Workpiece insulating detection mechanism in pneumatic and hydraulic punching machine

A detection mechanism, stamping machine technology, applied in the direction of presses, manufacturing tools, mechanical equipment, etc., can solve the problems of personal injury, small workpiece size, punch down, etc., to prevent hidden dangers in operation and improve operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

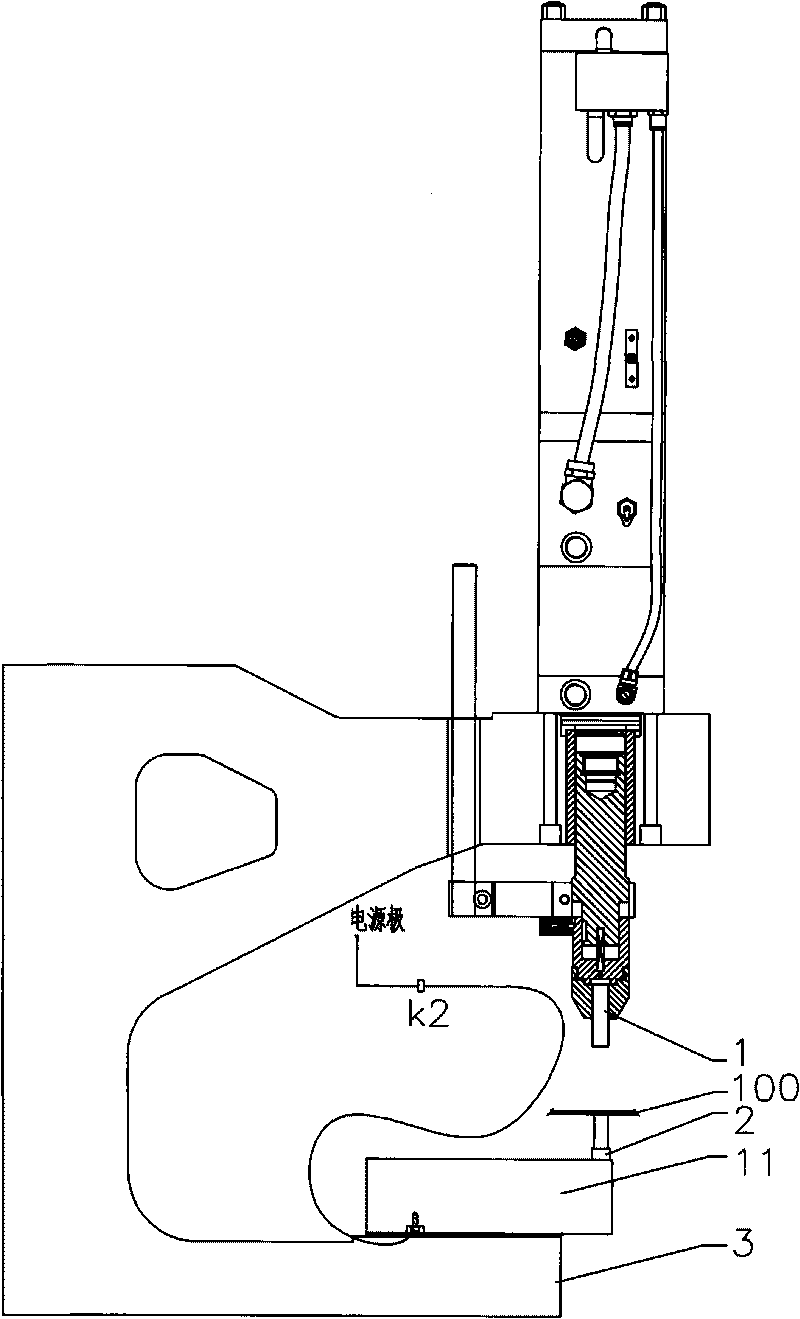

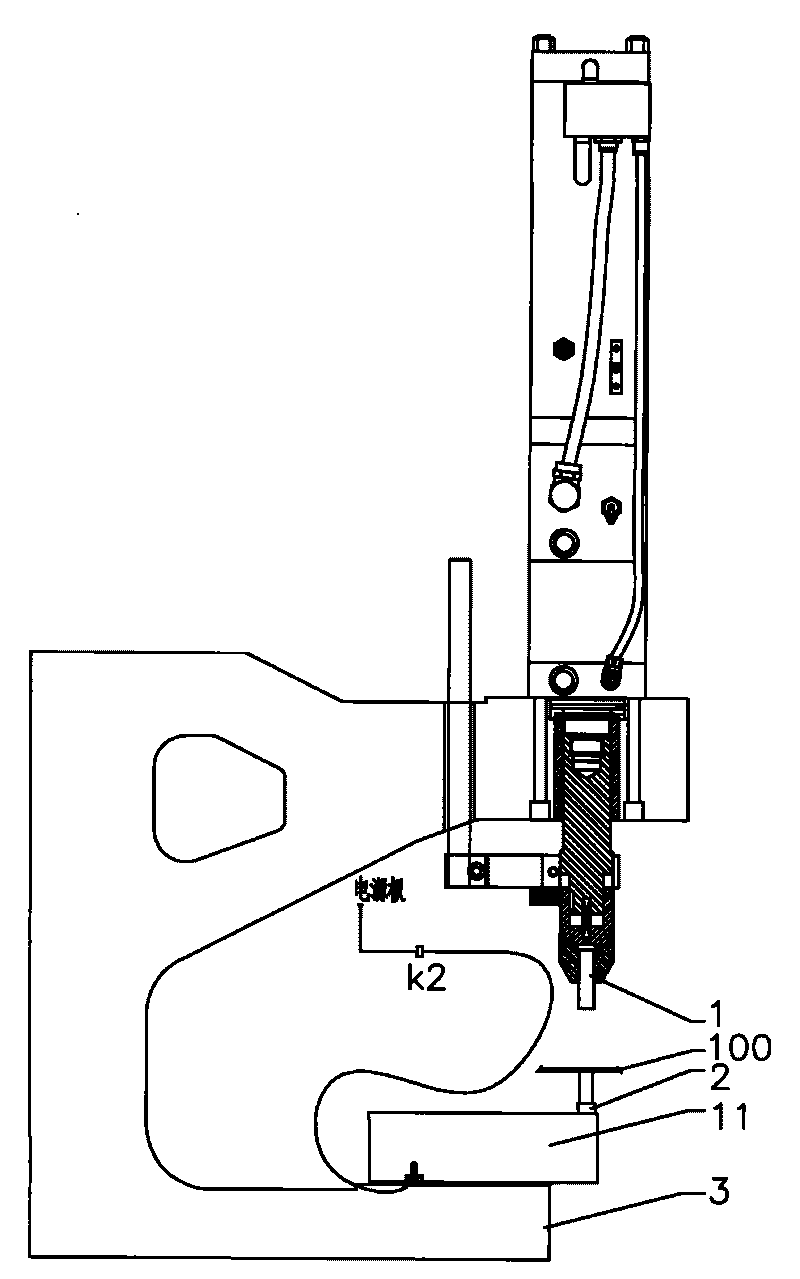

[0008] A workpiece insulation detection mechanism in a pneumatic hydraulic punching machine, installed between an upper mold 1 and a lower mold 2, the upper mold 1 is fixed on the punching spindle, and the lower mold 2 is fixed on the punching machine console 3, characterized in that, The insulation detection mechanism is an insulation detection circuit composed of a power supply pole, the insulation detection relay K2, a lower mold 2, a workpiece 100 placed on the lower mold, an upper mold 1, a stamping spindle and a grounding electrode. The machine consoles 3 are insulated and fixed, and the lower mold 2 is fixed on the lower mold base 11, and the lower mold base 11 and the punching machine console 3 are fixed by an insulating plate.

[0009] The stamping power of the above-mentioned stamping machine adopts gas-hydraulic hybrid power, which is a well-known mature technology, such as the SMART gas-hydraulic booster cylinder stamping equipment produced by the applicant, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com