Glue immersion technological method for breaking capillarity of engine wiring harness

A technology of capillary phenomenon and process method, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of polluting the ECU electrical interface, the decline of the electrical performance of the electrical interface, and affecting the normal operation of the engine, so as to achieve simple production process and high effect obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

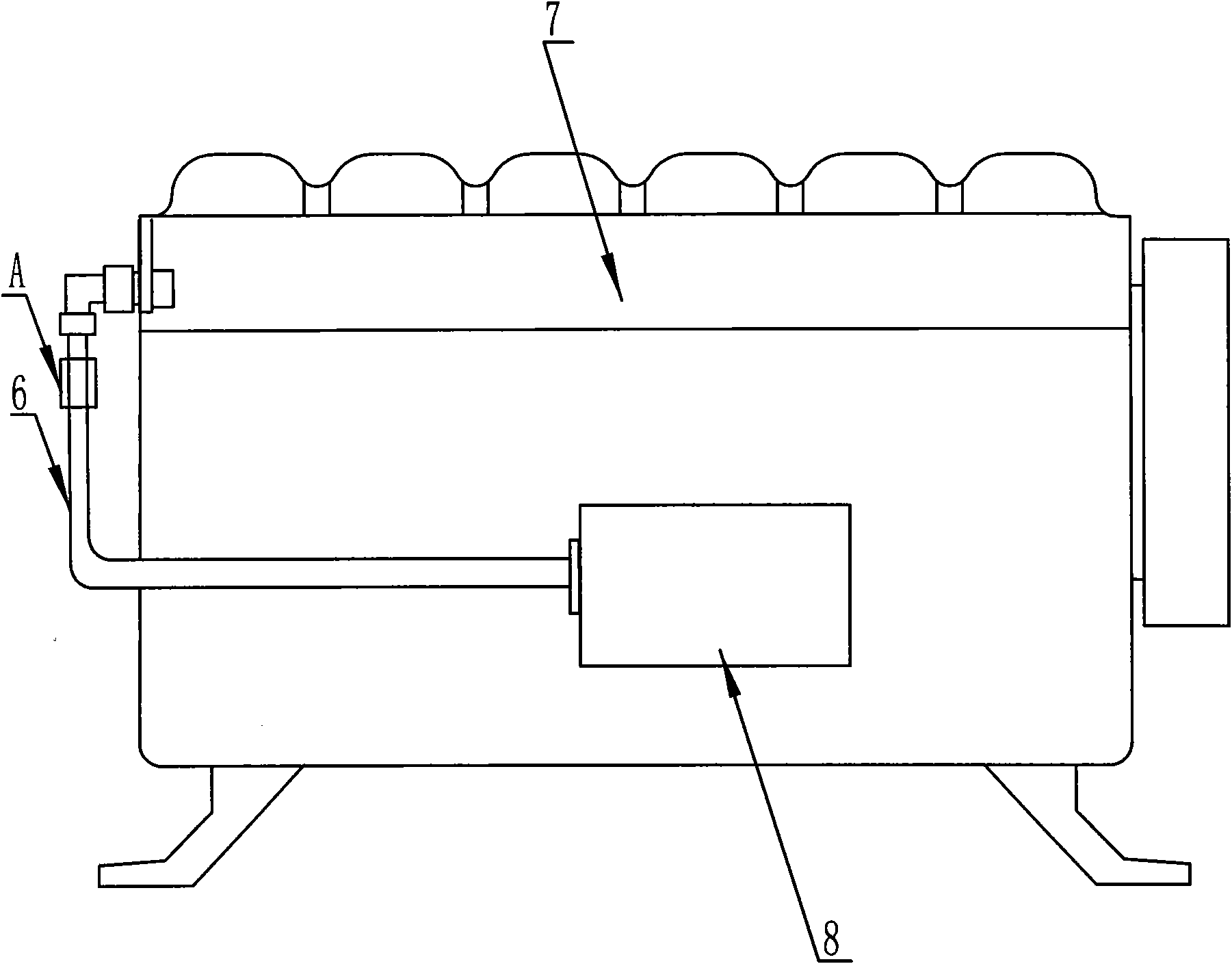

[0011] Such as figure 2 As shown, one end of the engine wiring harness 6 is connected to the ECU 8 and the other end is connected to the rocker arm chamber 7 .

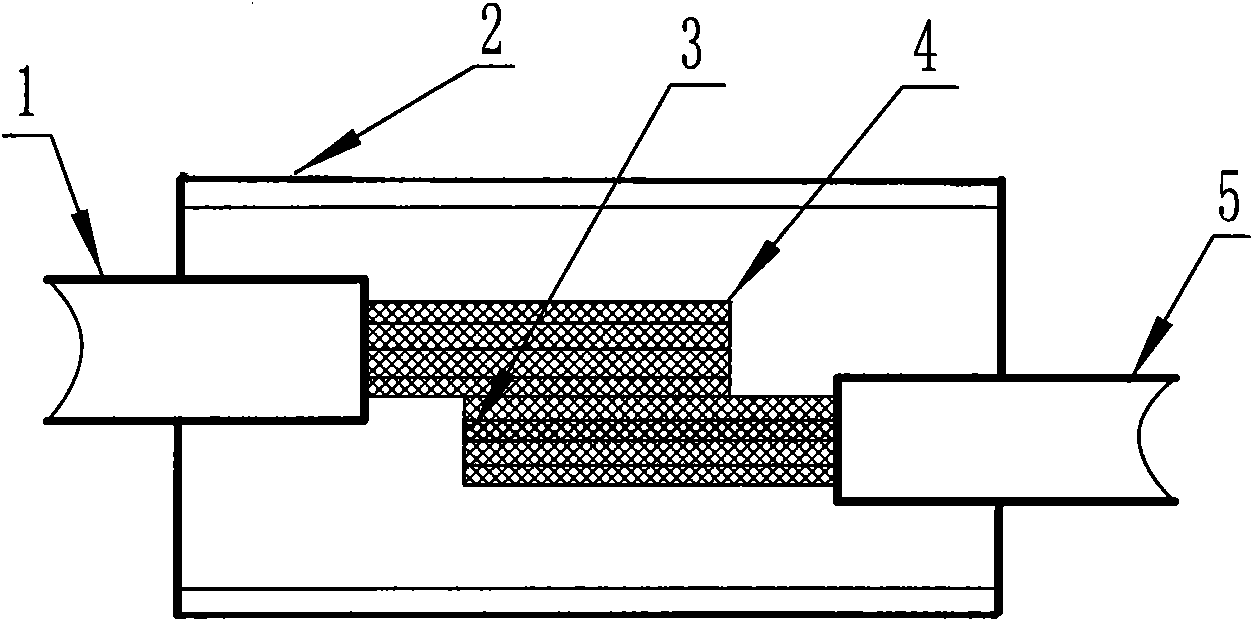

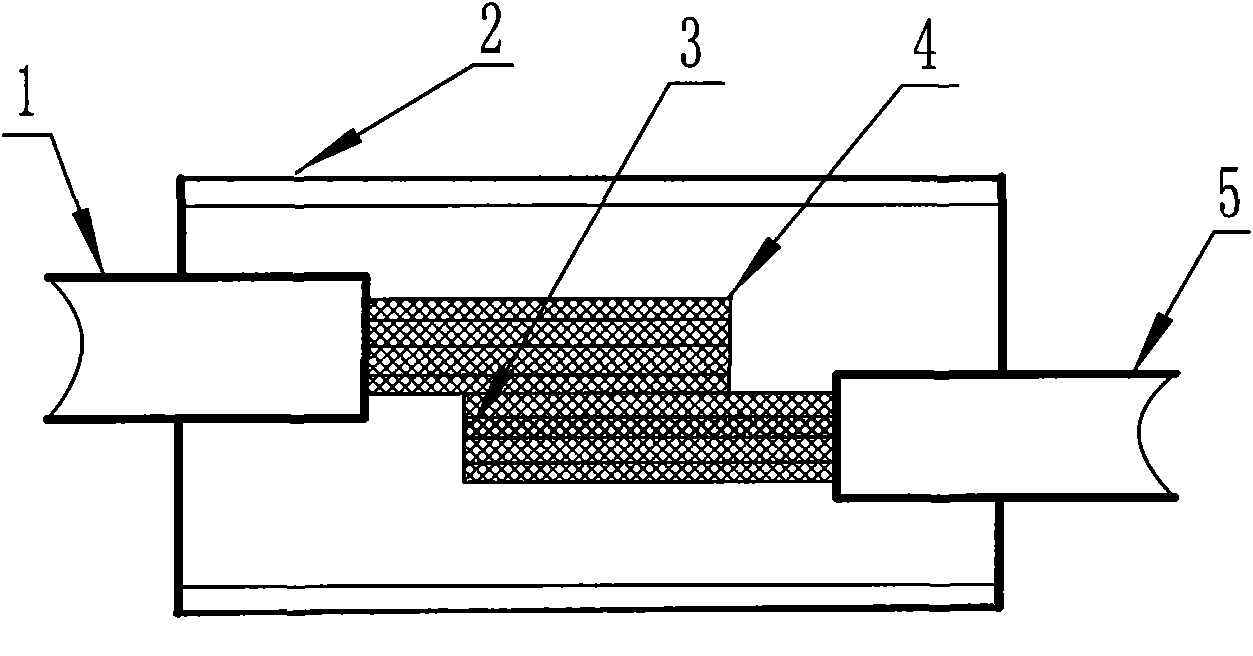

[0012] Such as figure 1 , 2 As shown in the engine wiring harness 6, the wires are interrupted at A, welded by a copper wire ultrasonic welding machine, dipped in glue, and then covered with an oil-resistant glue-containing heat shrinkable tube for insulation and sealing treatment. Specifically: interrupt the part of the wire harness connected to the fuel injector in the automobile engine wire harness, use T3 wire 5 for the section connected to the ECU, and use T6 wire 1 for the other section, and then disconnect the copper cores 3 and 4 of the interrupted parts in sequence Staggered, using an ultrasonic wire welding machine to weld the copper cores 3 and 4 of the wires together; soak the anaerobic adhesive in the welding part, use the capillary phenomenon generated by the gaps in the copper cores of the wires to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com