Copper alloy material, and method for production thereof

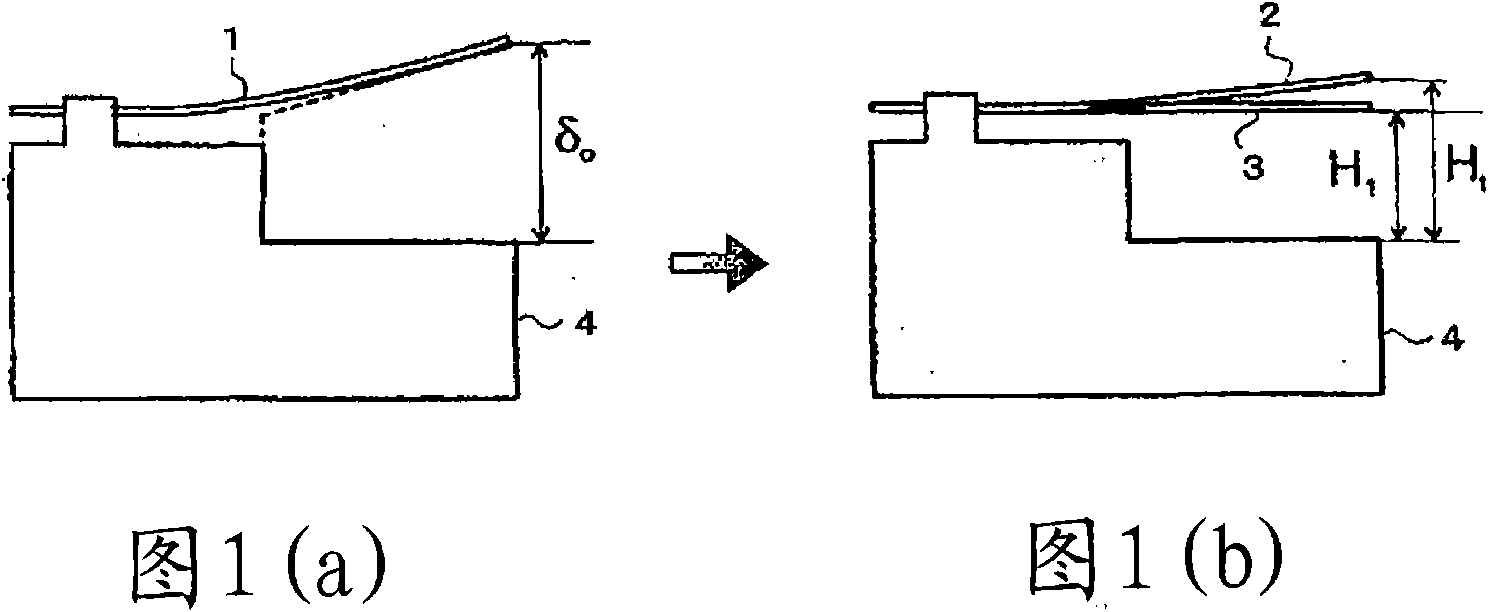

A manufacturing method and technology of copper alloys, applied in the direction of metal rolling, etc., can solve the problems of increased surface wrinkles on the curved part, difficulty in combining strength, electrical conductivity, stress relaxation resistance, bending workability, coating cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

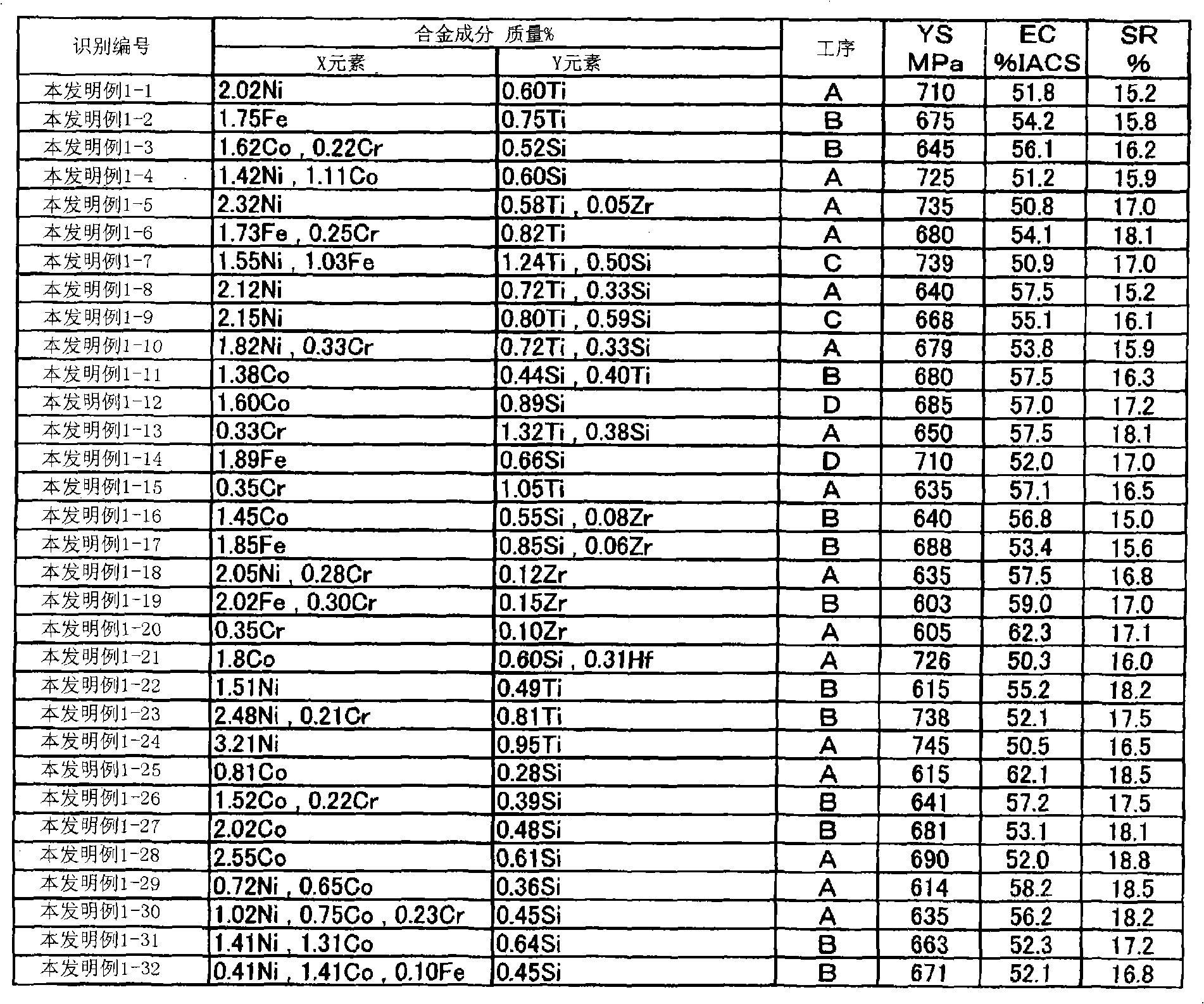

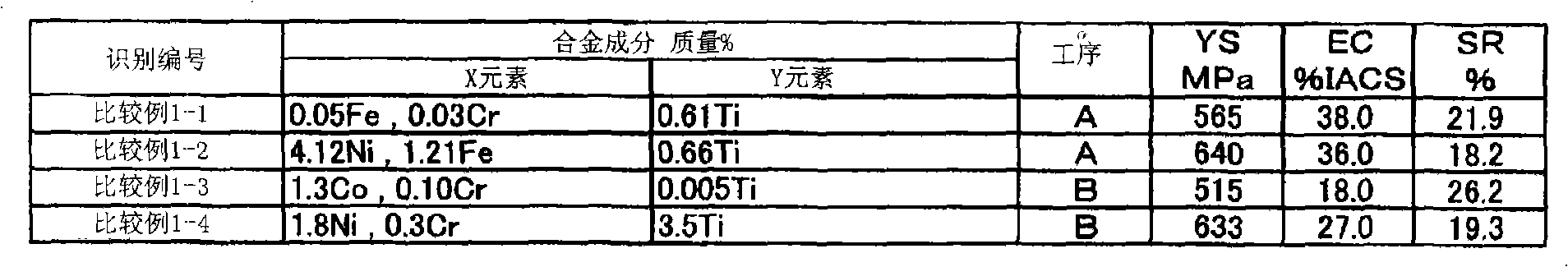

[0072] By following the following Table 1-1, Table 1-2 shown in the composition / composition (mass %) mixed X element and Y element, the balance including Cu and unavoidable impurities alloy with high frequency melting furnace melting, its Casting is performed at a cooling rate of 0.1 to 100°C / sec to obtain an ingot. After homogenizing heat treatment at 900-1050°C for 0.5-10hrs, hot working with a reduction in area of 50% or more at a treatment temperature of 650°C or higher, water quenching, and face cutting to remove scale .

[0073] In the subsequent process, any (shown) treatment in the following steps A to D is performed, thereby producing a copper alloy material.

[0074] Step A: implement cold working with an area reduction rate of 50-98%, implement melt heat treatment at 800-1000°C, implement cold working with an area reduction rate of 5-50%, implement aging precipitation heat treatment at 400-650°C, and implement 5 ~50% finishing cold working (Shishangげ inter-col...

Embodiment 2

[0085] According to the same manufacturing method as described in the above-mentioned Example 1, X elements, Y elements, and Z elements were mixed with the ingredients / compositions shown in the following Table 2-1 and Table 2-2, and the remainder included Cu and optional elements. Copper alloys with impurities to be avoided are made into alloy materials, and each part of them is used as the test material. The properties of each test material were investigated in the same manner as in Example 1, and the results obtained are shown in Table 2-1 and Table 2-2.

[0086] [table 2-1]

[0087]

[0088] [Table 2-2]

[0089]

[0090] It can be seen from Table 2-1 that Example 2-1 of the present invention to Example 2-32 of the present invention are excellent in yield strength, electrical conductivity, and stress relaxation resistance. However, as shown in Table 2-2, when the predetermined value of the component amount of this invention is not satisfied, a characteristic is not g...

Embodiment 3

[0092] According to the same manufacturing method as described in the above-mentioned Example 1, X elements, Y elements, and Z elements were mixed with the components / compositions shown in the following Table 3-1 and Table 3-2, and the remainder included Cu and optional elements. Copper alloys with impurities to be avoided are made into alloy materials, and each part of them is used as the test material. However, comparative examples 3-1 to 3-3 performed solution heat treatment at a temperature higher by about 20 to 30° C. than the respective production steps of Invention Example 3-1 to Invention Example 3-3.

[0093] In the same manner as in Example 1, the properties of the test material were investigated for yield strength [YS], electrical conductivity [EC] and stress relaxation rate [SR]. In addition, average grain size [GS] and bending workability [R / t], the obtained results are shown in Table 3-1 and Table 3-2.

[0094] [Table 3-1]

[0095]

[0096] [Table 3-2]

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com