Method for simulating load test with transformer substation bus differential protection current

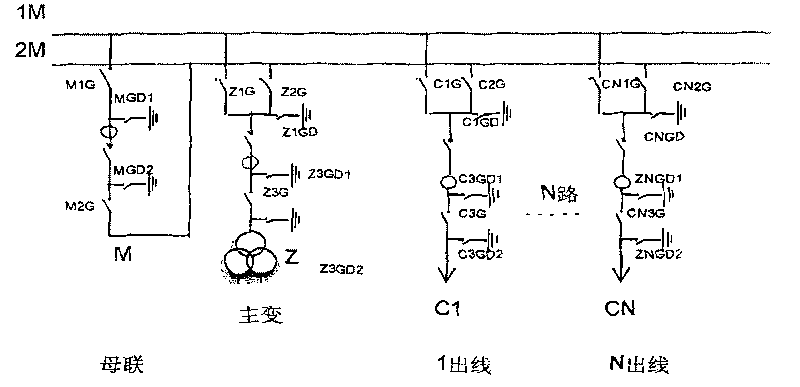

A busbar differential protection and test method technology, applied in the direction of measuring electricity, measuring electrical variables, instruments, etc., can solve problems such as inability to judge the correctness, small current in the secondary circuit of the busbar difference, inconsistent completion time of substation and line installation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

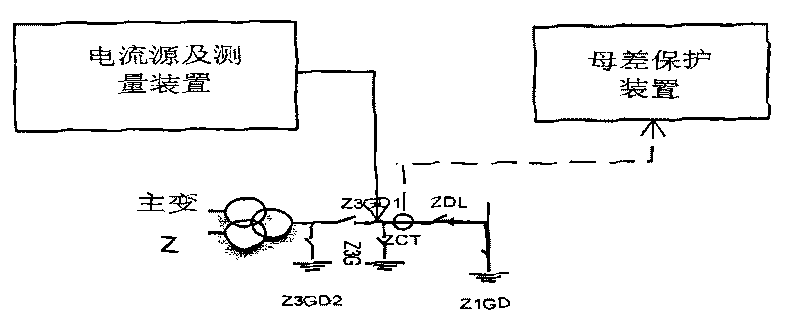

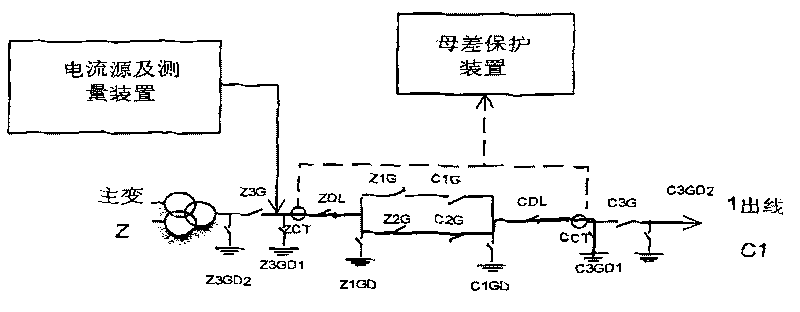

[0015] 1. Transformation ratio test of bus differential with load circuit ( figure 2 shown)

[0016] For the transformation ratio test of the bus differential with load circuit (take the main transformer CT as an example), the outlet pressure plate of the protection device is withdrawn, the main transformer isolating switch Z3G is disconnected, the large current test device is connected between the grounding isolating switch 3GD1 and ZCT, and the main transformer circuit breaker ZDL and the main transformer I female grounding isolating switch Z1GD are closed (check the control circuit of the circuit during the operation process, and the auxiliary contacts related to protection can be found to be open circuit or poor contact of the circuit and the correctness of the wiring), and the current of each phase can be passed in respectively. Check the correctness of phases A, B, and C (neutral wire grounding).

[0017] The current displayed in the high-current test device is compare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com