Patents

Literature

37 results about "Axial data" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

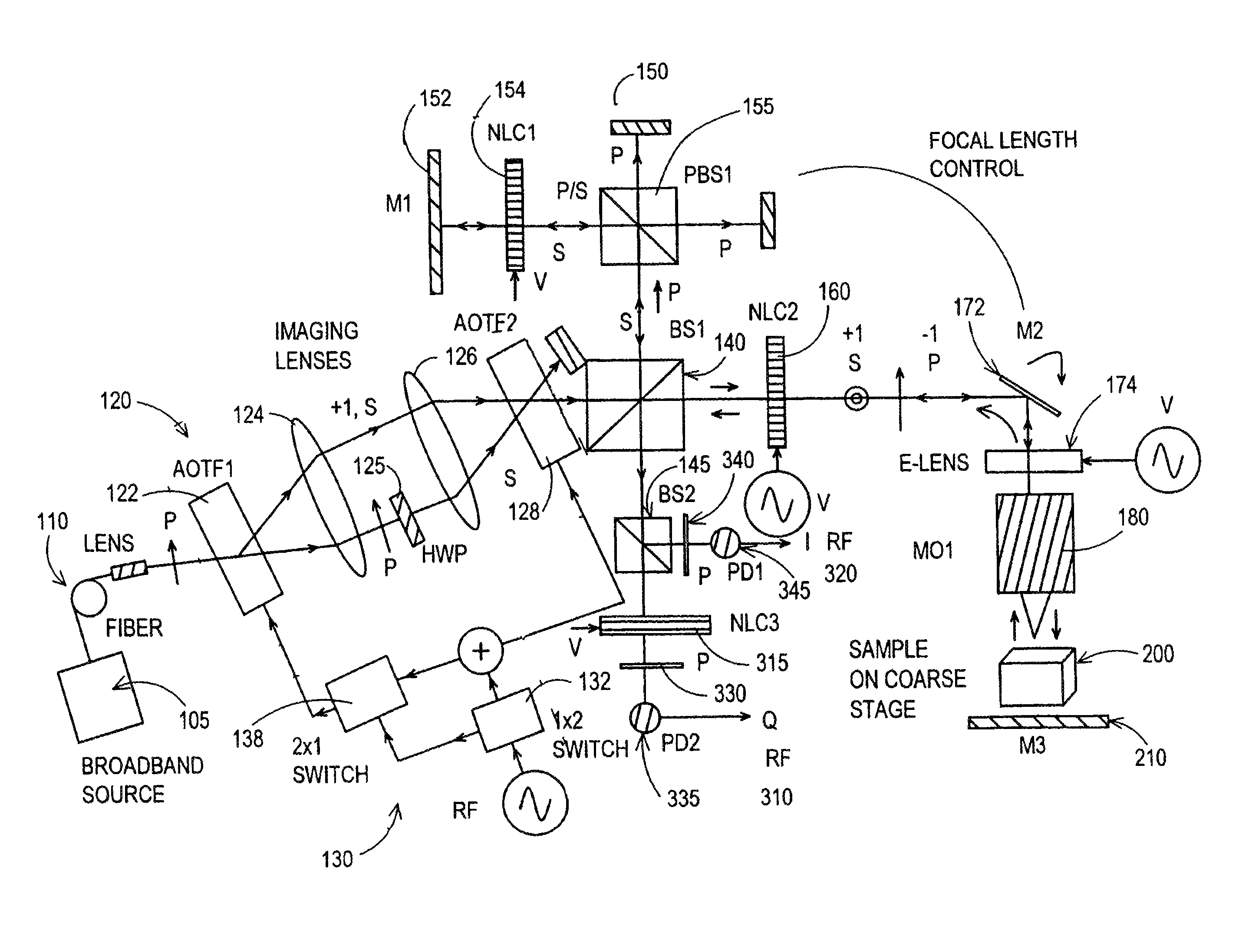

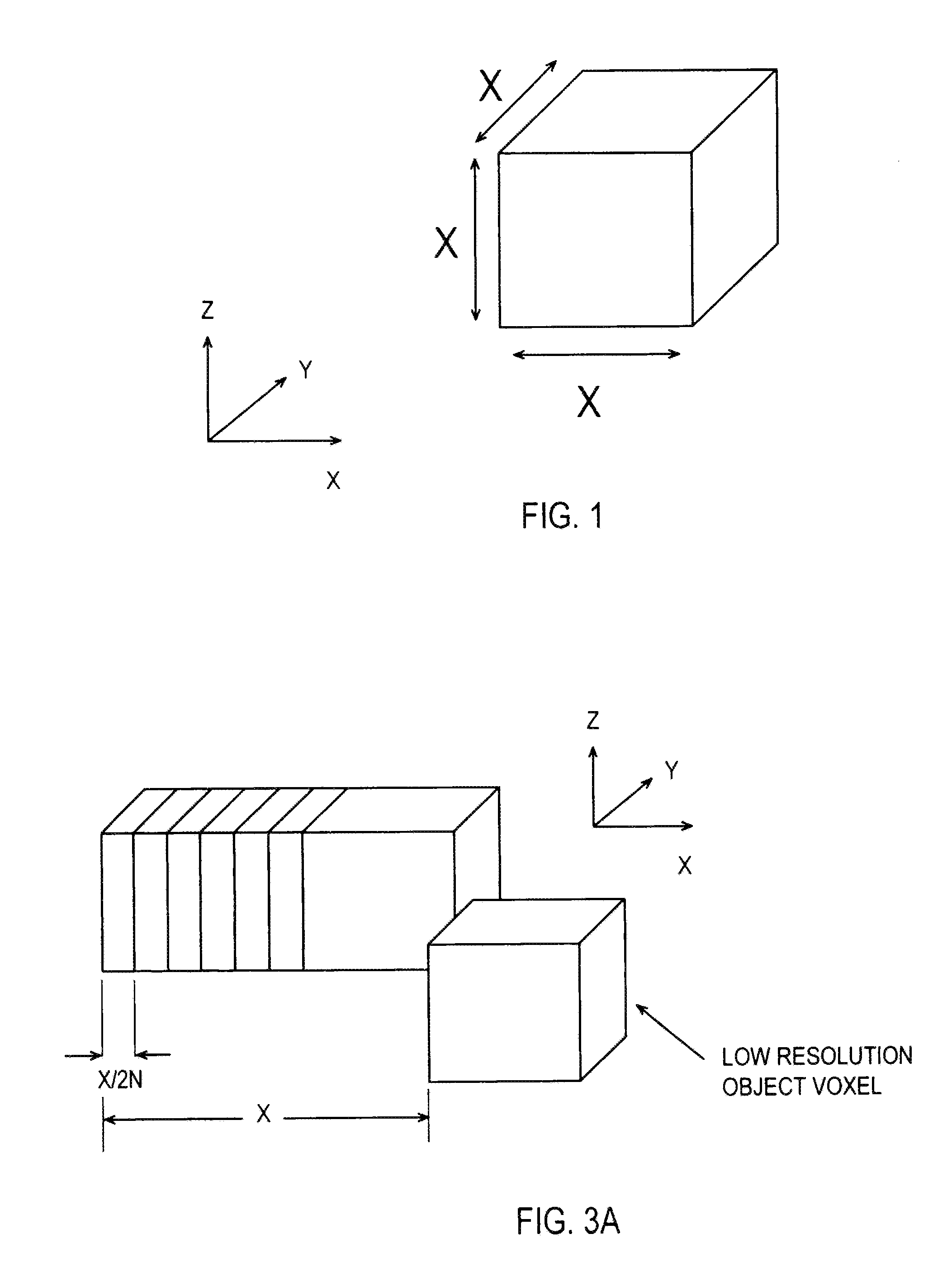

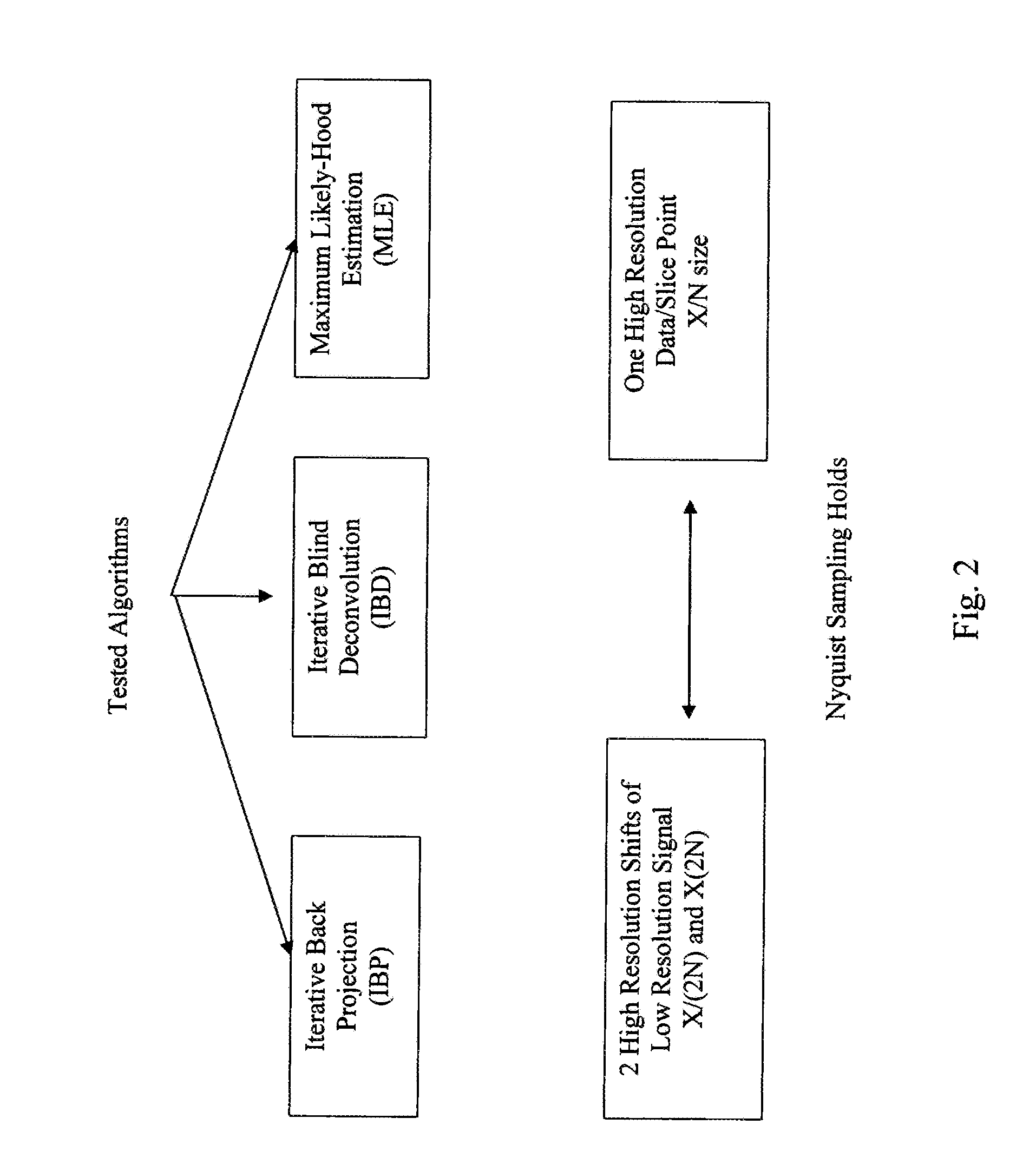

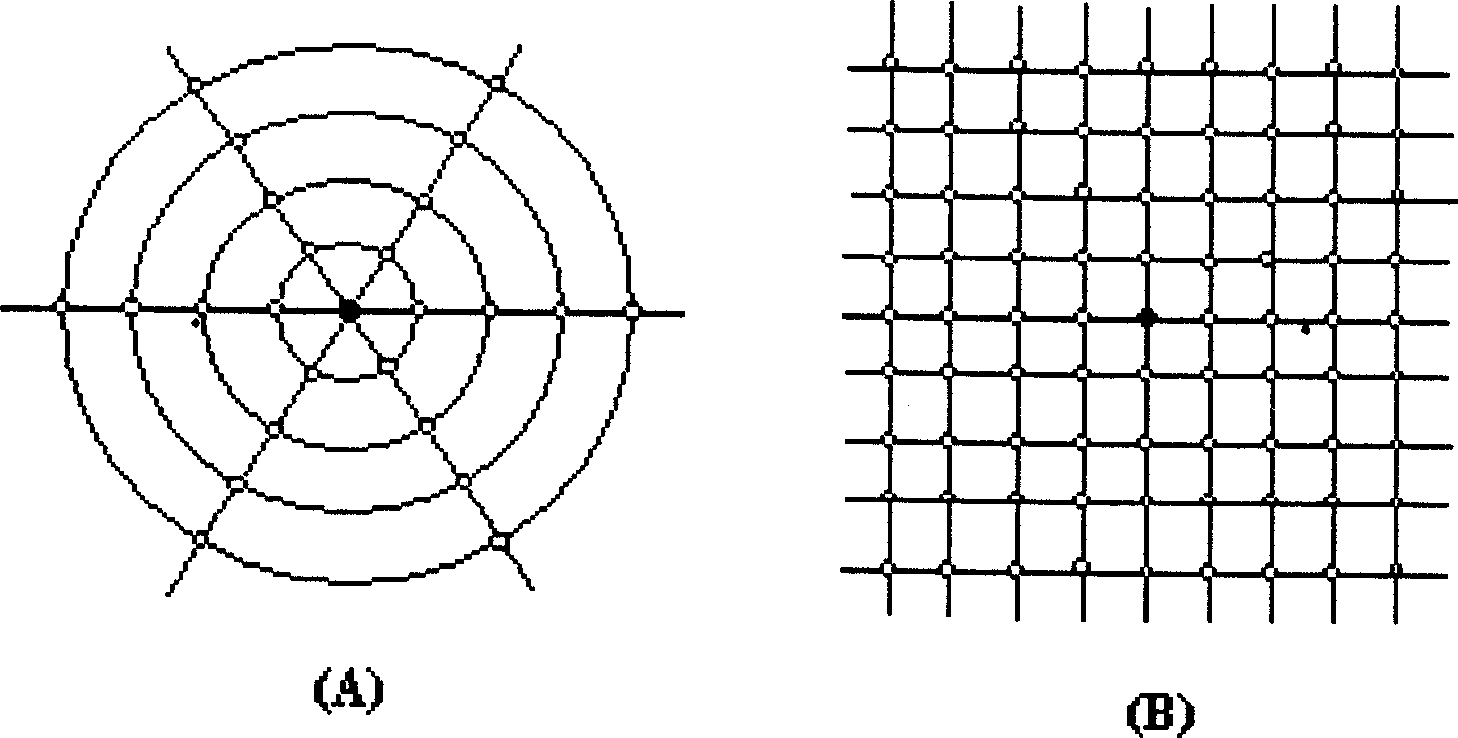

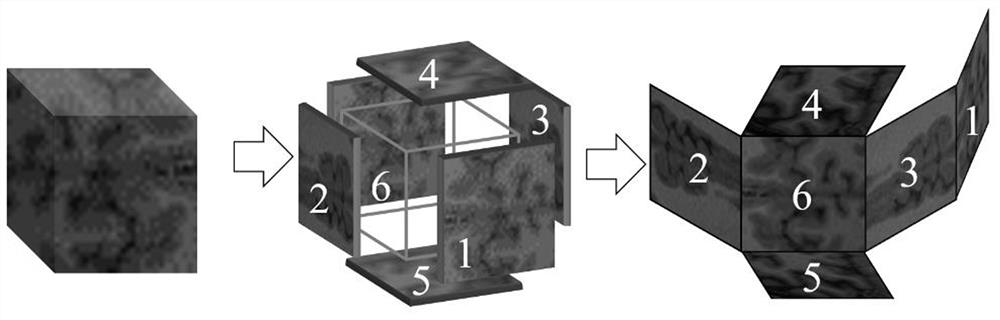

Methods and systems for realizing high resolution three-dimensional optical imaging

InactiveUS7978346B1Reduced dynamic rangeAccurate measurementUsing optical meansMicroscopesData setTest object

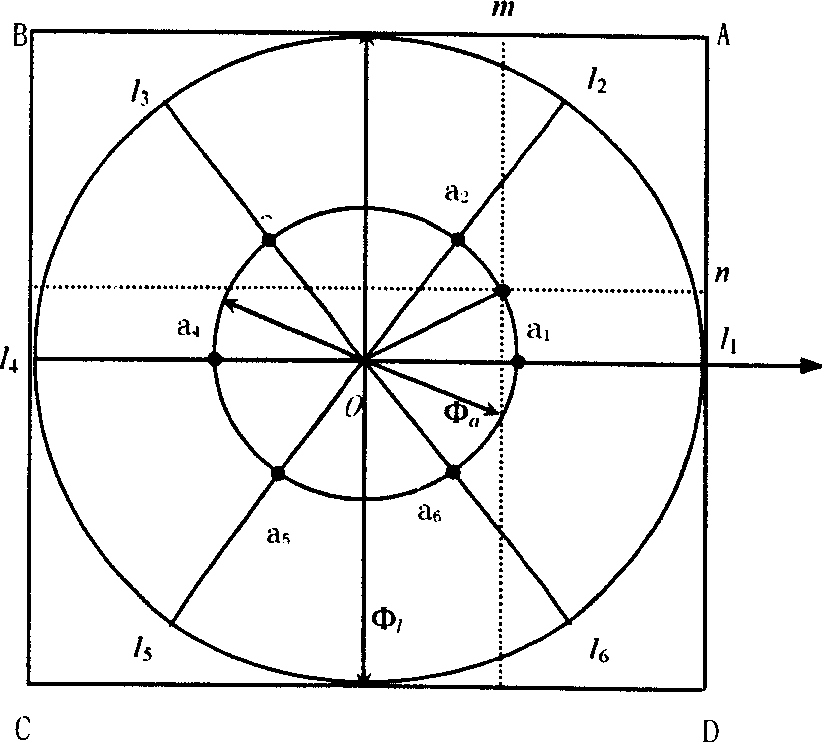

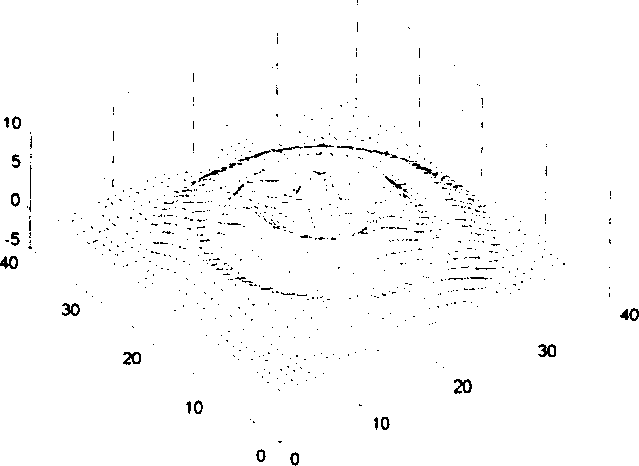

Methods and systems for realizing high resolution three-dimensional (3-D) optical imaging using diffraction limited low resolution optical signals. Using axial shift-based signal processing via computer based computation algorithm, three sets of high resolution optical data are determined along the axial (or light beam propagation) direction using low resolution axial data. The three sets of low resolution data are generated by illuminating the 3-D object under observation along its three independent and orthogonal look directions (i.e., x, y, and z) or by physically rotating the object by 90 degrees and also flipping the object by 90 degrees. The three sets of high resolution axial data is combined using a unique mathematical function to interpolate a 3-D image of the test object that is of much higher resolution than the diffraction limited direct measurement 3-D resolution. Confocal microscopy or optical coherence tomography (OCT) are example methods to obtain the axial scan data sets.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

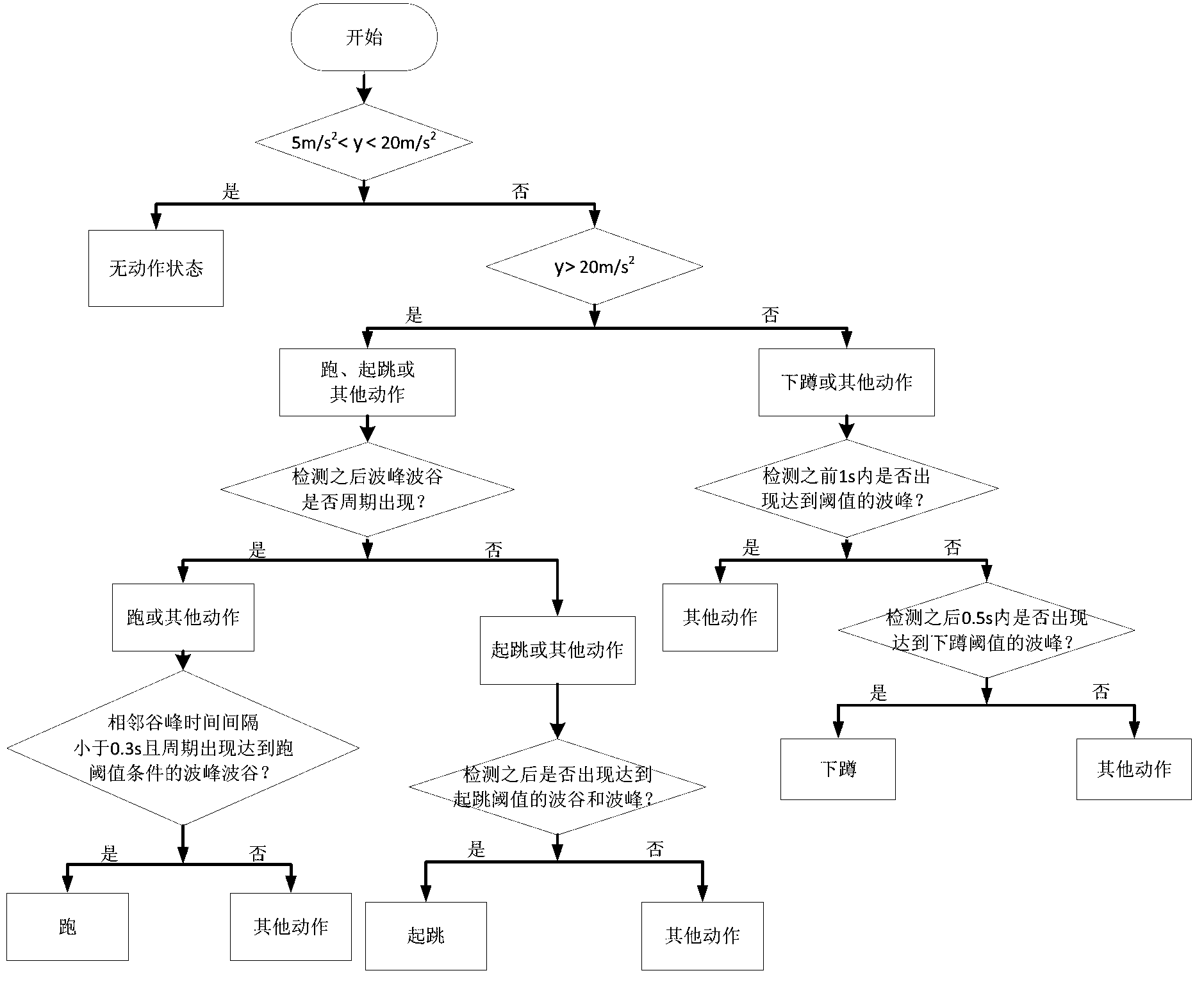

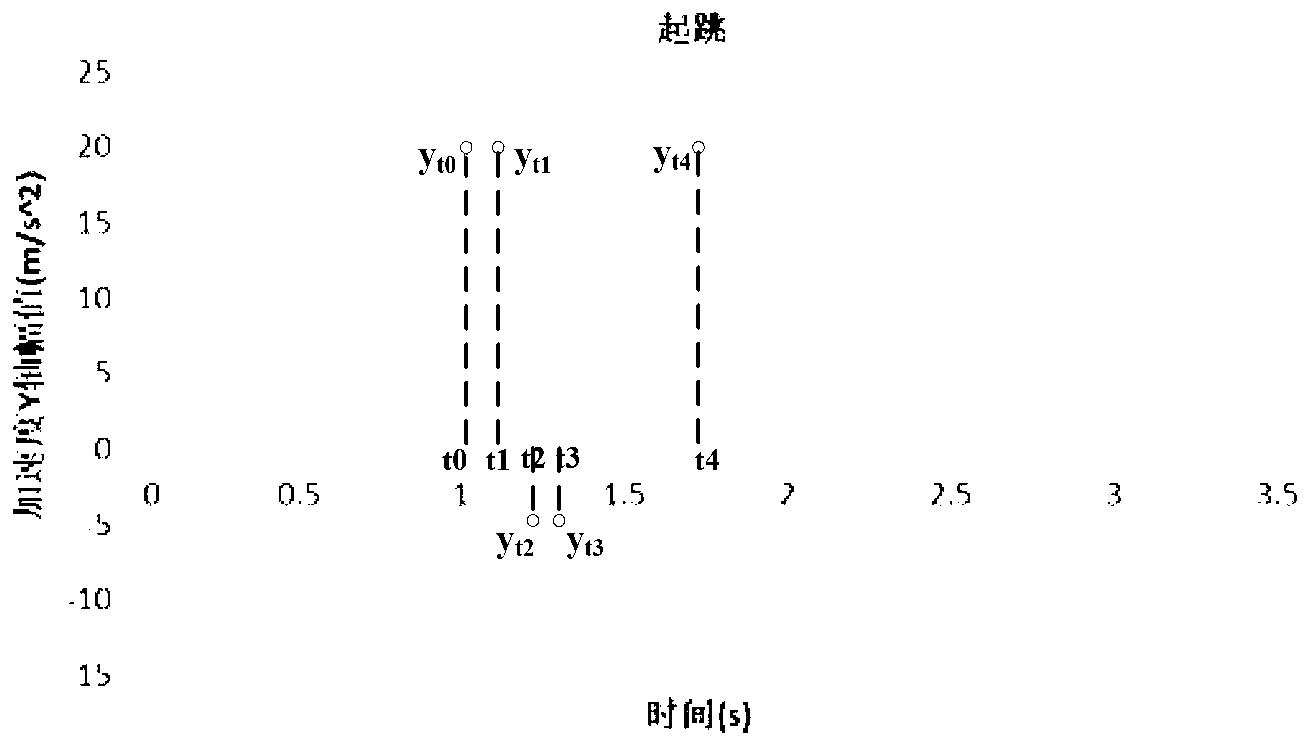

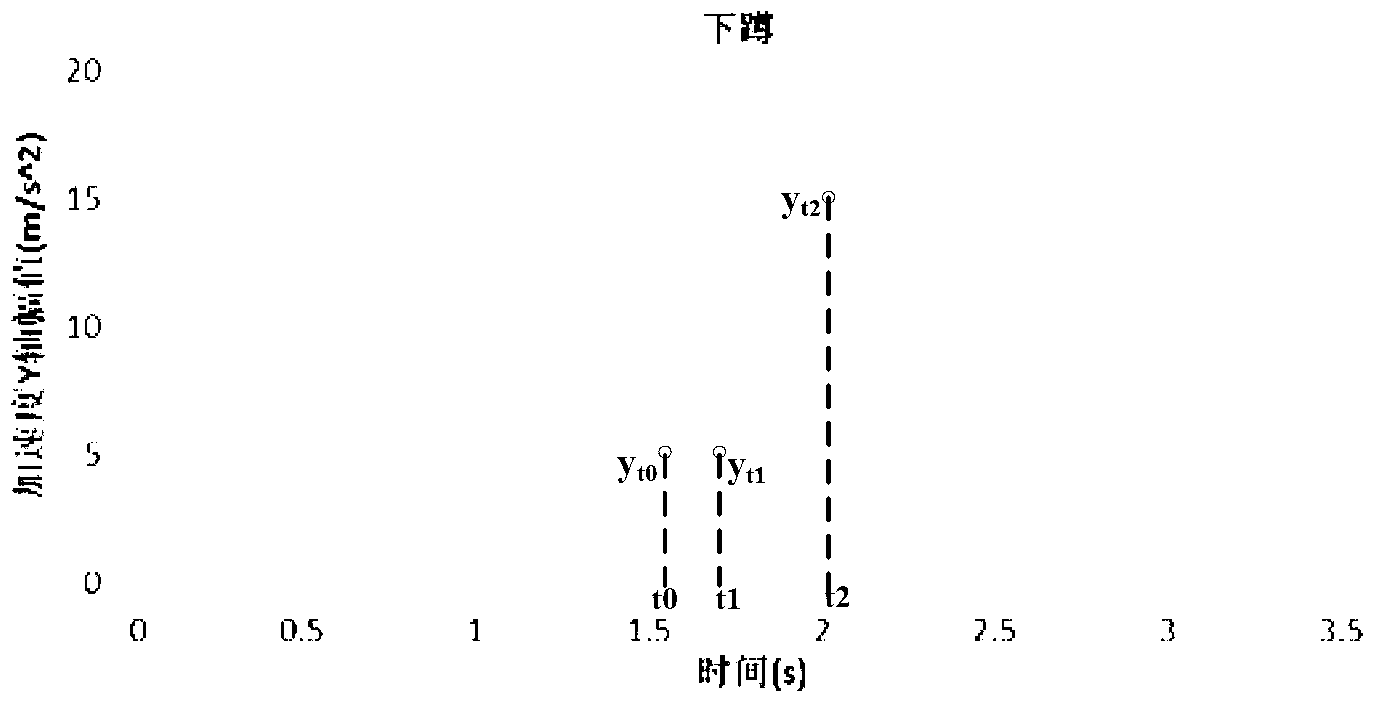

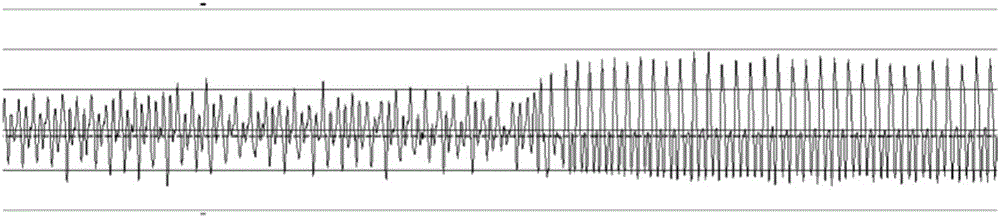

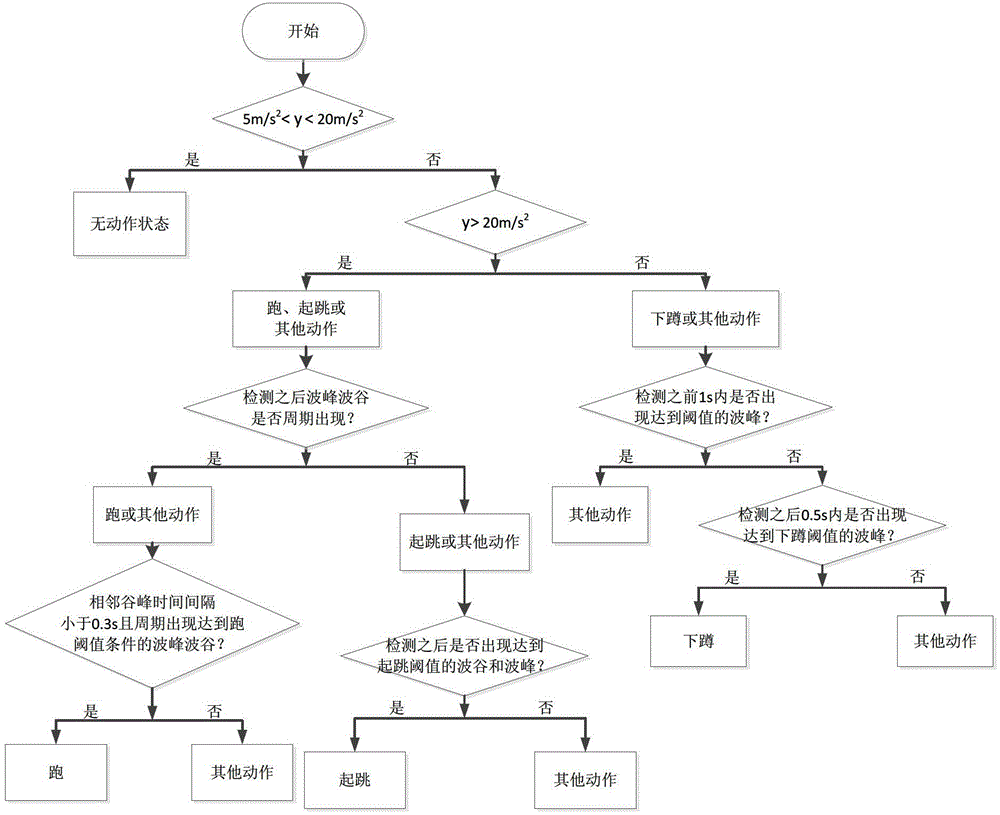

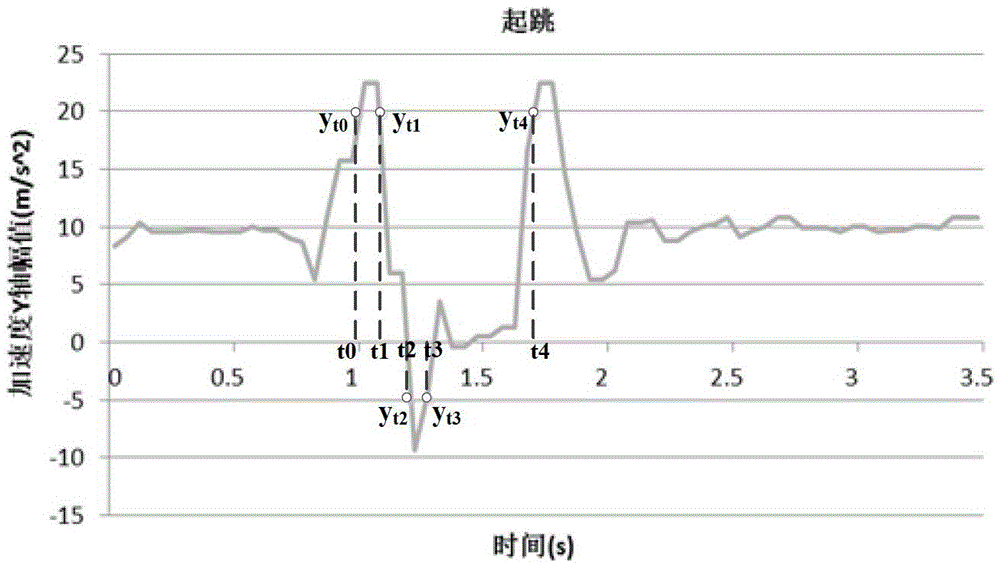

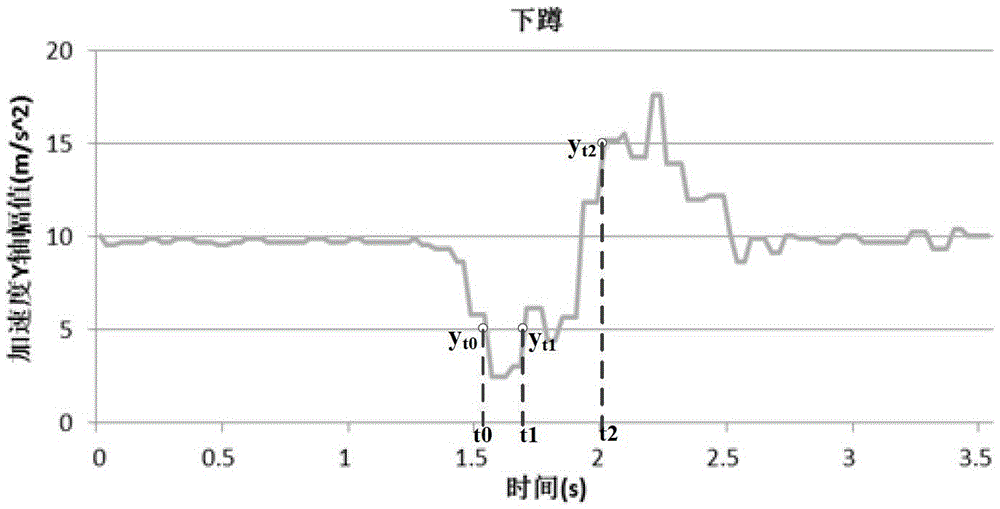

Movement behavior recognition method based on axial acceleration sensor

InactiveCN103310192AReduce computational overheadEasy to analyzeCharacter and pattern recognitionExercise behaviorData information

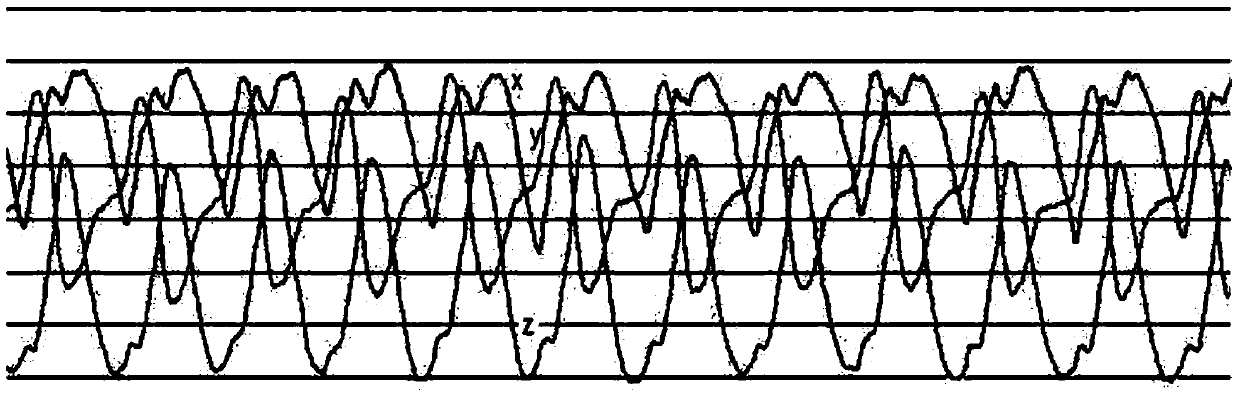

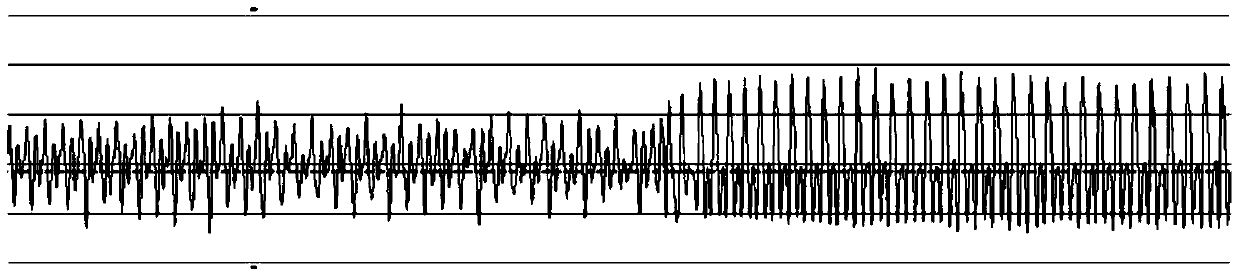

The invention provides a movement behavior recognition method based on an axial acceleration sensor. According to the existing movement behavior recognition method based on multiple sensors or multiple axial sensors, data of multiple sensors or data of multiple axial sensors are required to combine, accordingly high computing cost is resulted, cost is increased, and meanwhile, real-time recognition is reduced. The method includes adopting axial data information of one acceleration sensor, extracting human body features, particularly three feature values of threshold in front of the peak of wave, threshold in front of the trough of wave, and time interval between the peak of wave and the trough of wave, in movement by waveforms formed through comparing the axial data information acquired by the sensor, and realizing accurate recognition of movement behaviors like squat, jump, run and the like. By the aid of the method, high recognition accuracy is achieved, computing cost is reduced, real-time recognition is improved, and cost is reduced.

Owner:NANJING UNIV OF POSTS & TELECOMM

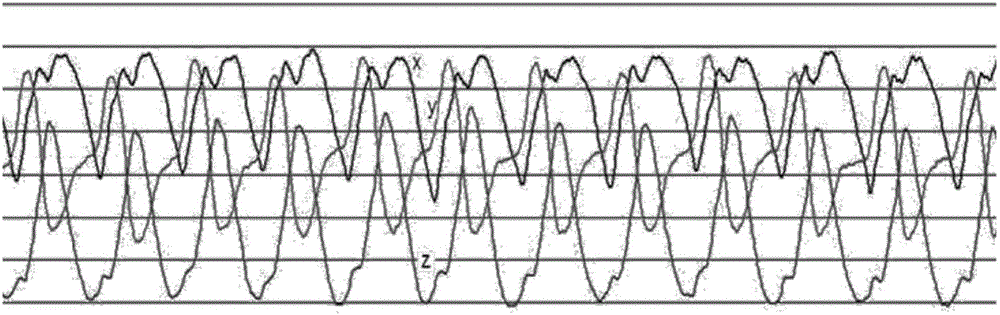

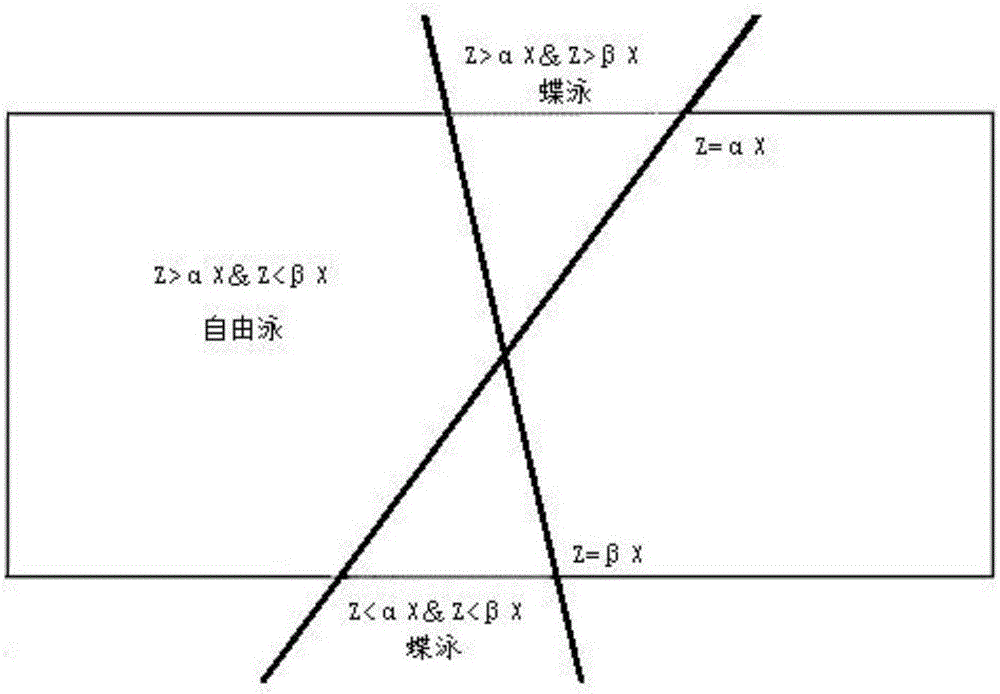

Method for monitoring swimming

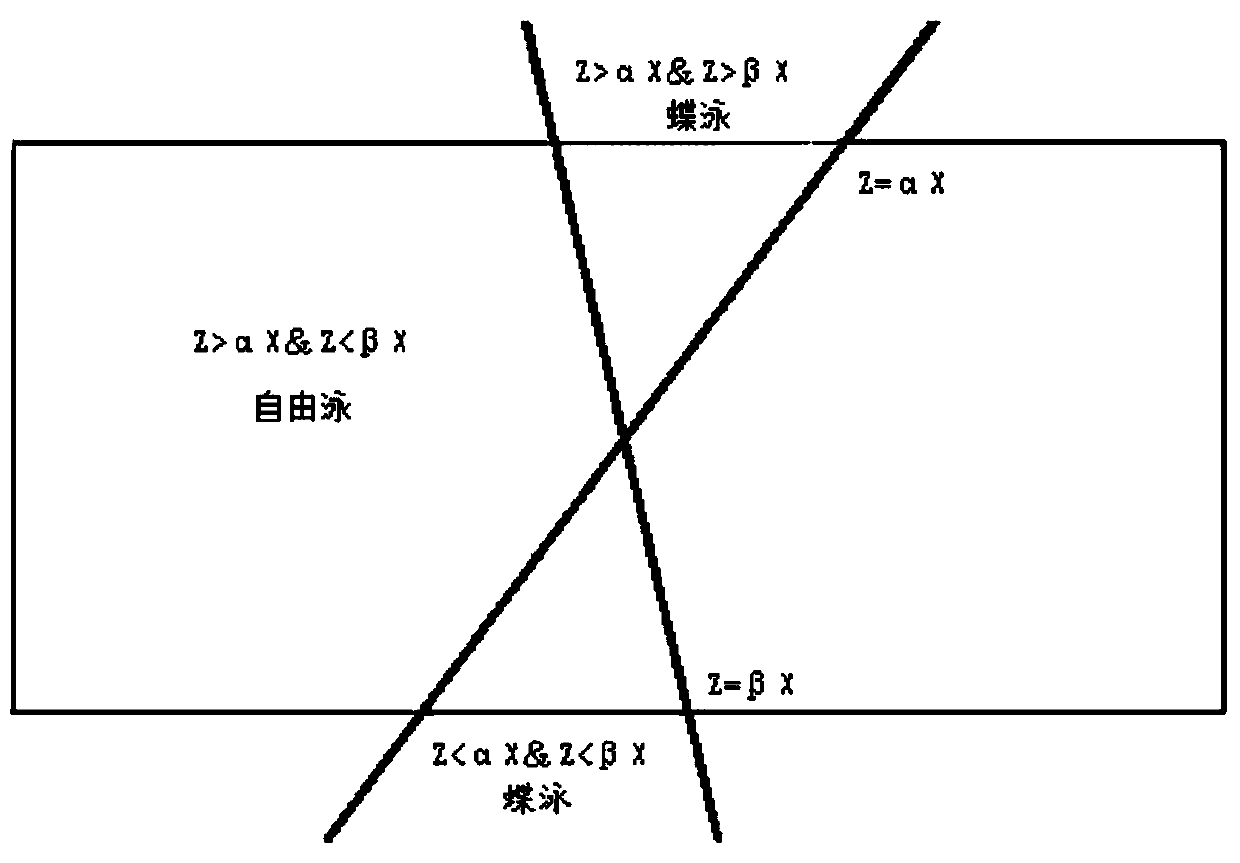

InactiveCN106334307AAddressing a less studied problem in swim monitoringSolve less-studied problemsNavigation instrumentsSport apparatusAxial dataRisk stroke

The invention belongs to the field of sport monitoring and relates to a method for monitoring swimming. A gravity sensor of a device of the invention determines different swimming strokes through average value filtering of X, Y and Z axial data, in combination with a judgment formula, and according to the shape and the numerical value of data result. Compared with the prior art, the gaps in swimming detection of sport detection devices are filled up; wearable devices can be addedincluded to add the function of present wearable devices; the method has great market economic value and prospect.

Owner:SKY LIGHT ELECTRONICS SHENZHEN

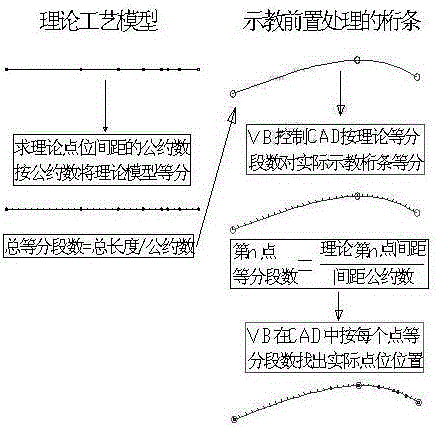

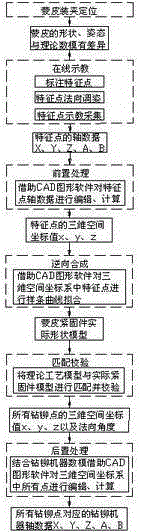

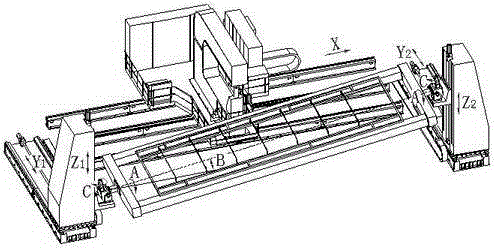

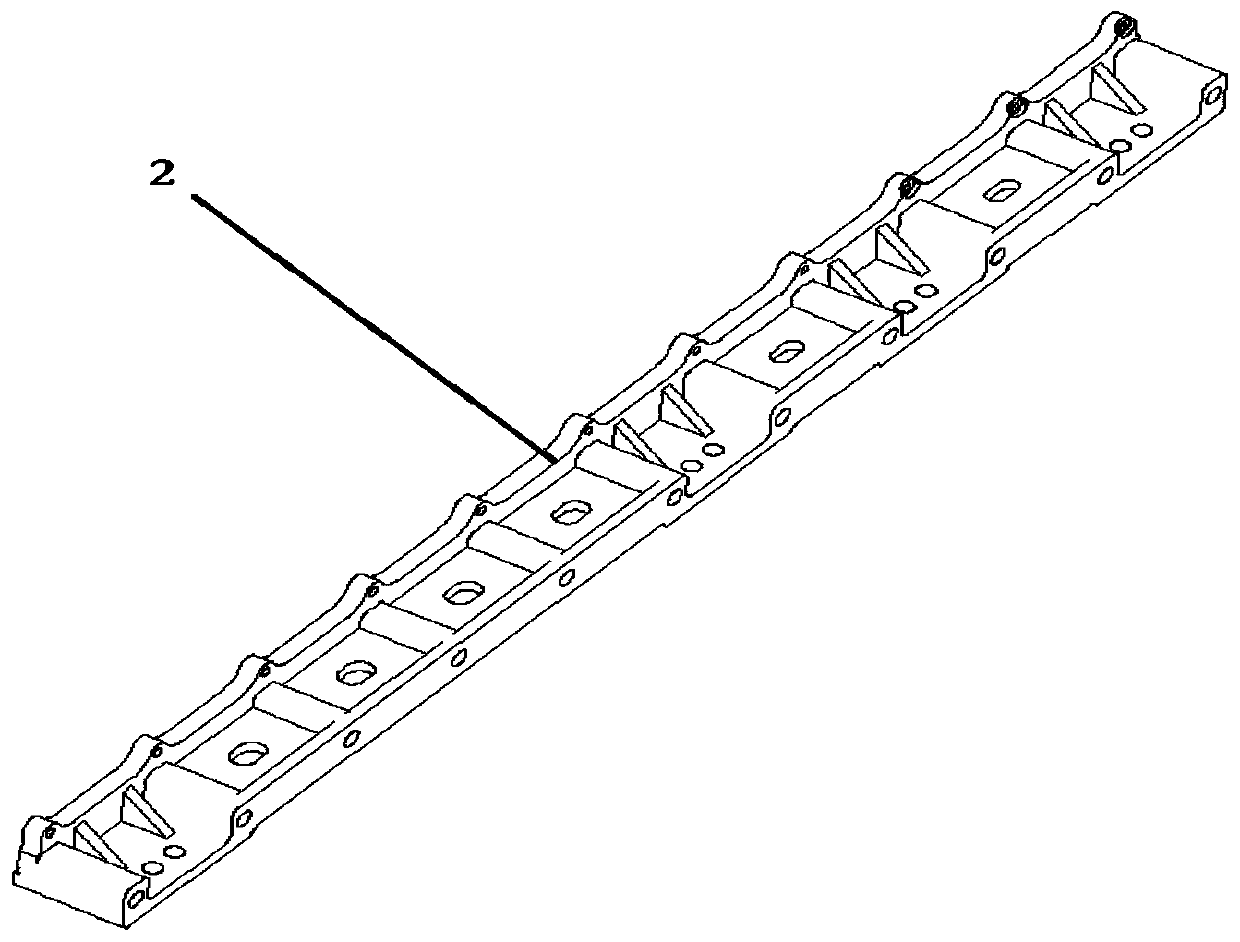

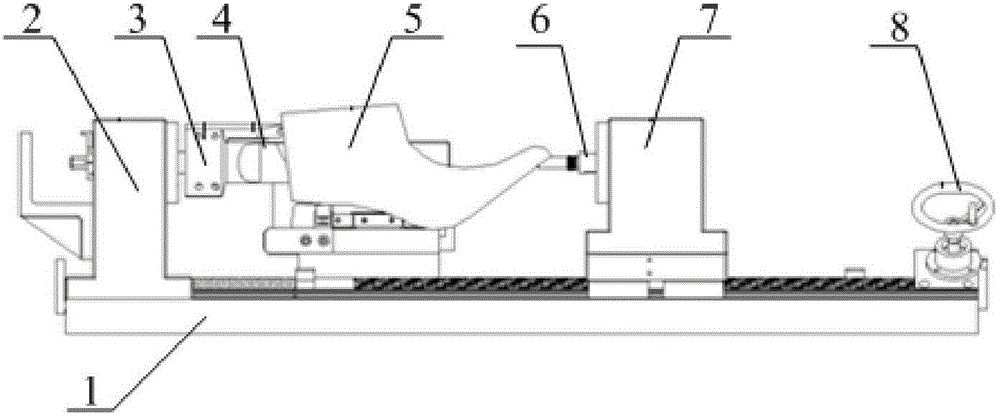

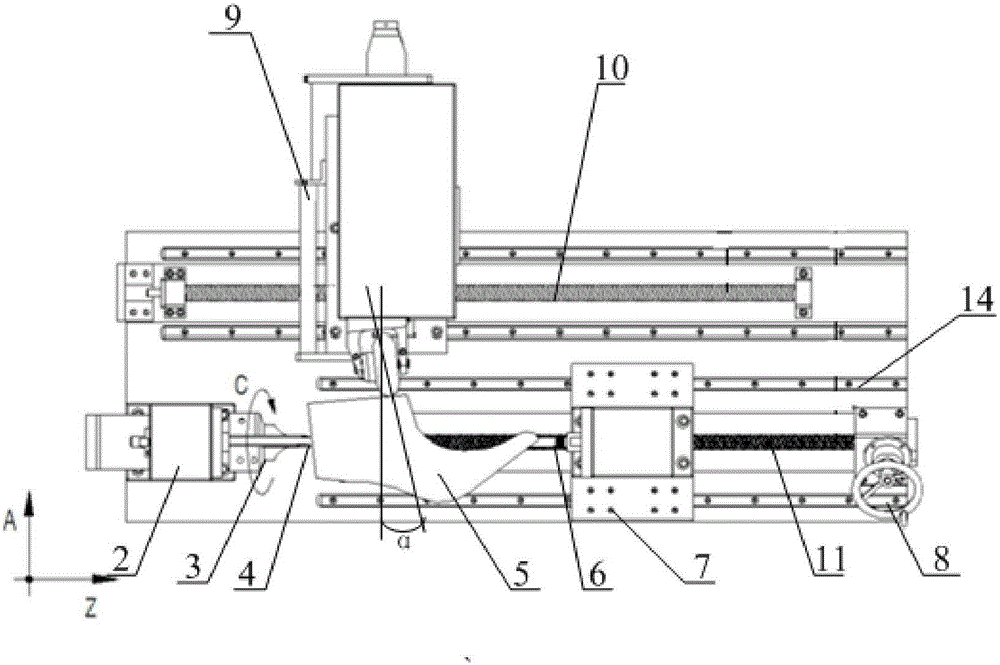

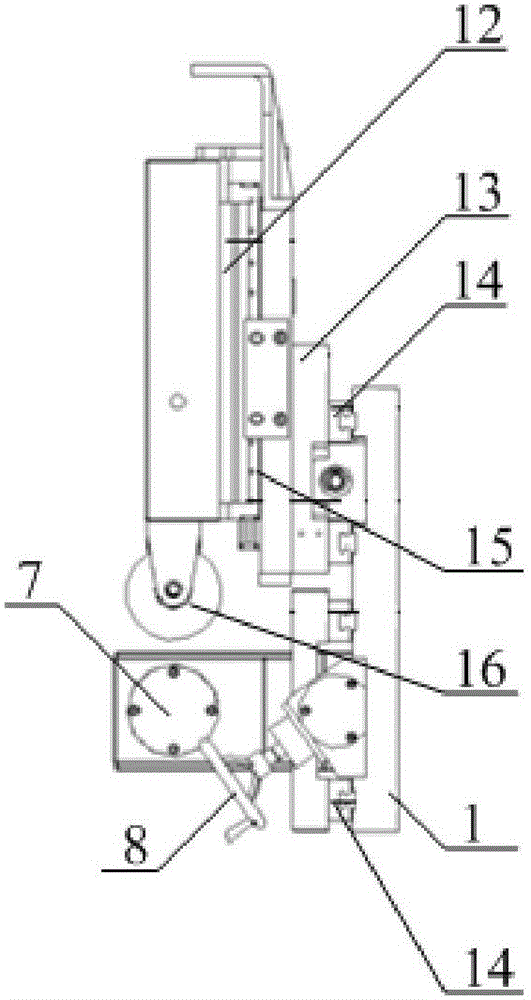

Programming method for airplane thin-wall curved surface skin automatic drilling and riveting

The invention discloses a programming method for airplane thin-wall curved surface skin automatic drilling and riveting. The programming method comprises preprocessing: after an airplane skin is clamped and positioned, normal adjustment and teaching acquisition are performed on the characteristic points of the deformed skin online via multiple sensors arranged on a drilling and riveting bracket, the axial data of the teaching characteristic points are preprocessed into three-dimensional space coordinate system coordinate values, and curve graphic fitting is performed on the three-dimensional space coordinate point positions of the characteristic points by means of CAD; reverse synthesis: a shape model of an actual deformed skin fastener is synthesized, and then the space coordinate system coordinate values and the normal angles of all the drilling and riveting points are extracted via matching through combination of the technological model of the skin fastener; and post-processing: the axial data of an automatic drilling and riveting machine corresponding to all the drilling and riveting pints are calculated according to the structural geometrical size of the drilling and riveting bracket so that the real deformed skin automatic drilling and riveting processing program can be obtained. Programming is performed on the actually deformed airplane skin so that the assembling effect of the airplane thin-wall curved surface skin which is liable to deform can be greatly enhanced.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

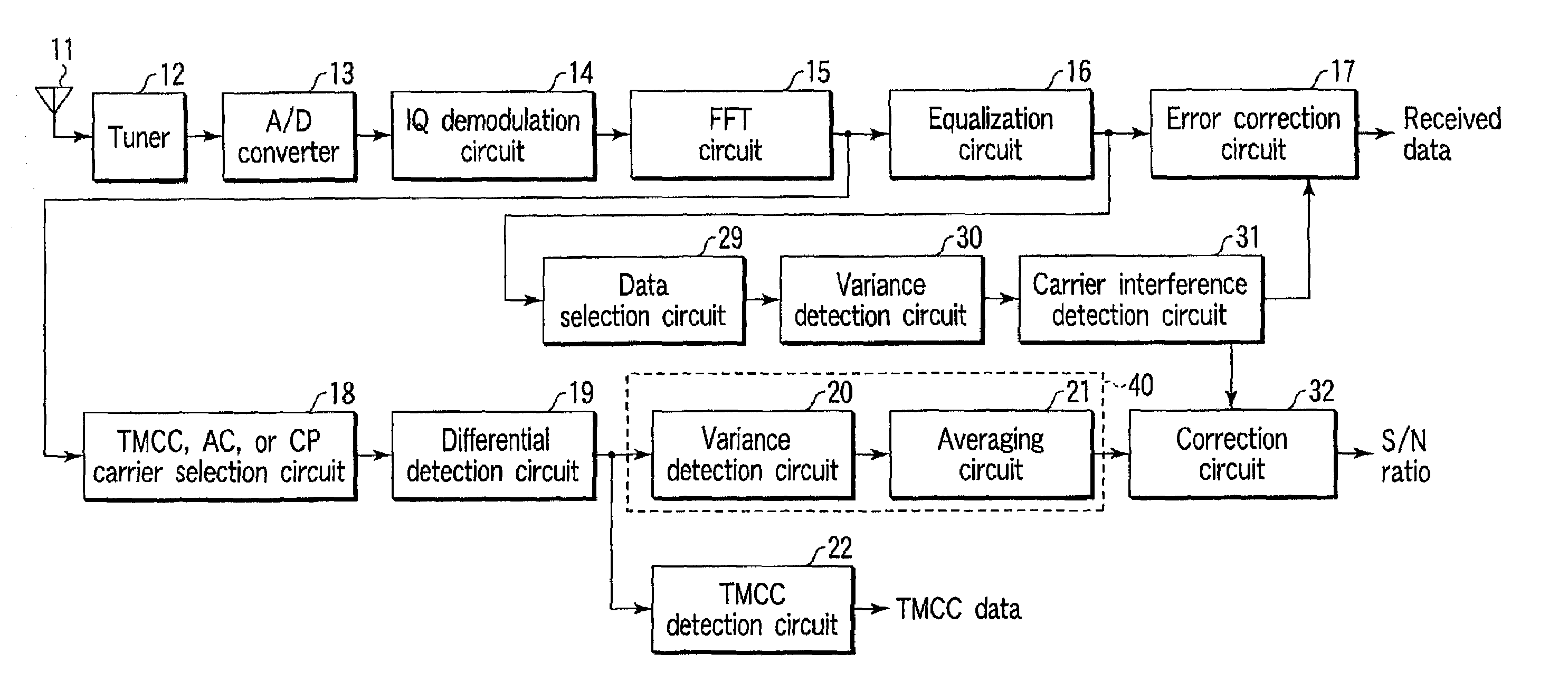

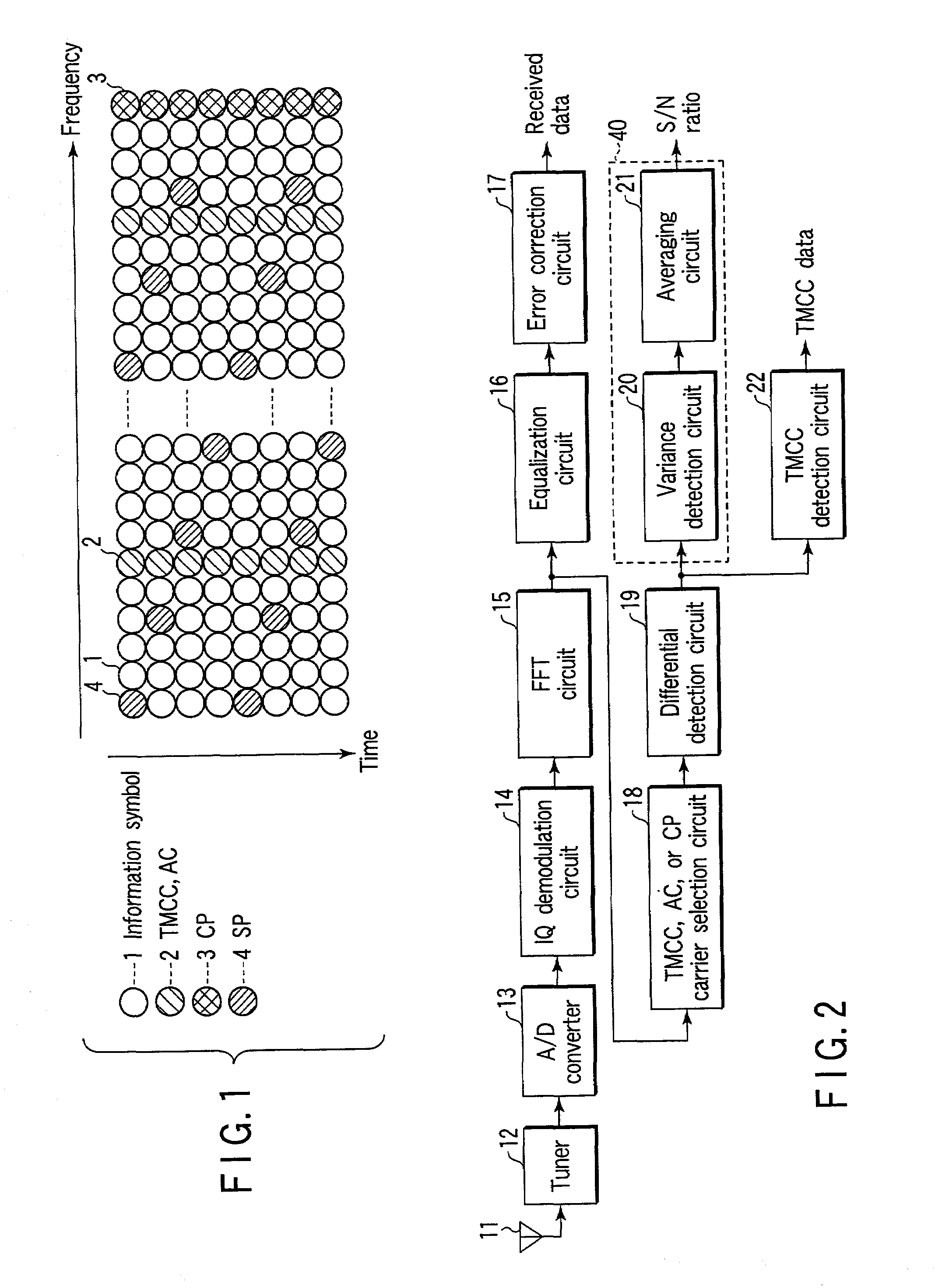

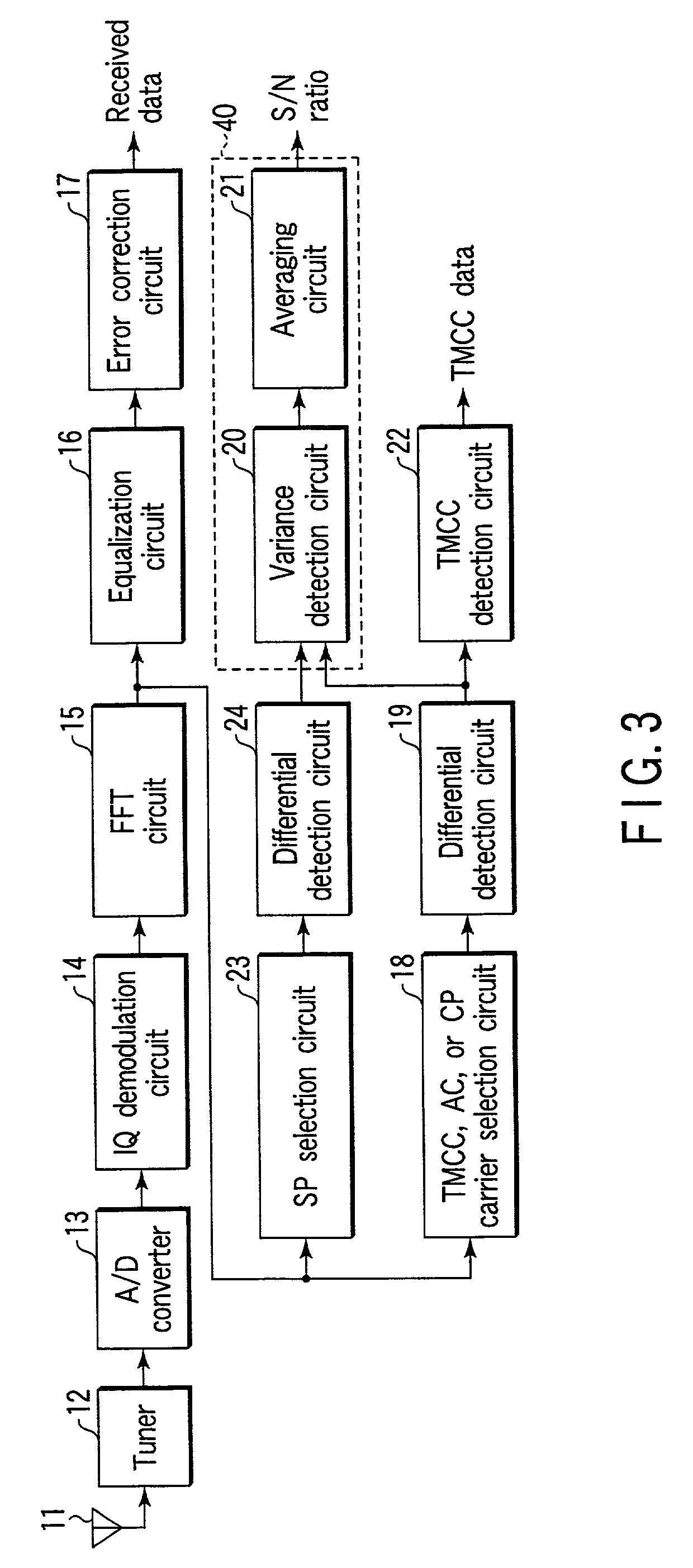

OFDM transmit signal receiver

ActiveUS6983027B2Degree of modulation to degradeEasy to detectError detection/prevention using signal quality detectorMulti-frequency code systemsInformation transmissionCarrier signal

A demodulation circuit receives an OFDM transmit signal containing an information carrier, an additive-information transmission carrier, and a reception-synchronization pilot signal to convert these carriers and signal into frequency-axial data. The information carrier transmits information data. The additive-information transmission carrier and the reception-synchronization pilot signal have a lower multi-valued modulation degree than the information carrier. A differential detection circuit conducts detection processing by using a detection-subject symbol of a plurality of symbols indicated at a predetermined interval in the same frequency range and a symbol ahead that detection-subject symbol by a predetermined time in either one output of the additive-information transmission carrier and the reception-synchronization pilot signal output from the demodulation circuit. A first S / N ratio generating circuit generates an S / N ratio based on a detection output provided from the differential detection circuit. The S / N ratio indicates the reception quality of the OFDM transmit signal.

Owner:KK TOSHIBA

Continuous system based spray irrigation uniformity measurement method

InactiveCN1908615AHigh measurement accuracyMovable spraying apparatusStructural/machines measurementAxial dataMeasurement precision

The disclosed sprinkling even level detection method based on continuous system comprises: interpolating the detected data to obtain the unknown rainfall depth; when arranging the rainfall cylinders radially, taking two times cubic-spline interpolation to the radial and axial data for the unknown rainfall depth; or when arranging the cylinder as mesh structure, taking two times cubic-spline interpolation to the horizontal and vertical data for the unknown rainfall depth. This invention improves detection precision in theory.

Owner:NORTHWEST A & F UNIV

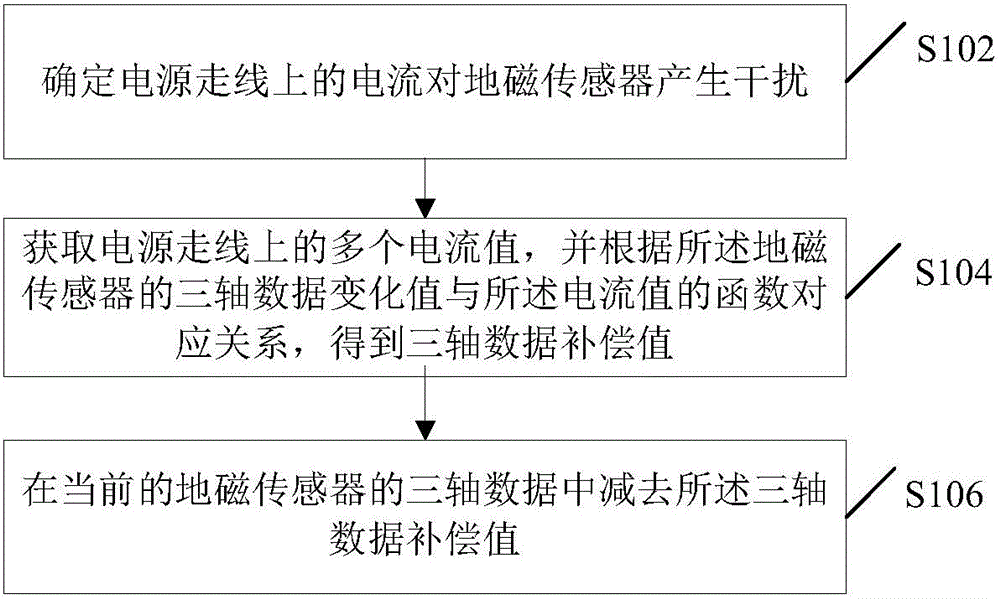

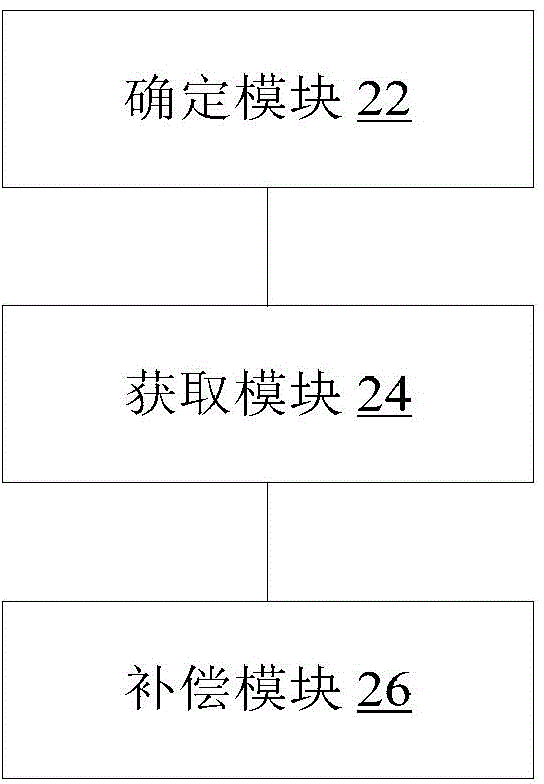

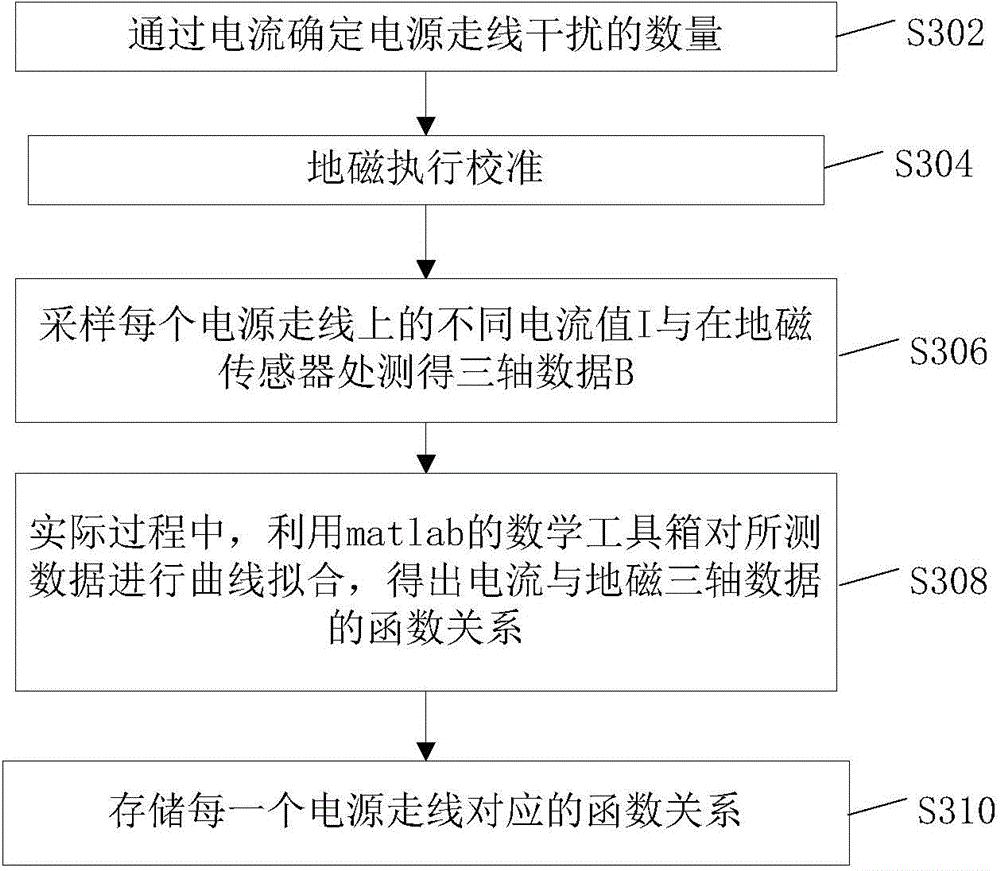

Interference compensation method and device of geomagnetic sensor

ActiveCN105277995ASolve the problem of unavoidable interferenceImprove the actual experience effectElectric/magnetic detectionAcoustic wave reradiationPower flowAxial data

The invention discloses an interference compensation method and device of a geomagnetic sensor. The method comprise that it is determined that current of a power line interfere in the geomagnetic sensor; current values of the power line are obtained, and a tri-axial data compensation value is obtained according to the functional correspondence between the tri-axial data change value of the geomagnetic sensor and the current values; and the tri-axial data compensation value is subtracted from the present tri-axial data of the geomagnetic sensor. The method and device can be used to solve the problem that interference of the PCB power line in the geomagnetic sensor is hard to avoid, the output geomagnetic tri-axial data is more accurate, and thus abundant experience is provided when the geomagnetic sensor is applied.

Owner:ZTE CORP

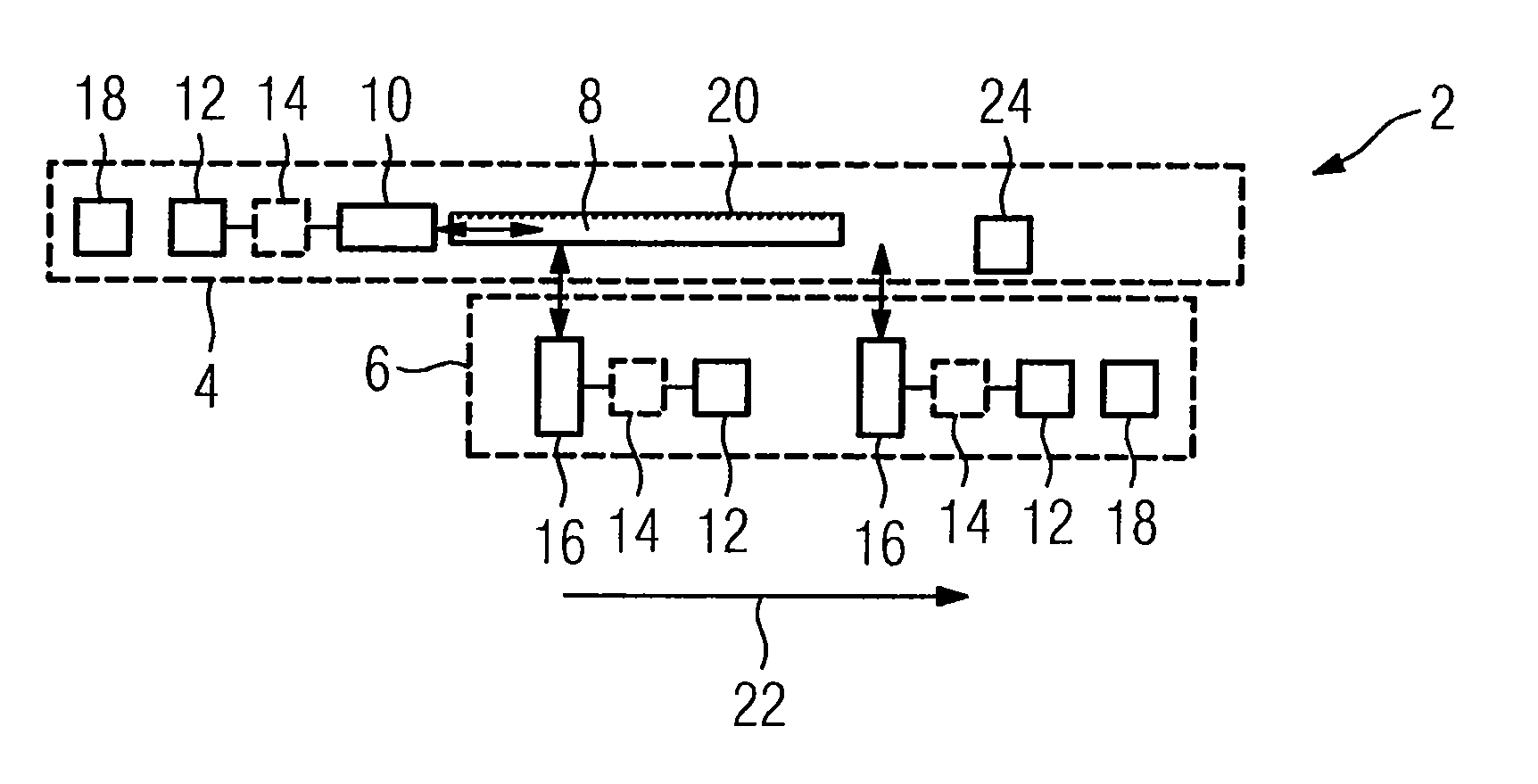

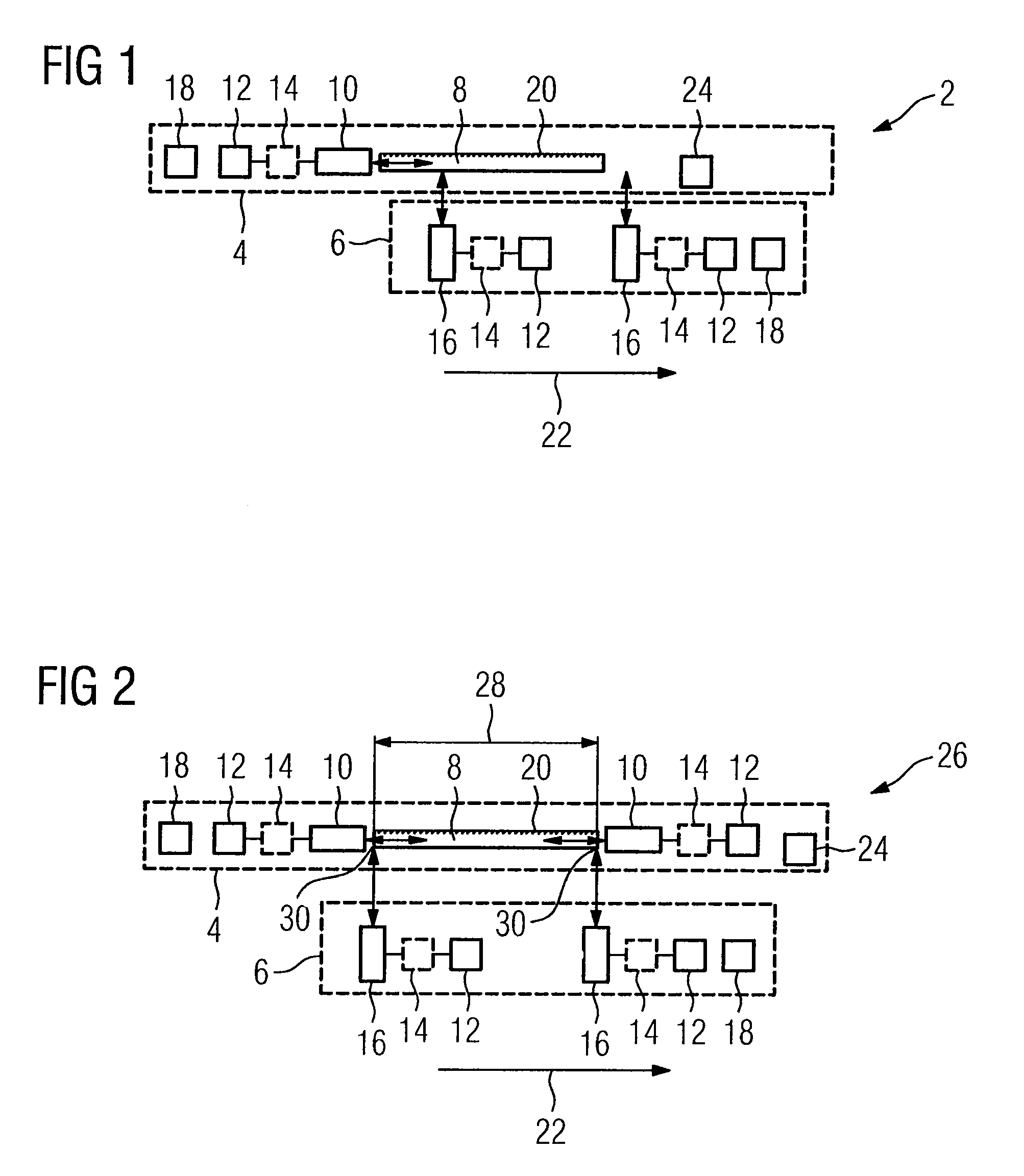

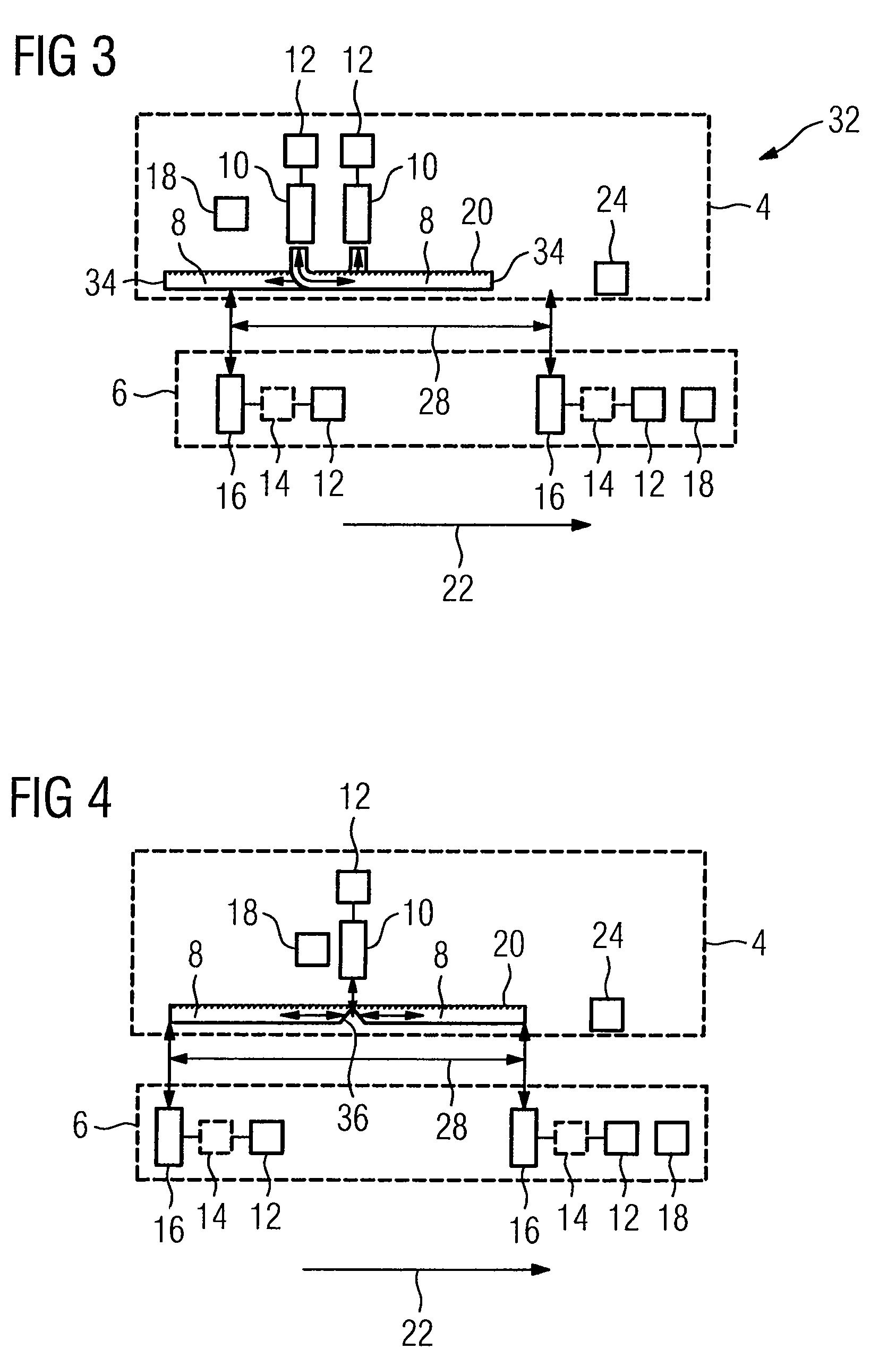

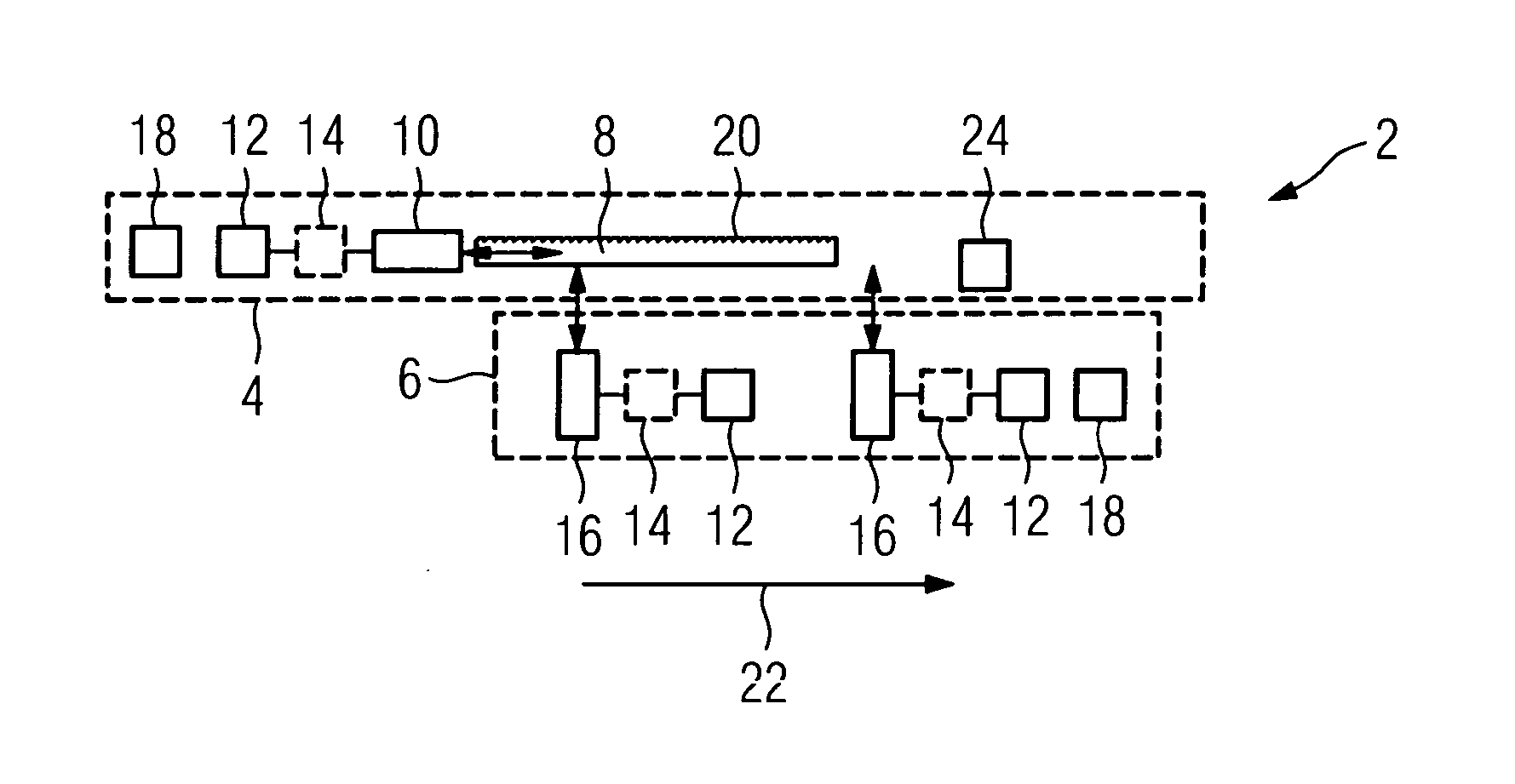

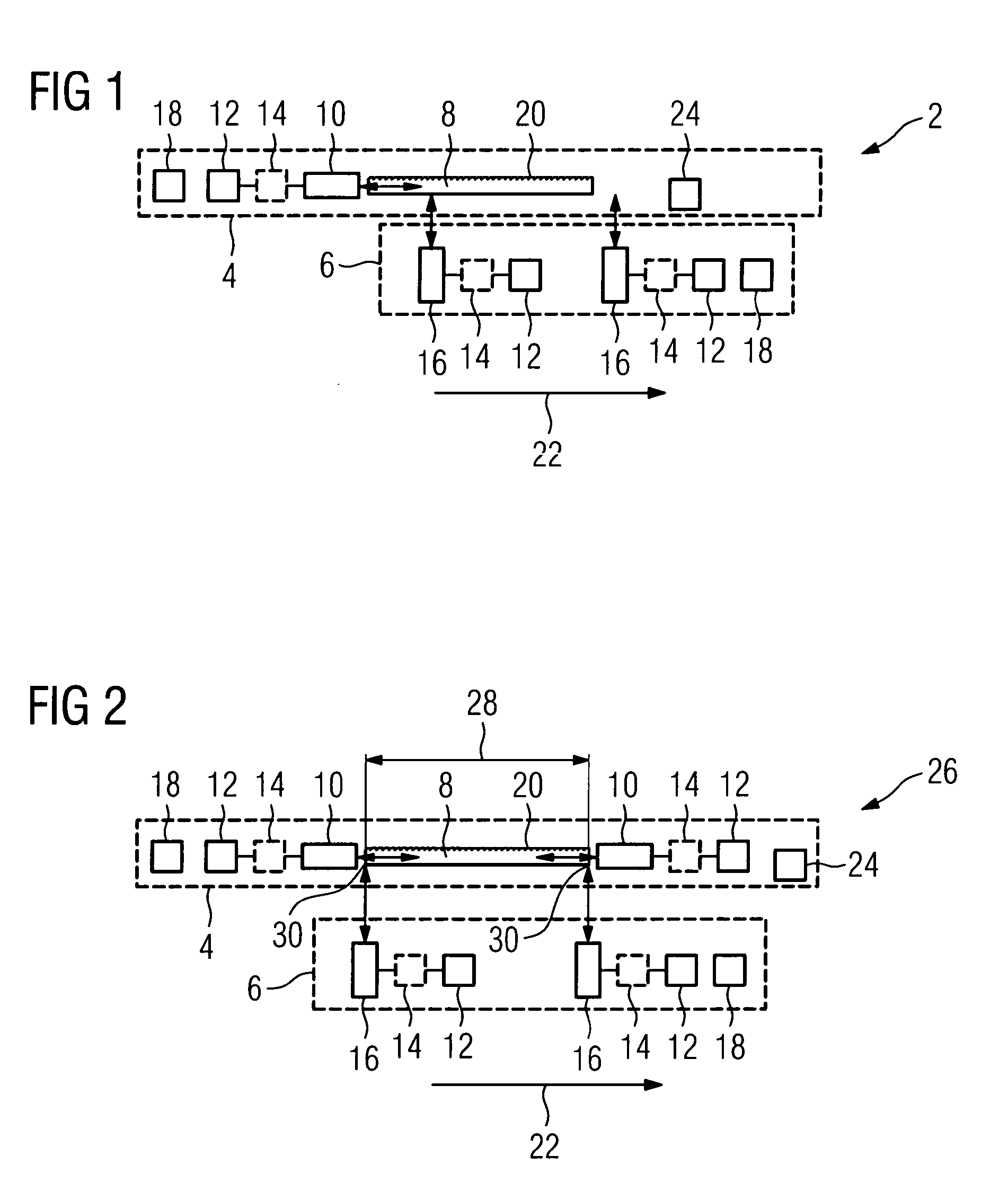

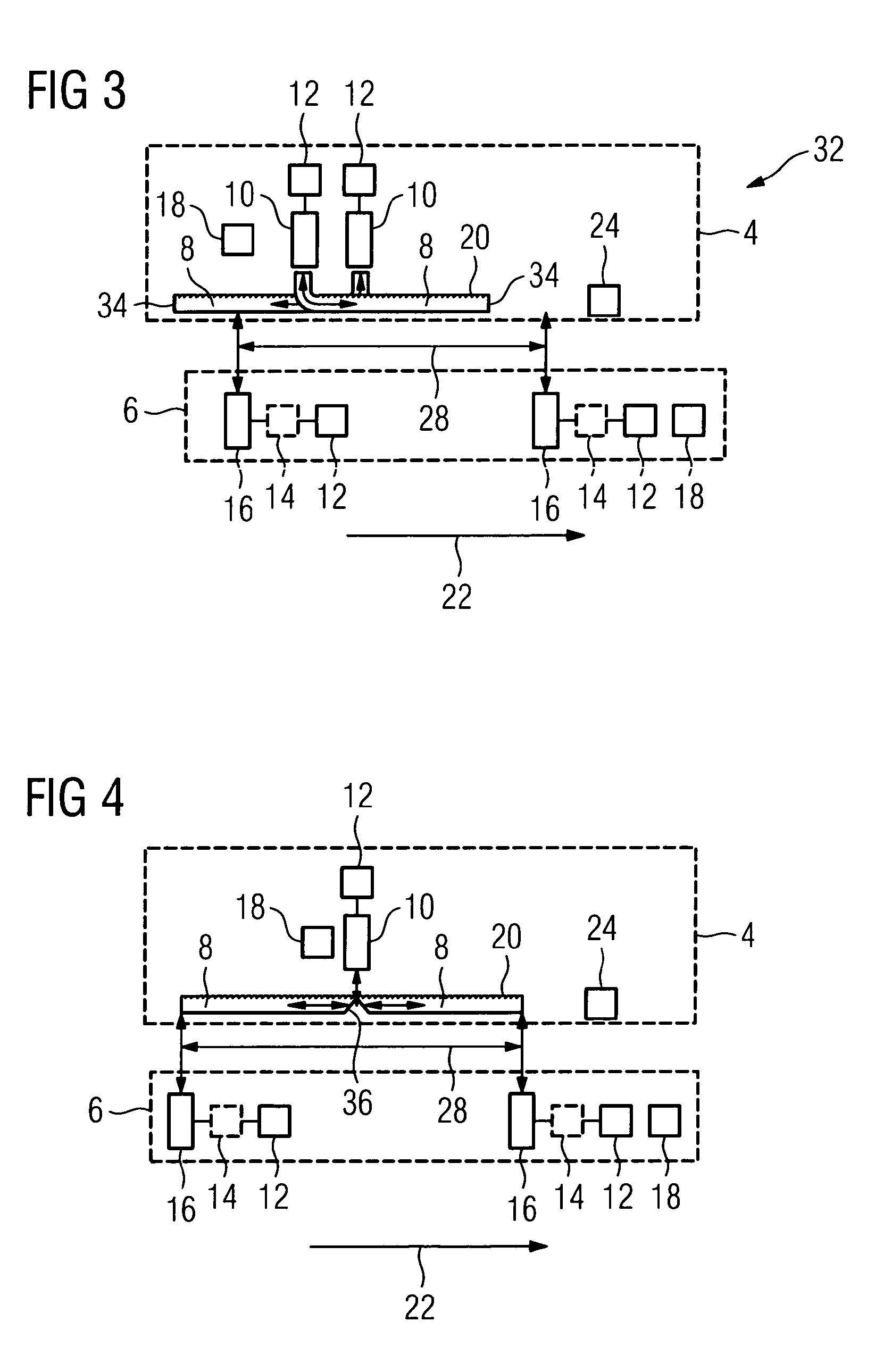

Apparatus for transmitting data between two systems which move relative to one another

InactiveUS8374506B2Improve data transfer rateRun fastCoupling light guidesElectromagnetic transmissionCouplingAxial data

An apparatus for transmitting data at high data rates, between two systems that move relative to one another is provided. The apparatus includes an optical fiber and an axial module on one of the two systems for the purpose of axial data coupling, using the optical fiber and a lateral module on another of the two systems for the purpose of lateral data coupling using the optical fiber.

Owner:SIEMENS HEALTHCARE GMBH

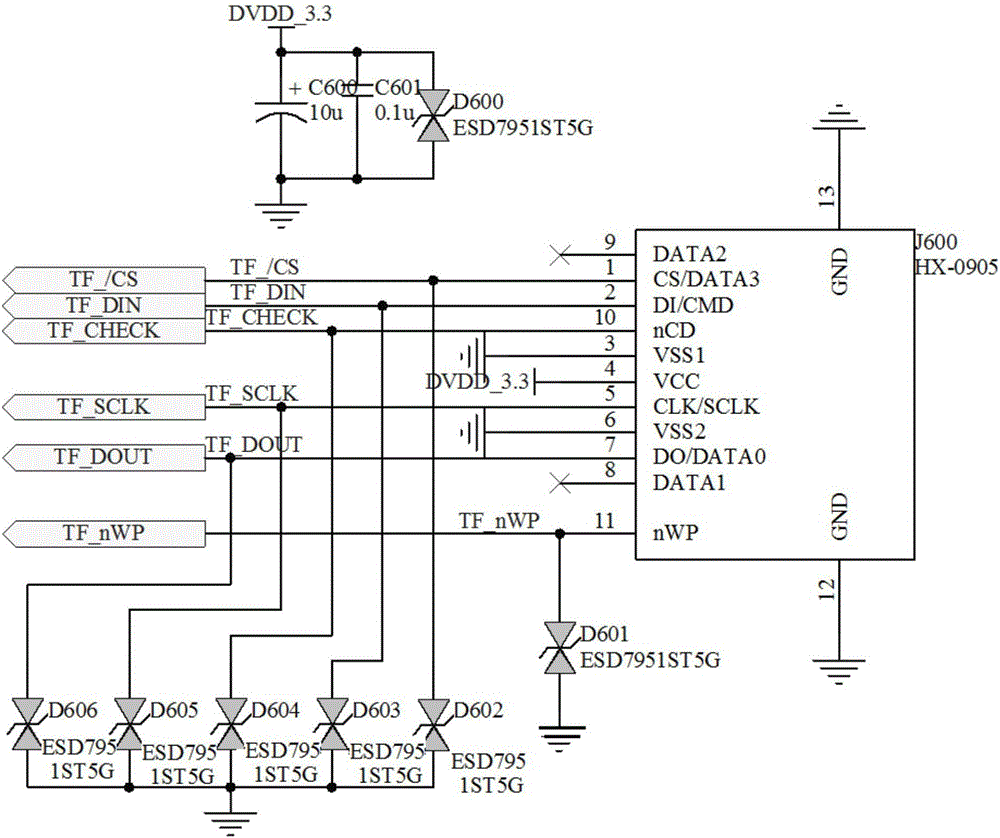

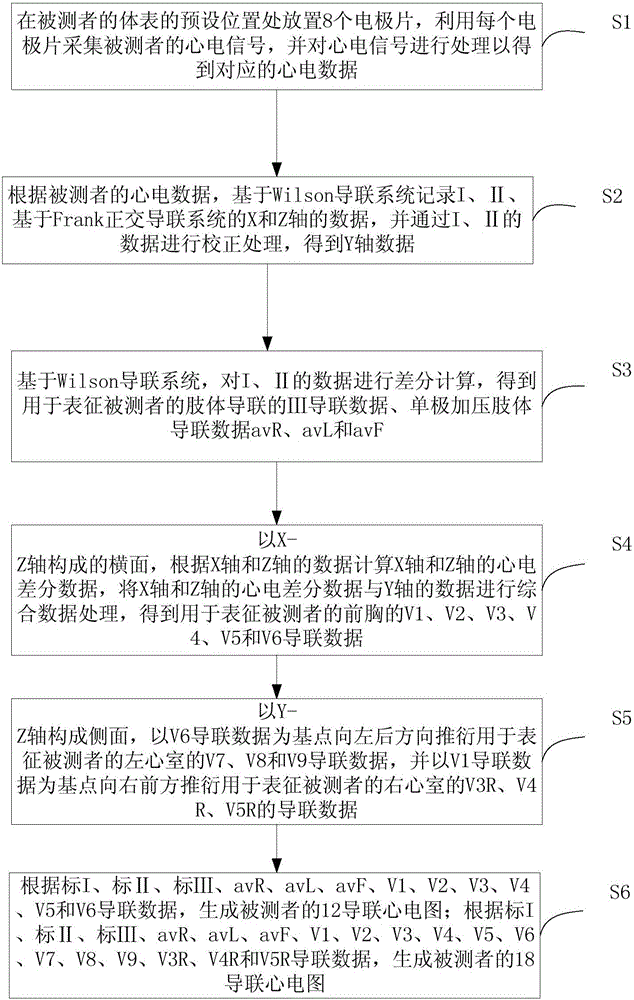

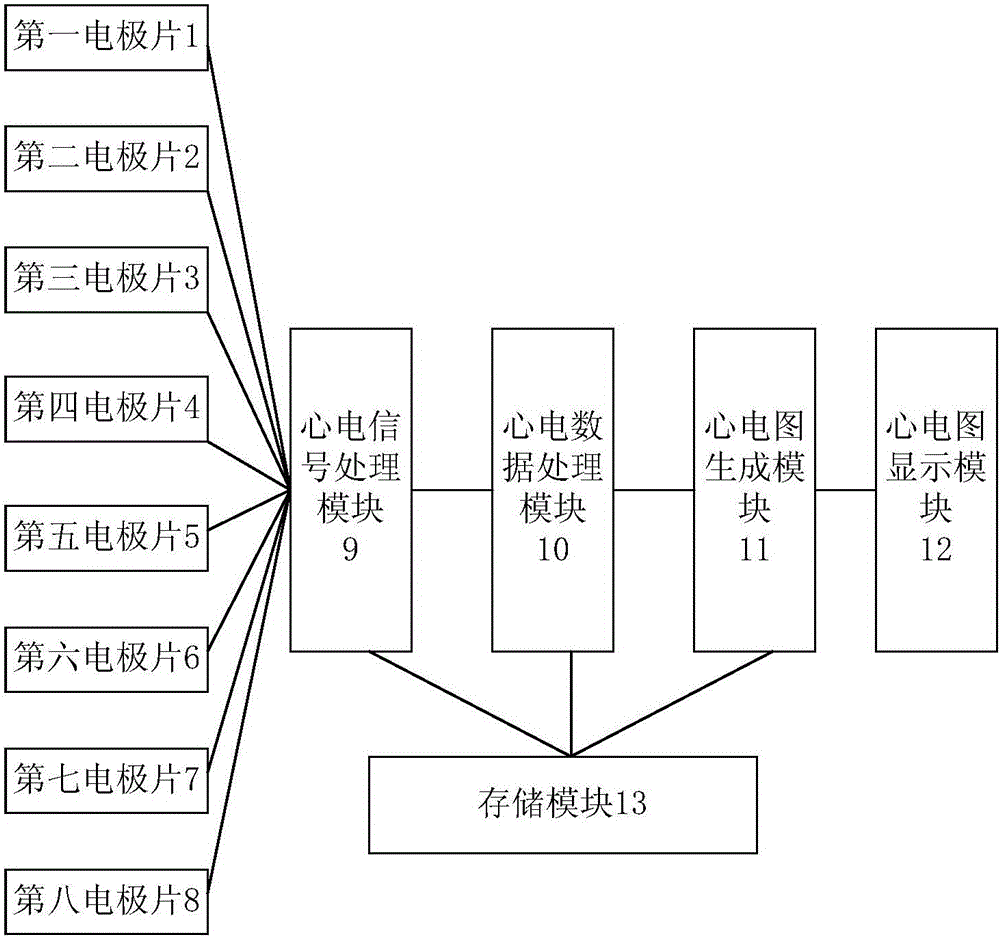

18-Lead holographic dynamic and static electrocardiographic analysis method and system

InactiveCN106073753AImprove diagnostic accuracyReduce missed diagnosis rateDiagnostic recording/measuringSensorsEcg signalAxial data

The invention provides an 18-lead holographic dynamic and static electrocardiographic analysis method and system, comprising: placing 8 electrodes at preset positions on the body surface of a subject to collect electrocardiogram signals of the subject; based on Wilson lead system recordings I and II and X-axis and Z-axis data of Frank lead system, using I and II data and Y-axial data as basis; acquiring I, II, III, avR, avL and avF based on the Wilson lead system; acquiring V1-V6 lead data representative of the chest of the subject by using a cross section composed of X-Z axes; deriving V7-V9 lead data representative of the left ventricle of the subject by using Y-Z axes to form a side, and deriving to the front right, V3R-V5R lead data of the right ventricle of the subject by using V1 lead data as a basal point; generating 12 and 18 lead electrocardiograms of the subject. The invention implements the detection of 18-lead electrocardiograms based on the modified Wilson lead system and Frank orthogonal lead system.

Owner:BEIJING MEDSUN MEDICAL EQUIP

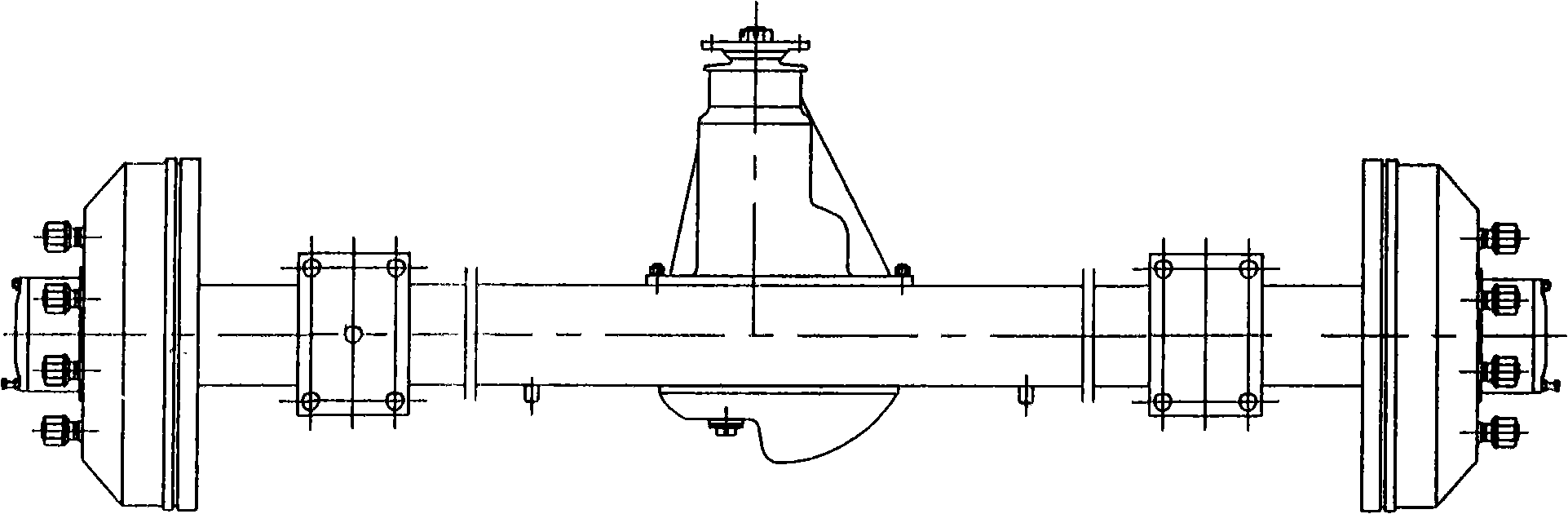

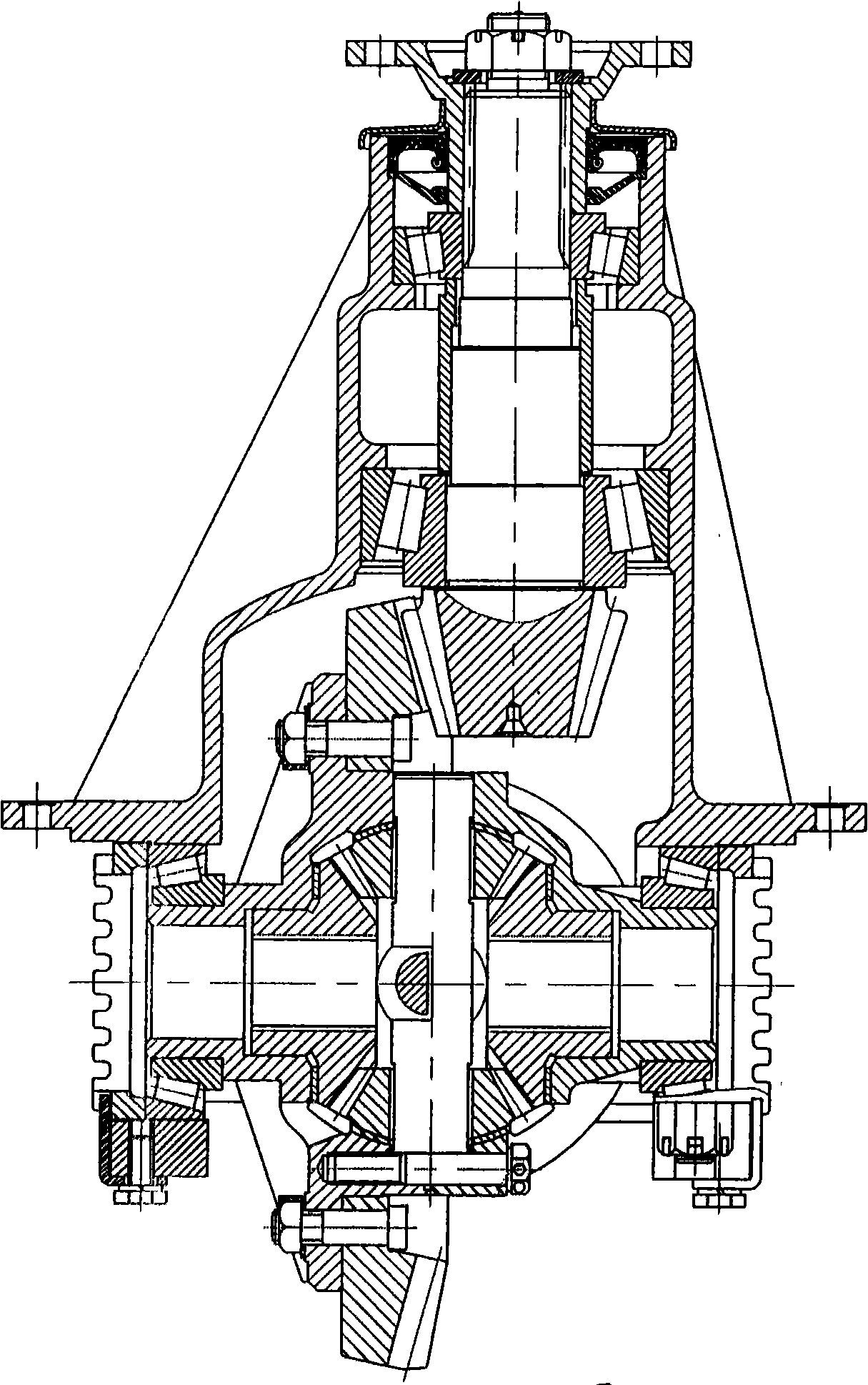

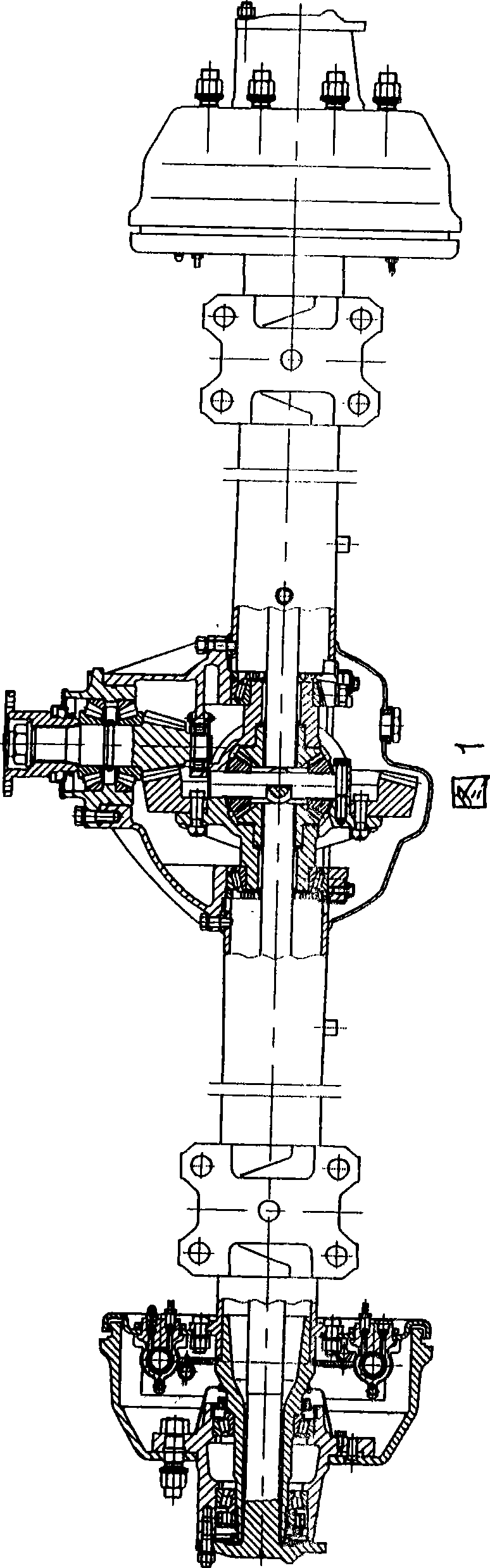

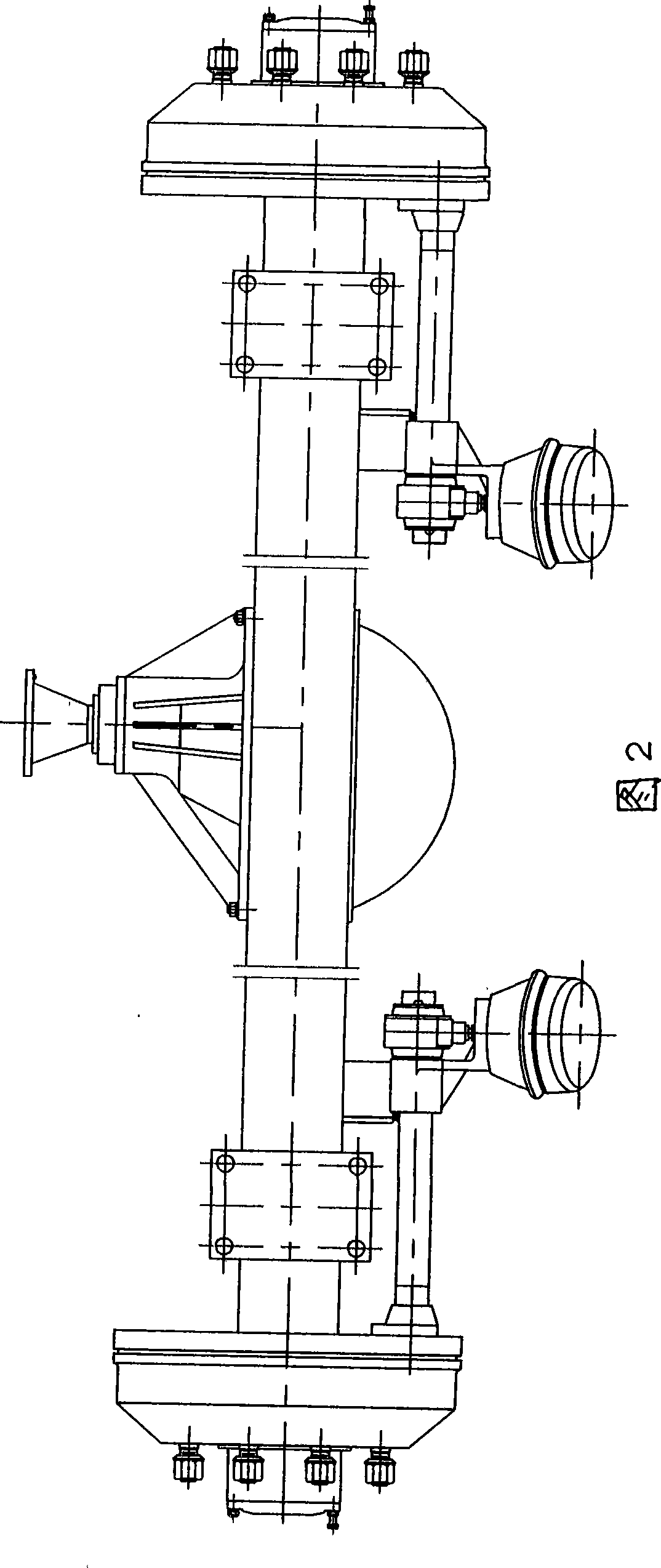

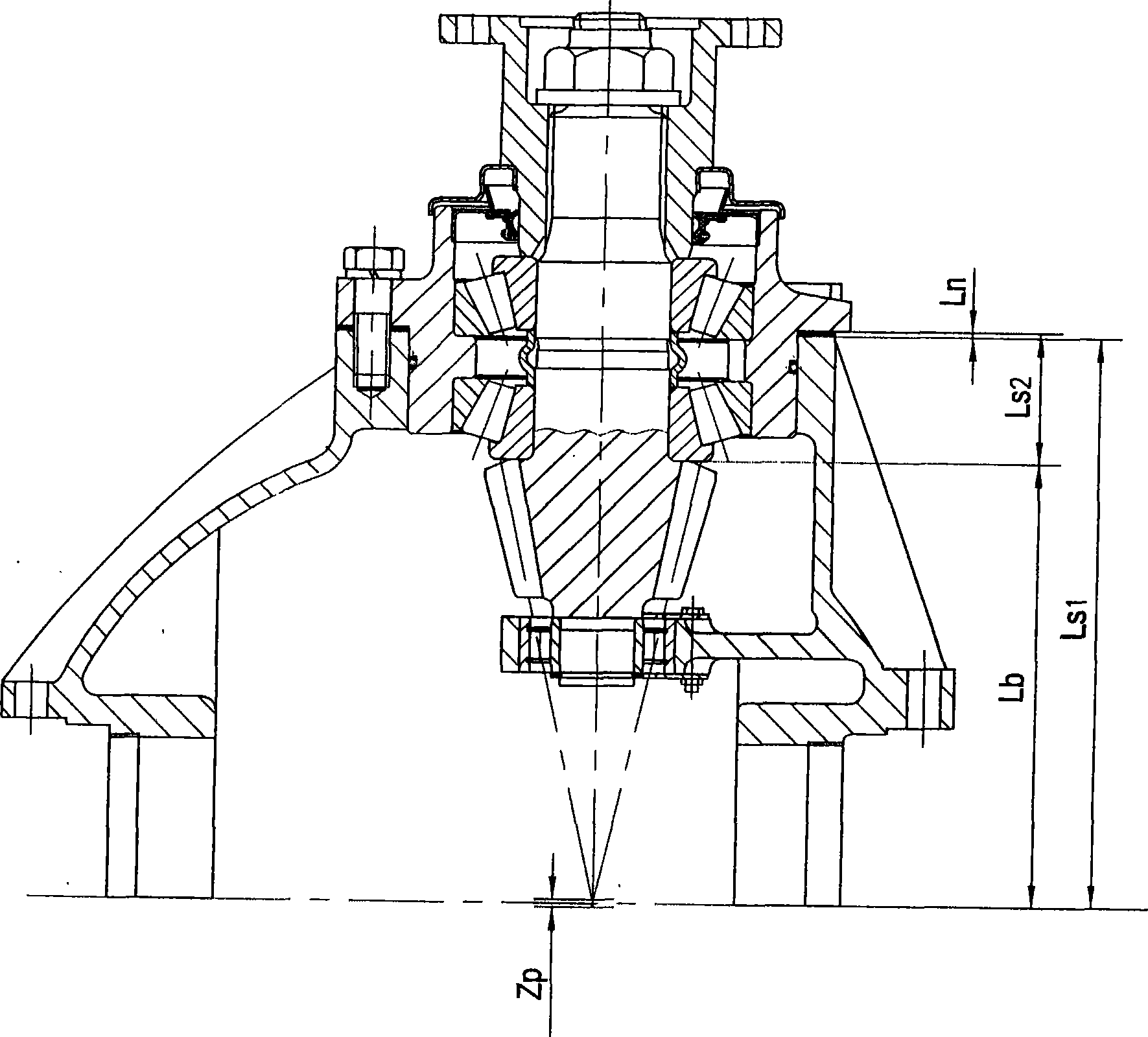

Drive gear installation moment and bearing pretension moment shim adjusting, measuring and selecting system and method

ActiveCN101493377AAvoid human interferenceReduce measurement variationMachine gearing/transmission testingUsing electrical meansElectronic control systemControl system

The invention relates to a measuring method and a measuring system of a driving gear mounting distance adjusting spacer and a driving gear bearing pre-tightening torque adjusting spacer of an integrated main reducer assembly. The measuring system comprises a first detection service position for completing axial data measurement of a combination piece of an internal bearing and an external bearing of the driving gear, and a shell of the main reducer, a second detection service position for completing data measurement of the combination piece of the internal bearing and the external bearing of the driving gear, and a rigid distance sleeve and an electronic control system; an induction signal of a displacement sensor at the first detection service position is converted to obtain a value of the axial data measurement of the combination piece of the internal bearing and the external bearing of the driving gear, and the shell of the main reducing gear; the induction signal of the displacement sensor at the second detection service position is converted to obtain a value of the axial data measurement of the combination piece of the internal bearing and the external bearing of the driving gear and the rigid distance sleeve; and the desired spacer value is obtained by computing with a mathematical model program. The technical scheme helps eliminate interference of human factors and improve measurement precision.

Owner:LIAONING SG AUTOMOTIVE GRP CO LTD

Apparatus for transmitting data between two systems which move relative to one another

InactiveUS20100202782A1Easy to manufactureEffective alignmentCoupling light guidesElectromagnetic transmissionCouplingComputer module

An apparatus for transmitting data at high data rates, between two systems that move relative to one another is provided. The apparatus includes an optical fiber and an axial module on one of the two systems for the purpose of axial data coupling, using the optical fiber and a lateral module on another of the two systems for the purpose of lateral data coupling using the optical fiber.

Owner:SIEMENS HEALTHCARE GMBH

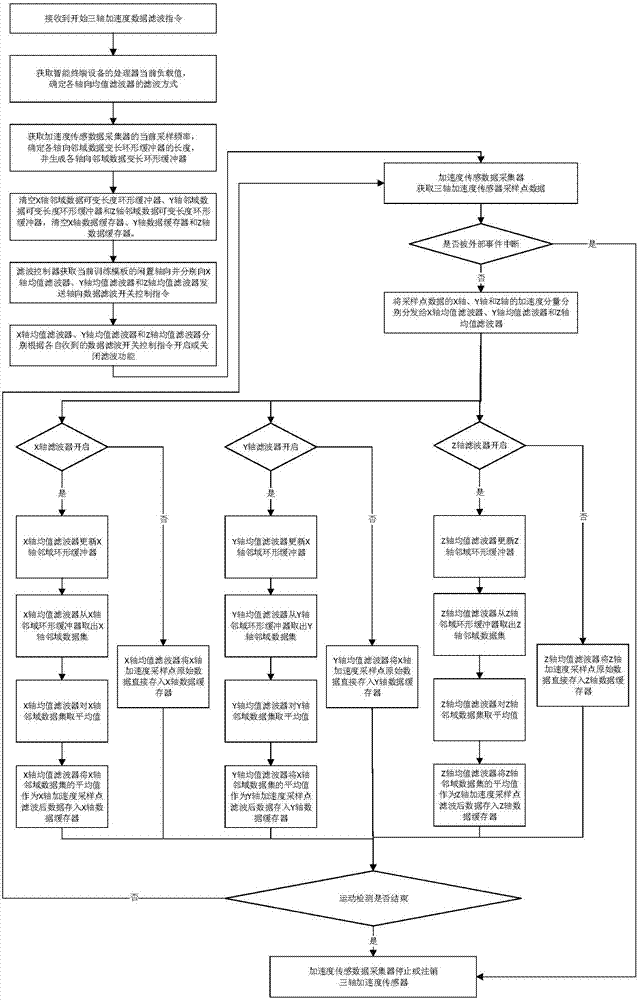

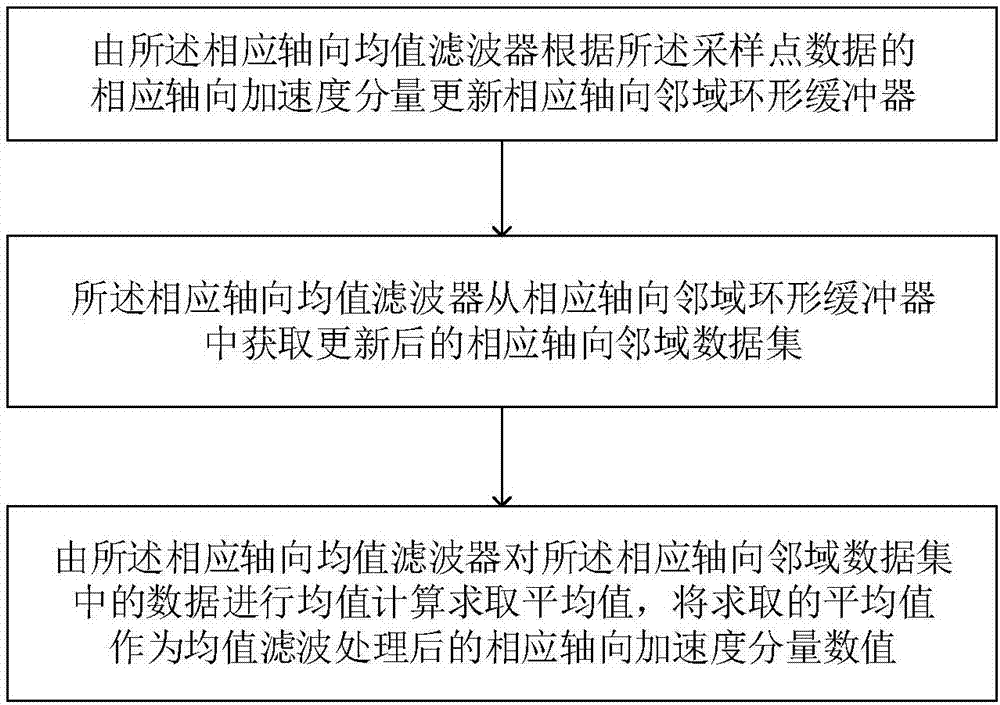

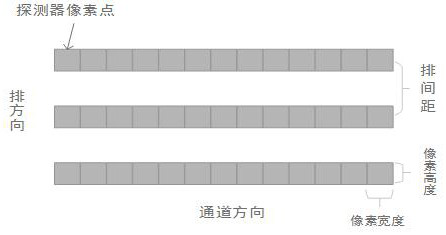

Flexible filtering method of triaxial acceleration data for motion detection

InactiveCN107271723AEffective filteringImprove filtering effectAcceleration measurement using interia forcesAcceleration measurement in multiple dimensionsSignal onData acquisition

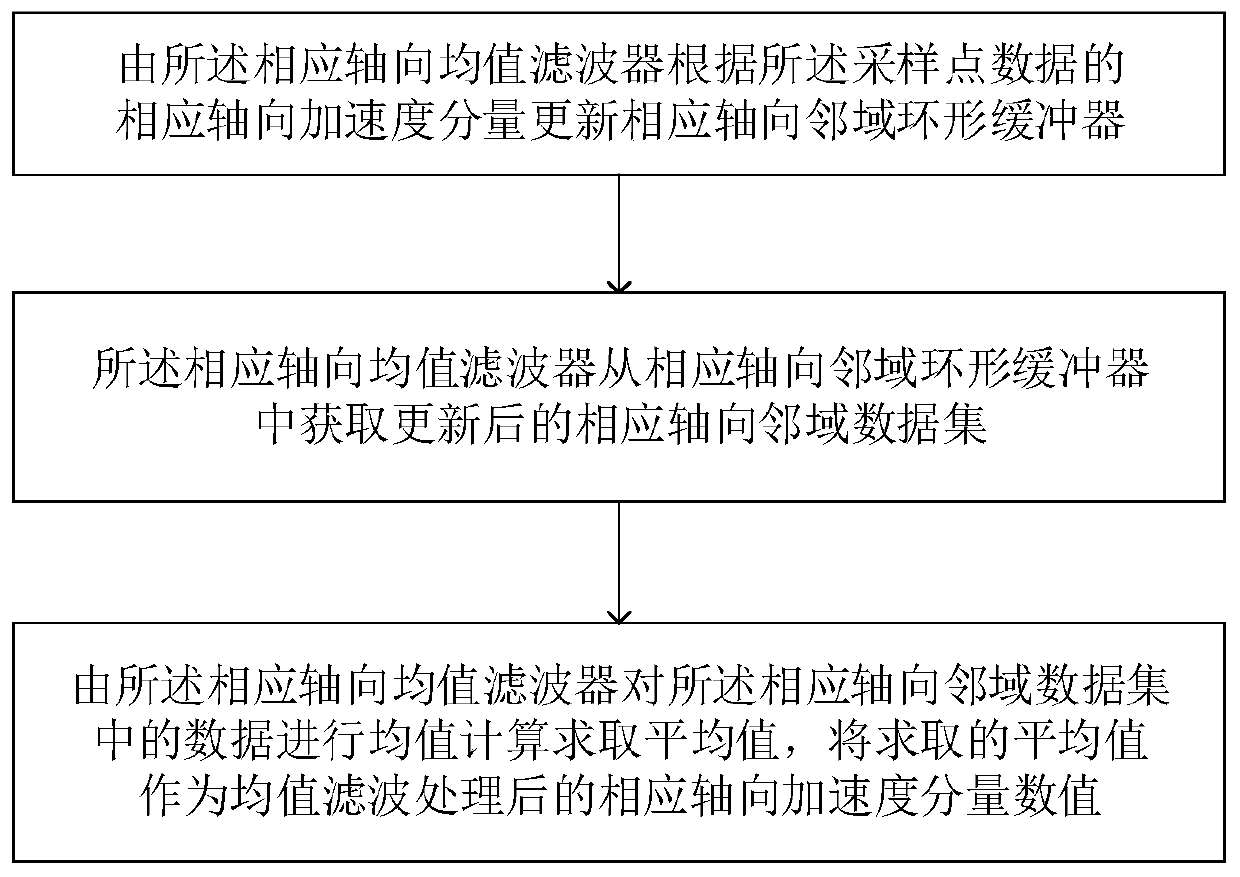

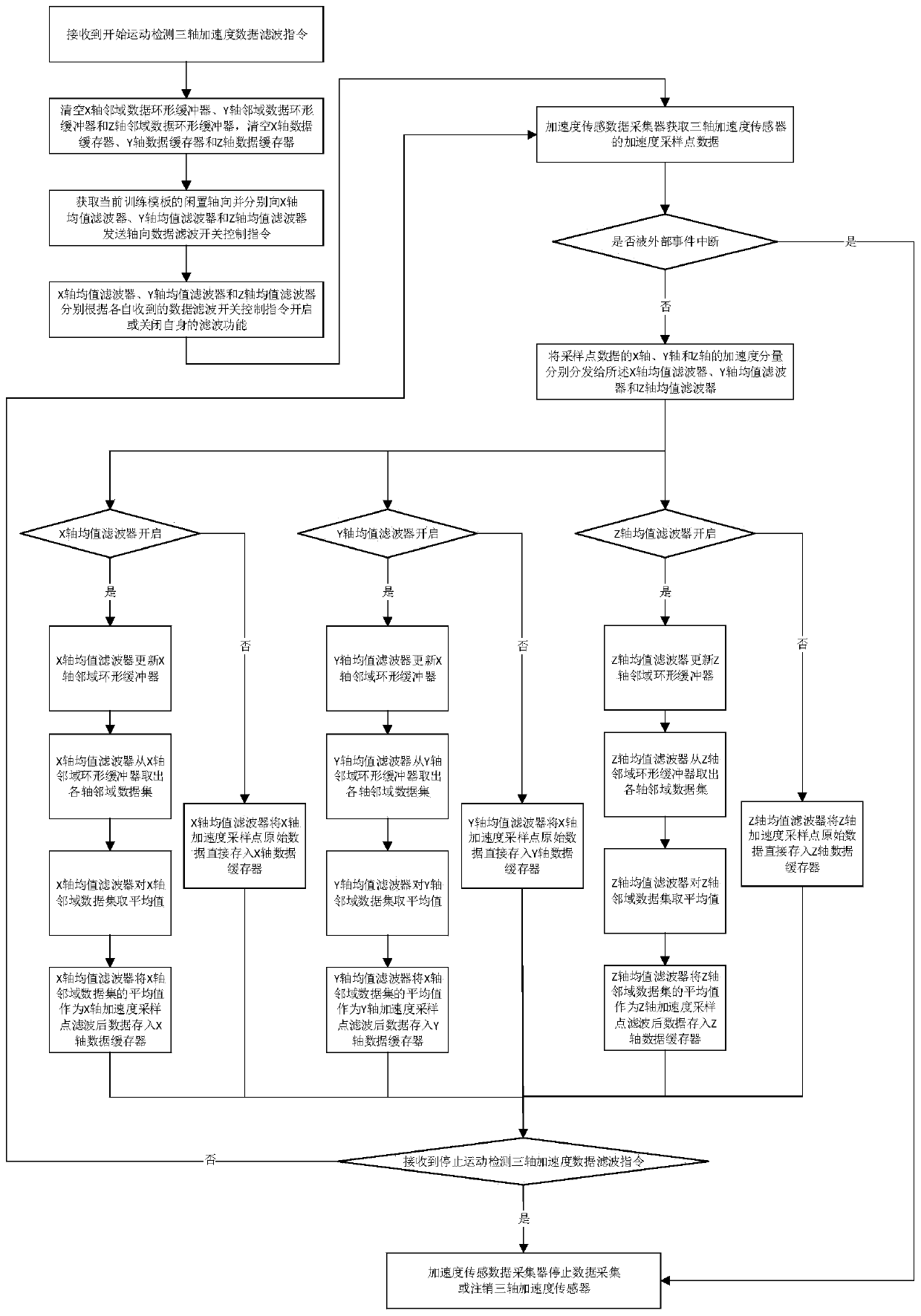

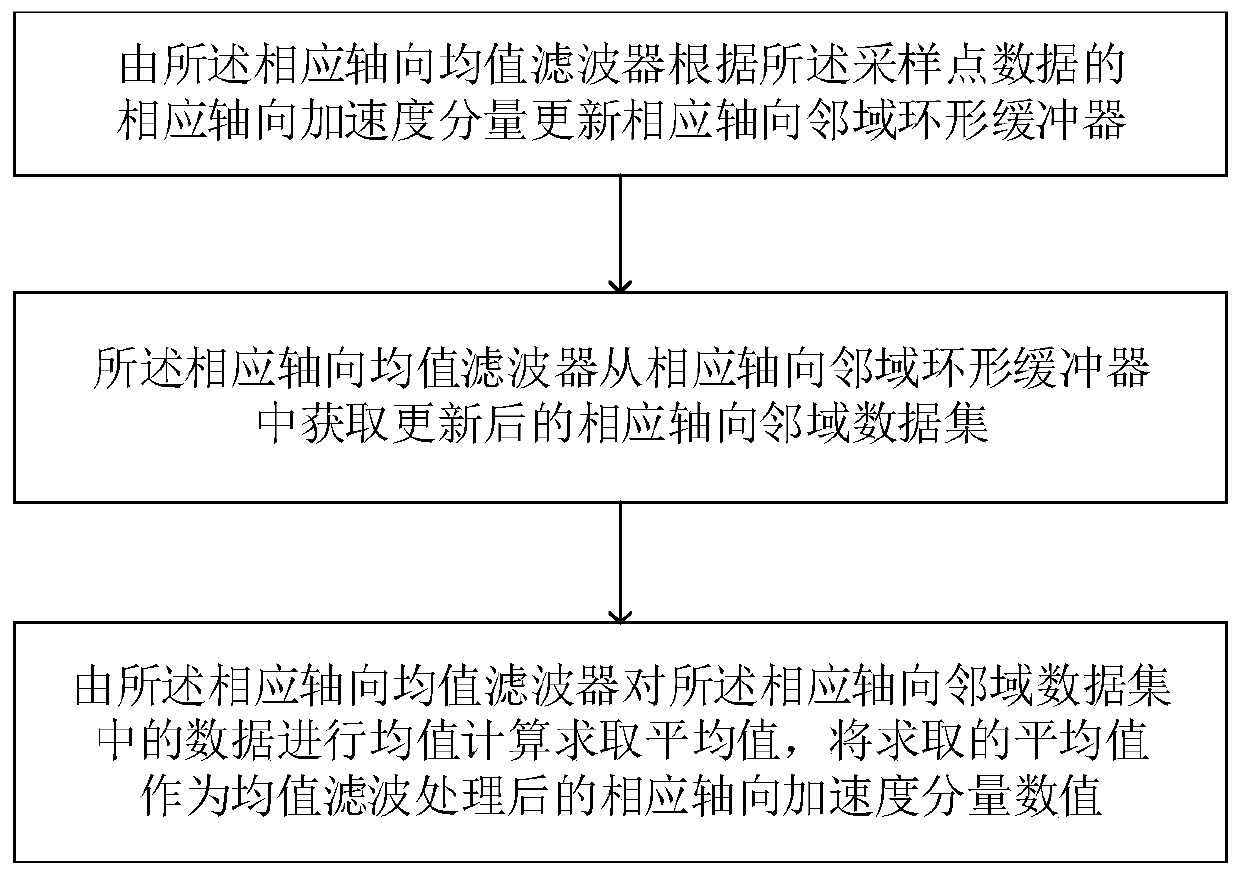

The invention discloses a flexible filtering method of triaxial acceleration data for motion detection. Different filtering modes are determined according to the current load value of the processor of an intelligent terminal. The length of each axial neighborhood data elongation annular buffer is determined according to the current sampling frequency of an acceleration sensing data acquisition unit. A corresponding axial filtering function is switched on or switched off according to an idle axial direction of a training template. Furthermore each axial neighborhood data annular buffer and each axial data buffer are set. Furthermore averaging filtering is performed on each axial data by means of each buffer and each filter. Furthermore when an external event is interrupted, the acceleration sensing data acquisition unit stops data acquisition or a triaxial acceleration sensor is cancelled for stopping data filtering. The flexible filtering method realizes effective filtering of a high-frequency noise in a low-frequency motion signal on the condition of relatively low system resource consumption in a motion detection process, and furthermore settles problems of incapability of effectively filtering noises in the motion signal and relatively high system resource consumption.

Owner:温胜洁

Numerical-control scanner

ActiveCN102724380AReal-time adjustment of clamping forceReduce wearGearingNumerical controlNumerical controlControl system

The invention discloses a numerical-control scanner which comprises a scanning device, a positioning device and a control system, wherein the scanning device can move through a power device and is used for real-time acquisition of axial data of a scanned file; the positioning device is used for positioning and rotating the scanned file and used for real-time acquisition of circumferential data of the scanned file; and the control system is connected with the scanning device and the positioning device and used for collecting and processing the real-time acquisition data of the scanning device and controlling the scanning device to move and the scanned file to rotate. The scanning device is movable, and the positioning device enables the scanned file to rotate axially, so that 360-degree scanning of the scanned file can be achieved during scanning, scanning effects can be guaranteed, and scanned data are processed and stored by the control system to facilitate use for numerical-control mechanical production.

Owner:DONGGUAN EMMA CNC TECH CO LTD

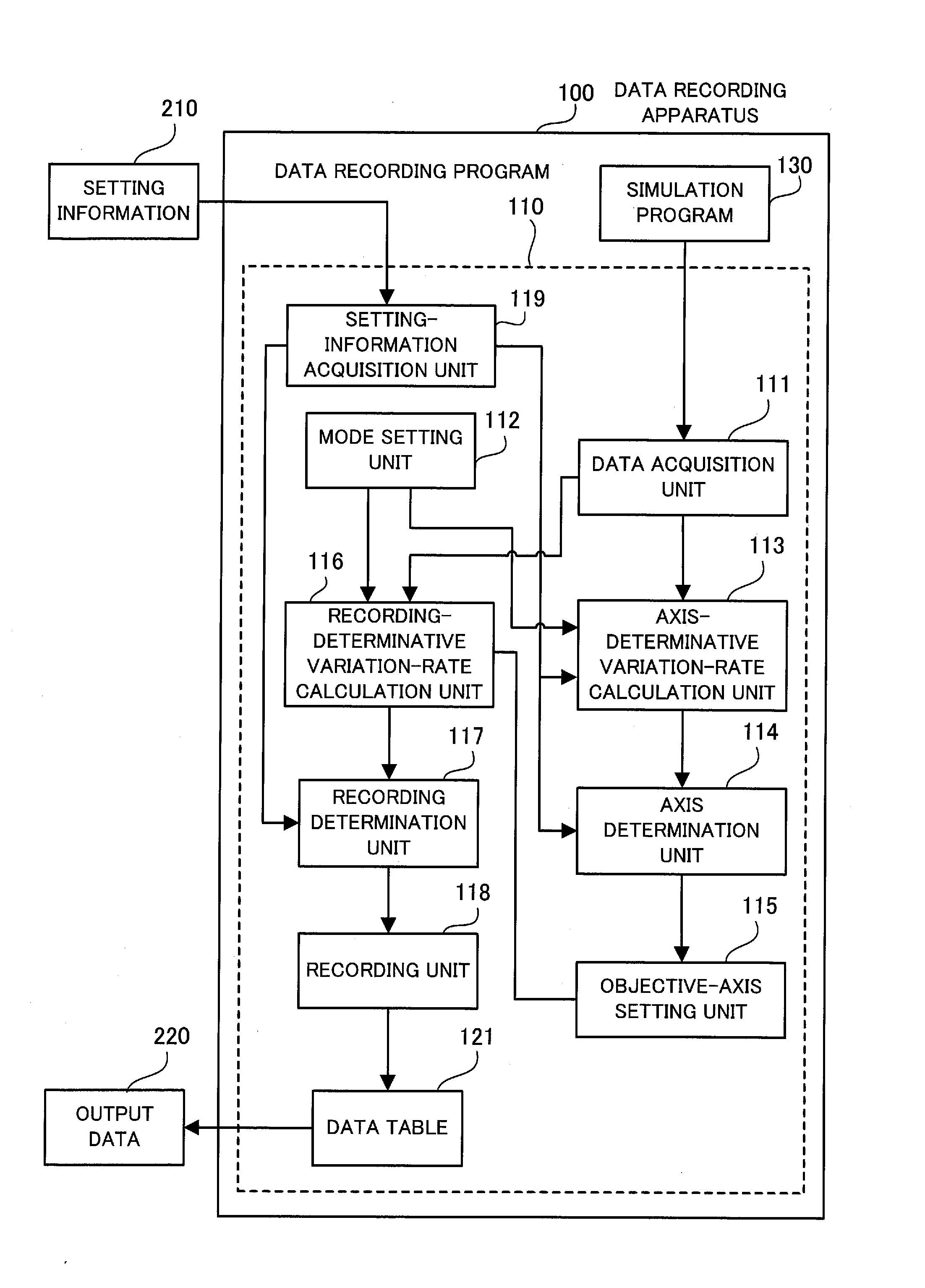

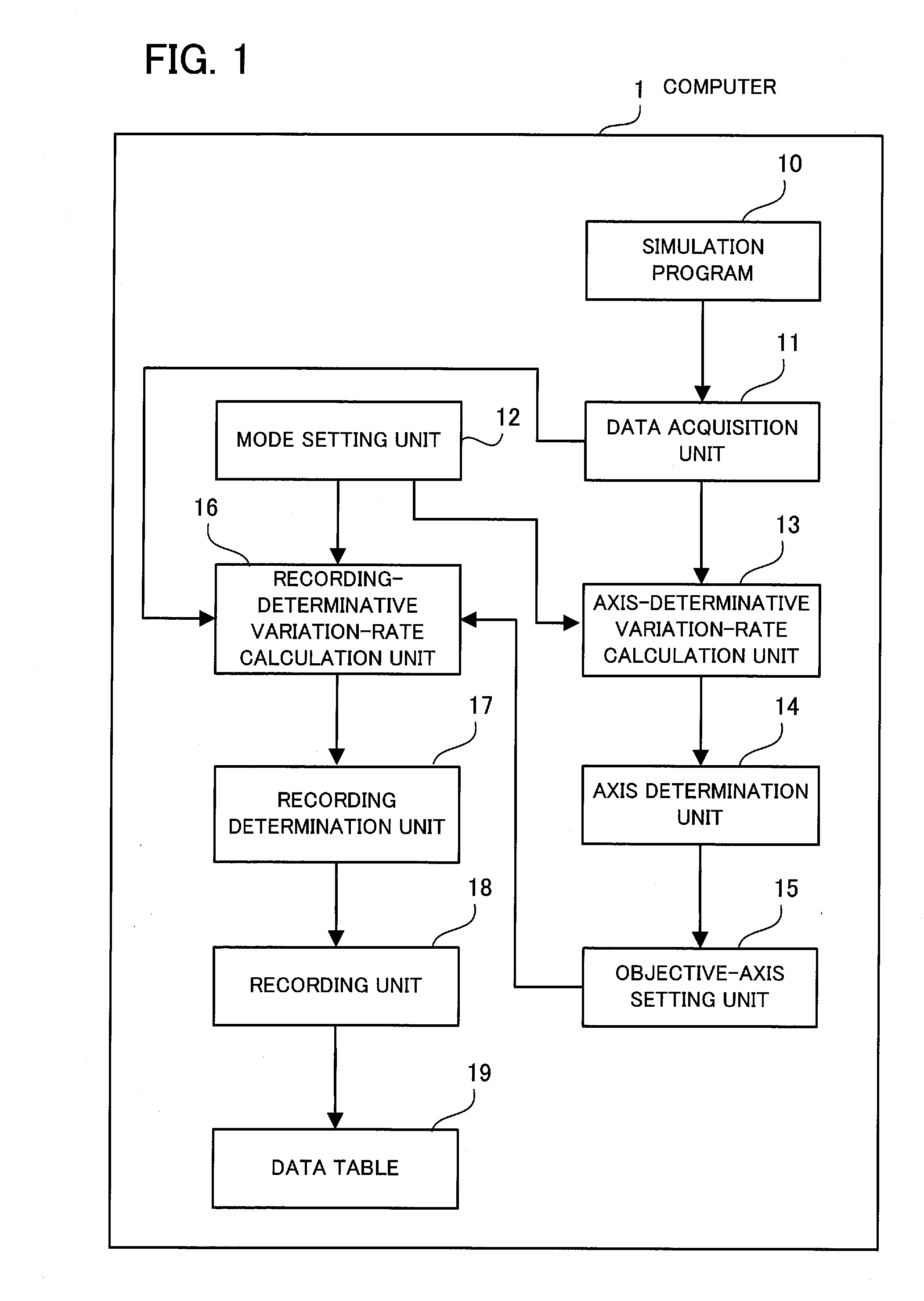

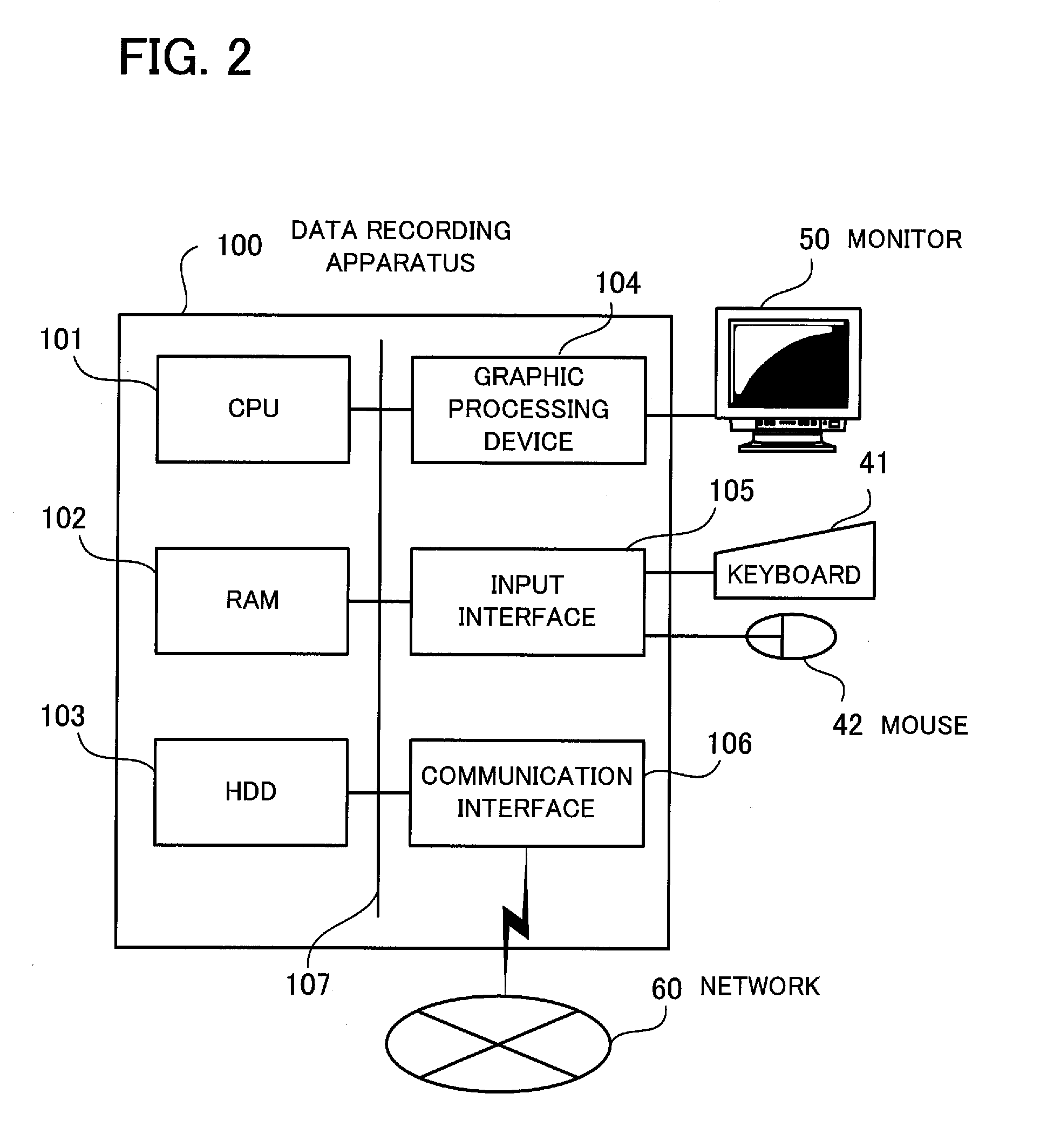

Data recording program, data recording apparatus, data recording process, and recording medium

InactiveUS20100161624A1Cathode-ray tube indicatorsComputation using non-denominational number representationAxial dataData recording

The data acquisition unit acquires data in correspondence with each dimensional axis and the time axis. The mode setting unit makes setting and clearing of a dimensionality investigation mode. In the dimensionality investigation mode, the axis-determinative variation-rate calculation unit calculates axial data variation rates. The axis determination unit determines whether or not the axial data variation rate corresponding to each axis is low. The objective-axis setting unit sets each axis as an objective axis when the axial data variation rate corresponding to the axis is determined to be high. While the dimensionality investigation mode is cleared, the recording-determinative variation-rate calculation unit calculates axial data variation rates. The recording determination unit determines, on the basis of the axial data variation rate, whether to record the acquired data. The recording unit does not record the data when the data is determined not to be recorded.

Owner:FUJITSU LTD

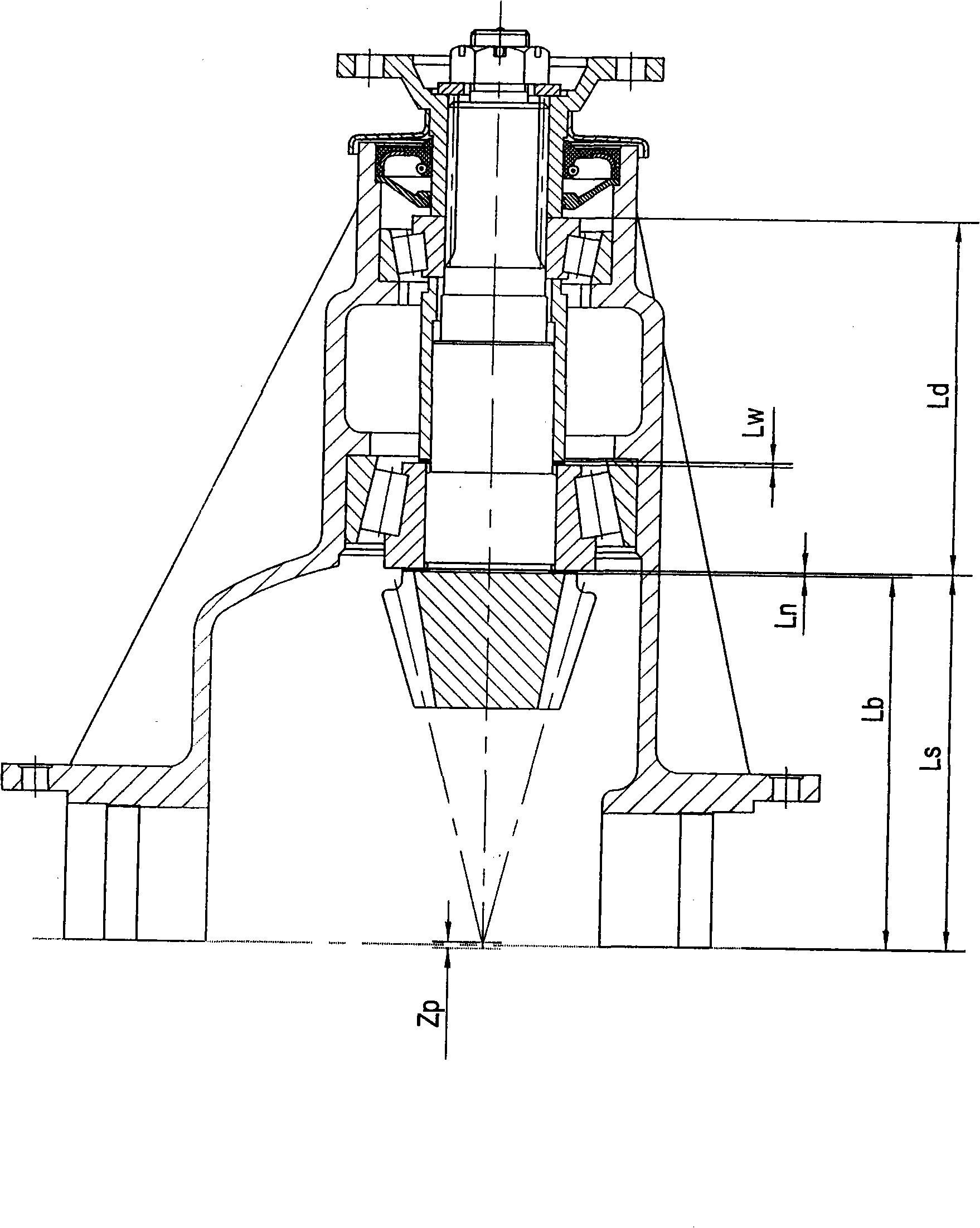

System and method for measuring and selecting drive gear installation distance adjusting shim of separated main gearbox assembly

ActiveCN101419121AAvoid interferenceReduce measurement variationMachine gearing/transmission testingUsing electrical meansCar drivingElectronic control system

The invention relates to a method and a system for selecting and measuring driving gear mounting distance adjusting shims of a driving gear pair and a driven gear pair in a core component, namely an up-and-down split-type main reducer assembly of an automobile driving bridge assembly. The selecting and measuring system comprises an online monitoring first detection station, a second detection station of a driving gear bearing pedestal subassembly, and an electronic control system, wherein the first detection station is a displacement sensing detection station of axial data of a main differential case and adopts a displacement station device which is shifted to an online follower fixture; the second detection station is a displacement sensing detection station of axial data of a driving gear inner bearing, a driving gear outer bearing and a driving gear bearing pedestal; and the electronic control system obtains corresponding data values respectively through acquisition and conversion of an axial data signal acquisition channel of the main differential case and an axial data signal acquisition channel of a driving gear bearing pedestal assembly, and obtains the thickness Ln of the driving gear mounting distance adjusting shims by calculation through a determined mathematic model. The technical proposal realizes online monitoring in a real sense, simultaneously suppresses interference of personal factors, reduces the measuring variation, and improves the measuring precision.

Owner:LIAONING SG AUTOMOTIVE GRP CO LTD

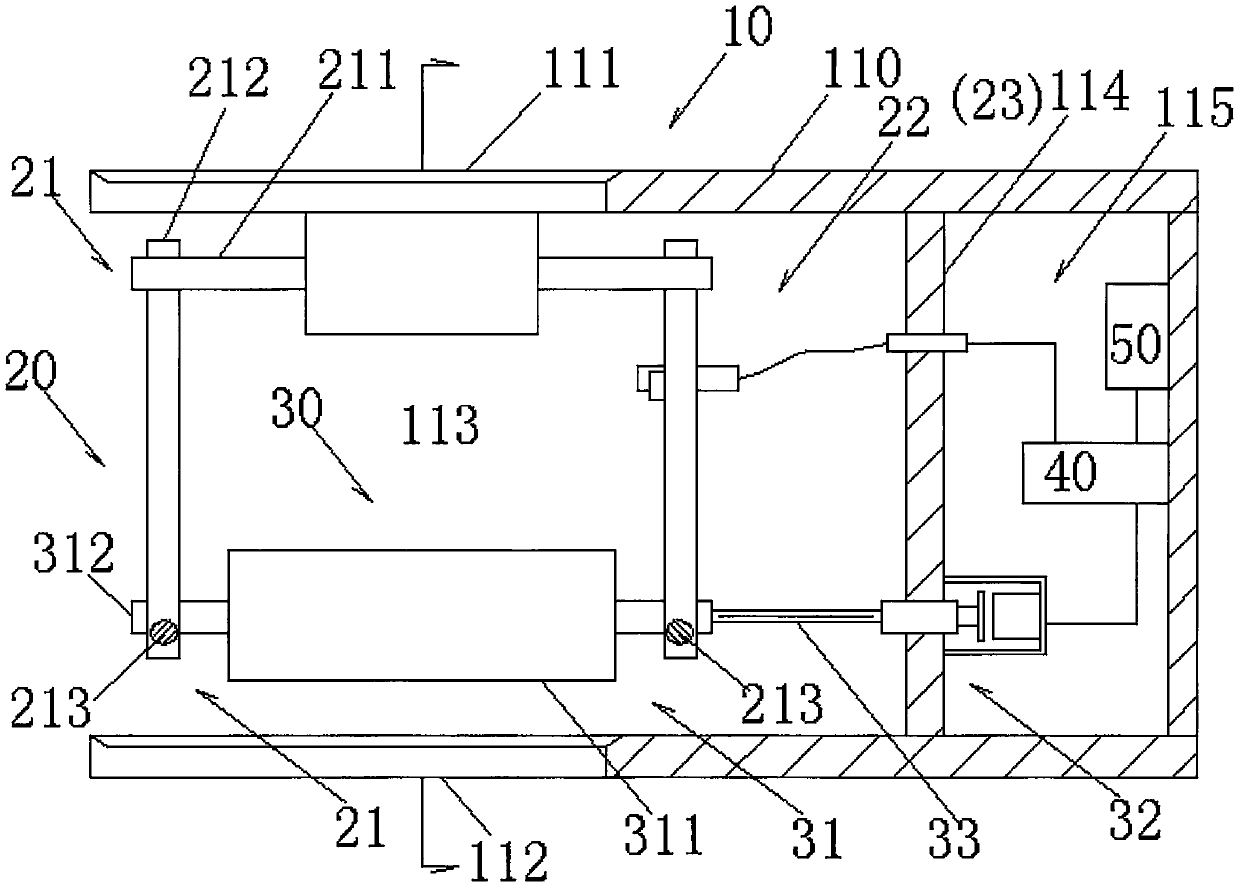

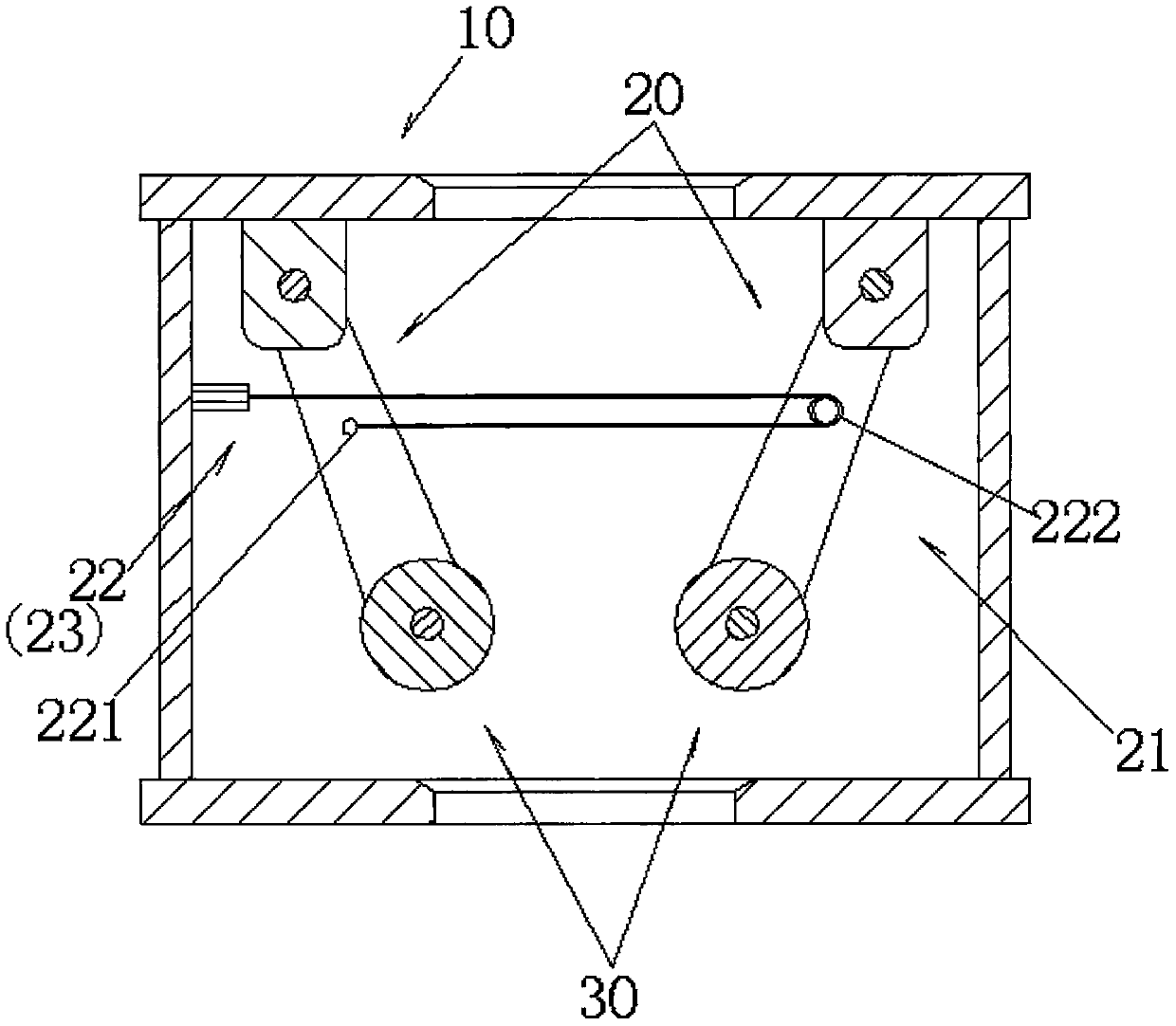

Centrifugal impeller static balance automatic debugging machine

The invention relates to a centrifugal impeller static balance automatic debugging machine. The machine comprises a machine bench. The machine bench is provided with an impeller rotating shaft. The impeller rotating shaft is connected to a rotation driving motor in a transmission mode. A radial data monitoring component and / or an axial data monitoring component are arranged beside the impeller rotating shaft. The radial data monitoring component comprises a radial measuring component which is radially adjusted and moved along the impeller rotating shaft and a concentricity adjusting component.The axial data monitoring component comprises an axial measuring component which is axially adjusted and moved along the impeller rotating shaft and a verticality adjusting component. The radial measuring component of the invention can collect the radius data of the centrifugal impeller on the impeller rotating shaft during an impeller rotating shaft rotation process, and the axial measuring component can collect the bottom bounce data of the centrifugal impeller on the impeller rotating shaft during the impeller rotating shaft rotation process. After the above data is collected, the concentricity adjusting component is combined to push the periphery of the centrifugal impeller and the verticality adjusting component is used to push the bottom surface of the centrifugal impeller so that the centrifugal impeller is debugged to a state according with the usage requirement of the centrifugal impeller.

Owner:王东林

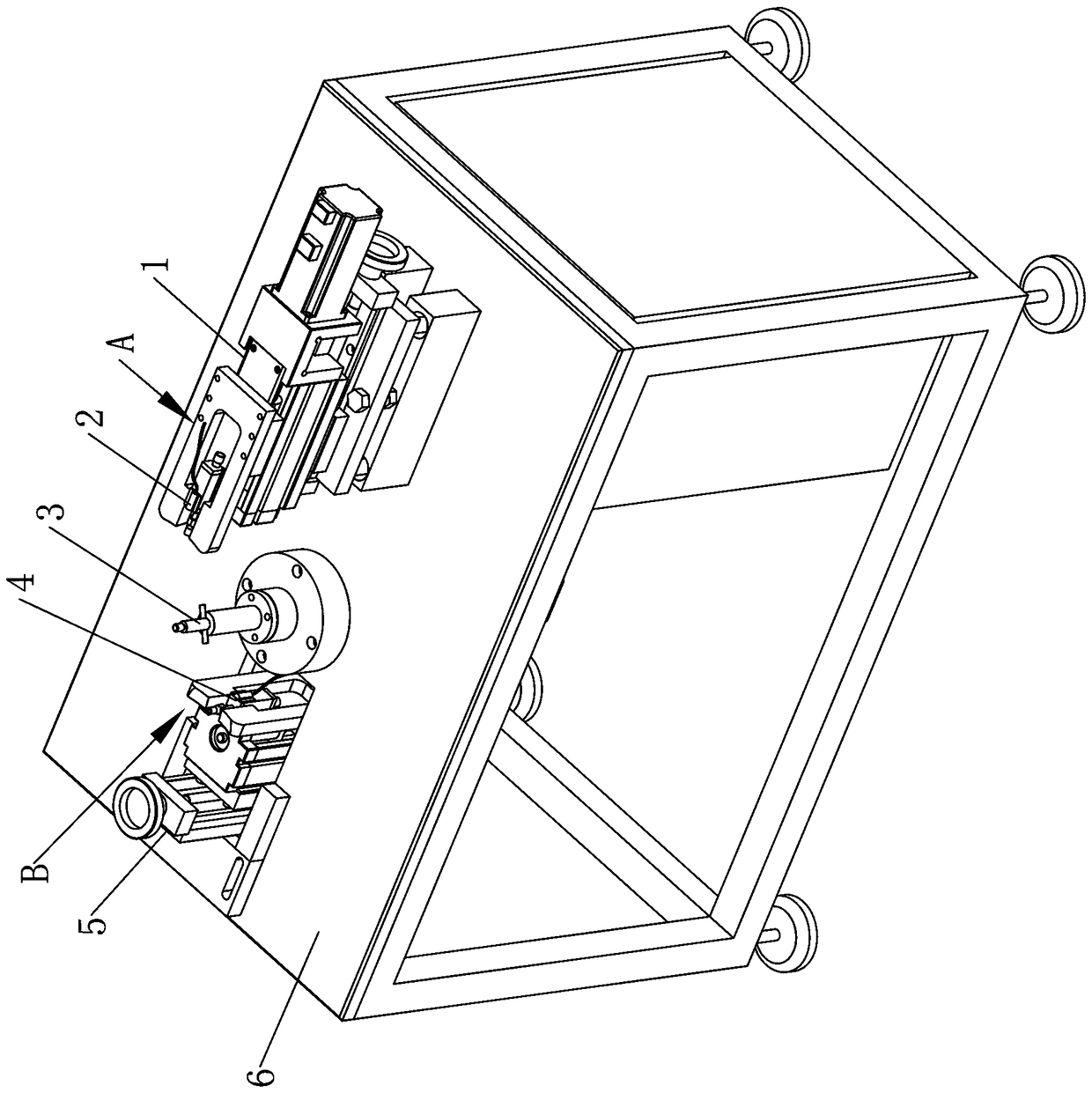

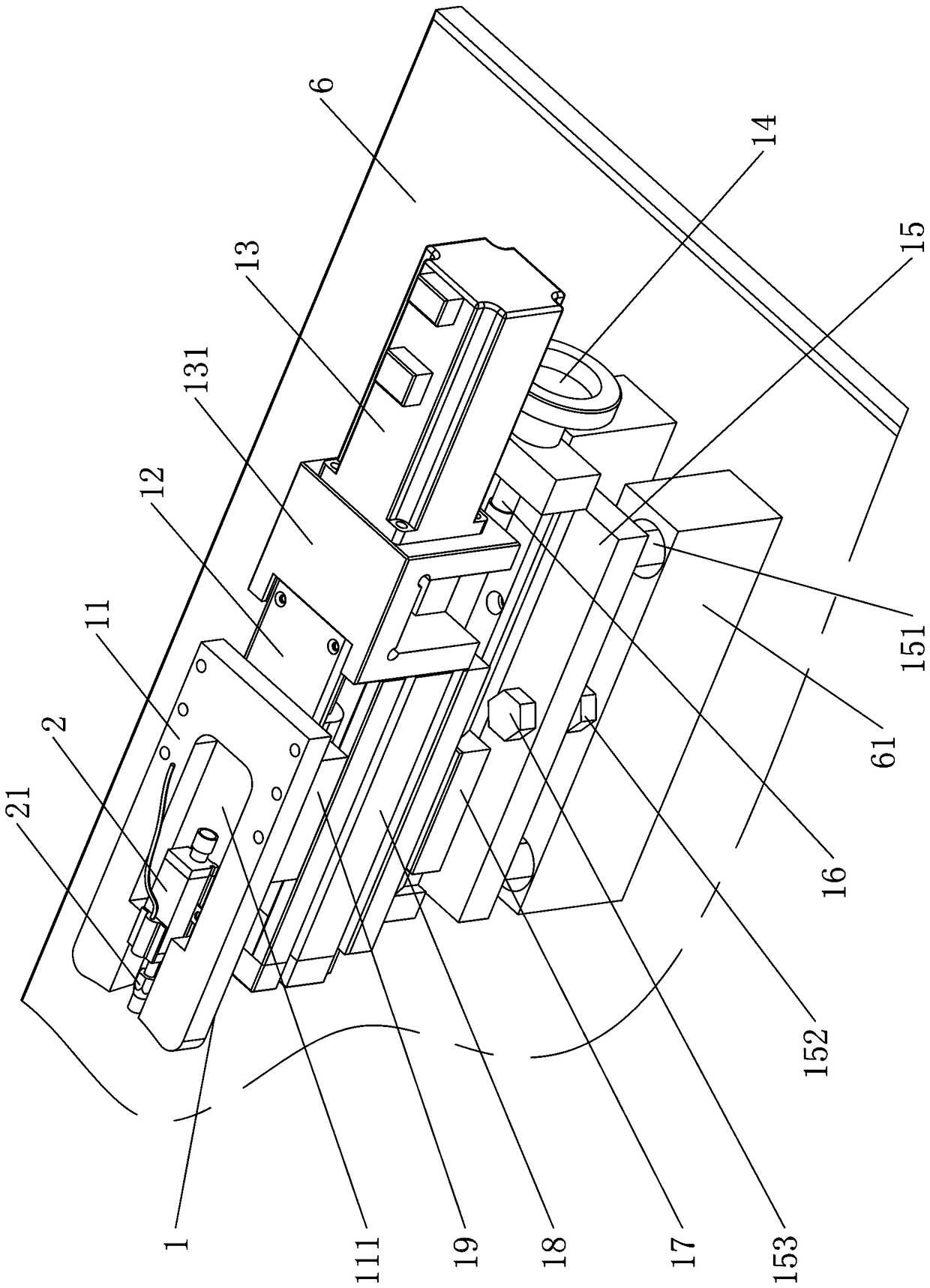

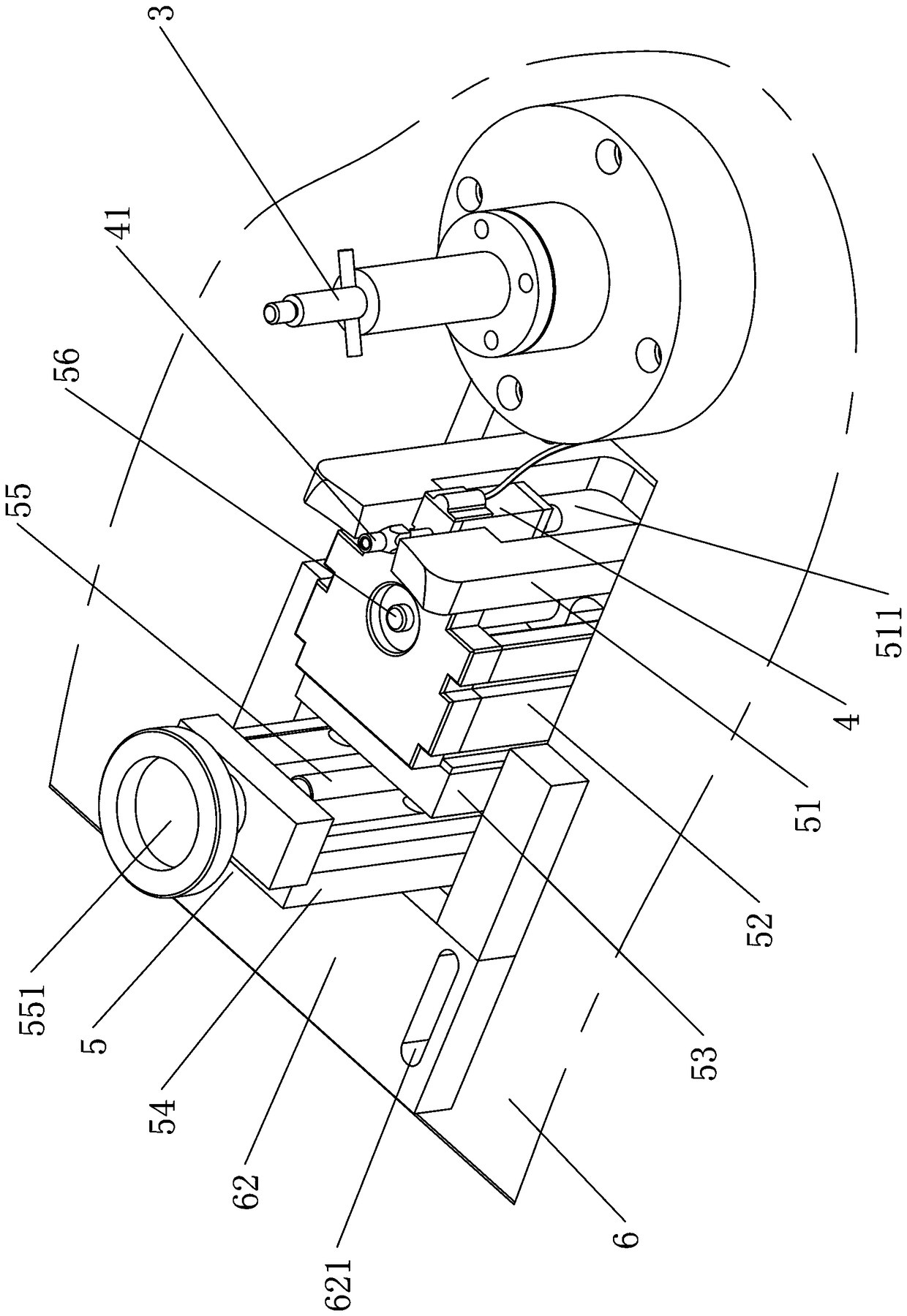

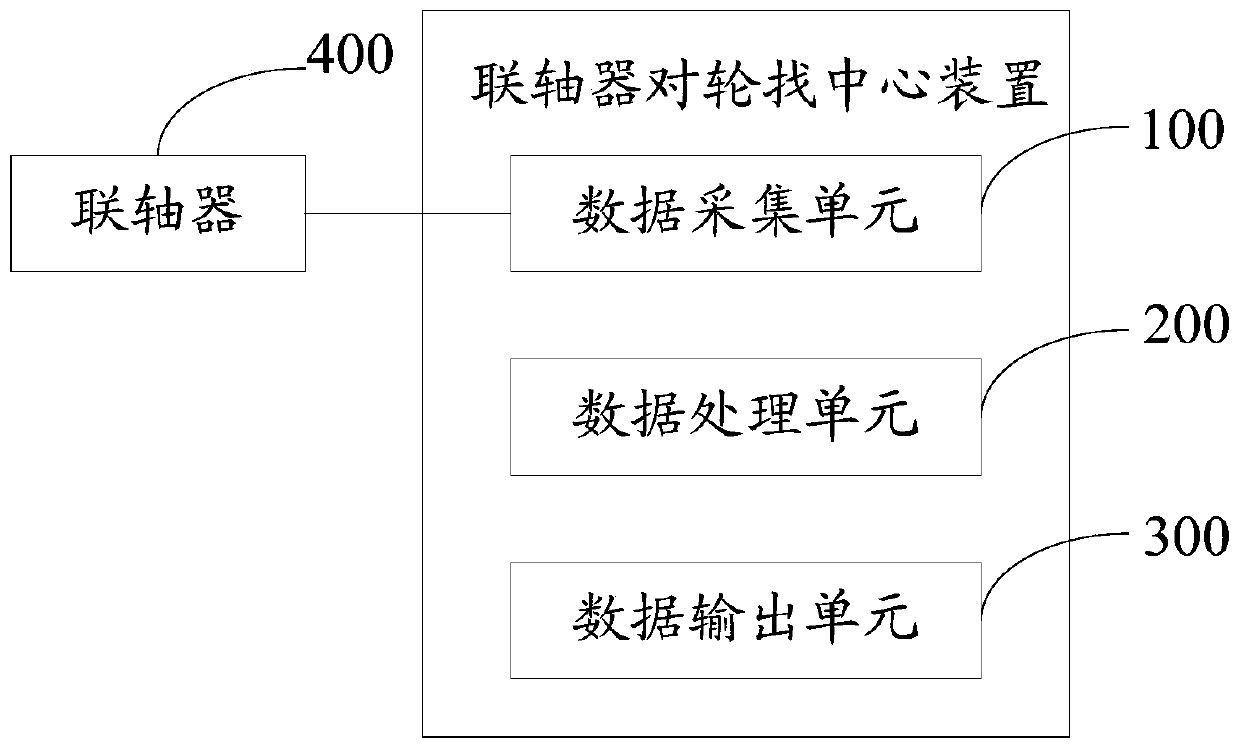

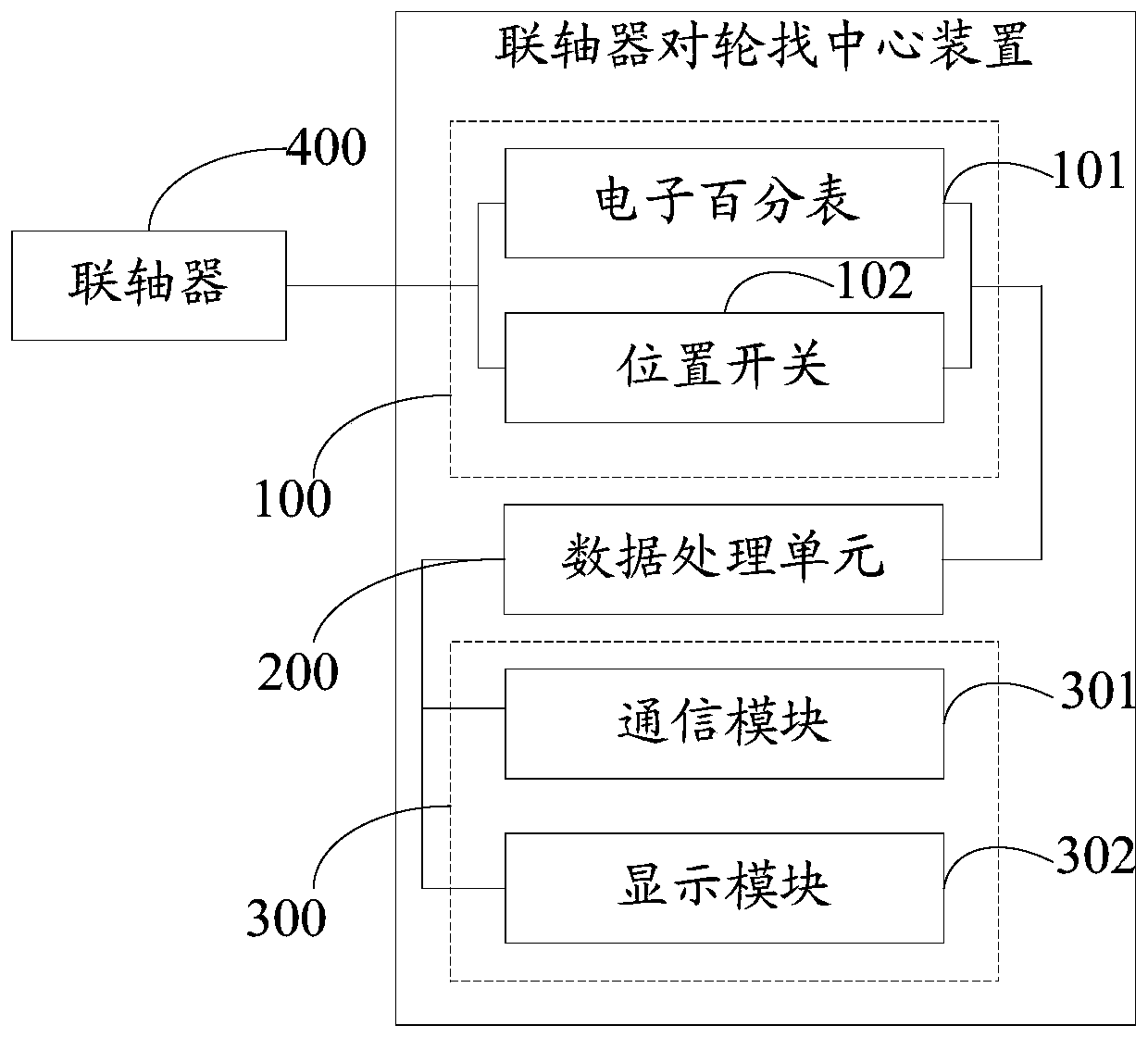

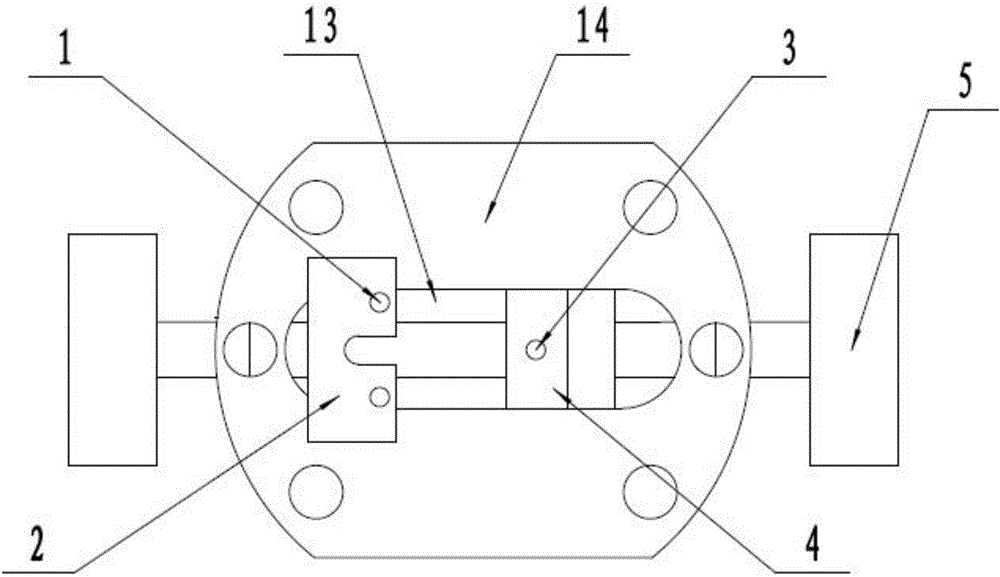

Coupler paired wheel centering device and method

InactiveCN110926296AHigh precisionImprove labor efficiencyMechanical measuring arrangementsAlgorithmAxial data

The invention relates to the technical field of coupler centering, and discloses a coupler paired wheel centering device and method. The device comprises a data acquisition unit, a data processing unit and a data output unit; the data acquisition unit is used for detecting the radial data and the axial data when the paired wheels of a coupler are centered, and sending the radial data and the axialdata to the data processing unit, the data processing unit is used for calculating a deviation value between the paired wheels of the current coupler according to the radial data and the axial data,generating a deviation adjustment scheme according to the deviation value and sending the deviation value and the deviation adjustment scheme to the data output unit, and the data output unit is usedfor displaying the deviation adjustment scheme to a user. The invention further provides a coupler paired wheel centering method which enables the labor efficiency to be improved, the equipment maintenance cost to be reduced, and the coupler centering precision to be improved.

Owner:华润电力(宜昌)有限公司

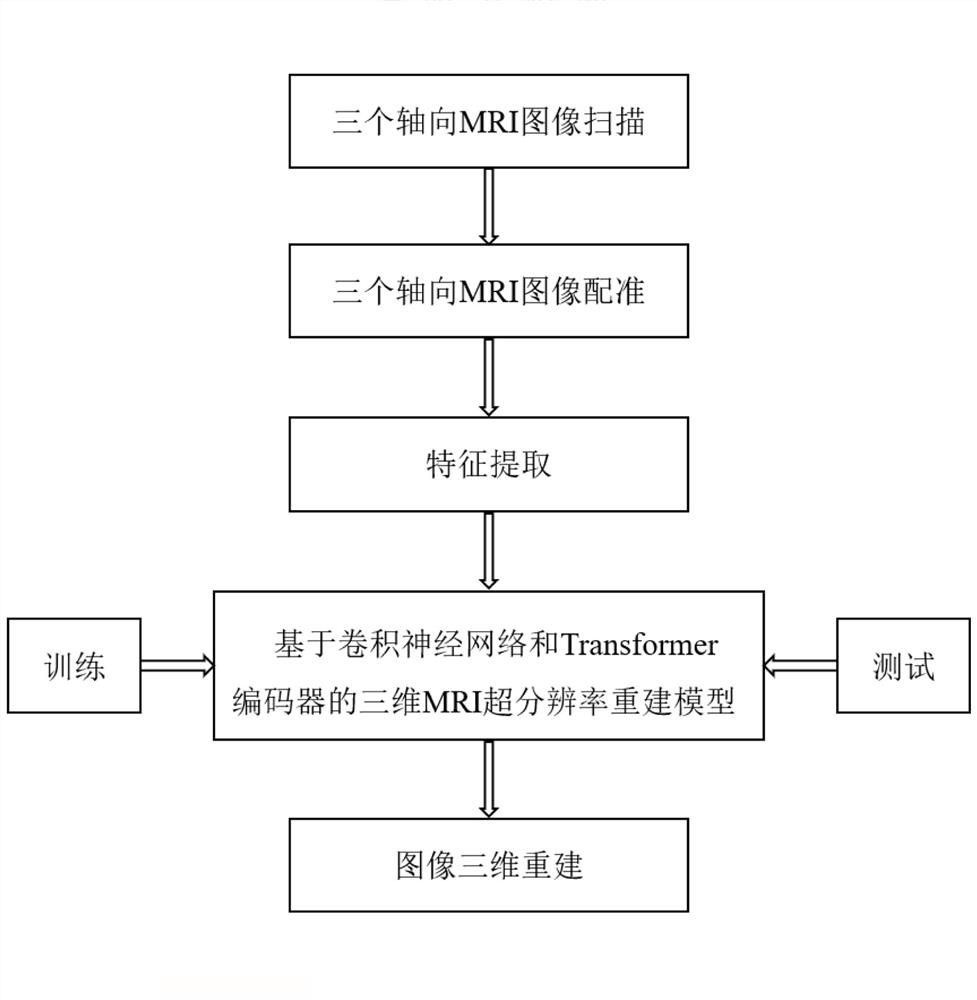

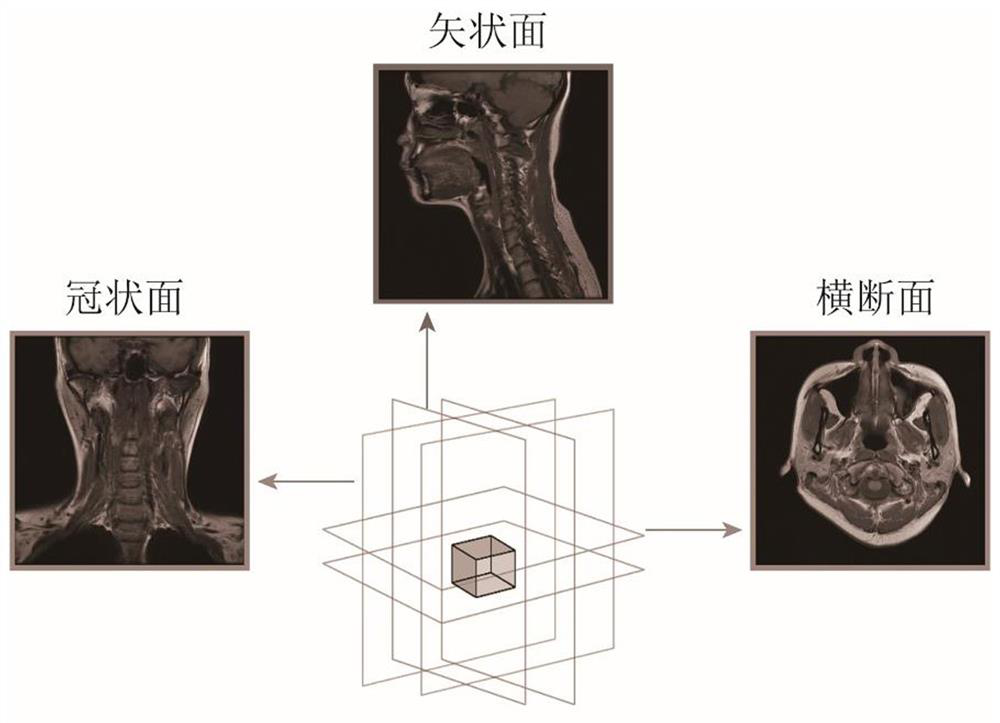

Head three-dimensional MRI super-resolution reconstruction method

The invention discloses a head three-dimensional MRI super-resolution reconstruction method, which comprises the following steps: firstly, selecting high-resolution MRI image data, preprocessing the selected MRI data to obtain small data blocks, and taking the small data blocks as training data; then establishing a three-dimensional MRI super-resolution reconstruction model based on a convolutional neural network and a Transform encoder, and training the model by taking the small data blocks as input to obtain the three-dimensional MRI super-resolution reconstruction model; and finally, processing the three axial MRI data to obtain cube cavity data, inputting the cavity data into the trained model to obtain small cubes with filled cavities, and splicing the small cubes with filled cavities to form a complete data space. The method is small in model scale, high in image reconstruction speed and high in reconstructed image quality, and provides more precise data for medical image processing.

Owner:GUILIN UNIV OF ELECTRONIC TECH

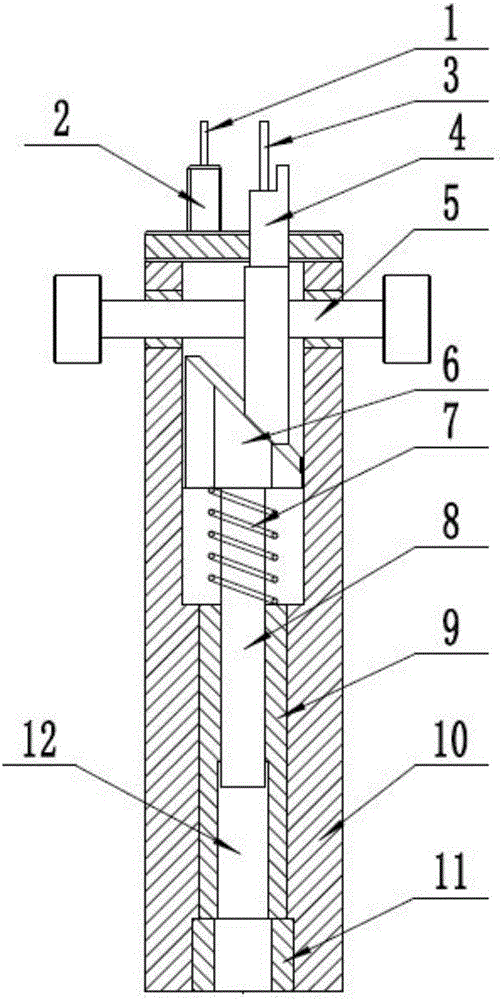

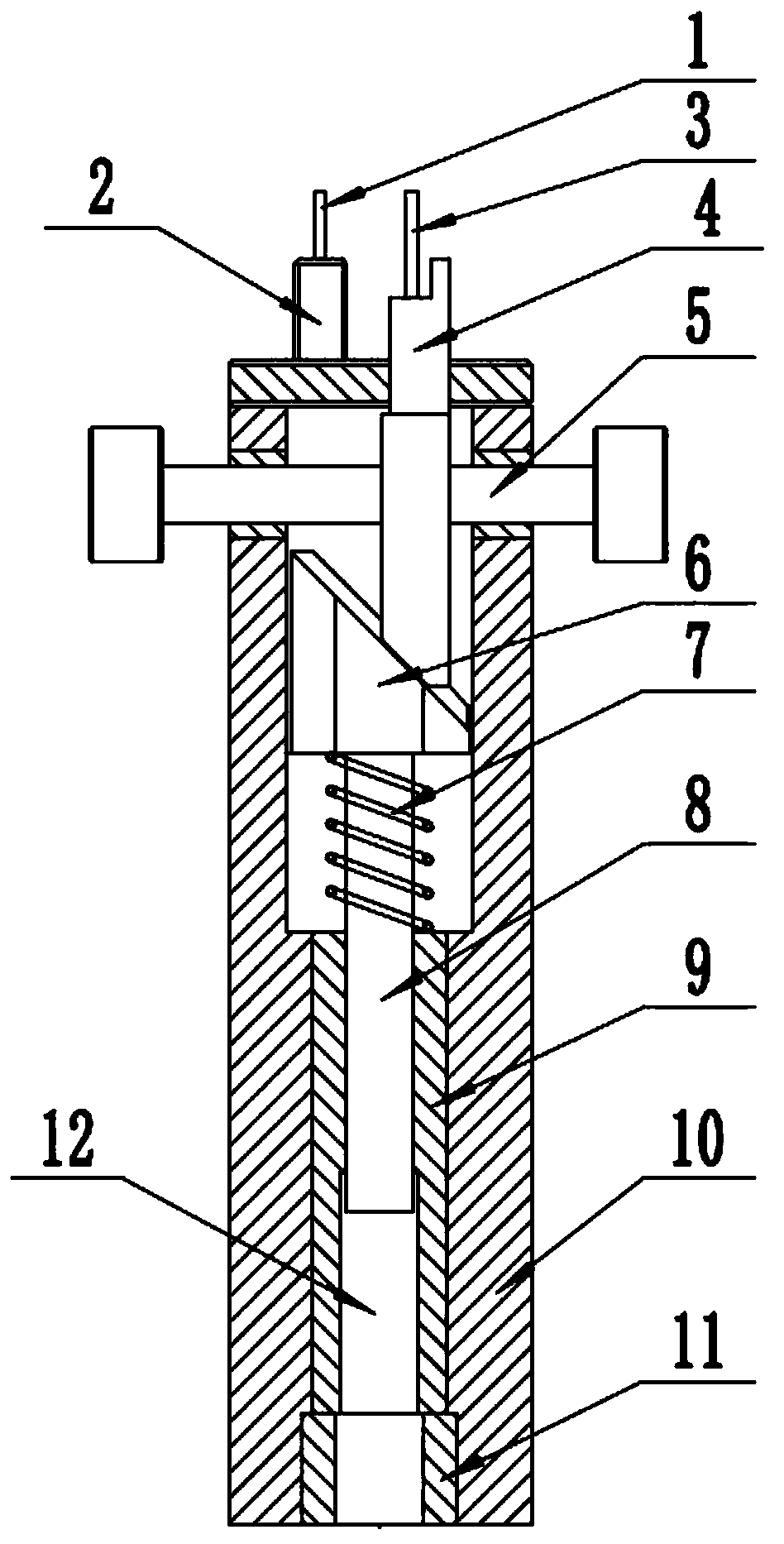

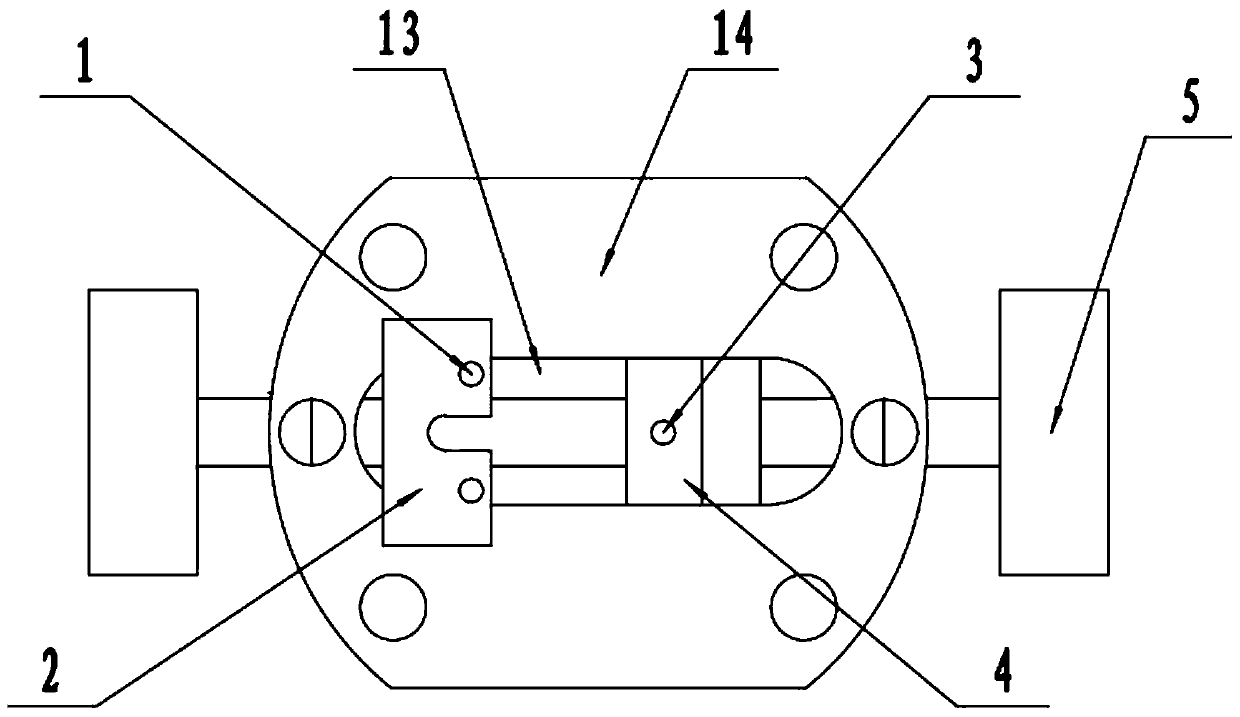

Device for measuring part concealed portion gap value

InactiveCN106767263AImprove stabilityConvenient toggle operationMechanical clearance measurementsAxial dataBiomedical engineering

The invention discloses a device for measuring the part concealed portion gap value. The device comprises a handheld base, an end cover, a fixed measuring needle, a movable measuring needle, a radial poking rod, a sliding wedge, a longitudinal push rod and a reading device; the handheld base is internally of a hollow structure, the end cover is installed at one end of the handheld base, a fixed measuring needle base and a movable measuring needle base are arranged on the upper portion of the end cover, the fixed measuring needle is arranged on the fixed measuring needle base, the movable measuring needle is arranged on the movable measuring needle base, and the movable measuring needle base penetrates through a transverse sliding groove formed in the and abuts against the inclined face at one end of the sliding wedge located in the handheld base; the radial poking rod penetrates through the handheld base and the movable measuring needle base on the lower portion of the end cover in the radial direction; the reading device is arranged in the other end of the handheld base, and the longitudinal push rod is arranged between the other end of the sliding wedge and the reading device. By adopting the fixed measuring needle, the movable measuring needle and the longitudinal push rod moving in the axial direction, the data obtained through transverse measurement is converted into axial data to be displayed, and then the part gap value is measured.

Owner:SHANGHAI DIE TECH INST +1

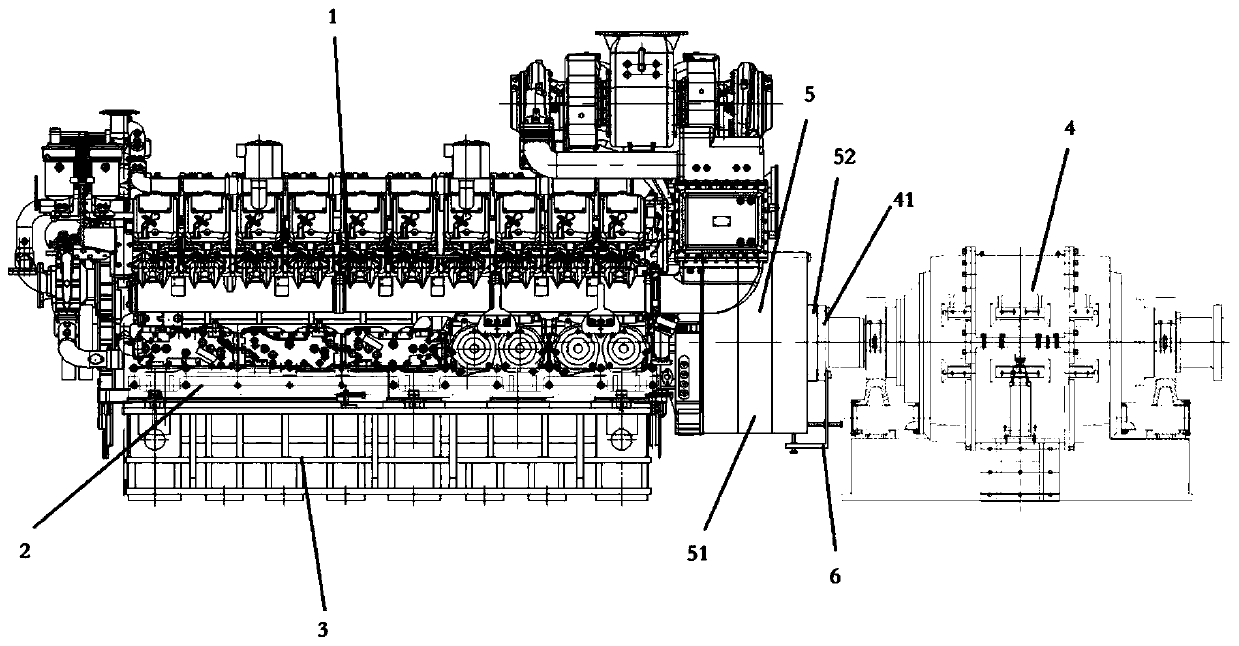

Centering method of diesel engine with integral support leg and dynamometer

PendingCN110530645ASimple stepsShort measuring cycleInternal-combustion engine testingAngles/taper measurementsWhole bodyEngineering

To solve the problem that the centering is difficult when a diesel engine with an integral support leg is connected to a dynamometer in the prior art, the invention provides a centering method of a diesel engine with an integral support leg and a dynamometer. The method comprises the steps of (S1) performing pre-centering on the dynamometer and a base of the diesel engine according to a designed size requirement, (S2) connecting the diesel engine, the integral support legs and the diesel engine base and connecting a connection high-elasticity unit and the dynamometer into a whole body, (S3) measuring the connection high-elasticity unit for one time by using a centering frame every fixed angle, recording axial and radial data, and adjusting the position of the diesel engine according to thedata, and (S4) repeating the step (S3) until technological requirements are met to complete the centering. According to the method, the radial and axial data of the diesel engine are measured every 90 degrees through the centering frame, then the diesel engine is adjusted according to the data, and the diesel engine and the dynamometer are connected in a centering mode step by step.

Owner:HENAN DIESEL ENGINE IND

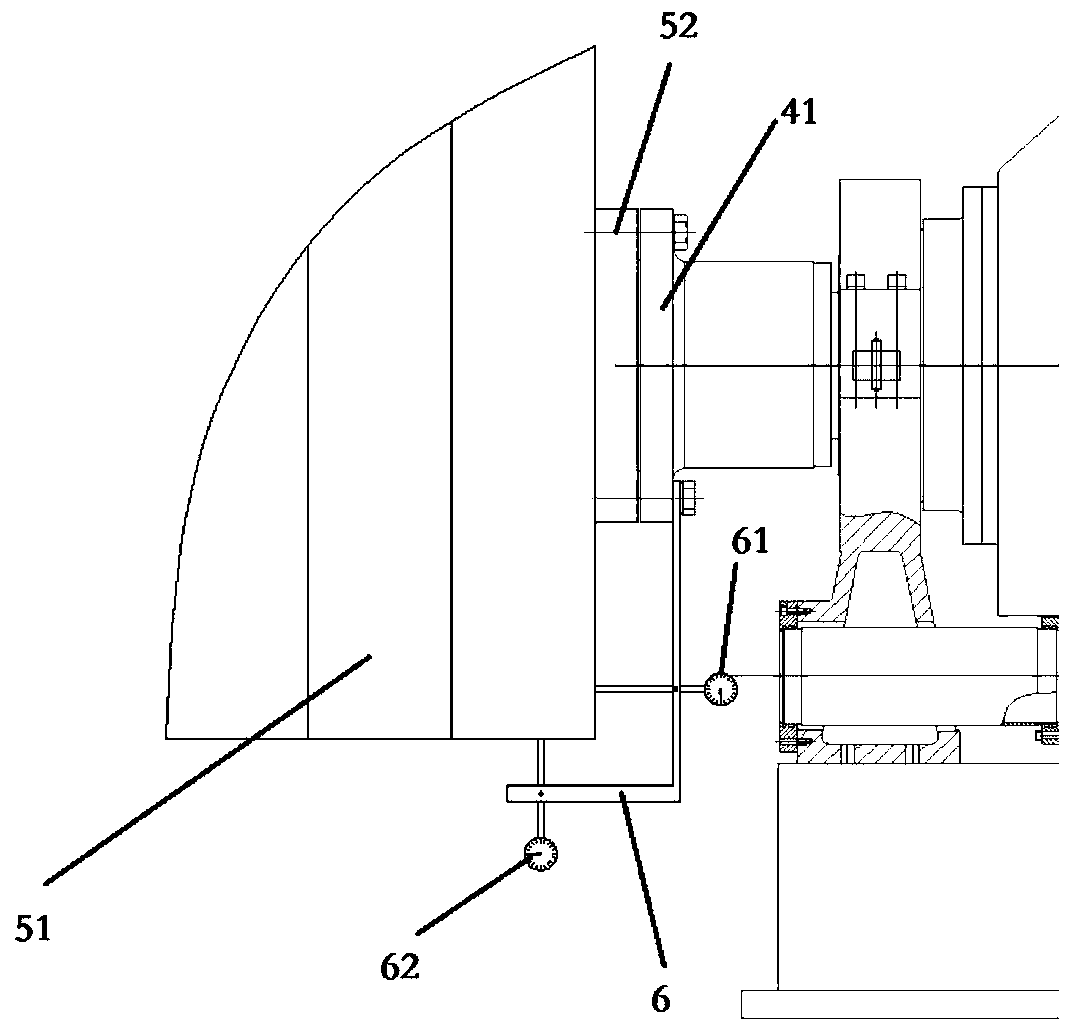

Installing and positioning method for parts on outer surfaces of blades of wind turbine generator

PendingCN112677512AEasy to findReduce operating hoursFinal product manufactureMachines/enginesMarking outEngineering

The invention discloses an installing and positioning method for parts on outer surfaces of blades of wind turbine generator. The method comprises the following steps that corresponding data on the inner surface of a blade production female mold are measured according to chordwise and axial data of part installing positions or part operation positions, and marks are drawn; the drawn marks are converted into permanent marks, and the inner surfaces of the marks need to be processed to be smooth; when the number of the positions needing to be marked is large and the distance between the positions is short, character labels are pasted near the positions, the labels are pasted to the surface of the female mold, and the surfaces of the labels need to be covered with small demolding cloth or easy-to-tear films; for the positioning position of a lightning arrester, a mark is drawn on the upper surface of the cloth layer according to the marks on the inner surface of the female mold after the laying is finished; and the outer surface of the blade separated from the female mold can present protruding marks corresponding to the marks on the female mold, the protruding marks can be used as the direct basis for subsequent root cutting, lightning arrester installation, weighing and balance weight positioning, and the protruding marks only need to be polished to be flat and coated with paint before the blade leaves a factory. By means of the method, part installation and necessary production operation can be conducted rapidly, easily, conveniently and accurately.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

Method and device for processing security check CT (Computed Tomography) reconstructed image

InactiveCN112884855AIncrease sampling rateReduce artifactsReconstruction from projectionImage generationData expansionImaging processing

The invention discloses a method and a device for processing a security check CT (Computed Tomography) reconstructed image. According to the method, projection data collected by a security check CT wide-row detector is subjected to inter-row expansion, the pixel height after expansion becomes half of the pixel height before expansion, and the expansion row data is obtained through correlation calculation according to two rows of projection data closest to the expansion row data; and iterative inter-row data expansion is performed on the projection data according to the row spacing and the actual pixel width until the pixel height of the expanded projection data is smaller than or equal to the actual pixel width. A CT image processing device comprises a data acquisition module, a wide-row CT projection data expansion module and a reconstruction module. The invention has the advantages that the expanded projection data is used for reconstruction without changing existing scanning conditions, the axial data sampling rate is increased, windmill artifacts are greatly reduced, and the quality of reconstructed images is obviously improved.

Owner:BEGOOD TECH

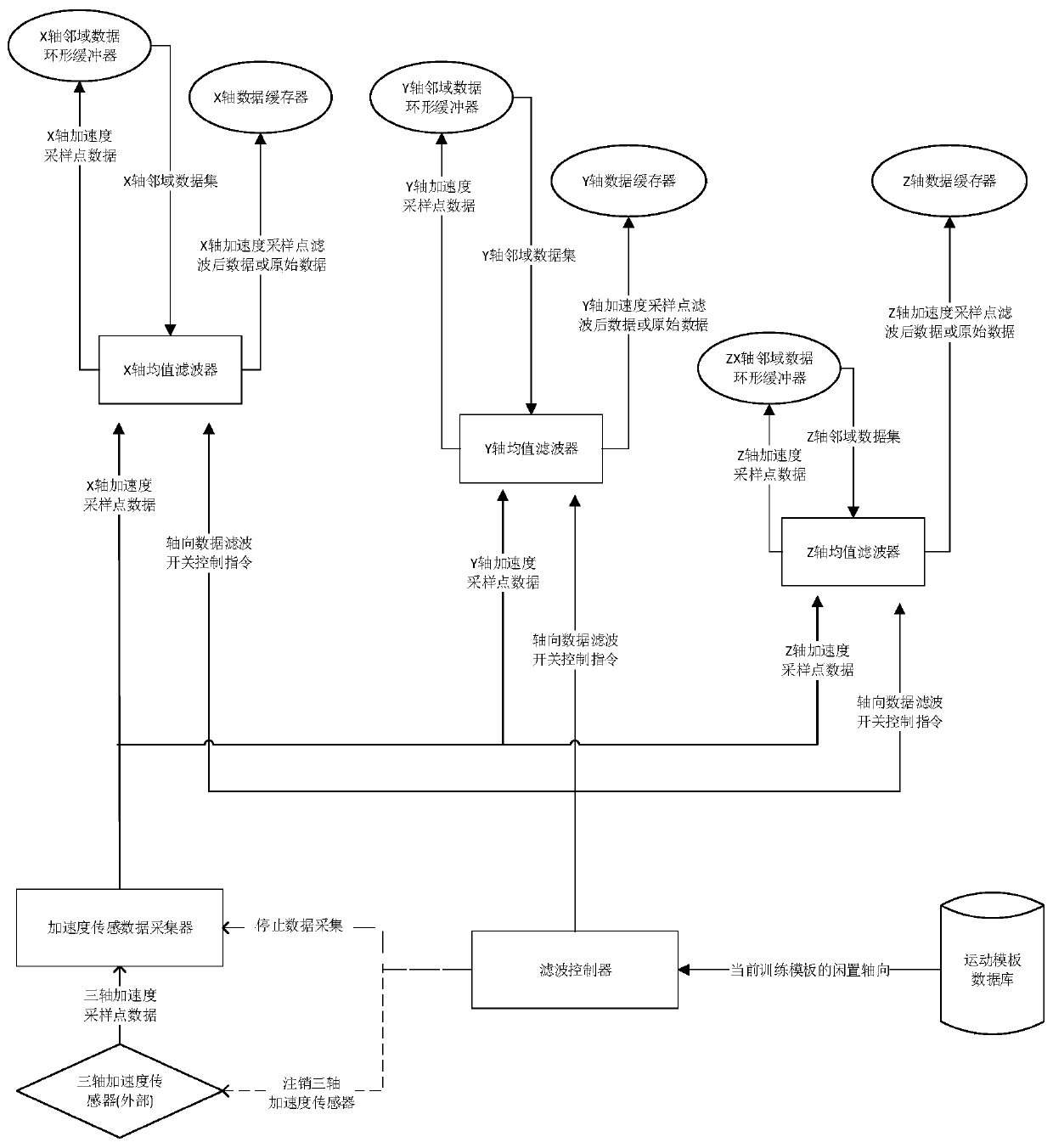

A Mean Filtering Device for Three-axis Acceleration Data Used in Motion Detection

ActiveCN107314767BEffective filteringReduce occupancyDigital technique networkNavigation by speed/acceleration measurementsSensing dataAlgorithm

The invention discloses a mean filtering device for triaxial acceleration data applied to motion detection. The device comprises a motion template database, a filtering controller, an acceleration sensing data collector, an X-axis neighborhood data circular buffer, a Y-axis neighborhood data circular buffer, a Z-axis neighborhood data circular buffer, an X-axis data buffer, a Y-axis data buffer, a Z-axis data buffer, an X-axis mean filter, a Y-axis mean filter and a Z-axis mean filter. According to the idle axial directions of a training template, the filtering functions of corresponding axial directions are turned on or off and each axial neighborhood data circular buffer and each axial data buffer are set; each buffer and each filter are used for mean filtering of data of each axial direction; and thus, high-frequency noise in low-frequency motion signals is effectively filtered out in the process of motion detection under the condition of low consumption of system resources, and the technical problems of incapability of effectively filtering out noise in motion signal and high consumption of system resources in the prior art are overcome.

Owner:泉州味盛食品有限公司

A Mean Filtering Method for Three-axis Acceleration Data Used in Motion Detection

InactiveCN107091638BEffective filteringHigh speedNavigation by speed/acceleration measurementsCharacter and pattern recognitionSensing dataData acquisition

The invention discloses a mean value filtering method for three-axis acceleration data used for motion detection. When using a three-axis acceleration sensor for data collection in motion detection, the filter function of the corresponding axis is switched according to the idle axis of the training template. , each axial neighborhood data ring buffer and each axial data buffer are set, each buffer and filter are used to perform mean value filtering on each axial data, and when interrupted by an external event, the acceleration sensing data The collector stops data collection or logs off the three-axis acceleration sensor, and stops three-axis acceleration data filtering. In this way, the effective filtering of the high-frequency noise in the low-frequency motion signal is realized in the motion detection process under the condition of low system resource consumption, and the problems of the inability to effectively filter the motion signal noise and the high consumption of system resources in the prior art are solved. technical problem.

Owner:温胜洁

Multi-parameter measurement recorder of downhole tool string

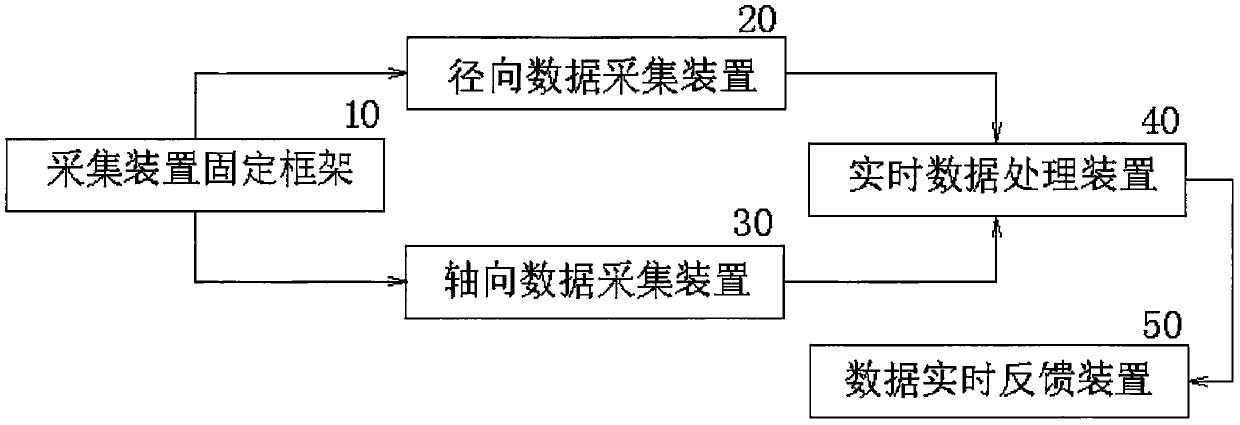

ActiveCN107941187AIncrease flexibilityAvoid measurement errorsUsing optical meansReal-time dataFixed frame

The invention relates to a multi-parameter measurement recorder of a downhole tool string. The multi-parameter measurement recorder comprises a collection device fixed frame, a radial data acquisitiondevice, an axial data acquisition device, and a real-time data processing device. The collection device fixed frame is used for forming a passing channel and providing a connection structure for encircling the passing channel by the data acquisition devices. The radial data acquisition device is used for collecting a real-time radial width of passing through the passing channel by a measured object. The axial data acquisition device applied to a follow-up radial data acquisition device is used for collecting a real-time axial length of passing through the passing channel by the measured object. The real-time data processing device is used for forming a radial width and axial continuously changing data when the measured object passes through the passing channel continuously based on the obtained width data and length data. According to the invention, a measurement reference is established and thus the downward length and the width of each downhole part can be measured accurately basedon measurement reference when the downhole tool string passes through the passing channel, so that the flexibility of series part combination mode of the downhole tool string is improved. Meanwhile, aphenomenon of forming a measurement error by human intervention during the measurement process is avoided.

Owner:长春市斯普瑞新技术有限责任公司

A Motion Behavior Recognition Method Based on Single-axis Acceleration Sensor

InactiveCN103310192BReduce computational overheadEasy to analyzeCharacter and pattern recognitionHuman bodyAccelerometer

The invention provides a movement behavior recognition method based on an axial acceleration sensor. According to the existing movement behavior recognition method based on multiple sensors or multiple axial sensors, data of multiple sensors or data of multiple axial sensors are required to combine, accordingly high computing cost is resulted, cost is increased, and meanwhile, real-time recognition is reduced. The method includes adopting axial data information of one acceleration sensor, extracting human body features, particularly three feature values of threshold in front of the peak of wave, threshold in front of the trough of wave, and time interval between the peak of wave and the trough of wave, in movement by waveforms formed through comparing the axial data information acquired by the sensor, and realizing accurate recognition of movement behaviors like squat, jump, run and the like. By the aid of the method, high recognition accuracy is achieved, computing cost is reduced, real-time recognition is improved, and cost is reduced.

Owner:NANJING UNIV OF POSTS & TELECOMM

Numerical-control scanner

ActiveCN102724380BReal-time adjustment of clamping forceReduce wearGearingNumerical controlNumerical controlControl system

The invention discloses a numerical-control scanner which comprises a scanning device, a positioning device and a control system, wherein the scanning device can move through a power device and is used for real-time acquisition of axial data of a scanned file; the positioning device is used for positioning and rotating the scanned file and used for real-time acquisition of circumferential data of the scanned file; and the control system is connected with the scanning device and the positioning device and used for collecting and processing the real-time acquisition data of the scanning device and controlling the scanning device to move and the scanned file to rotate. The scanning device is movable, and the positioning device enables the scanned file to rotate axially, so that 360-degree scanning of the scanned file can be achieved during scanning, scanning effects can be guaranteed, and scanned data are processed and stored by the control system to facilitate use for numerical-control mechanical production.

Owner:DONGGUAN EMMA CNC TECH CO LTD

A kind of swimming monitoring method

InactiveCN106334307BAddressing a less studied problem in swim monitoringSolve less-studied problemsNavigation instrumentsSport apparatusAxial dataRisk stroke

The invention belongs to the field of sport monitoring and relates to a method for monitoring swimming. A gravity sensor of a device of the invention determines different swimming strokes through average value filtering of X, Y and Z axial data, in combination with a judgment formula, and according to the shape and the numerical value of data result. Compared with the prior art, the gaps in swimming detection of sport detection devices are filled up; wearable devices can be addedincluded to add the function of present wearable devices; the method has great market economic value and prospect.

Owner:SKY LIGHT ELECTRONIC (SHENZHEN) LIMITED CORPORATION

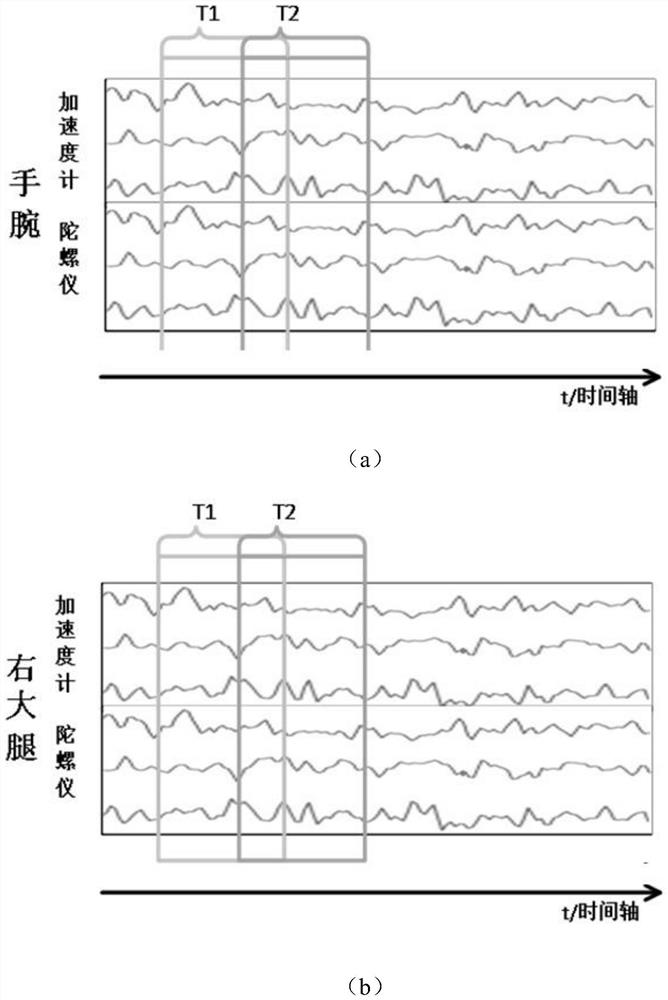

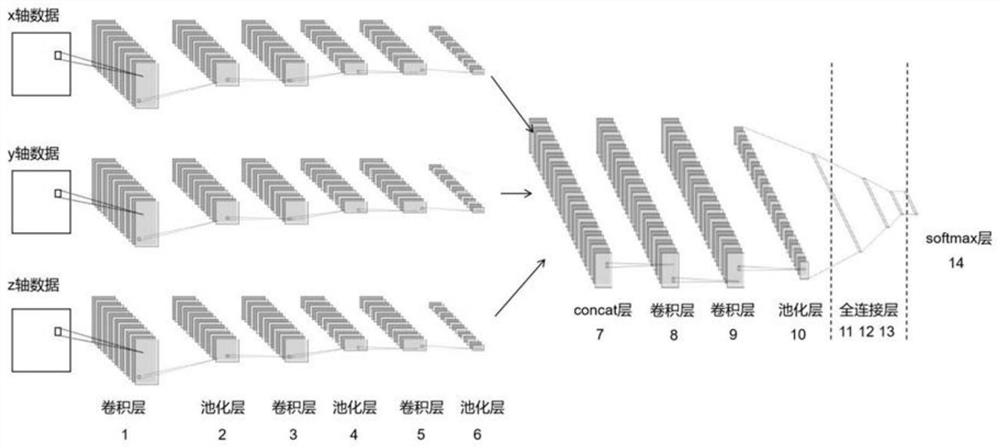

Behavior recognition system and method based on multi-position sensor feature fusion

PendingCN114881150AAccurate identificationEfficient identificationNavigation by speed/acceleration measurementsCharacter and pattern recognitionOriginal dataEngineering

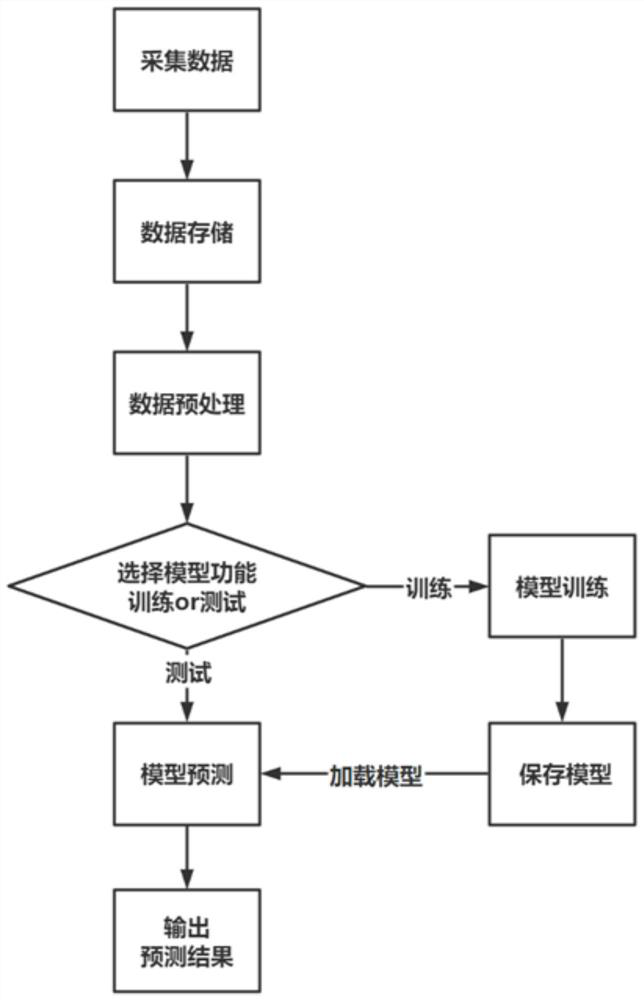

The invention belongs to the technical field of behavior recognition, and provides a behavior recognition system and method based on multi-position sensor feature fusion. The behavior recognition system based on multi-position sensor feature fusion comprises a data module and a model module, the data module stores and preprocesses collected original data to obtain action pictures for subsequent model training; the model module comprises a feature extraction sub-module and a classification sub-module, and a final prediction result is obtained. According to the method, spatial dependence among all data is abandoned, spatial dependence among same axial data of different sensors with stronger correlation is selected, three groups of action pictures are formed by extracting the data according to (x, y and z) three-axis directions and fusing the data, and feature fusion is performed through a secondary post-fusion model, so that the accuracy of the data fusion is improved. The time and space characteristics of the multi-dimensional time sequence data are effectively extracted, so that the aim of accurately identifying human behaviors is fulfilled.

Owner:NORTHEASTERN UNIV

A device for measuring the gap value of hidden parts of parts

InactiveCN106767263BImprove stabilityConvenient toggle operationMechanical clearance measurementsAxial dataEngineering

The invention discloses a device for measuring the part concealed portion gap value. The device comprises a handheld base, an end cover, a fixed measuring needle, a movable measuring needle, a radial poking rod, a sliding wedge, a longitudinal push rod and a reading device; the handheld base is internally of a hollow structure, the end cover is installed at one end of the handheld base, a fixed measuring needle base and a movable measuring needle base are arranged on the upper portion of the end cover, the fixed measuring needle is arranged on the fixed measuring needle base, the movable measuring needle is arranged on the movable measuring needle base, and the movable measuring needle base penetrates through a transverse sliding groove formed in the and abuts against the inclined face at one end of the sliding wedge located in the handheld base; the radial poking rod penetrates through the handheld base and the movable measuring needle base on the lower portion of the end cover in the radial direction; the reading device is arranged in the other end of the handheld base, and the longitudinal push rod is arranged between the other end of the sliding wedge and the reading device. By adopting the fixed measuring needle, the movable measuring needle and the longitudinal push rod moving in the axial direction, the data obtained through transverse measurement is converted into axial data to be displayed, and then the part gap value is measured.

Owner:SHANGHAI DIE TECH INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com