Punching-preventing safety device for pneumatic-hydraulic punch

A safety device, punching machine technology, applied in engineering safety devices, safety equipment, mechanical equipment and other directions, can solve problems such as personal injury, small workpiece size, punch down, etc., to prevent hidden dangers in operation and improve operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

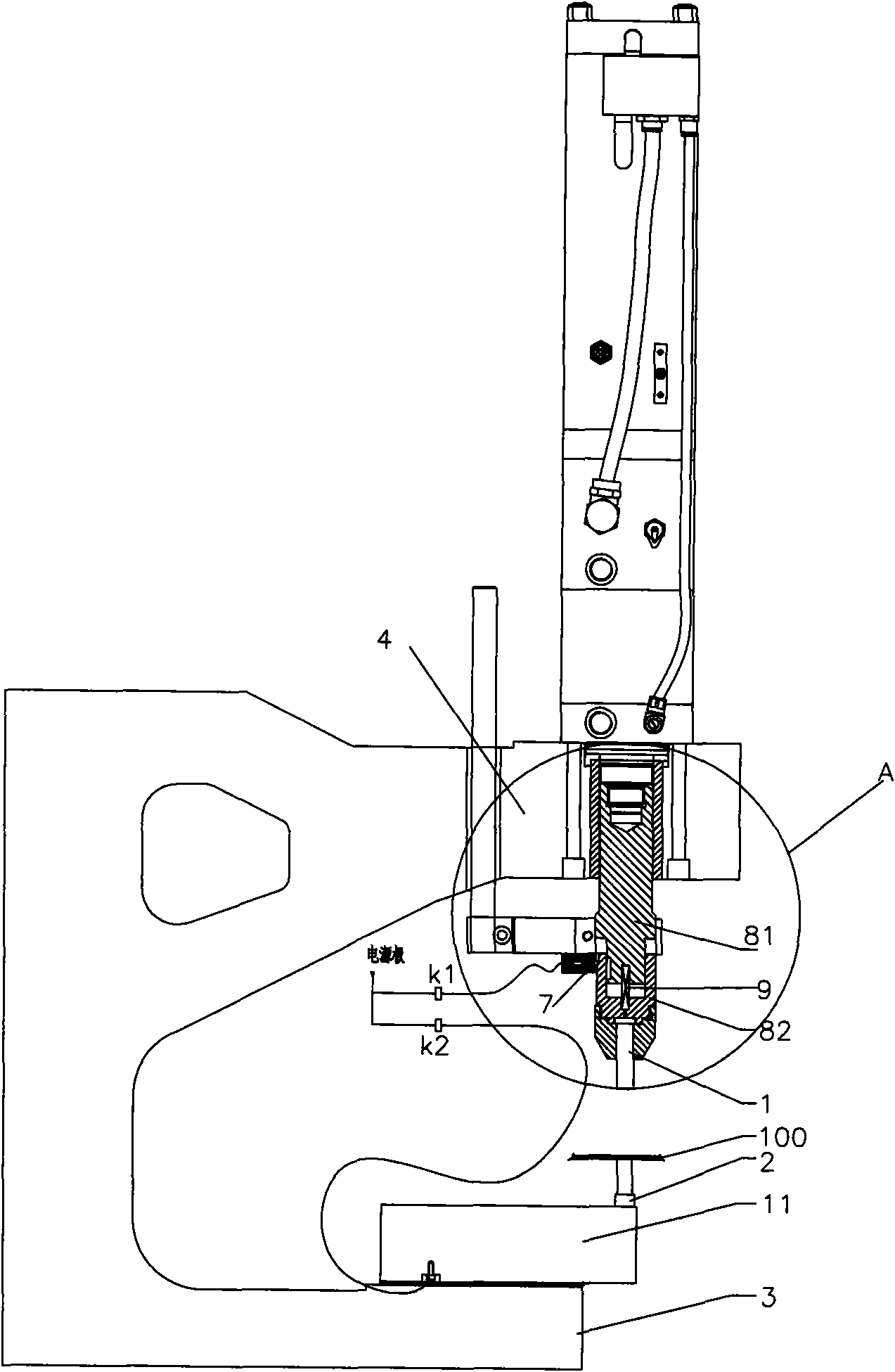

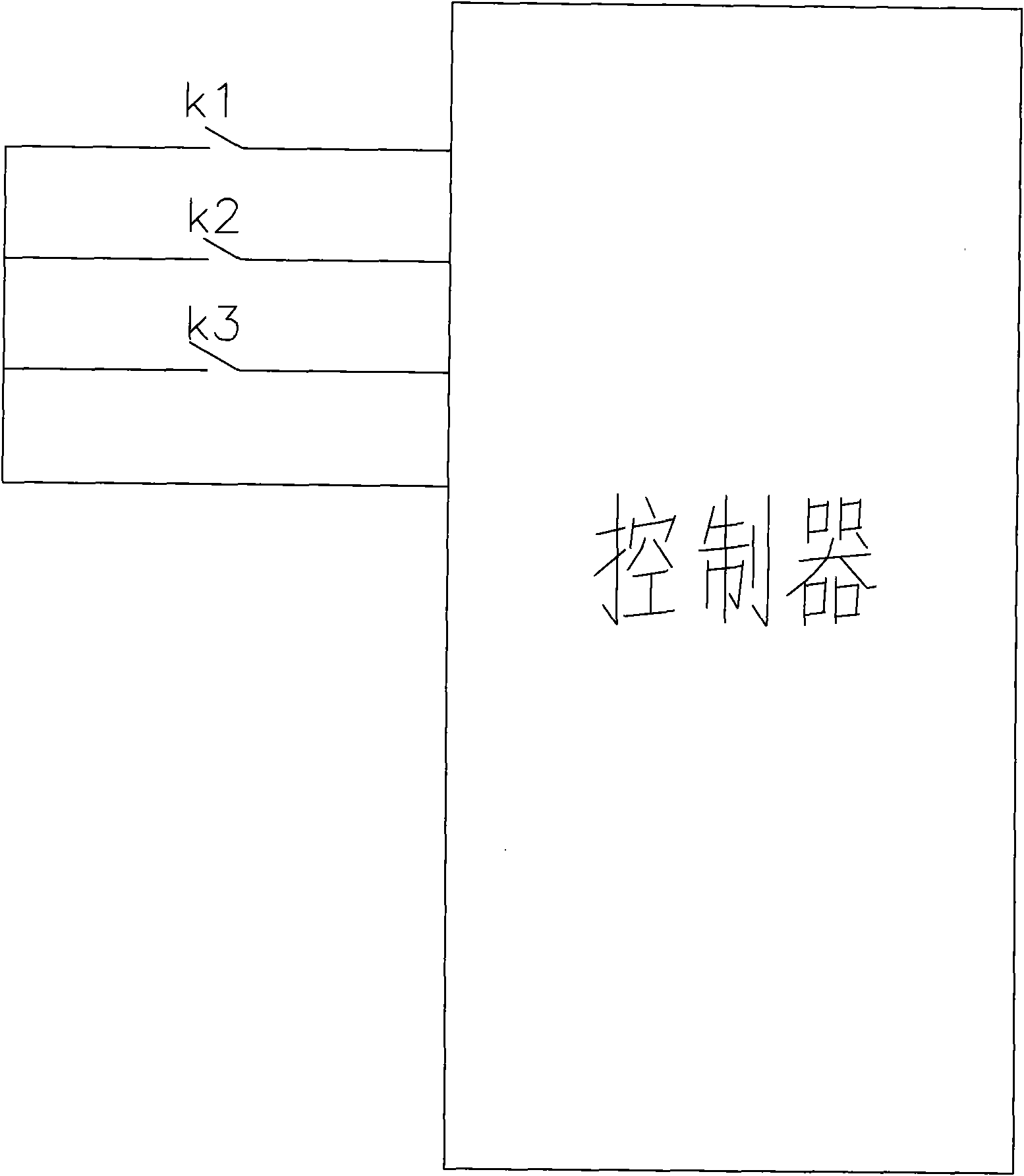

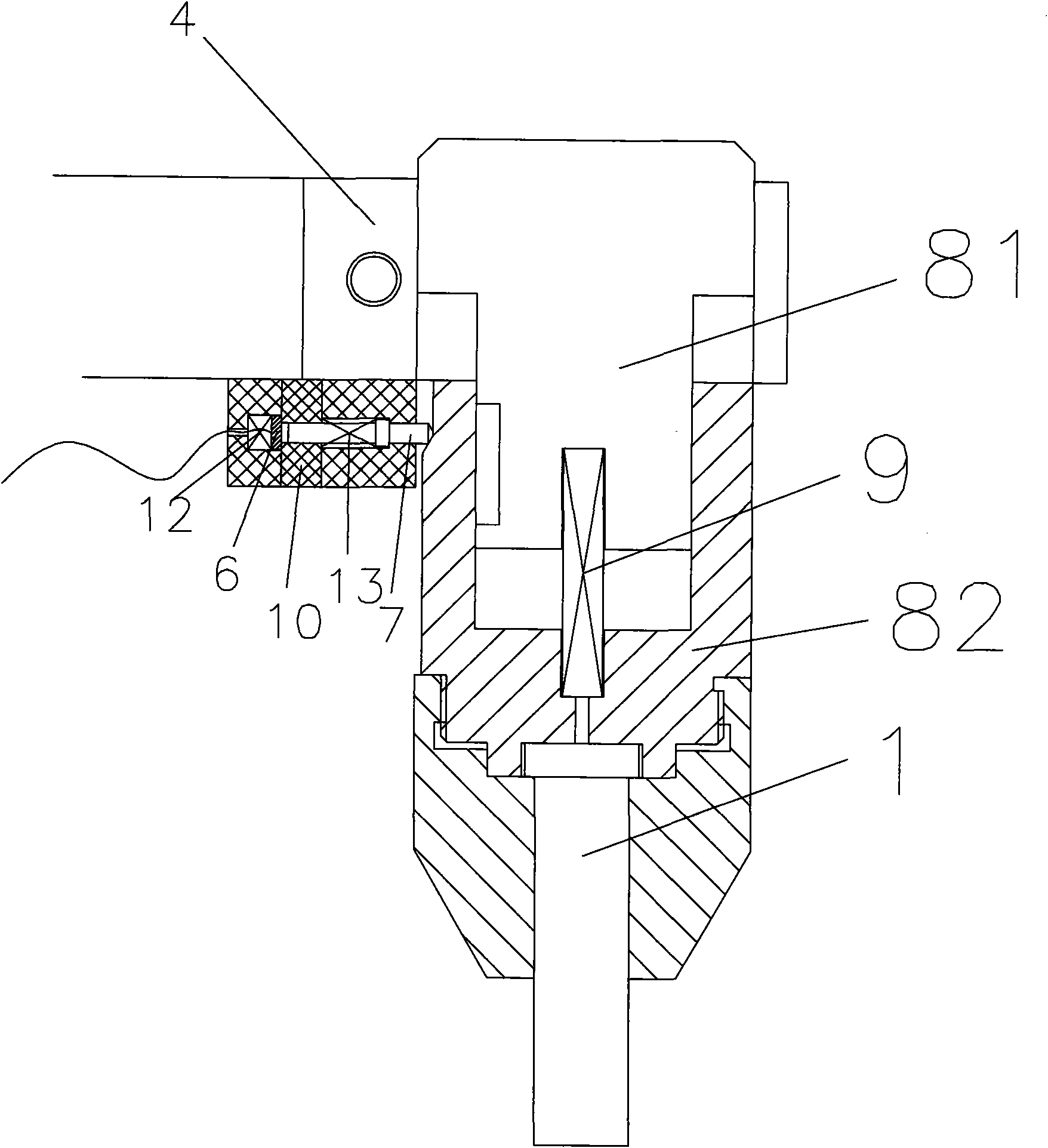

[0016] An anti-pressure safety device for a pneumatic hydraulic stamping machine, installed between an upper mold 1 and a lower mold 2, the upper mold 1 is fixed on the stamping spindle, and the lower mold 2 is fixed on the punching machine console 3, the device is provided with a function It detects that the upper mold 1 is in contact with the start-up detection mechanism placed on the workpiece 100 on the lower mold 2, and an insulation detection mechanism that can detect the insulation of the workpiece 100 is also provided, and an insulation detection mechanism that can be controlled according to the start-up detection mechanism and the insulation detection mechanism. The stamping controller of the pneumatic hydraulic punching machine, the upper pneumatic cylinder of the punching machine is started punching by the controller and stops punching when the start detection mechanism detects that the upper mold touches the workpiece, and the upper hydraulic cylinder of the punching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com