Drive gear installation moment and bearing pretension moment shim adjusting, measuring and selecting system and method

A technology of bearing preload and driving gear, which is used in machine gear/transmission mechanism testing, measuring devices, and electrical devices, etc., can solve unqualified products, low detection accuracy, and difficulty in assisting the assembly line of automobile drive axle assemblies, etc. To improve the measurement accuracy, avoid the interference of human factors, and reduce the measurement variation

Active Publication Date: 2010-12-01

LIAONING SG AUTOMOTIVE GRP CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the measurement selection of the driving gear installation distance adjusting gasket and the driving gear bearing pretightening torque adjusting gasket of the driving and passive gear pairs is still in the manual offline detection method, which involves too many human factors in the assembly operation. It often leads to the emergence of unqualified products, which must be reworked in time. The detection accuracy is low, and it is difficult to become a high-quality detection technology for auxiliary automobile drive axle assembly production lines.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

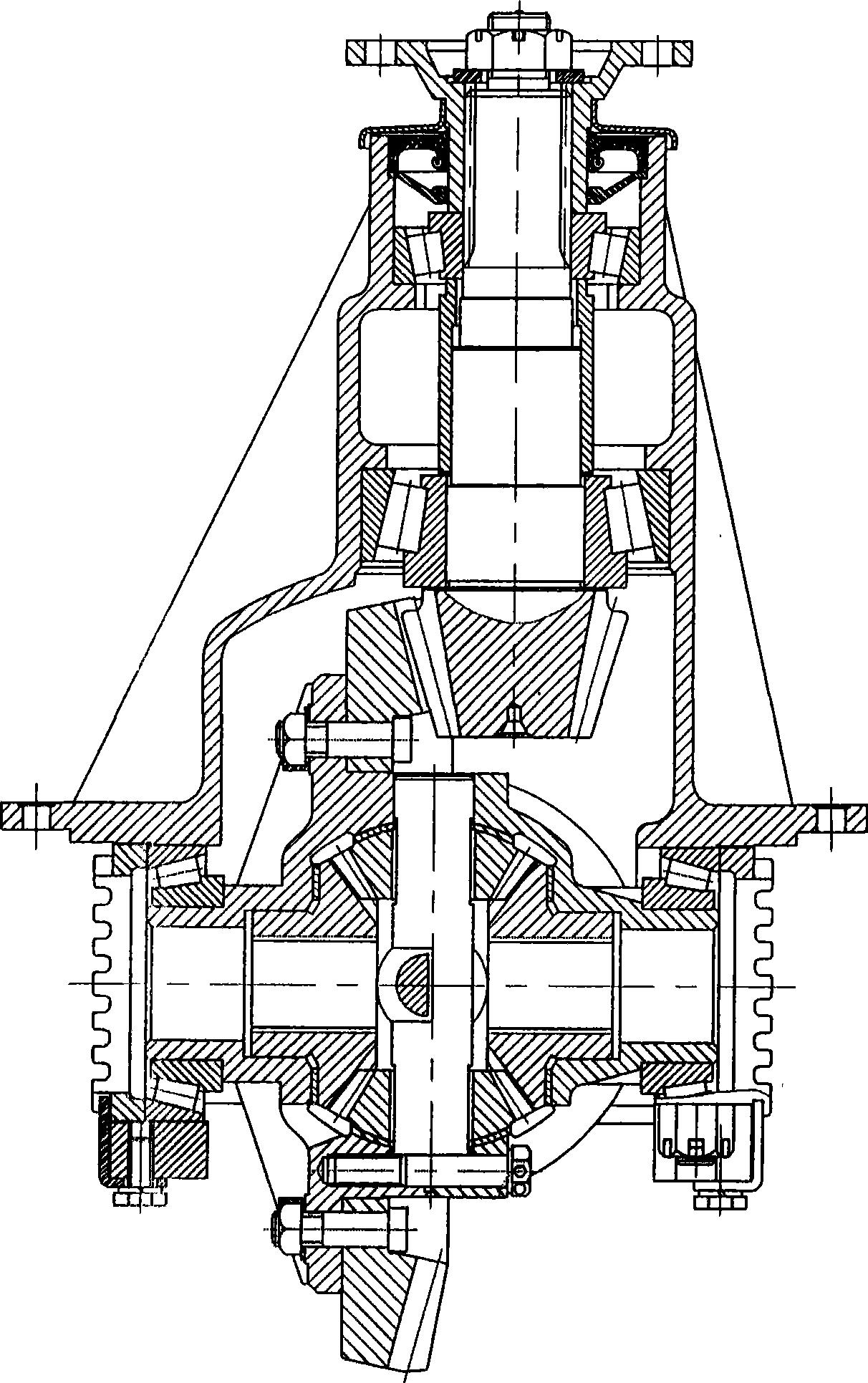

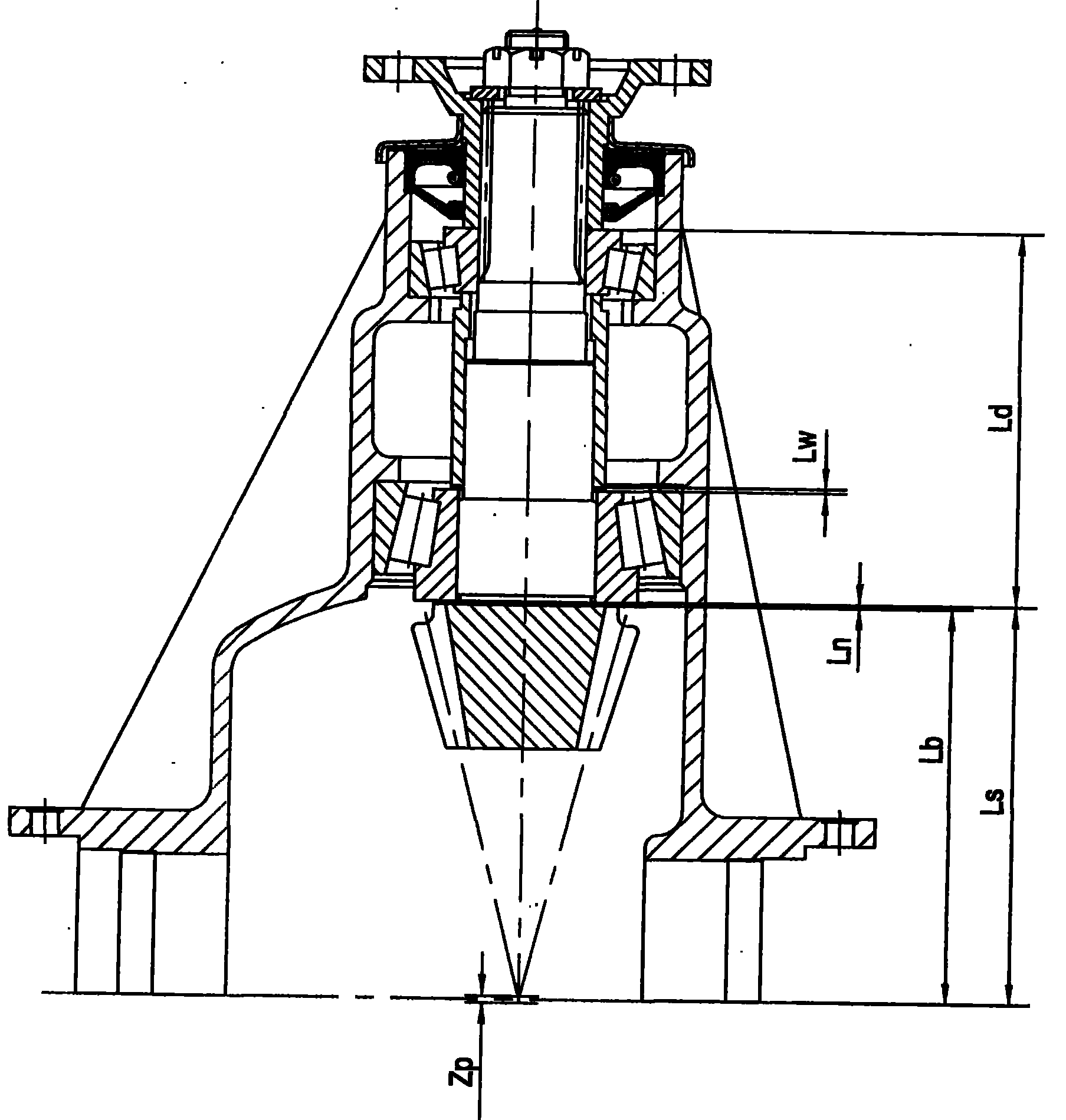

The invention relates to a measuring method and a measuring system of a driving gear mounting distance adjusting spacer and a driving gear bearing pre-tightening torque adjusting spacer of an integrated main reducer assembly. The measuring system comprises a first detection service position for completing axial data measurement of a combination piece of an internal bearing and an external bearingof the driving gear, and a shell of the main reducer, a second detection service position for completing data measurement of the combination piece of the internal bearing and the external bearing of the driving gear, and a rigid distance sleeve and an electronic control system; an induction signal of a displacement sensor at the first detection service position is converted to obtain a value of the axial data measurement of the combination piece of the internal bearing and the external bearing of the driving gear, and the shell of the main reducing gear; the induction signal of the displacement sensor at the second detection service position is converted to obtain a value of the axial data measurement of the combination piece of the internal bearing and the external bearing of the drivinggear and the rigid distance sleeve; and the desired spacer value is obtained by computing with a mathematical model program. The technical scheme helps eliminate interference of human factors and improve measurement precision.

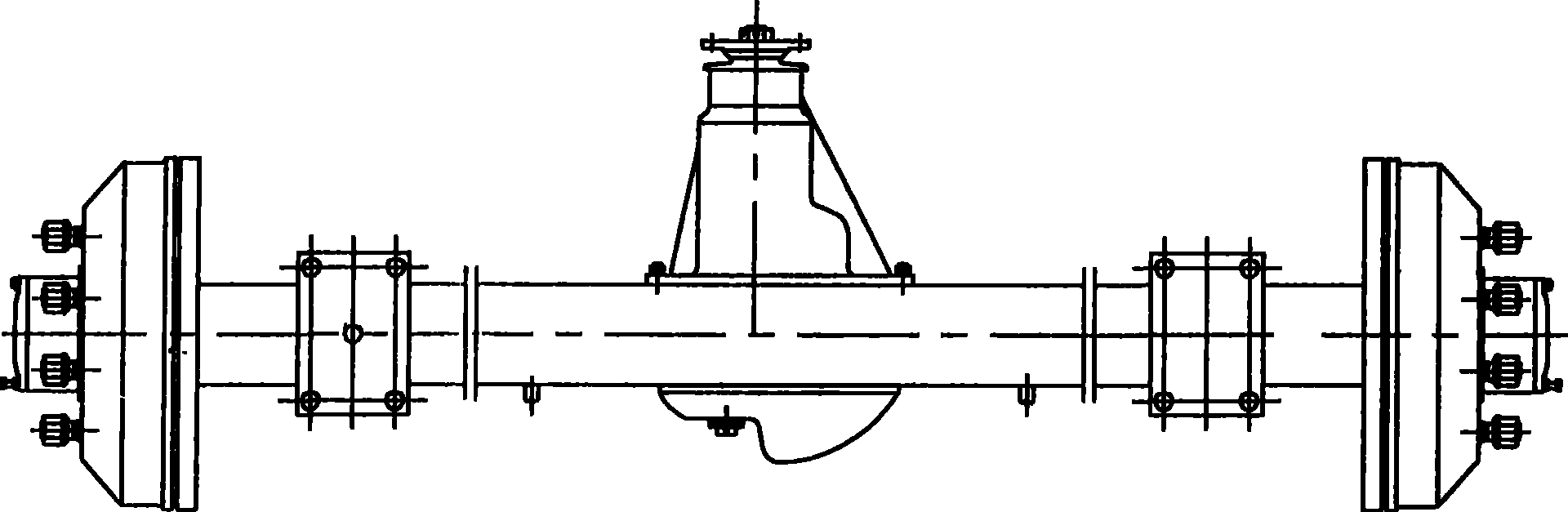

Description

The system and method for measuring and selecting the installation distance of the driving gear and the adjusting gasket of the bearing pretightening torque technical field The invention relates to a method for measuring and selecting the driving gear installation distance adjusting pad and the driving gear bearing pretightening torque adjusting pad in the integral final drive assembly, which is the core component of the automobile drive axle assembly, and to realize the measurement and selection The system device of the method. Background technique The main body of the automobile drive axle assembly includes the differential sub-assembly, the core components of the main reducer assembly, the axle shaft, the axle housing, the wheel hub, the brake drum and the brake and other main components. The assembly quality of main reducer assembly and differential sub-assembly is a key item that affects the comprehensive quality of automobile drive axle assembly products. At present...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01M13/02G01B7/02

Inventor 于刚张冯军

Owner LIAONING SG AUTOMOTIVE GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com