Centering method of diesel engine with integral support leg and dynamometer

A diesel engine and dynamometer technology, which is applied in the direction of internal combustion engine testing, using mechanical devices, mechanical measuring devices, etc., can solve problems such as alignment difficulties, and achieve the effects of high accuracy, simple steps, and good reference significance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

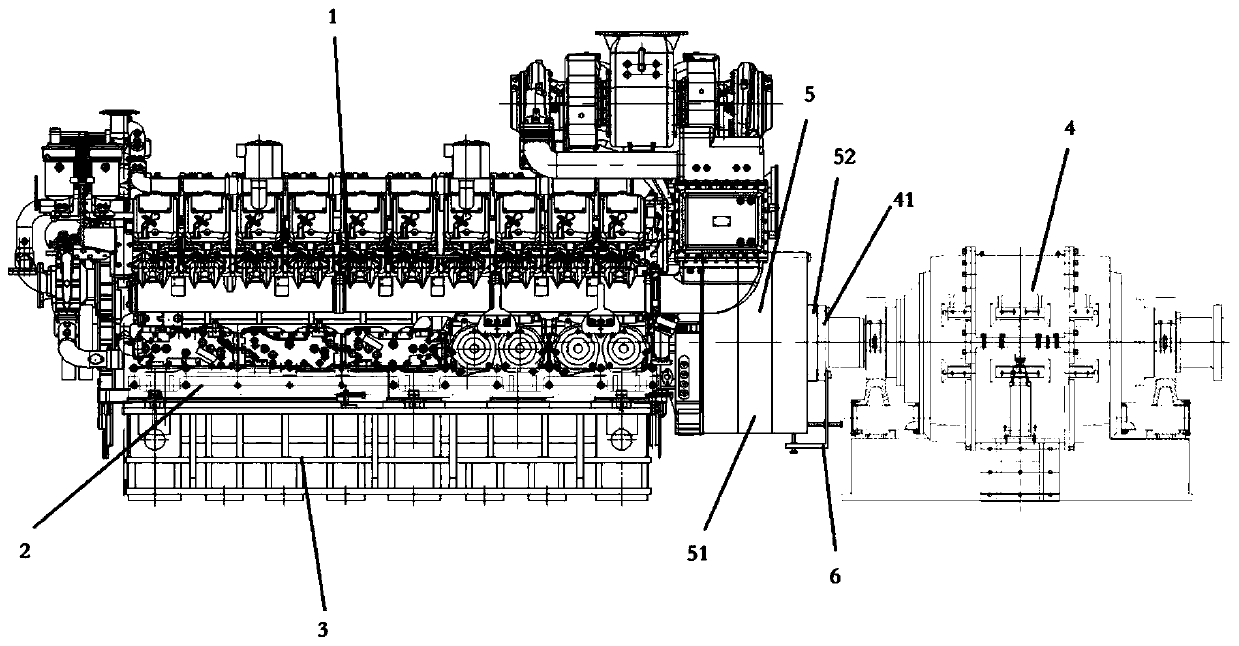

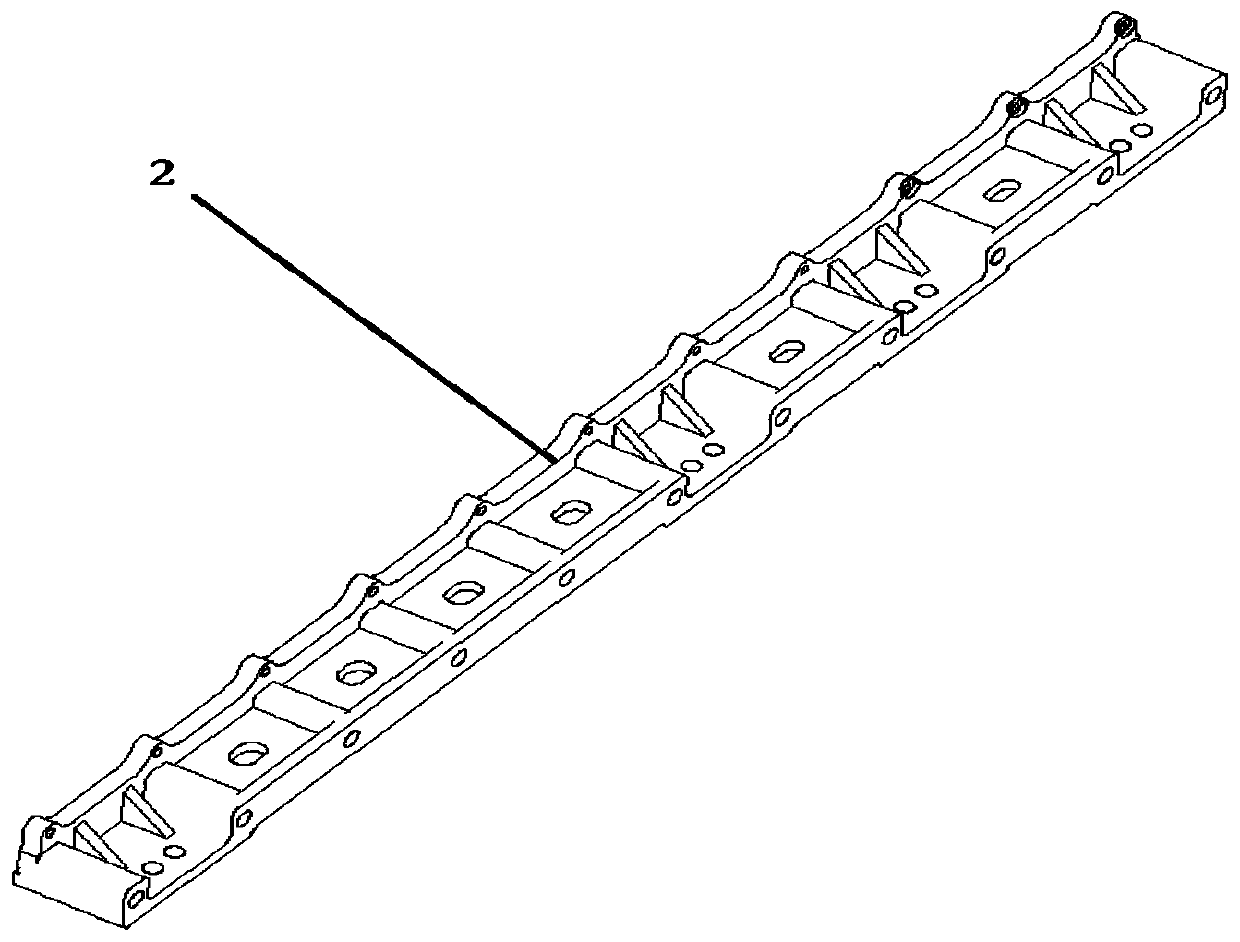

[0017] as attached Figure 1~4 As shown, a method of centering a diesel engine and a dynamometer using an integral foot consists of a diesel engine 1, an integral foot 2, a diesel engine bottom 3, a dynamometer 4, a connecting high elastic 5, and a centering bracket 6.

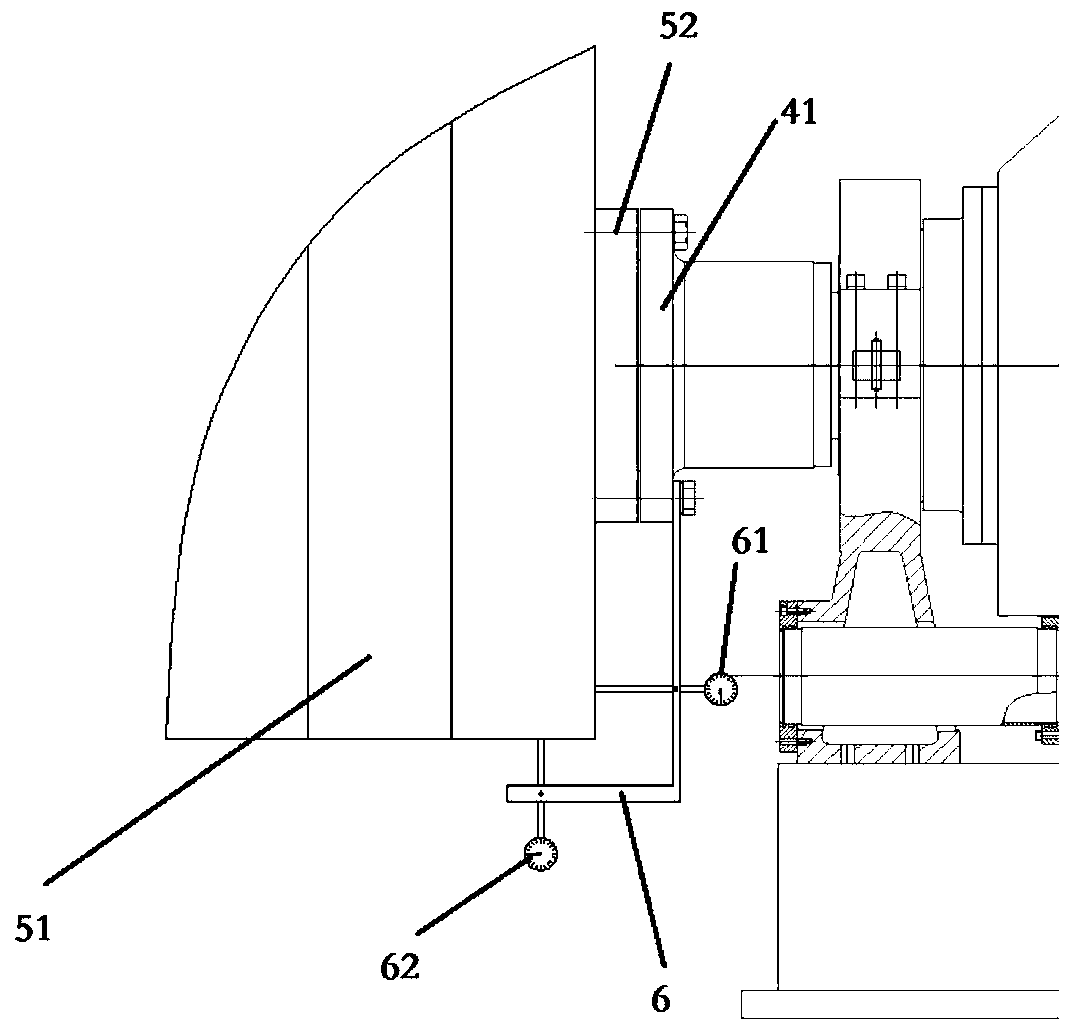

[0018] The centering frame 6 includes a centering bracket 65, a measuring bolt a63 and a measuring bolt b64; wherein, the end of the vertical long side of the centering bracket 65 is arranged on the dynamometer 4 and its horizontal short side Set towards the diesel engine 1; the vertical long side of the centering bracket 65 is provided with a measuring bolt a63 in axial contact with the high elastic 5 for measuring the axial alignment error of the diesel engine 1; on the horizontal short side of the centering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com