Method for determining combined insulation thermal resistance of cable and method for calculating current-carrying capacity of cable

A technology of combining insulation and determining methods, applied in the direction of measuring resistance/reactance/impedance, measuring electrical variables, measuring electricity, etc., can solve the problems of inaccurate current carrying capacity of cables, inaccurate calculation of insulation thermal resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

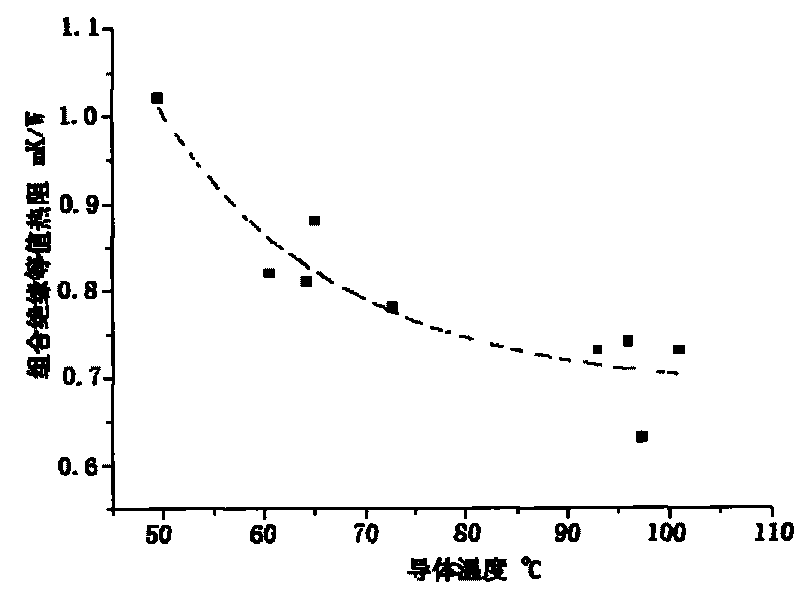

[0021] Considering the strong correlation between cross-linked polyethylene insulation material and temperature, the irregular structure of corrugated sheathed cables, the existence of air gaps in the metal sheath, and the comparison between the thermal resistivity of materials such as buffer layer water-blocking tape and the main insulation The present invention proposes the concept of combined insulation, that is, each layer between the conductor and the metal sheath is regarded as a whole, and the thermal resistance of the whole is used to express its role in cable heat dissipation, in order to achieve accurate cable ampacity calculate.

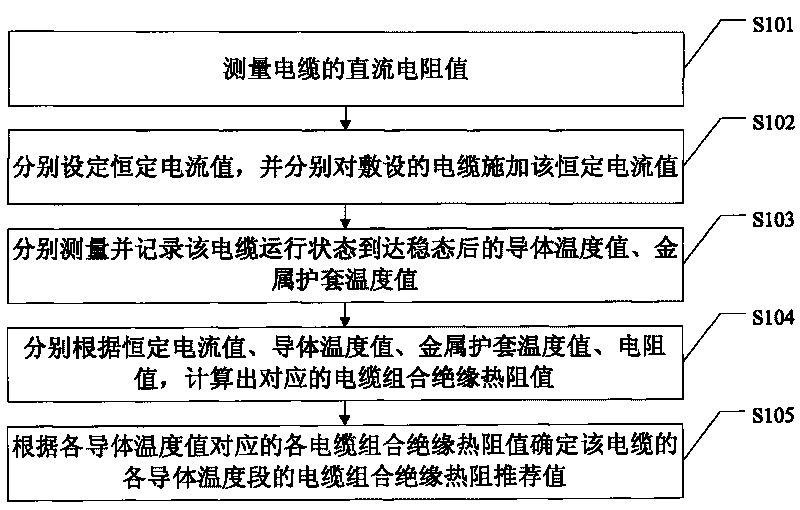

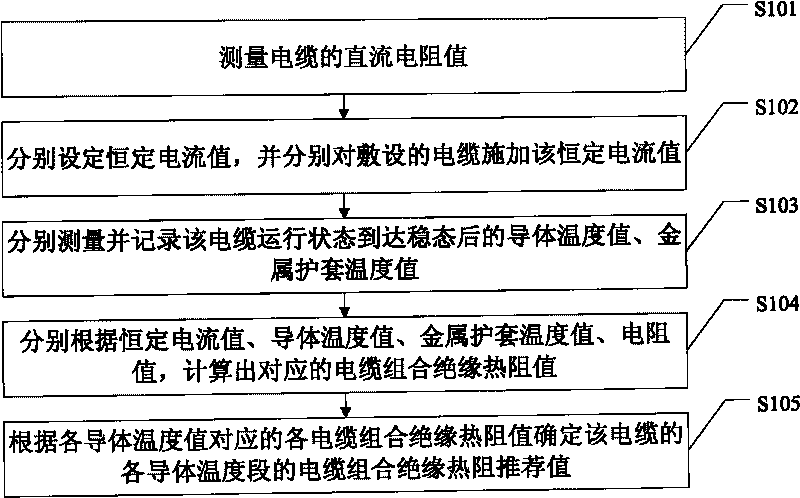

[0022] In order to obtain the combined insulation thermal resistance value of the cable, the present invention suggests that when the cable leaves the factory, a section of the cable should be intercepted to carry out the temperature rise test of a single cable for air laying and direct buried laying, and the recommended value of the combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com