Push type power socket

A power socket and push-type technology, which is applied in the direction of circuits, electrical components, and devices to prevent contact with live contacts, can solve problems such as laborious plugging and unplugging, accidents, and failure to eliminate power sockets, so as to avoid accidental touch and increase safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

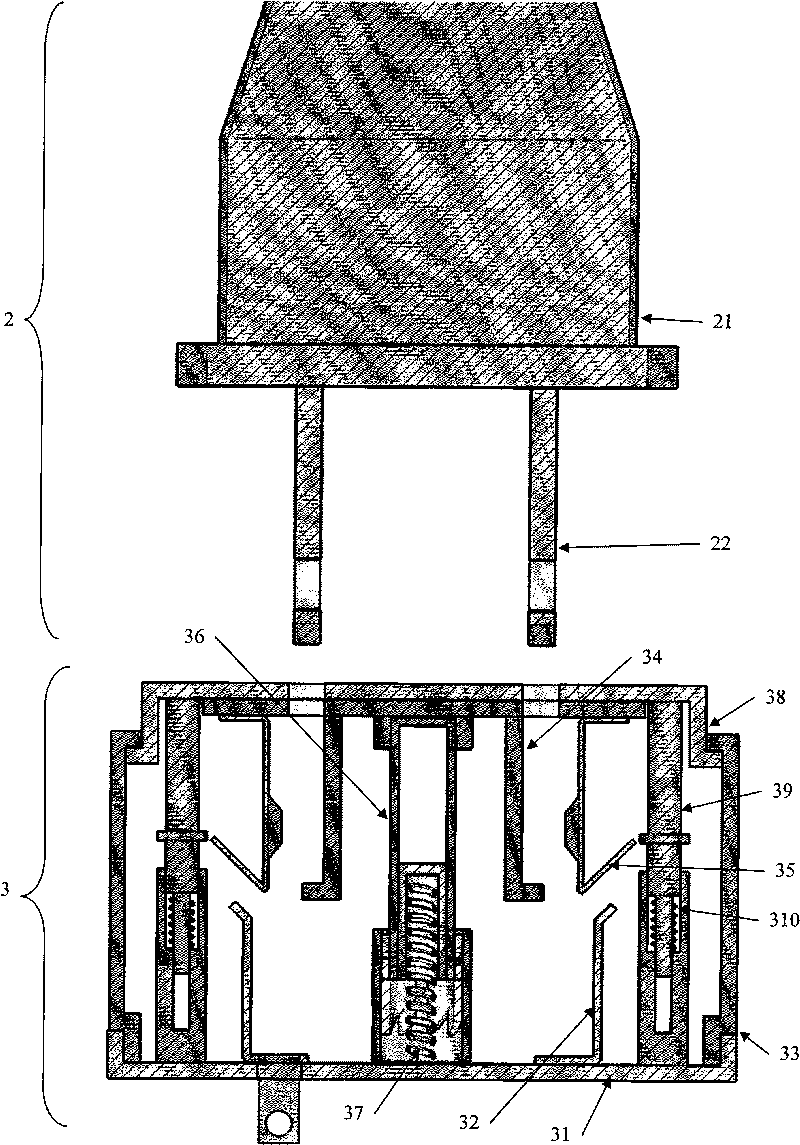

[0032] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

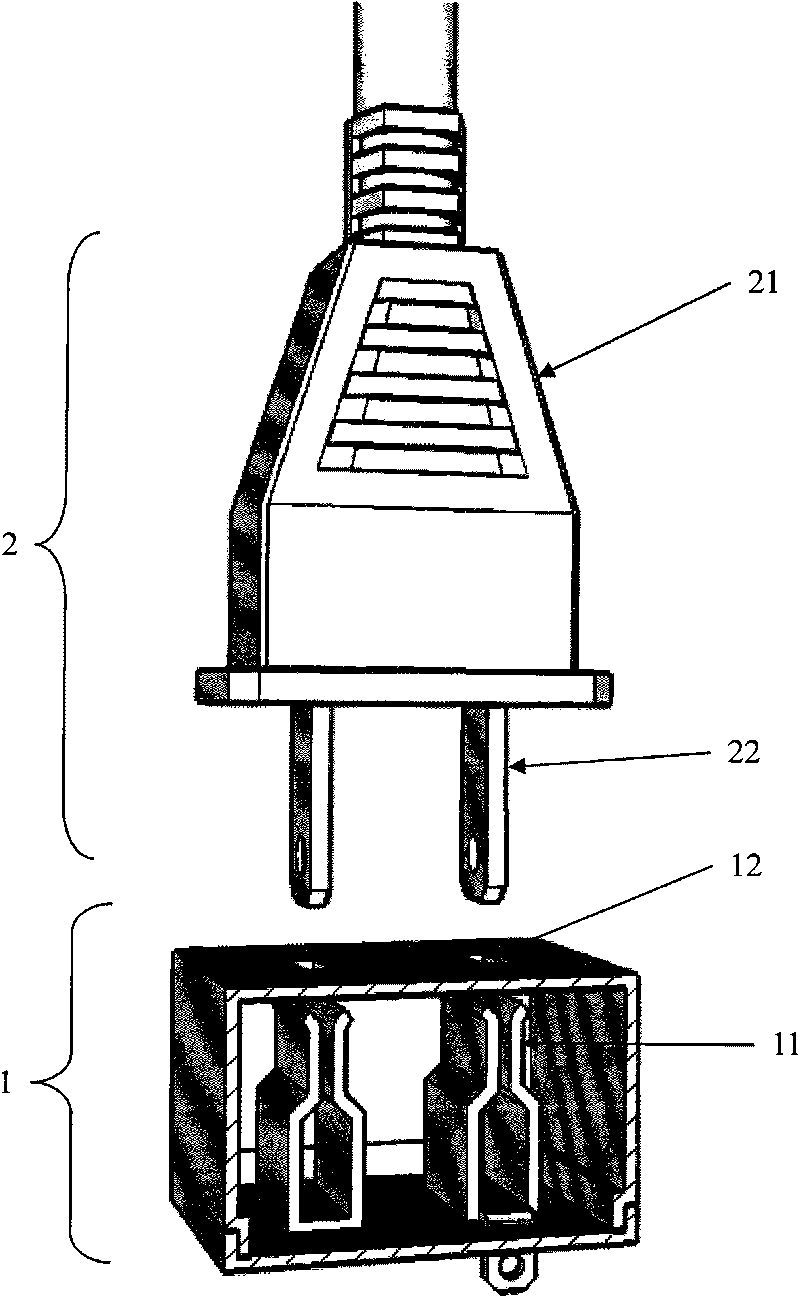

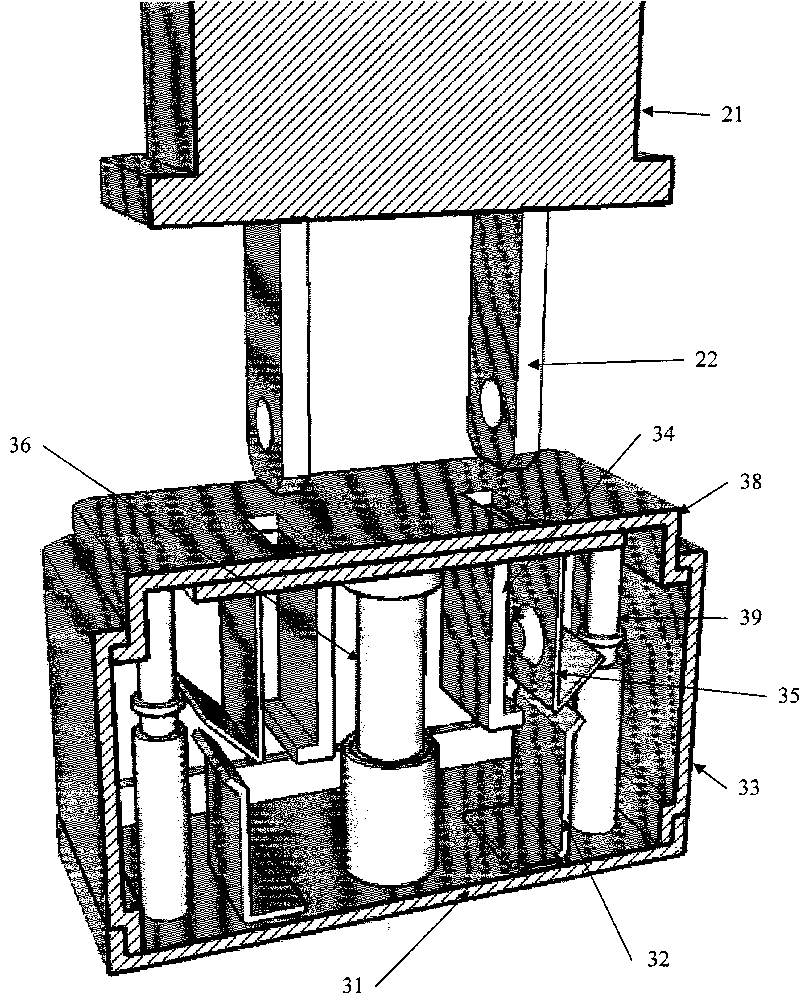

[0033] Figure 2-Figure 6 It is the first embodiment of the present invention. Such as figure 2 , image 3 , Figure 4 As shown, the power socket of the present embodiment has a base 31, two conductive sheets 32 fixed on the base, a side cover 33, a movable frame 34, two conductive clips 35 fixed on the movable frame, a two-section The button structure 36 of the type is fixed between the base and the movable frame. This two-stage button structure is similar to the two-stage button on the general ballpoint pen. After pressing it once and letting go, it can maintain the pressed state. will return to its original state.

[0034] Such as Figure 5 As shown, when the user inserts the conductive blade 22 of the plug 2 into the power socket 3, the user exerts force on the plug base 21, and the conductive blade 22 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com