A sensorized bearing unit

A technology of bearings and sensing devices, applied in the direction of bearing components, bearings of rotating motion, bearings, etc., can solve problems such as no size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

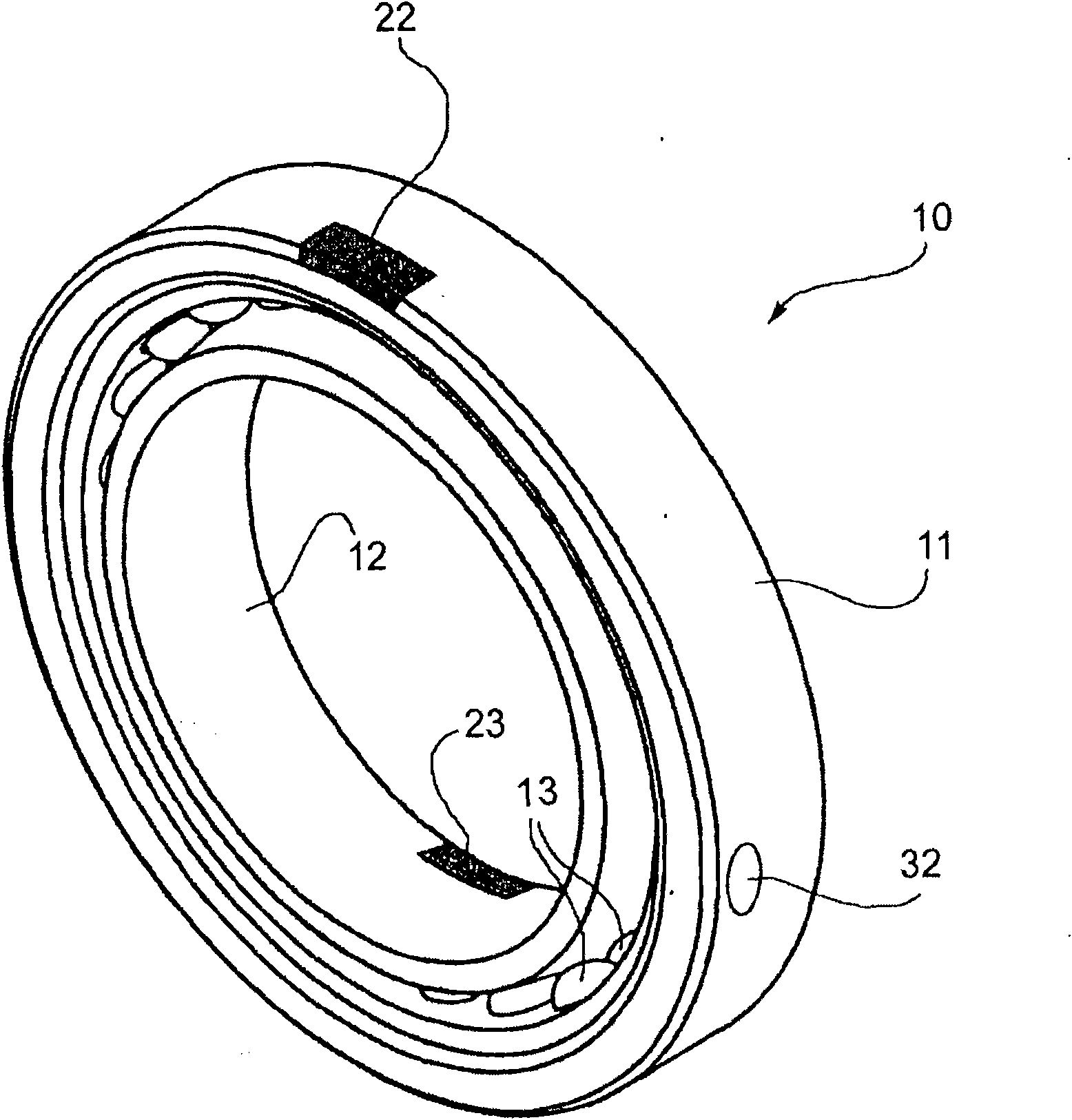

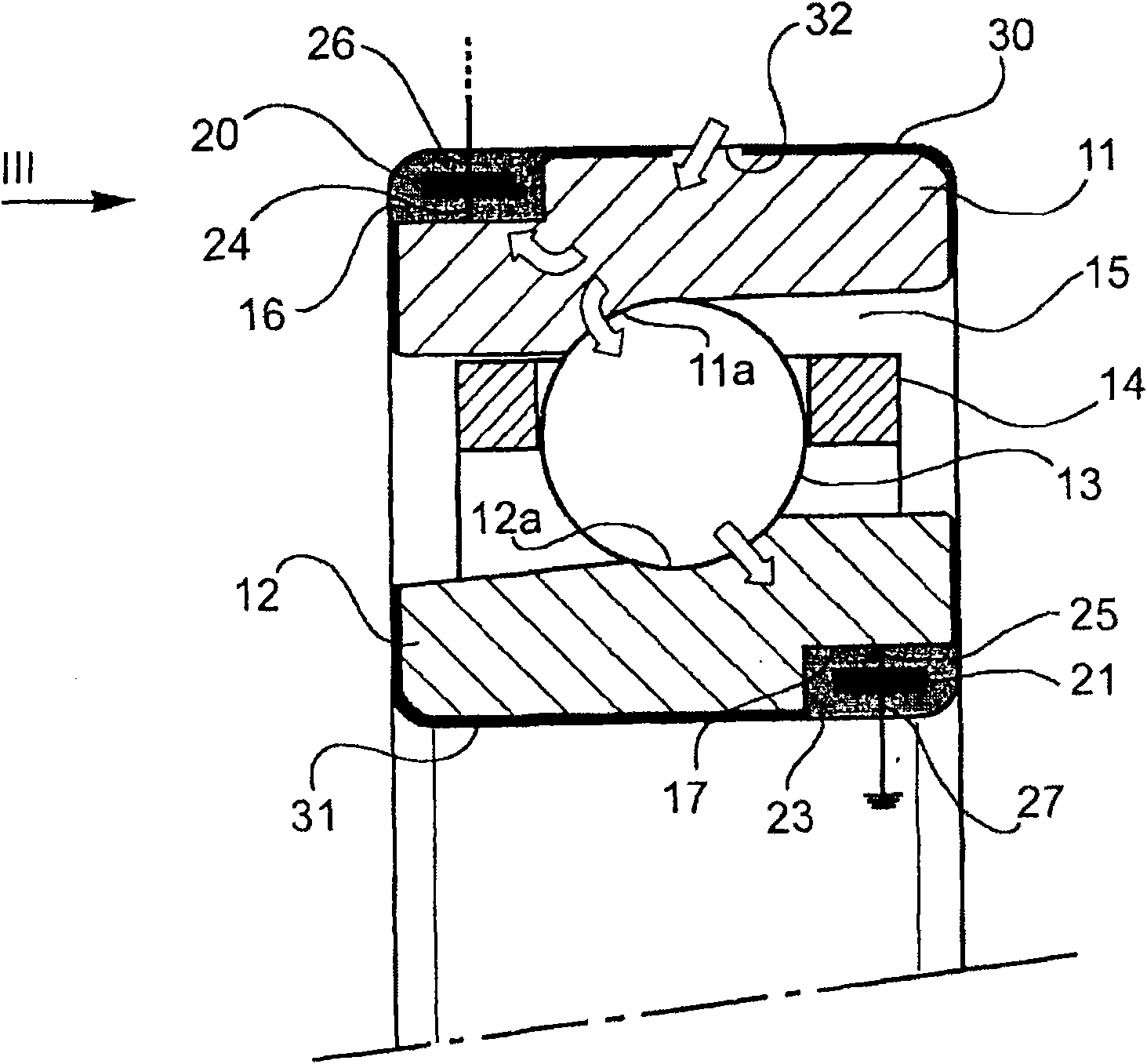

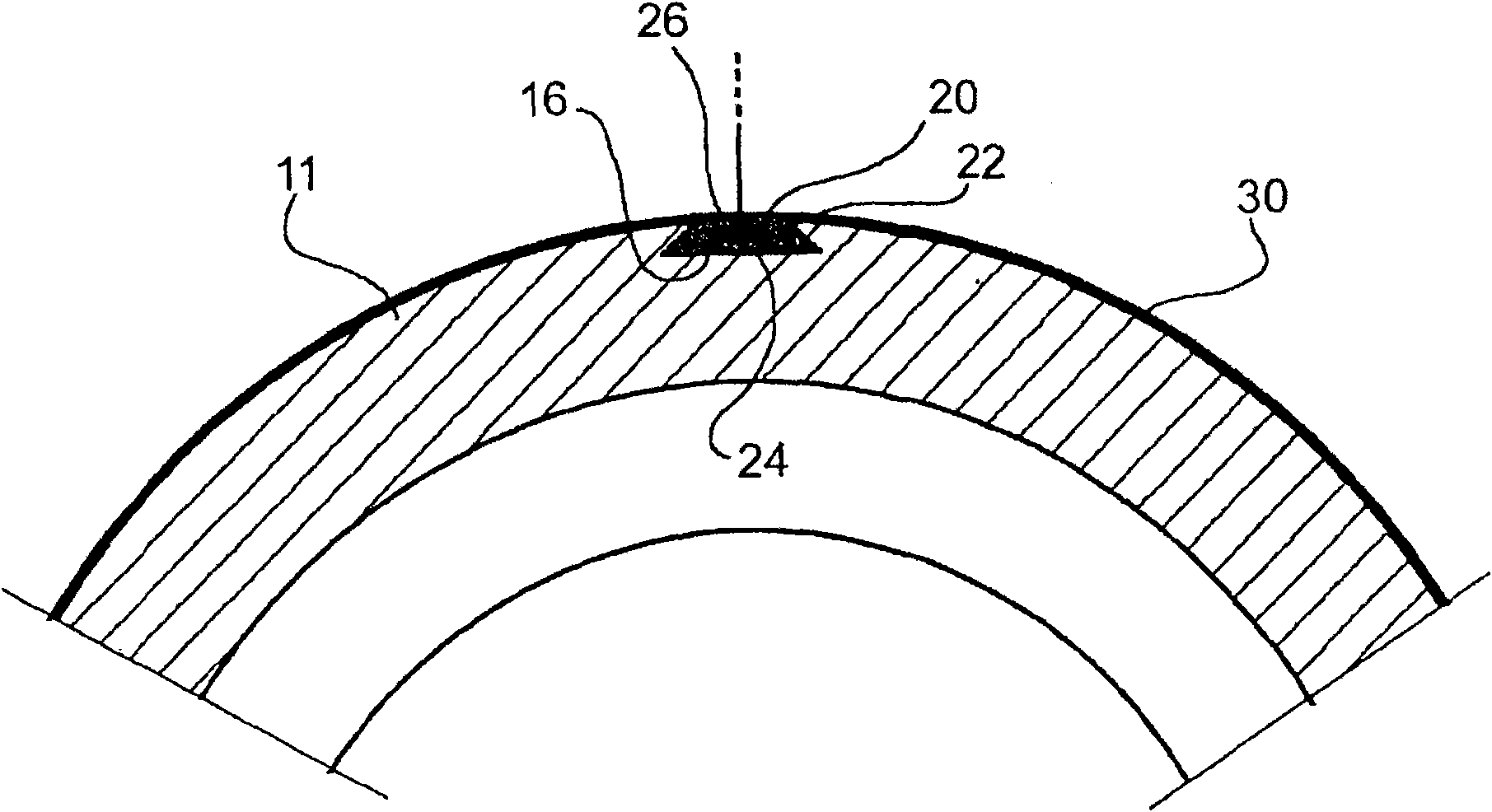

[0011] First refer to figure 1 and 2 , indicated by 10 as a whole is a bearing, which has a fixed outer race 11 and a rotating inner race 12, which respectively form a set of raceways 11a, 12a for two-way rolling elements. In this example, the rolling elements These are balls 13 arranged between the races 11 , 12 and spaced at equal intervals in the circumferential direction by spacer rings 14 . In order to maintain the grease that normally fills the annular gap 15 between the races 11 and 12, sealing means (not shown) may be mounted at both sides of the bearing. The bearing unit shown in the drawings is a so-called first generation type angular contact bearing unit with axially non-approximate races without radial flanges. However, mention of this possible field of application should in no way be construed as limiting the scope of this patent. The invention can also be applied, for example, to flanged bearings.

[0012] The bearing unit 10 is equipped with one or more sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com