High-speed dividing mechanism of back connection type cam connecting rod

A technology of indexing mechanism and cam link, applied in mechanical equipment, belt/chain/gear, transmission, etc., to achieve the effect of wide selection of design parameters, low manufacturing cost, and reduced manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The follow-up cam-link high-speed indexing mechanism of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

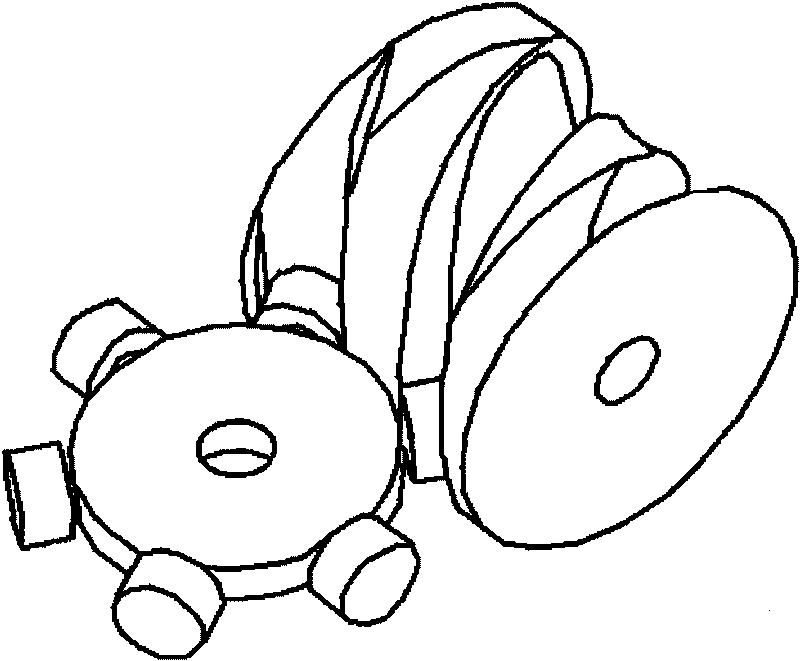

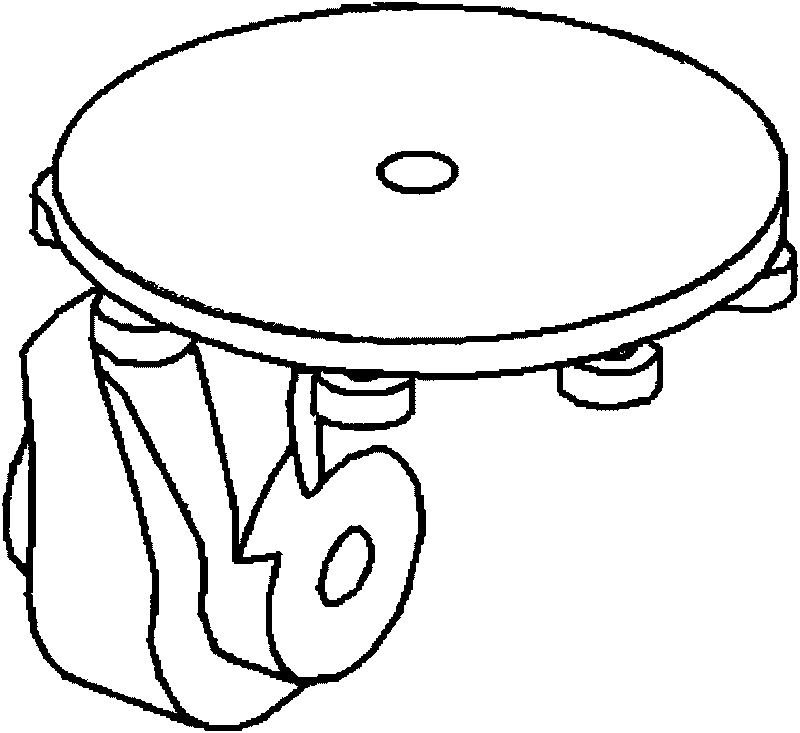

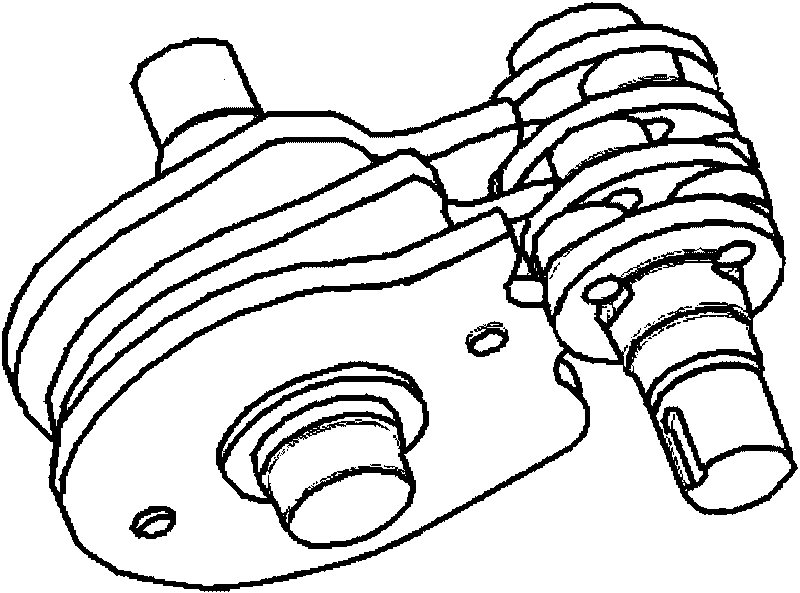

[0029] Pic 4-1 and Figure 4-2 Medium parts and details: 1 box, 2 input shaft, 3 input rod, 4 connecting rod, 5 connecting rod, 6 output rod, 7 output shaft, 8 conjugate cam, 81, 82 cam profile, 9 roller .

[0030] Such as Pic 4-1 and Figure 4-2 As shown, the high-speed indexing mechanism of the rear connected cam link of the present invention includes a box body 1, an input shaft 2 and an output shaft 7, and a conjugate cam 8 is fixedly connected to the box body 1, and the input shaft 2 and the output shaft The axis of 7 is on a straight line, and the transmission between the input shaft 2 and the output shaft 7 is realized by a parallel combined cam linkage mechanism, and the parallel combined cam linkage mechanism is composed of the above-mentioned conjugate cam 8 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com