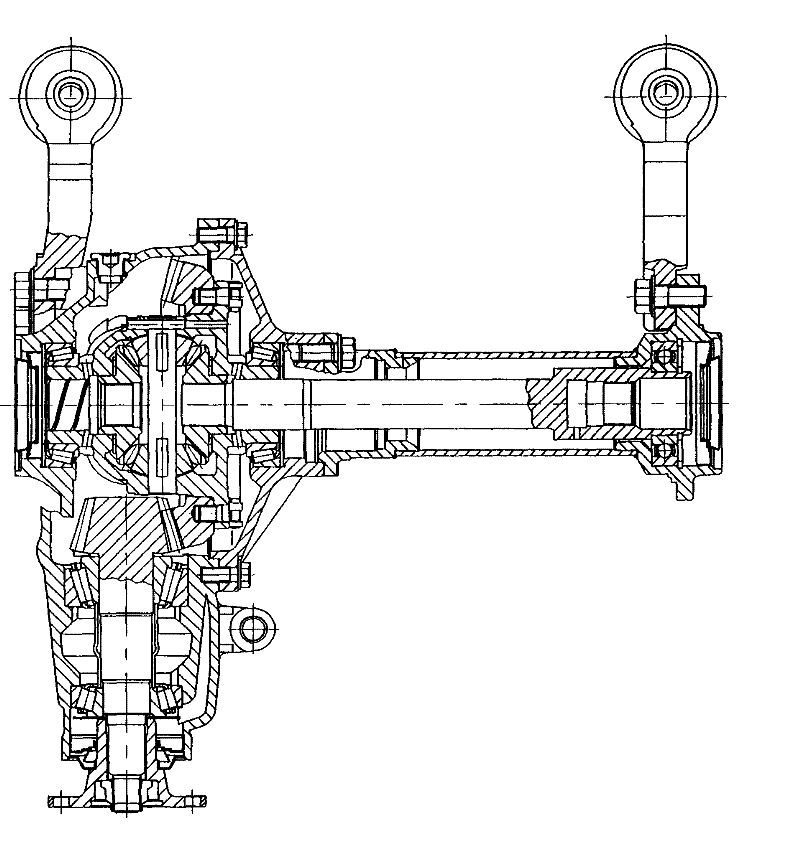

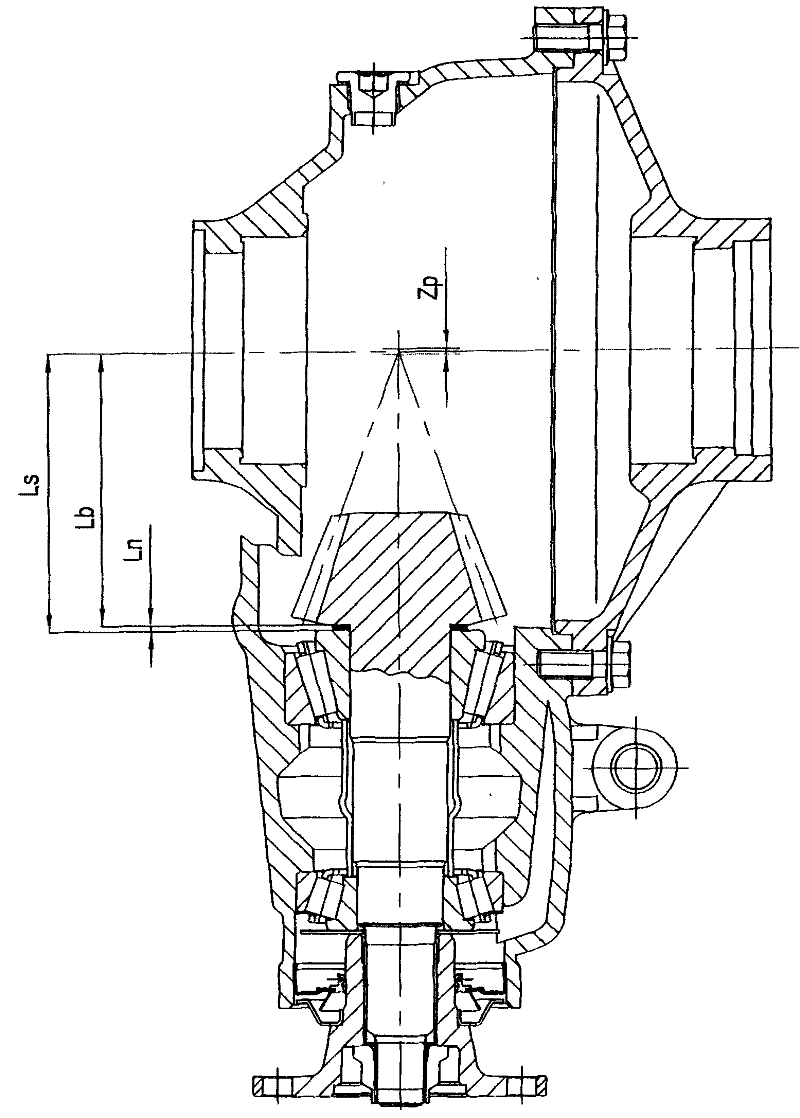

[0014] The disconnected steering drive axle assembly driving gear mounting distance adjusting gasket measuring and selecting method disclosed in the patent application of the present invention is based on Figure 4 The measurement and selection system shown is realized. The disconnected steering drive axle assembly driving gear mounting distance adjusting gasket measuring and selecting system includes an electronic control unit, a testing platform and a calibration block. The detection platform 1 is provided with left and right support frames 3 that horizontally support the reference measurement axis 2, and the upper elastic pressure rod 5 and the lower elastic pressure rod 6 are installed in the two support frames 3 to fix the reference measurement axis 2, and the displacement sensor 7 is inductively connected. It is dynamically arranged at the lower end of the lower elastic pressure rod 6, which constitutes the left and right displacement sensing devices that sense the up an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com