Oiltight structure of motor shaft tube

A technology of preventing oil leakage and motor shaft, which is applied in the direction of casing/housing/support, controlling mechanical energy, electrical components, etc. It can solve the problem of reducing the viscosity of lubricating oil, prolonging the leakage path of lubricating oil, and easy leakage of lubricating oil, etc. problem, to achieve the effect of preventing the loss of lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, and are described in detail as follows:

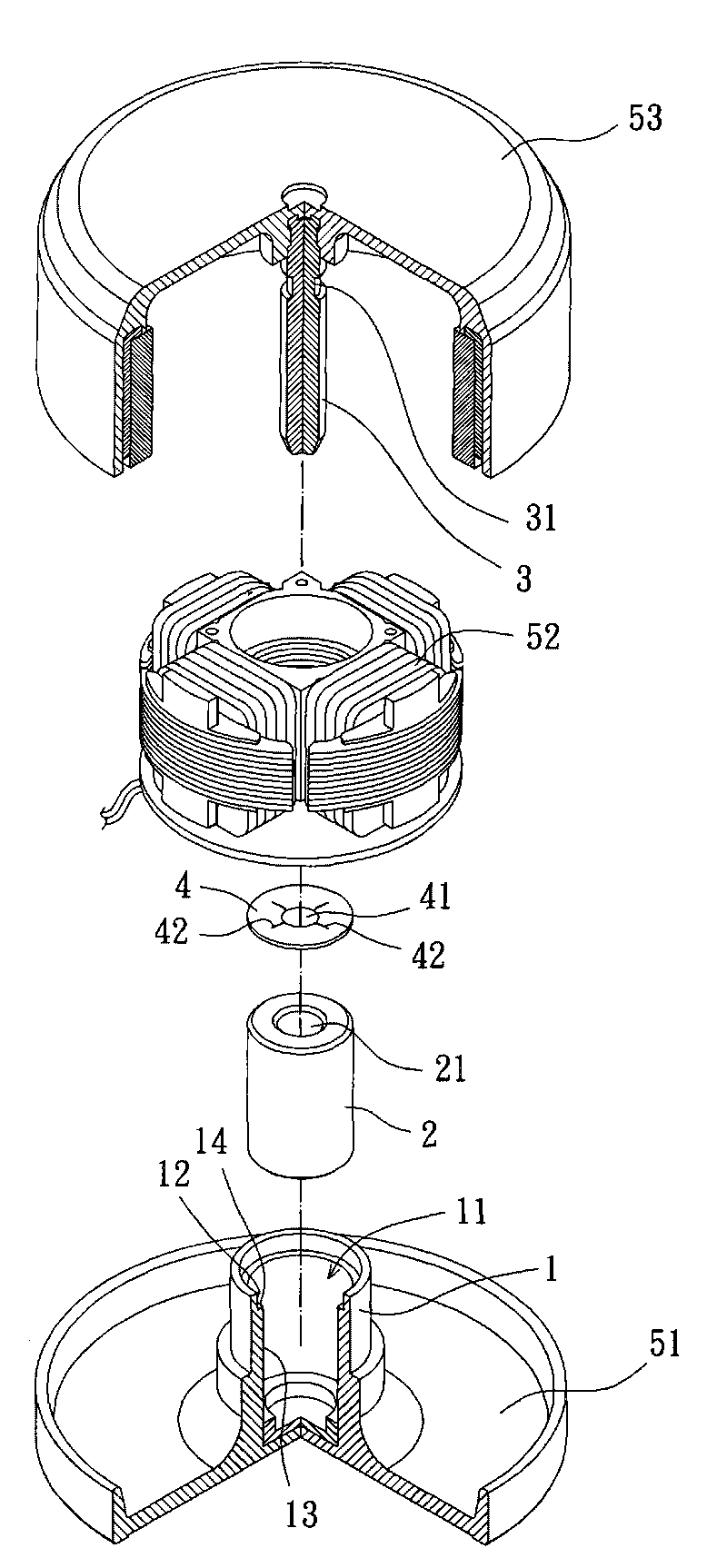

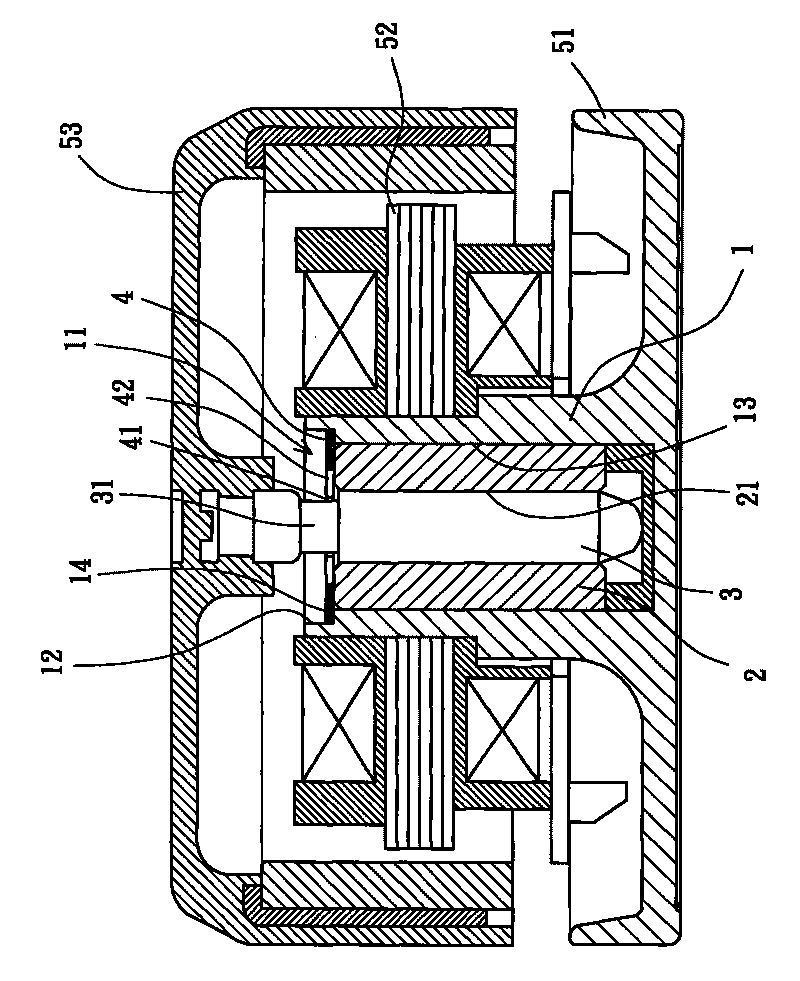

[0022] refer to figure 2 and 3 As shown, the anti-leakage structure of the motor shaft tube in the first embodiment of the present invention includes a shaft tube 1 , a bearing 2 , a rotating shaft 3 and a leak-proof sheet 4 .

[0023] The shaft tube 1 is disposed on a base 51 , and the base 51 can also be provided with a stator 52 . Wherein, the shaft tube 1 and the base 51 may be integrally formed as a single body, or may be composed of separate shaft tube 1 and base 51 (not shown). The shaft tube 1 has an inner hole 11 inside. One end of the inner hole 11 is a closed blind hole, and the end of the inner hole 11 is preferably closed with the base 51 . The inner hole 11 has a larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com