A device for measuring the gap value of hidden parts of parts

A gap value and position technology, which is applied in the field of devices for measuring the gap value of hidden parts of parts, can solve the problems of low measurement accuracy, poor repeatability and reproducibility, and achieve the effects of high measurement efficiency, no blocking feeling, and moderate length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

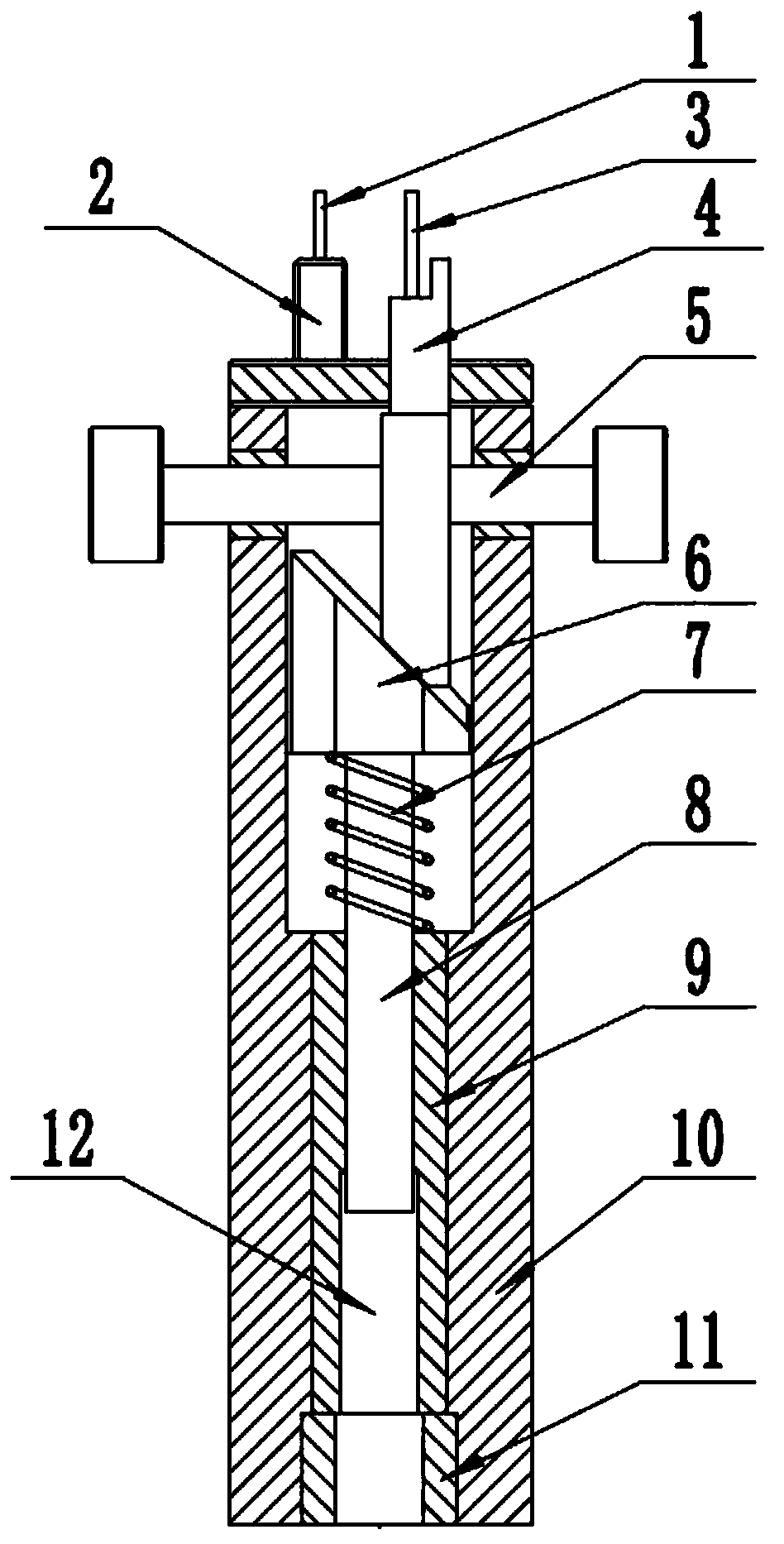

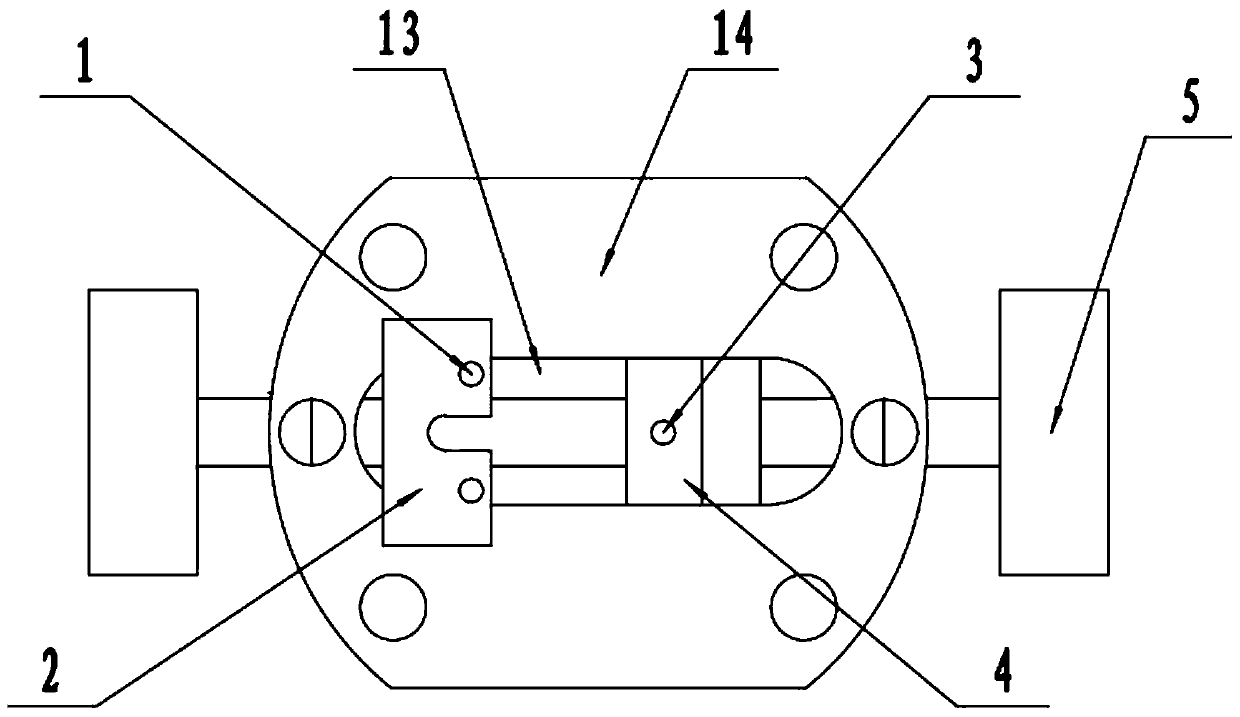

[0025] like figure 1 and 2 As shown, this embodiment provides a device for measuring the gap value of hidden parts, including a handheld base 10, an end cover 14, a fixed stylus 1, a movable stylus 3, a radial pull rod 5, a sliding wedge 6, Vertical push rod 8 and reading device 12; the interior of the hand-held base 10 is a hollow structure, and an end cover 14 is installed at one end of the hand-held base 10, and a transverse chute 13 is opened in the middle of the end cover 14, and the upper part of the end cover 14 is provided with a fixed The stylus seat 2 and the movable stylus seat 3, the fixed stylus seat 2 straddles the two sides of the transverse chute 13, the fixed stylus seat 2 is provided with the fixed stylus 1, and the movable stylus seat 4 is provided with the movable stylus 3. The movable stylus seat 4 runs through the transverse chute 13 opened on the end cover 14 and abuts against the slope at one end of the sliding wedge 6 inside the hand-held base 10, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com