Centrifugal impeller static balance automatic debugging machine

An automatic debugging and centrifugal impeller technology, applied in the static/dynamic balance test, machine/structural component test, measuring device, etc., can solve problems such as low efficiency, inconsistent concentricity between the wheel ring and the wheel disc, poor accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

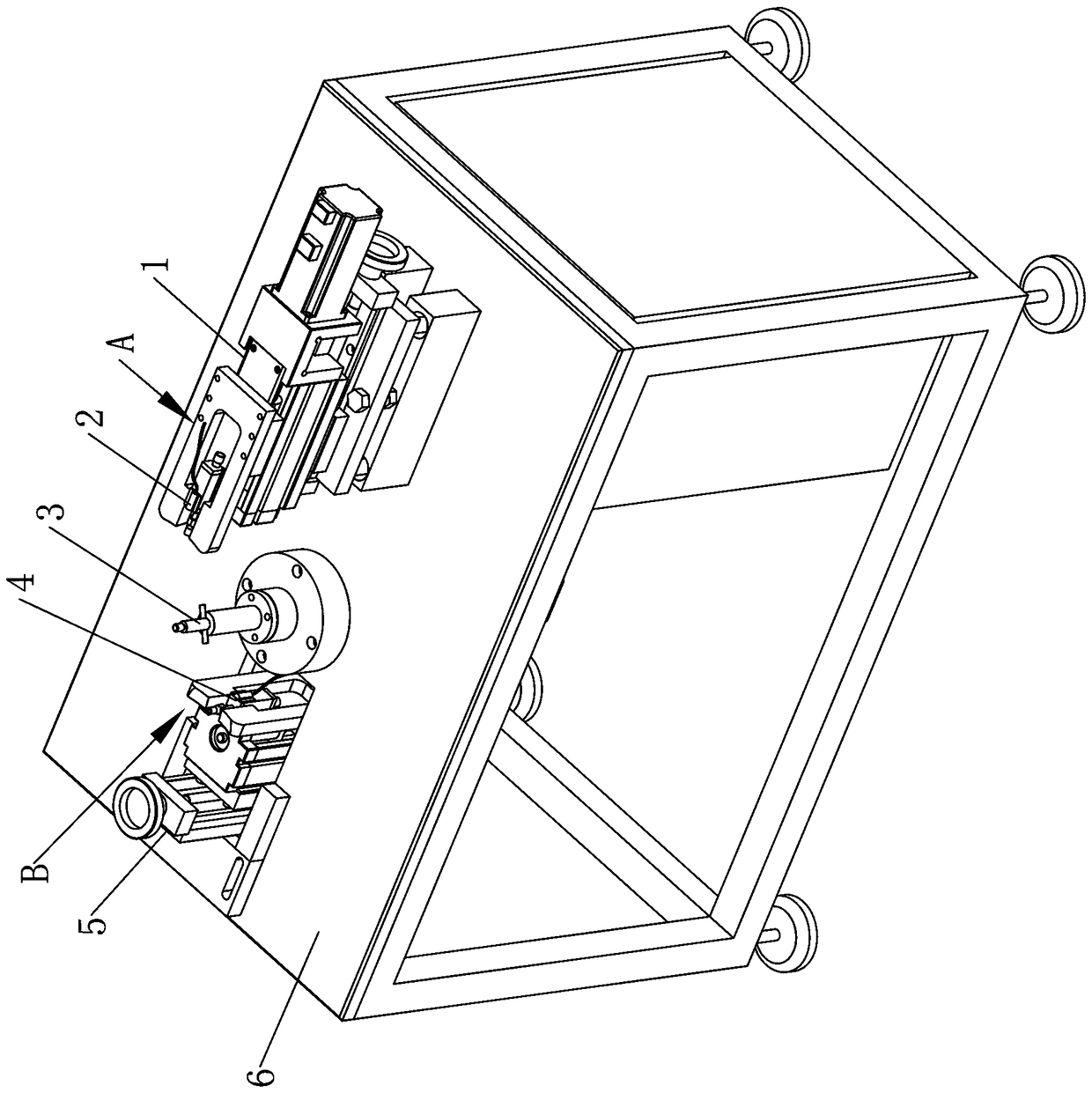

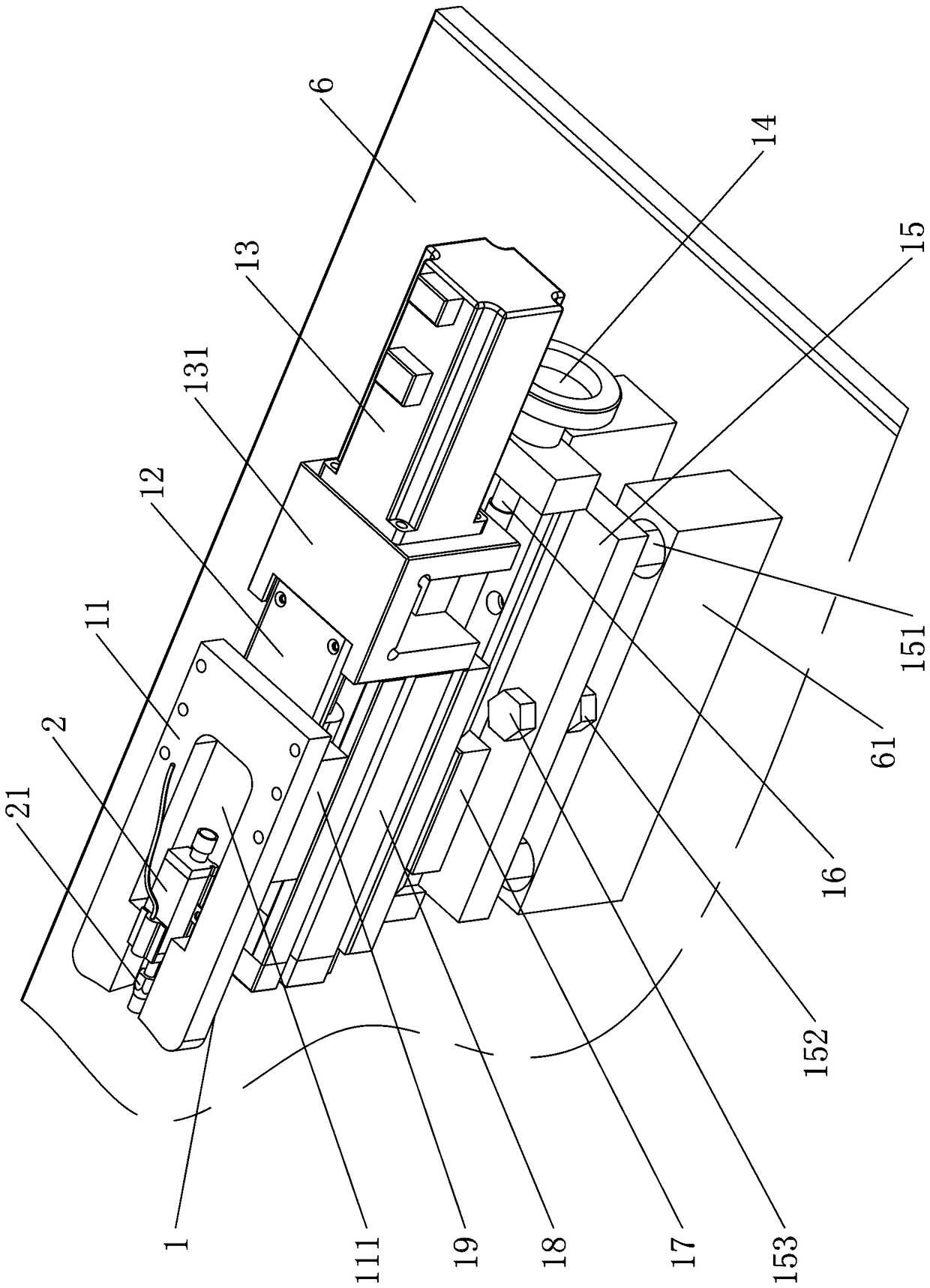

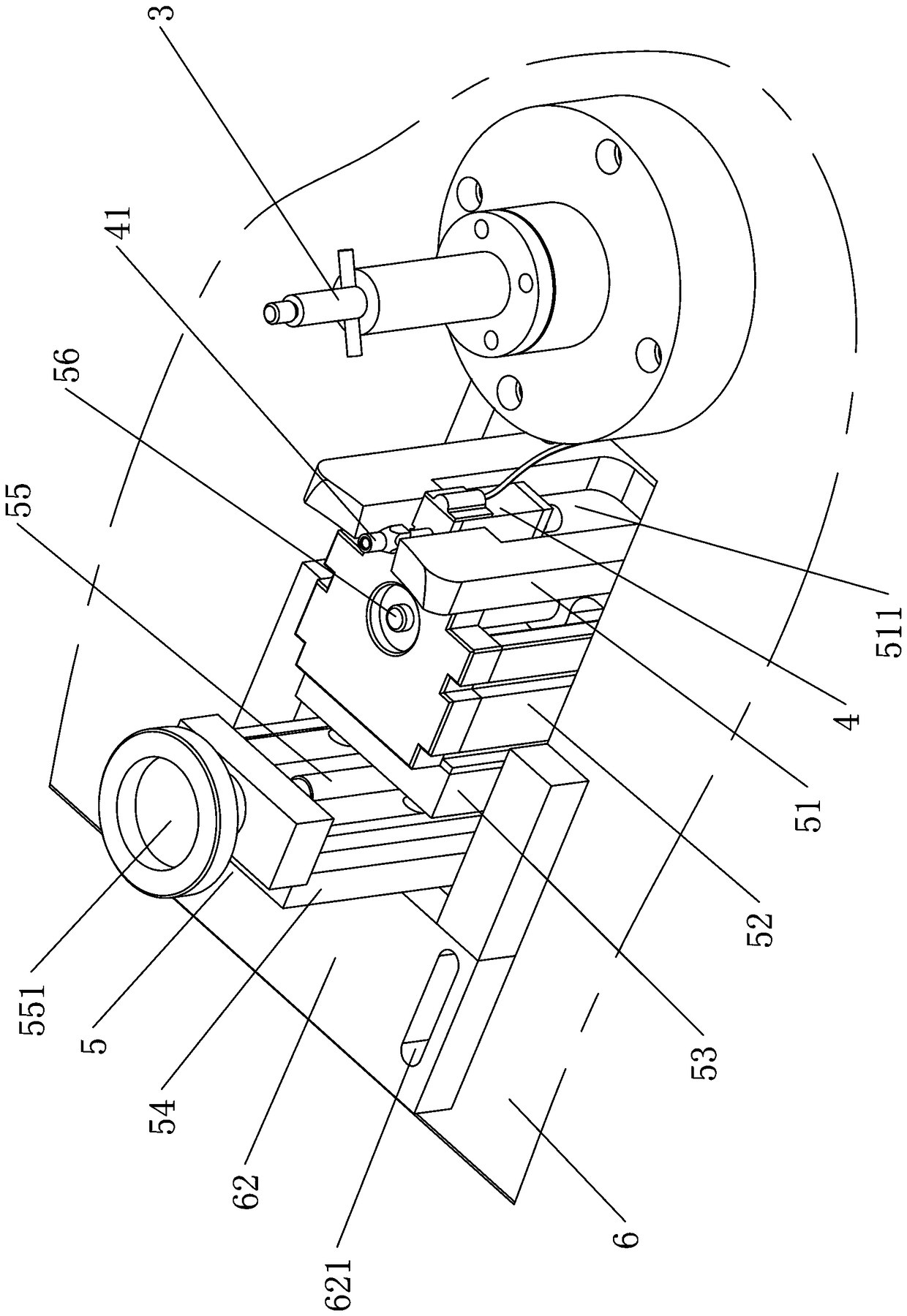

[0030] see Figure 1 to Figure 6 As shown, a centrifugal impeller static balance automatic debugging machine includes a machine platform 6, an impeller shaft 3 is arranged on the machine platform 6, and the impeller shaft 3 is connected to a rotary drive motor 32 in transmission, and a radial data is provided beside the impeller shaft 3. A monitoring assembly 1 and an axial data monitoring assembly 5; the radial data monitoring assembly 1 includes a radial measuring member 2 and a concentricity adjusting member 11 that move radially along the impeller shaft 3, and the axial data monitoring assembly 5 includes The rotating shaft 3 axially adjusts the moving axial measuring member 4 and the verticality adjusting member 51 .

[0031] The radial data monitoring assembly 1 also includes a transverse fixing seat 15, a transverse adjusting seat member, a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com